Ceramic base strip stacking mechanism

A technology based on base strips and ceramics, which is applied in the stacking, transportation and packaging of objects, which can solve the problems of low efficiency and achieve the effects of avoiding fixture displacement, improving success rate and reducing height difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

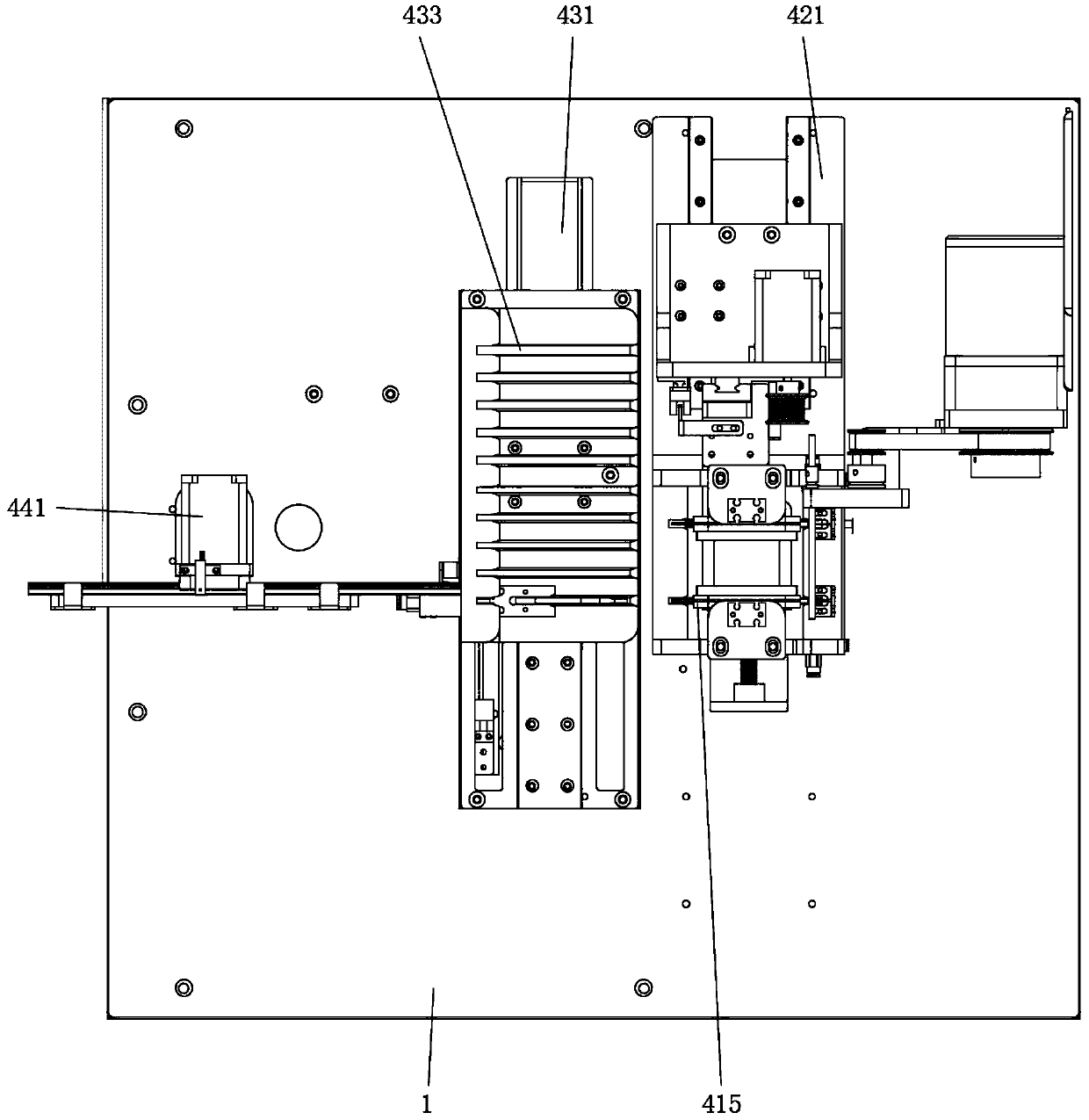

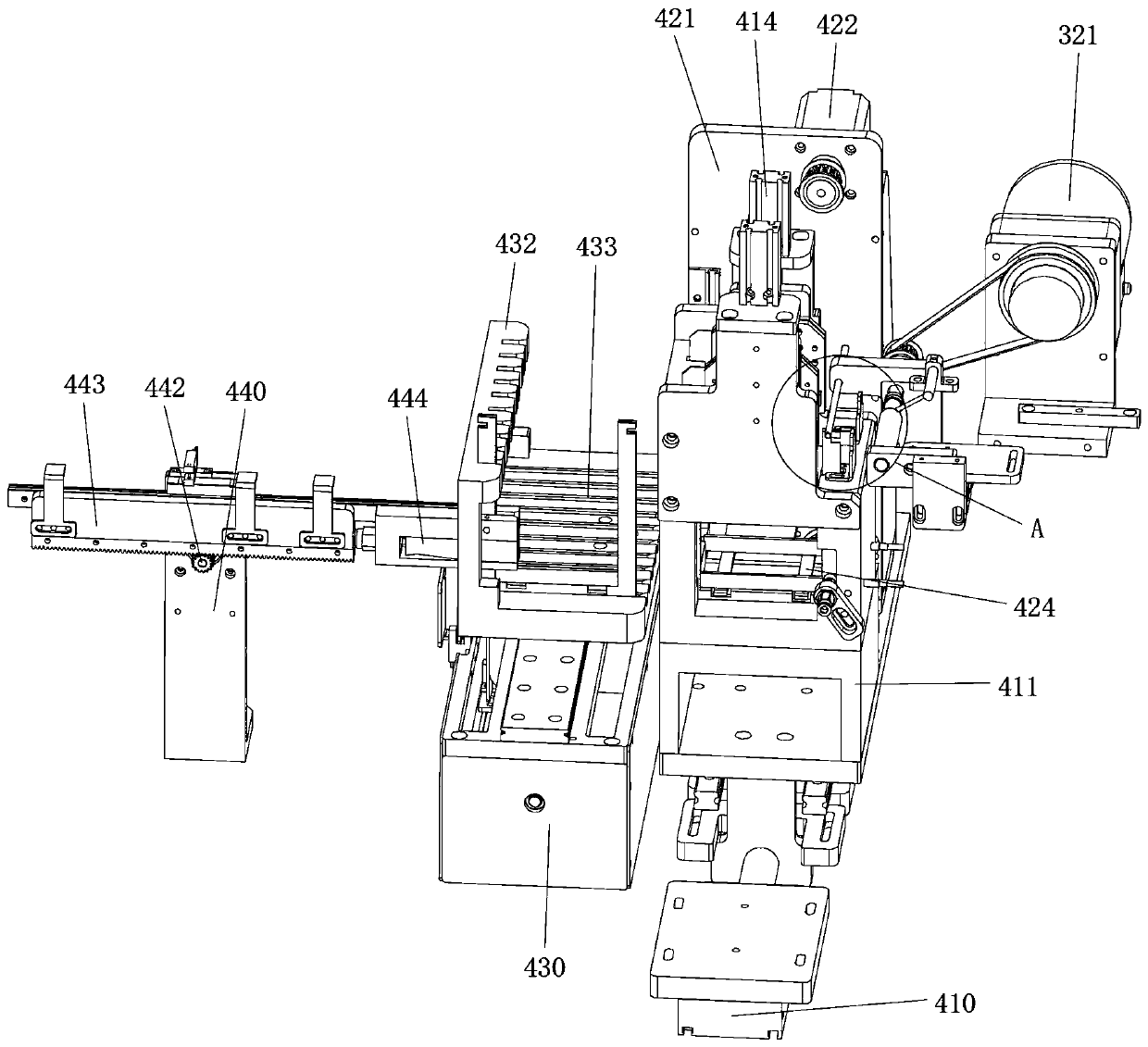

[0027] refer to Figure 1 to Figure 5 As shown, the present invention discloses a ceramic substrate stacking mechanism, which includes a base 1, a stacking unit and an upper and lower jig unit.

[0028] Stacking unit:

[0029] The above-mentioned stacking unit includes an entry acceleration component, a jig positioning component and a lifting component.

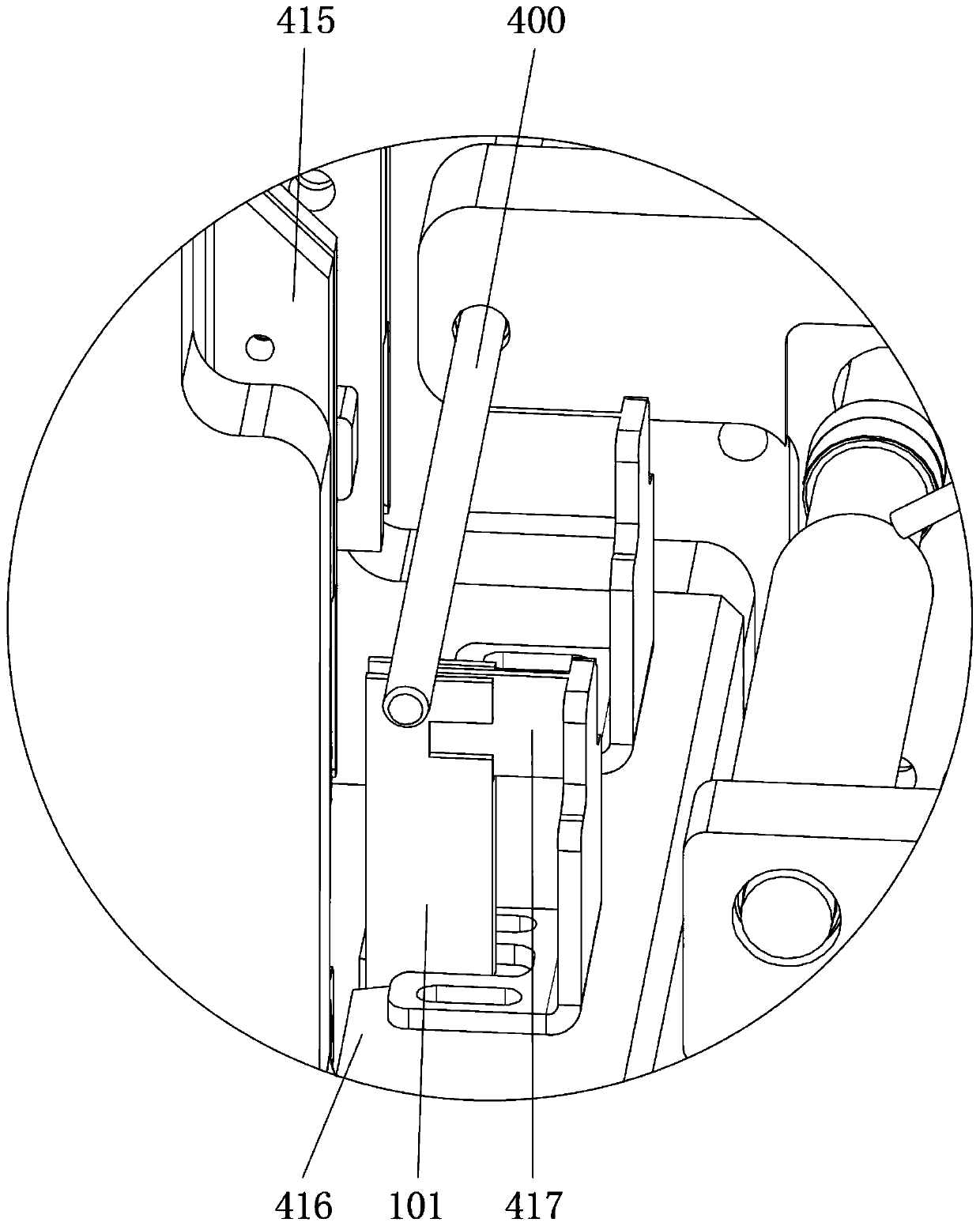

[0030] The above-mentioned entry acceleration assembly includes a drive motor 321 and an acceleration rod 400 both arranged on the base 1 . The accelerator rod 400 is connected to the free end of the drive motor 321 . The accelerator rod 400 continues at the end of the previous conveying section. The accelerating rod 400 has a higher rotational speed, which enables the ceramic substrate to be ejected at a higher initial speed.

[0031] The jig positioning assembly includes a stacking bracket 411 , a positioning drive source 414 and a positioning claw 415 .

[0032] The above-mentioned stacking bracket 411 is disposed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com