LCP/PBT/PET ternary alloy material and preparation method thereof

A ternary alloy, liquid crystal polymer technology, applied in the field of polymer materials, can solve the problems of impact strength, toughness, heat resistance, low processing performance, poor product formability, rising production costs, etc., and achieve good dimensional stability. , low cost, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

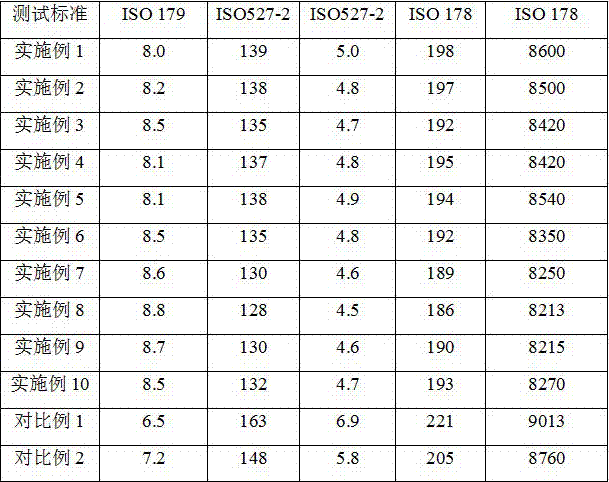

Examples

Embodiment 1

[0041] A kind of LCP / PBT / PET ternary alloy material, this ternary alloy material comprises the raw material of following weight portion:

[0042] Liquid crystal polymer 10 parts

[0043] Polybutylene terephthalate 20 parts

[0044] 40 parts polyethylene terephthalate

[0045] 5 parts glass fiber

[0046] Compatibilizer 3 parts

[0047] Flame retardant 15 parts

[0048] Antioxidant 0.1 parts

[0049] Lubricant 0.2 parts

[0050] Modifier 1 part.

[0051] The liquid crystal polymer has a molecular weight of 5000 and a characteristic density of 1.45 g / cm 3 thermotropic liquid crystal polymers.

[0052] The compatibilizer is styrene-acrylonitrile-maleic anhydride copolymer.

[0053] The flame retardant is at least one of polyphenylphosphate, tris(α-chloroethyl)phosphate and tris(1,3-dichloro-2-propyl)phosphate.

[0054] The antioxidant is triethylene glycol bis-3-(3-tert-butyl-4-hydroxyl-5-methylphenyl) acrylate.

[0055] The lubricant is polyethylene wax.

[0056] The...

Embodiment 2

[0063] A kind of LCP / PBT / PET ternary alloy material, this ternary alloy material comprises the raw material of following weight portion:

[0064] Liquid crystal polymer 20 parts

[0065] 10 parts polybutylene terephthalate

[0066] 30 parts polyethylene terephthalate

[0067] 13 parts glass fiber

[0068] 6 parts of compatibilizer

[0069] Flame retardant 12 parts

[0070] Antioxidant 0.2 part

[0071] Lubricant 0.6 parts

[0072] Modifier 1.2 parts.

[0073] The liquid crystal polymer has a molecular weight of 25,000 and a characteristic density of 1.42 g / cm 3 thermotropic liquid crystal polymers.

[0074] The compatibilizer is ethylene-acrylic acid-butyl grafted glycidyl methacrylate.

[0075] The flame retardant is at least one of decabromodiphenylethane and 1,2-bis(tetrabromophthalimide)ethane.

[0076] The antioxidant is pentaerythritol bis-diphosphite bis(2,4-di-tert-butylphenyl) ester.

[0077] The lubricant is hydrogenated ethylenebisstearamide.

[0078] Th...

Embodiment 3

[0085] A kind of LCP / PBT / PET ternary alloy material, this ternary alloy material comprises the raw material of following weight portion:

[0086] Liquid crystal polymer 30 parts

[0087] Polybutylene terephthalate 30 parts

[0088] 10 parts polyethylene terephthalate

[0089] 22 parts glass fiber

[0090] Compatibilizer 9 parts

[0091] Flame retardant 9 parts

[0092] Antioxidant 0.3 parts

[0093] Lubricant 1 part

[0094] Modifier 1.5 parts.

[0095] The liquid crystal polymer has a molecular weight of 45,000 and a characteristic density of 1.40 g / cm 3 thermotropic liquid crystal polymers.

[0096] The compatibilizer is hydrogenated styrene-butadiene-styrene copolymer grafted with glycidyl methacrylate or styrene-acrylonitrile copolymer grafted with glycidyl methacrylate.

[0097] The flame retardant is at least one of sodium antimonate, brominated polystyrene and brominated epoxy resin.

[0098] The antioxidant is tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com