Homogeneous crystallized TiO2 nano-scale solution, preparation method thereof and crystallization equipment

A nano-solution and crystallization technology, applied in titanium oxide/hydroxide, nanotechnology, nanotechnology and other directions, can solve the problems affecting the photocatalytic performance and optical properties of catalyst coatings, achieve good ion doping, expand light Response range, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

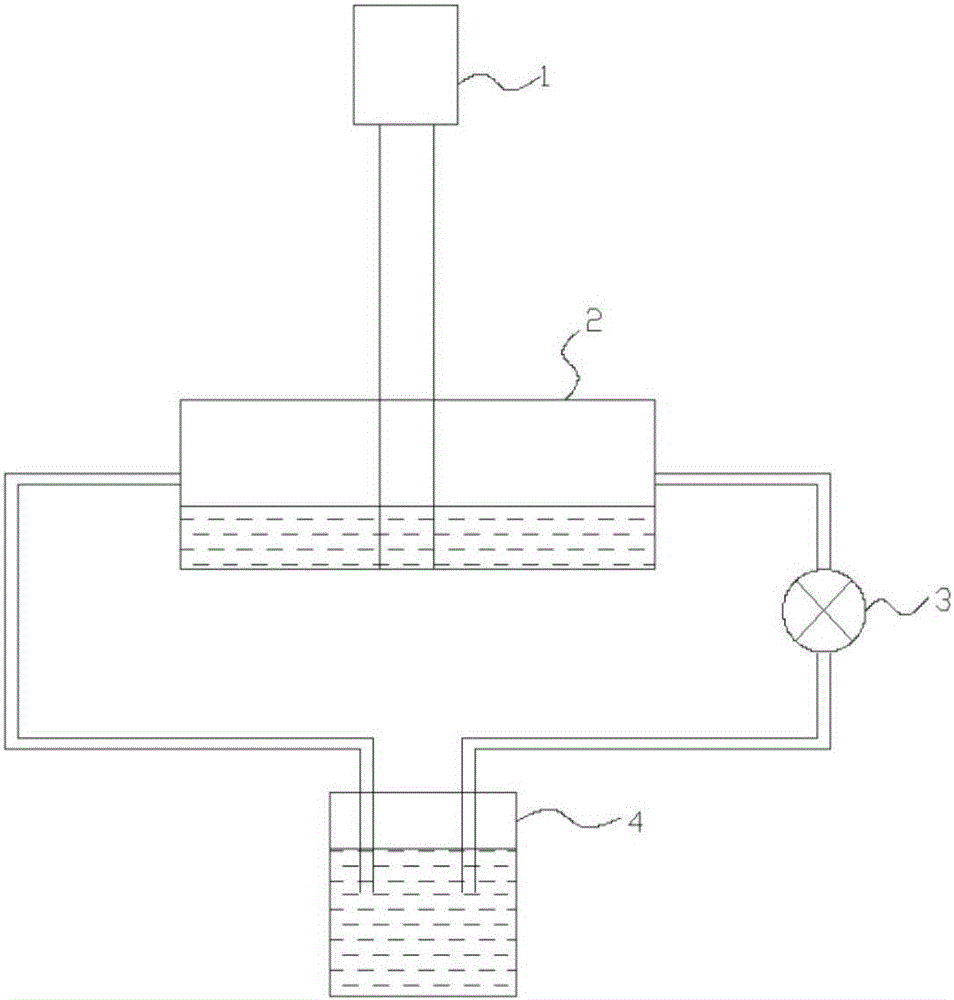

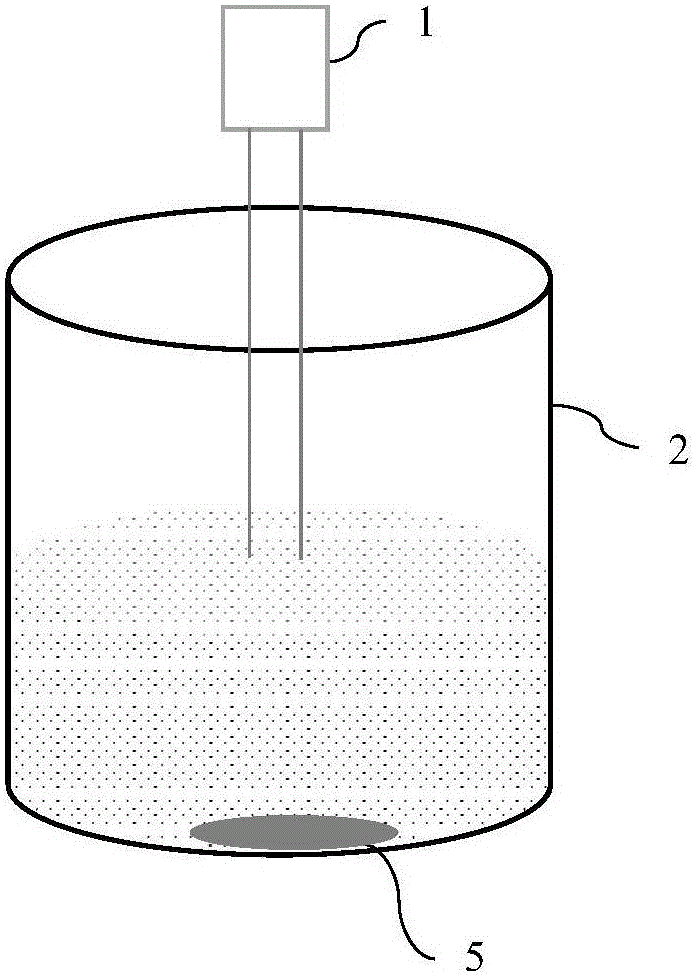

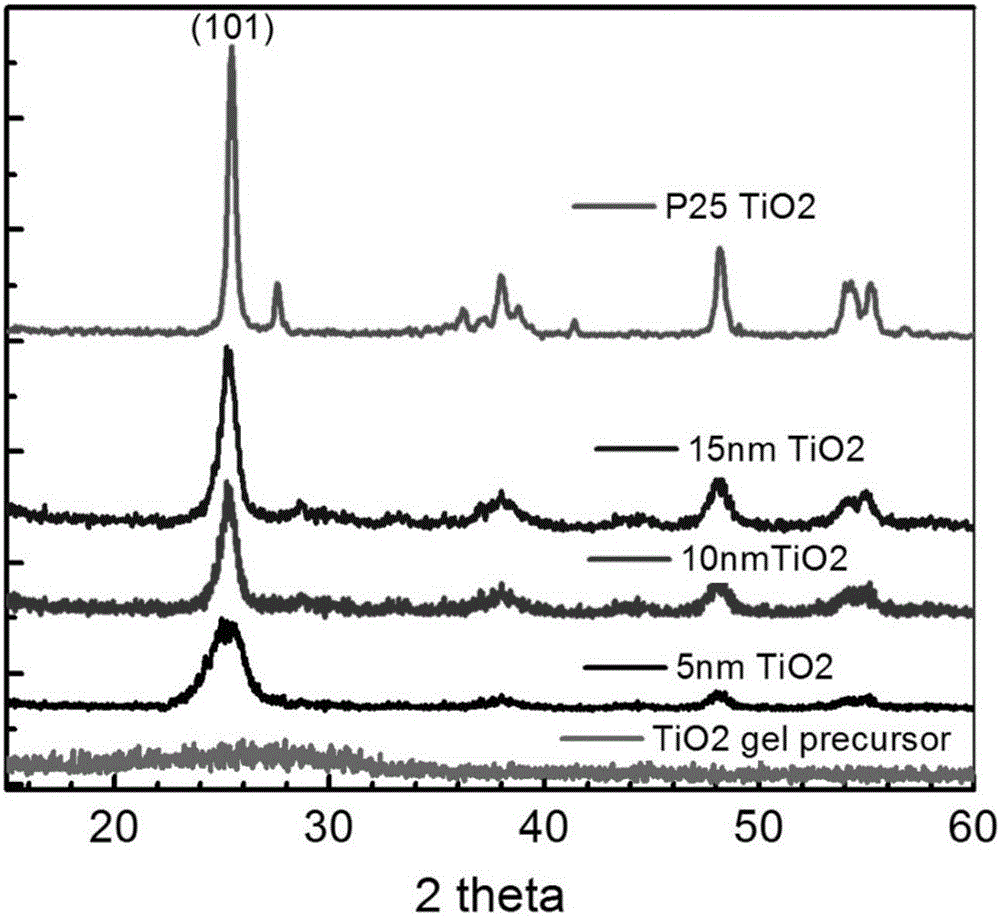

[0030] Anatase TiO of the present invention 2 The preparation method of the nanometer solution is to use titanate as the titanium source and hydrolyze it under acidic conditions to form a homogeneous TiO 2 sol precursor solution, and then TiO 2 The sol precursor solution is placed in a container, and the TiO 2 The sol precursor was irradiated. Under the irradiation of ultrafast laser, it can be in picosecond (10 -12 seconds) to femtoseconds (10 -15Seconds) to transfer a large amount of energy to specific nanoparticles to crystallize them. Since this time exceeds the time of heat conduction (nanoseconds to microseconds), the particles can be crystallized at room temperature (25±5°C), while effectively avoiding the agglomeration of nanoparticles at high temperatures.

[0031] The titanium source used in the present invention is selected from tetraethyl titanate: Ti(OC 2 h 5 ) 4 , Isopropyl titanate: Ti(OC 3 h 7 ) 4 , Tetrabutyl titanate: Ti(OC 4 h 9 ) 4 any one or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com