Novel martensitic heat-resistant steel and method for manufacturing thin-walled elbow of seamless steel pipe using same

A seamless steel pipe and martensite technology, which is applied in the field of additive manufacturing, can solve the problems of long production cycle and high production cost of pipe bending, and achieve the effect of avoiding uncertainty of arc position, improving quality, and fine and uniform grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

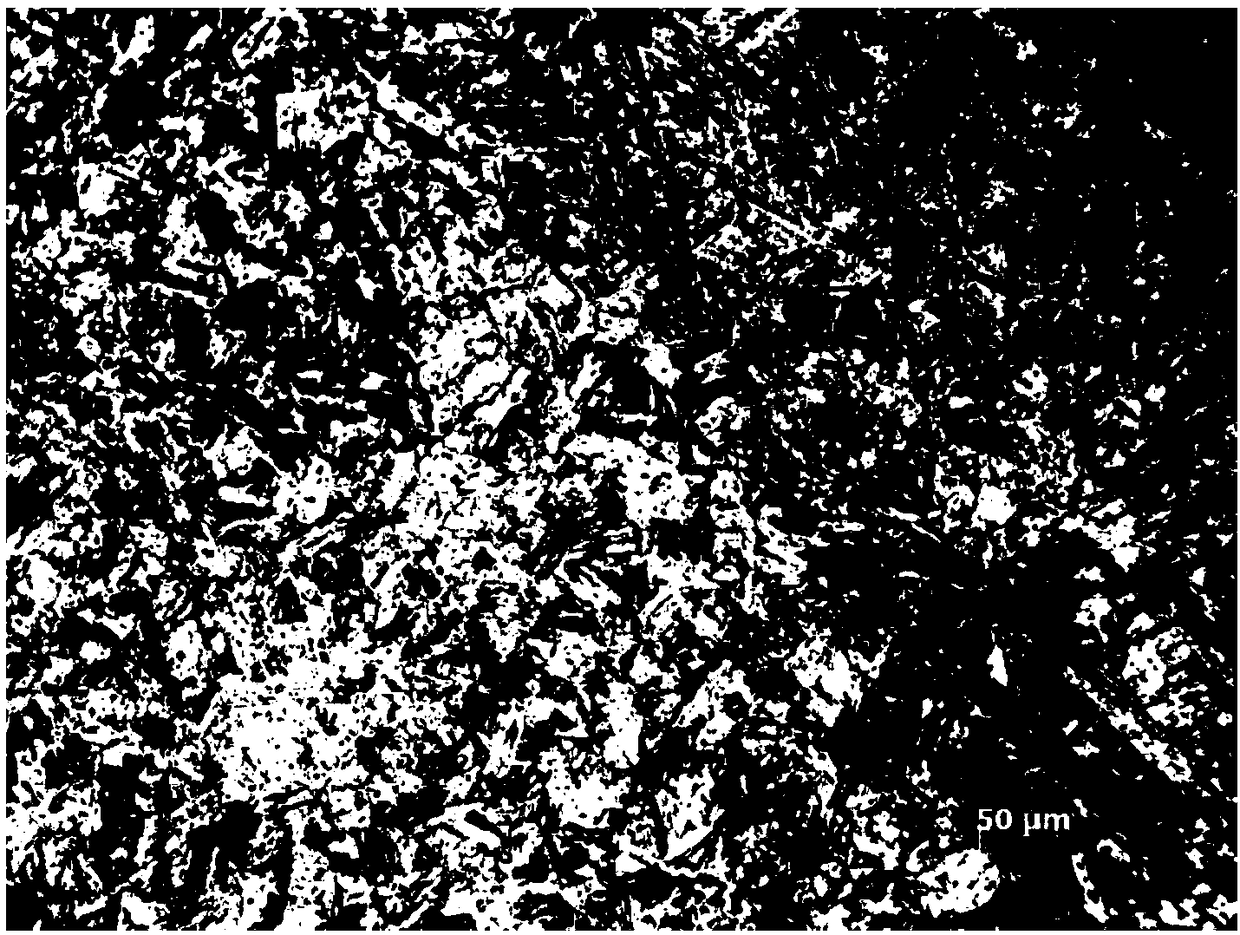

[0060] Establish a three-dimensional model according to the formed parts, use image layering software to slice and layer the three-dimensional model, the height of each layer is 0.02mm, and use path planning software to design the forming path. The new martensitic heat-resistant steel castings were forged into wire rods and cold drawn into wires with a diameter of 1 mm. Among them, the composition of the new martensitic heat-resistant steel castings includes: 0.07% carbon, 0.2% silicon, 0.5% manganese, 8.0% chromium, 1.5% tungsten, 0.2% molybdenum, 0.15% vanadium, 0.15% tantalum, 0.05% LaB6, the balance is iron.

[0061] Feed the obtained wire through the wire feeding device, energize and radiate the arc, and the laser beam of the laser induces the arc to scan according to the forming path of the current layer. The purity of the gas is ≥99.99%. The laser power is 400w, the energizing current is 132A, the energizing voltage is 14.6V, the wire feeding speed is 3m / min, the defo...

Embodiment 2

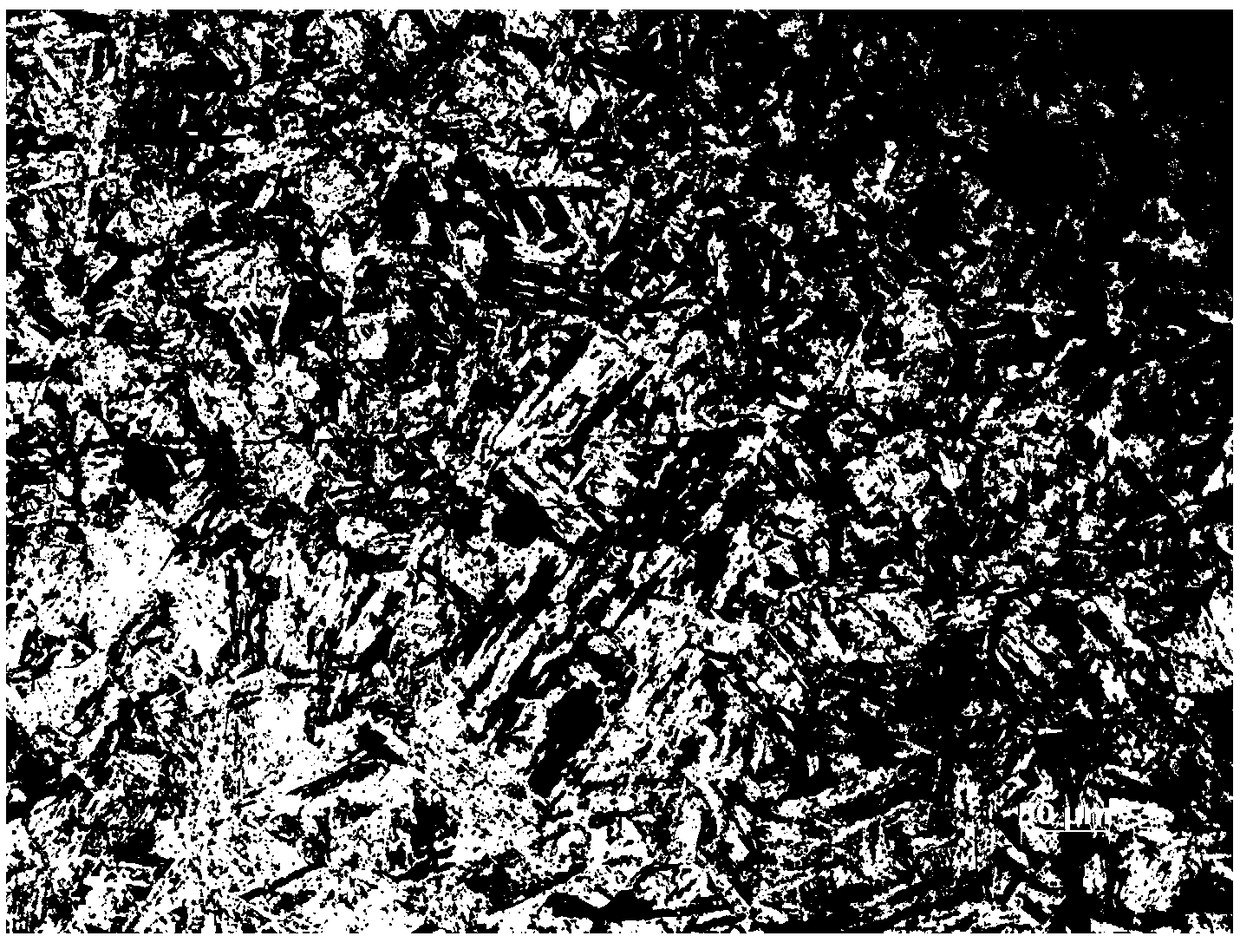

[0064] The seamless steel pipe thin-walled elbow was prepared according to the method described in Example 1. The difference from Example 1 is that the composition of the novel martensitic heat-resistant steel casting in this example includes: 0.11% carbon, 0.4% silicon, 0.5% manganese, 9.1% chromium, 1.5% tungsten, 0.4% molybdenum, 0.2% vanadium, 0.15% tantalum, 0.05% LaB6, and the balance is iron.

[0065] The above-mentioned new type of martensitic heat-resistant steel casting is prepared by laser additive manufacturing method for seamless steel pipe thin-walled elbow, the height of each layer is 0.06mm, the laser power is 500w, the current is 105A, and the voltage is 12.5V , the wire feeding speed is 4m / min, the defocus is 3mm, and the forming speed is 6mm / s. The process parameters of the stress relief annealing treatment are: 750° C. for 1.5 hours. attached figure 2 It is a picture of the metallographic structure of the seamless steel pipe thin-walled elbow prepared in...

Embodiment 3

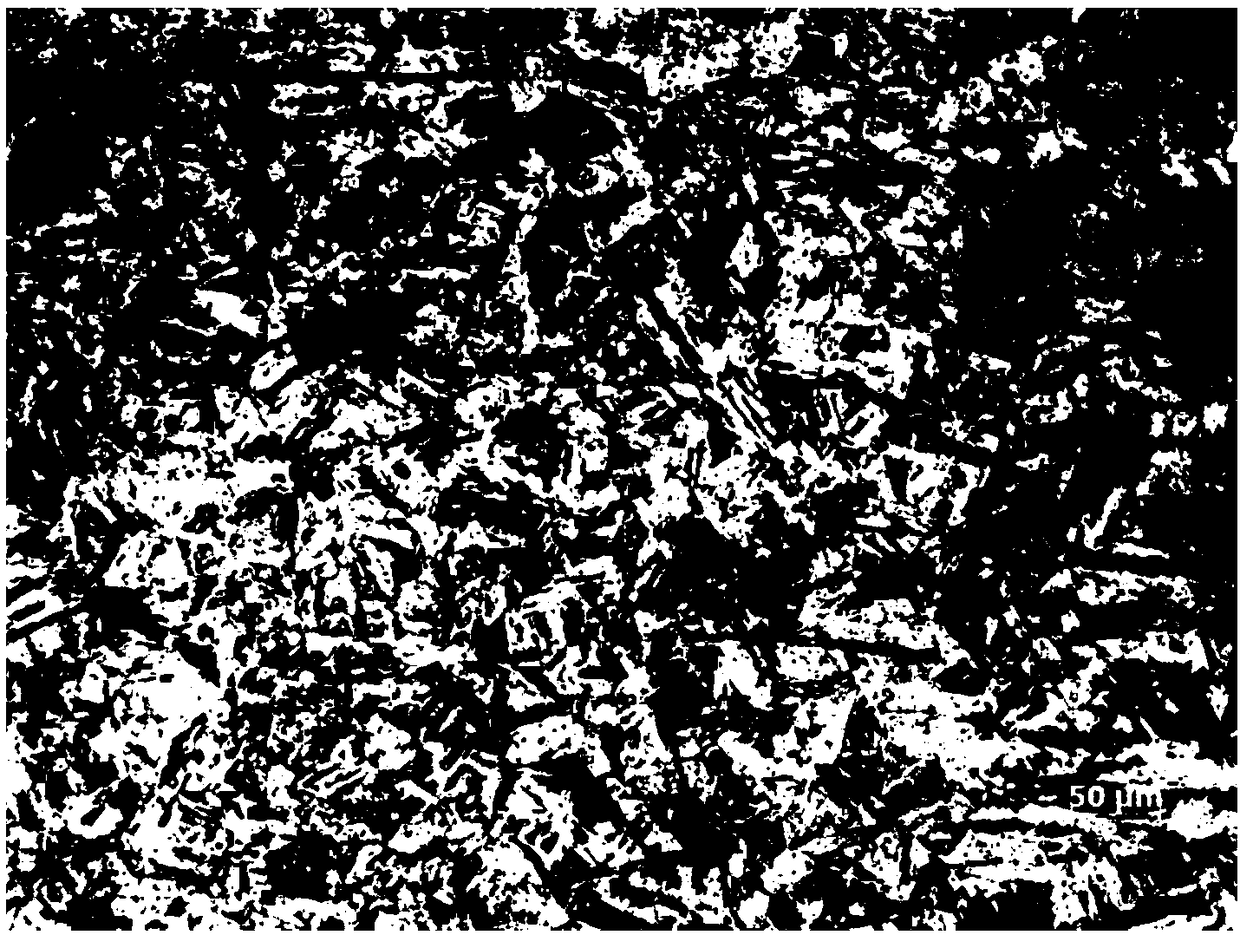

[0068] The seamless steel pipe thin-walled elbow was prepared according to the method described in Example 1. The difference from Example 1 is that the composition of the novel martensitic heat-resistant steel casting in this example includes: 0.15% carbon, 0.4% silicon, 0.5% manganese, 11.5% chromium, 1.5% tungsten, 0.6% molybdenum, 0.2% vanadium, 0.15% tantalum, 0.3% LaB6, and the balance is iron.

[0069] The above-mentioned new type of martensitic heat-resistant steel casting is prepared by laser additive manufacturing method for seamless steel pipe thin-walled elbow, the height of each layer is 0.1mm, the laser power is 600w, the current is 80A, and the voltage is 10.9V , the wire feeding speed is 5m / min, the defocus is 3mm, and the forming speed is 6mm / s. The process parameters of the stress relief annealing treatment are: 750° C. for 2 hours. attached image 3 It is a photo of the metallographic structure of the seamless steel pipe thin-walled elbow prepared in Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com