Highly flame retardant polypropylene material and preparation method and applications thereof

A polypropylene material and high flame retardant technology, applied in the field of high flame retardant polypropylene material and its preparation, can solve the problems of difficulty in reaching F1 outdoor grade, low flame retardant addition, little impact on mechanical properties, etc., and shorten the preparation time. cycle, improving assembly tightness, and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

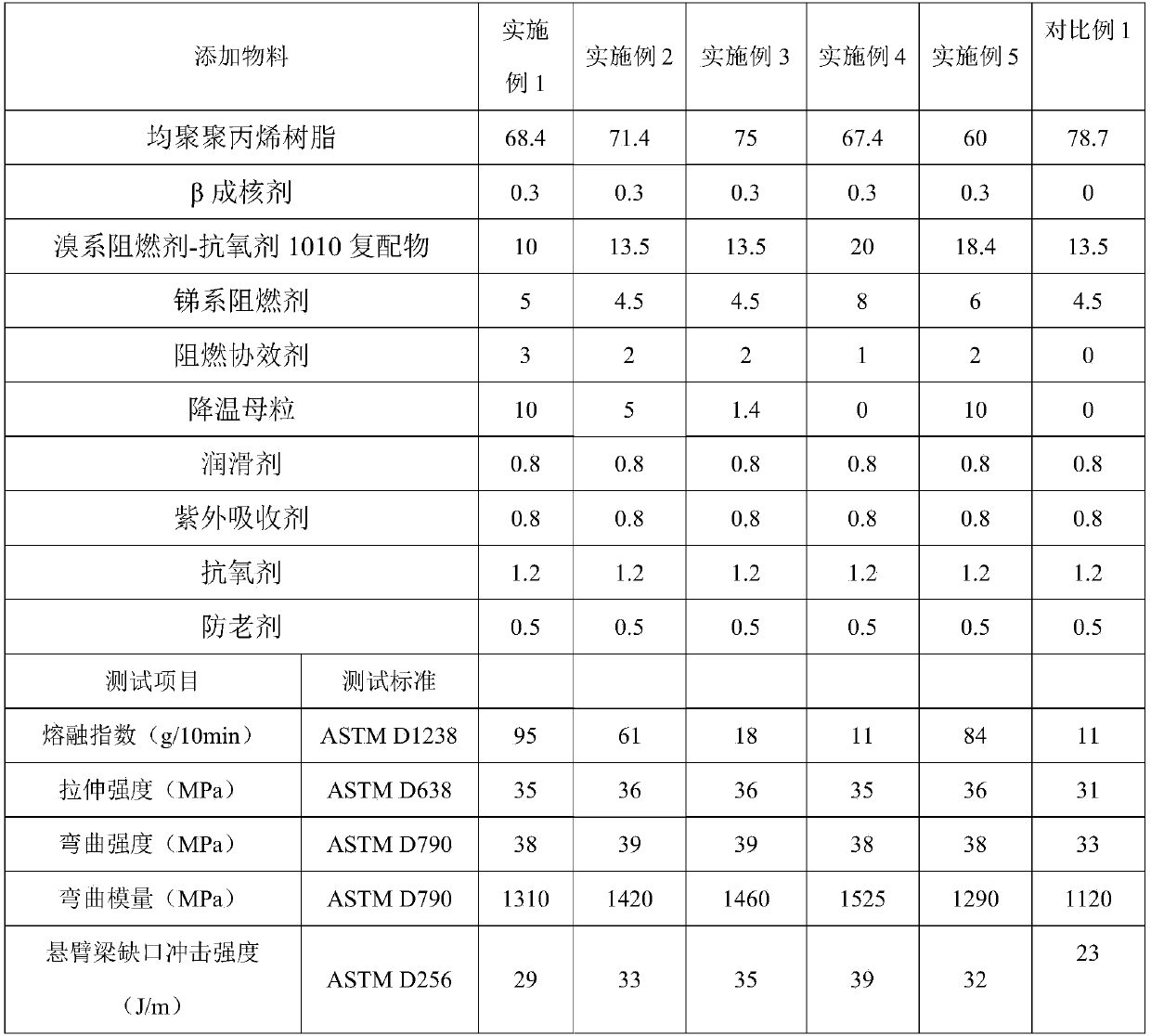

Embodiment 1

[0052] 1) Mix 68.4 parts of homopolypropylene resin with 0.3 part of aromatic amine β-nucleating agent (2,6-phthalic acid cyclic amide (DCHT)) and then granulate at 225-250°C to obtain rubber compound;

[0053] 2) Bake 10 parts of brominated flame retardant-antioxidant 1010 compound (octabromobisphenol S ether and antioxidant 1010 in a mass ratio of 98:2) at 70°C for 3 hours to remove moisture and other volatiles , bake 5 parts of antimony trioxide flame retardant with a purity of 99.9% at 90°C for 3 hours, sieve through a 60-mesh screen to remove large particles and impurities, and set aside;

[0054] 3) After mixing the sizing material in step 1) and 10 parts of cooling master batches evenly, add them into a twin-screw extruder;

[0055] 4) Screen brominated flame retardant-antioxidant 1010 compound and antimony trioxide flame retardant in step 2), 3 parts of flame retardant synergist (melamine cyanurate MCA), 0.8 part of lubricant (stearin The mass ratio of calcium acid ca...

Embodiment 2

[0059] 1) Mix 71.4 parts of homopolypropylene resin with 0.3 parts of aromatic amine β-nucleating agent (N,N-dicyclohexyl-2,6-naphthalenediamide) and pump pellets at 225-250°C to obtain gel material;

[0060] 2) Bake 13.5 parts of brominated flame retardant-antioxidant 1010 compound (the mass ratio of octabromobisphenol S ether to antioxidant 1010 is 98:2) at 70°C for 3 hours to remove water and other volatiles , bake 4.5 parts of antimony trioxide flame retardant with a purity of 99.9% at 90°C for 3 hours, sieve through a 60-mesh screen to remove large particles and impurities, and set aside;

[0061] 3) After mixing the sizing material in step 1) and 5 parts of cooling masterbatch evenly, add it to the twin-screw extruder;

[0062] 4) Screen brominated flame retardant-antioxidant 1010 compound and antimony trioxide flame retardant in step 2), 2 parts of flame retardant synergist (melamine cyanurate MCA), 0.8 part of lubricant (stearin The mass ratio of calcium carbonate to...

Embodiment 3

[0066] 1) Mix 75 parts of homopolypropylene resin with 0.3 part of aromatic amine β-nucleating agent (2,6-phthalic acid cyclic amide (DCHT)) and pump pellets at 225-250°C to obtain rubber compound;

[0067] 2) Bake 13.5 parts of brominated flame retardant-antioxidant 1010 compound (the mass ratio of octabromobisphenol S ether to antioxidant 1010 is 98:2) at 70°C for 3 hours to remove water and other volatiles , bake 4.5 parts of antimony trioxide flame retardant with a purity of 99.9% at 90°C for 3 hours, sieve through a 60-mesh screen to remove large particles and impurities, and set aside;

[0068] 3) After mixing the sizing material in step 1) and 1.4 parts of cooling masterbatch evenly, add the twin-screw extruder;

[0069] 4) Brominated flame retardant-antioxidant 1010 compound and antimony trioxide flame retardant, 2 parts of flame retardant synergist (melamine cyanurate MCA), 0.8 part of lubricant (hard The mass ratio of calcium fatty acid to polyethylene wax is 3:1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com