Patents

Literature

64results about How to "Accurate drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

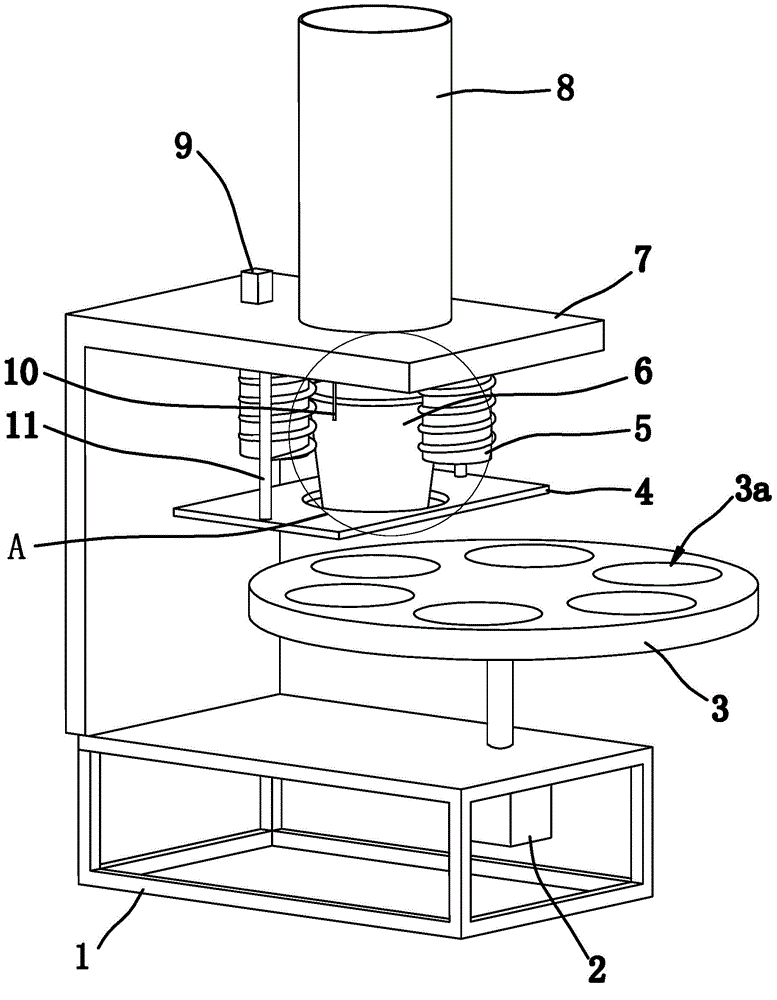

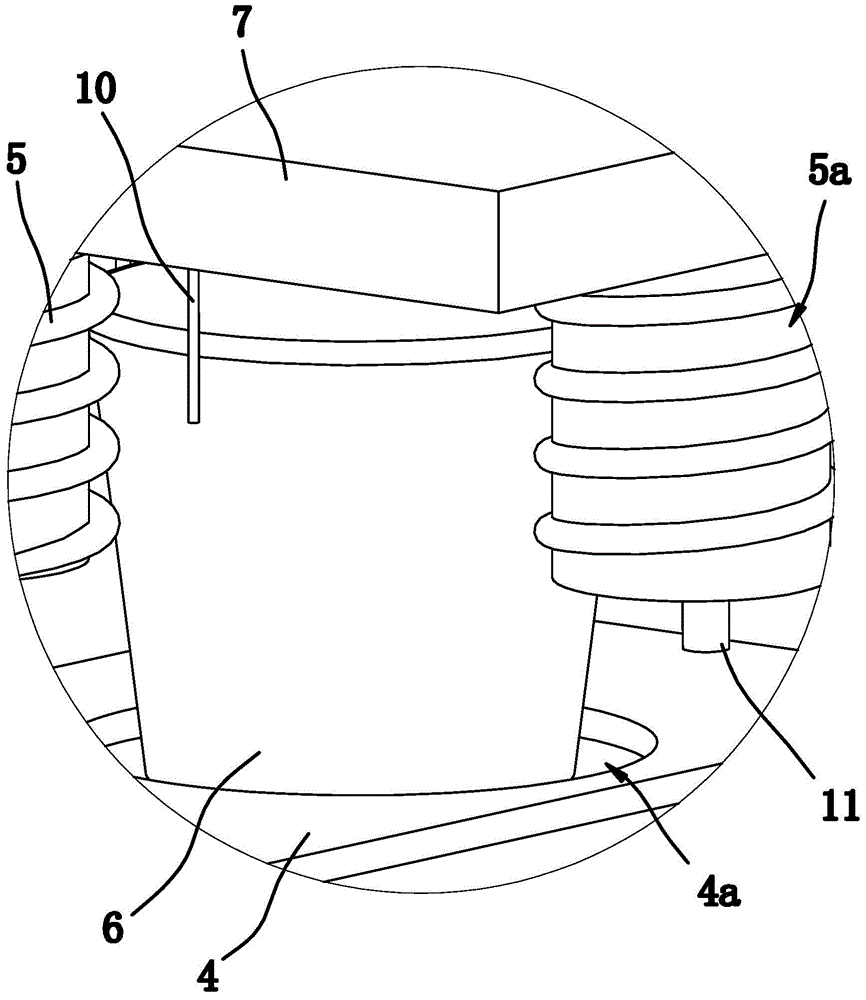

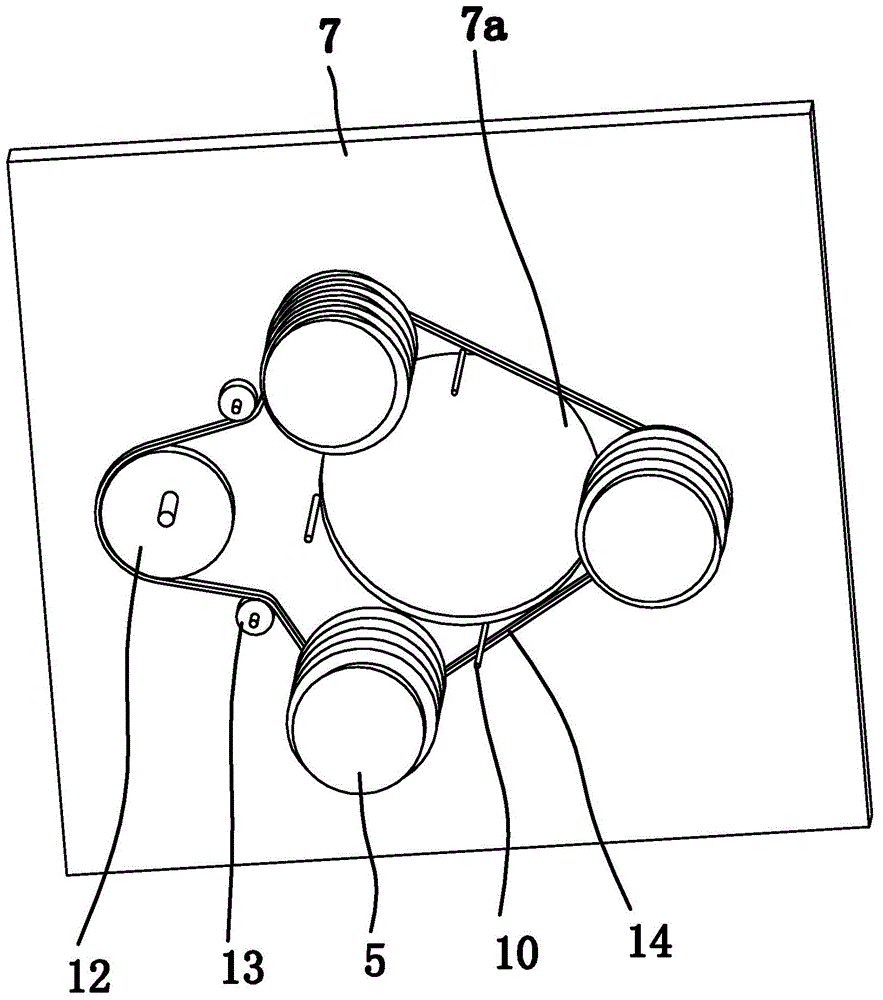

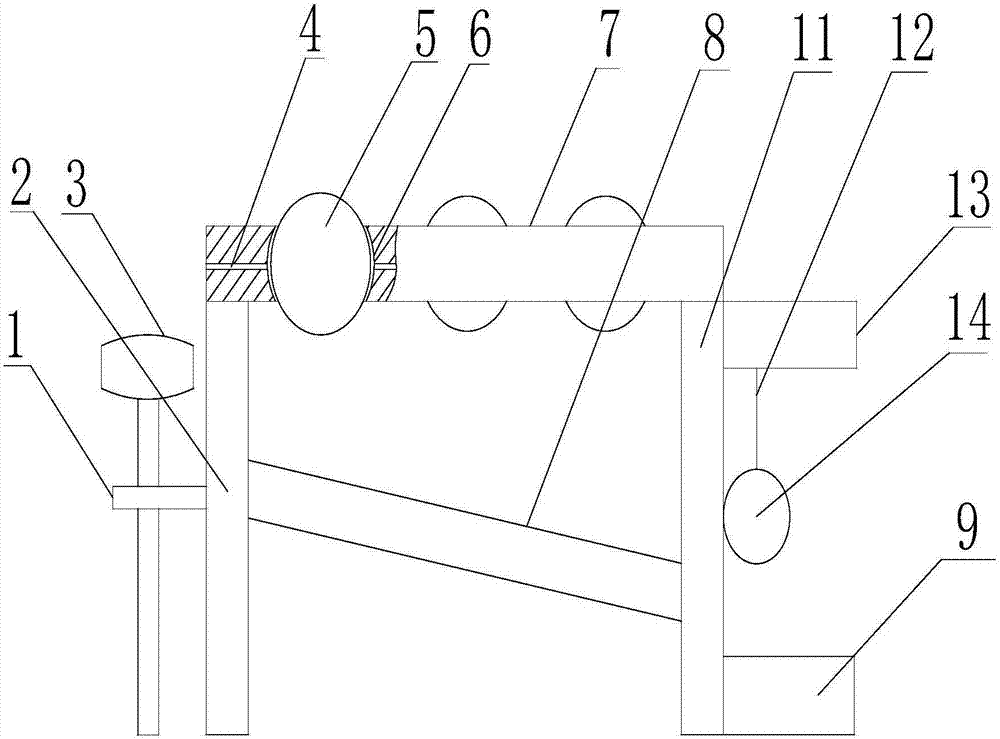

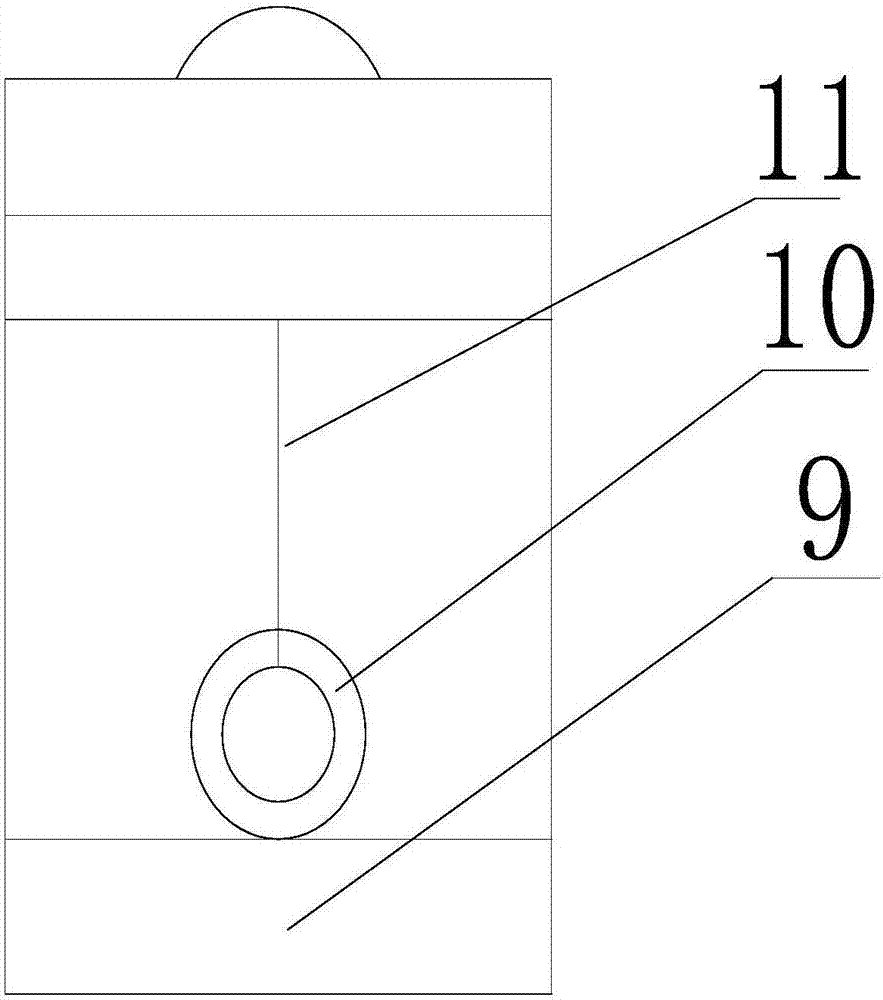

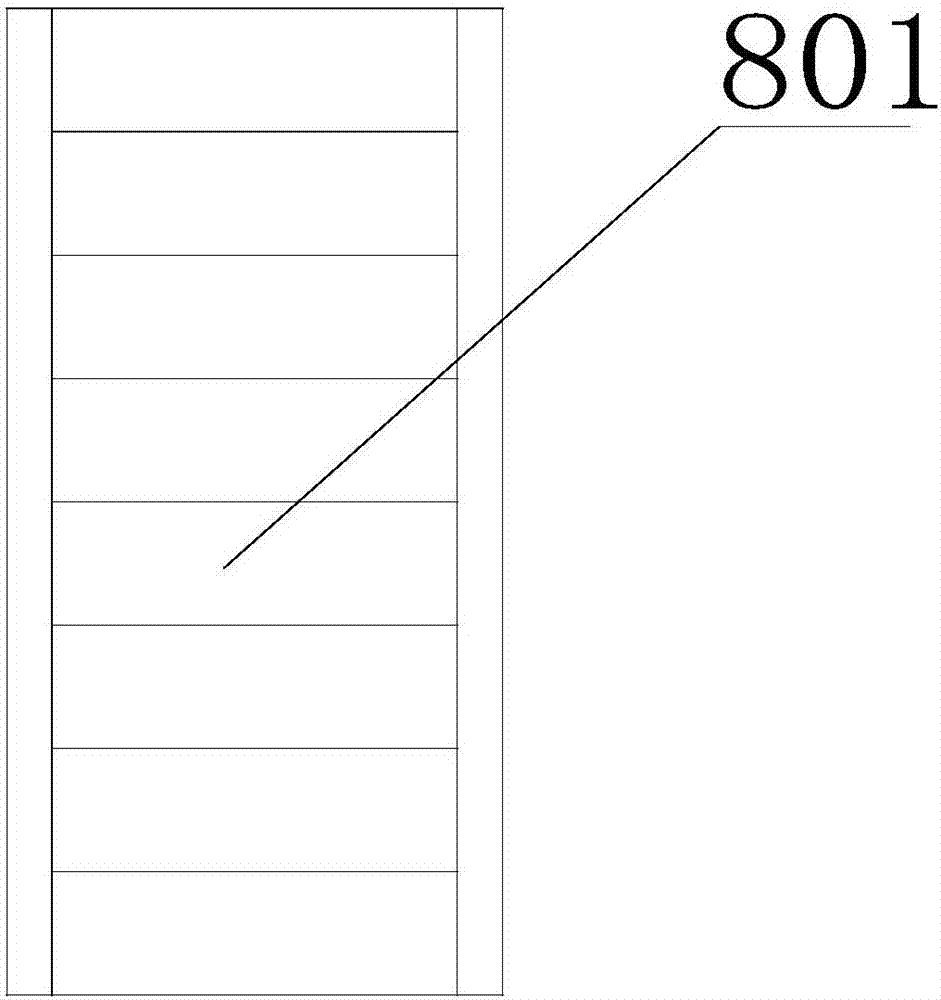

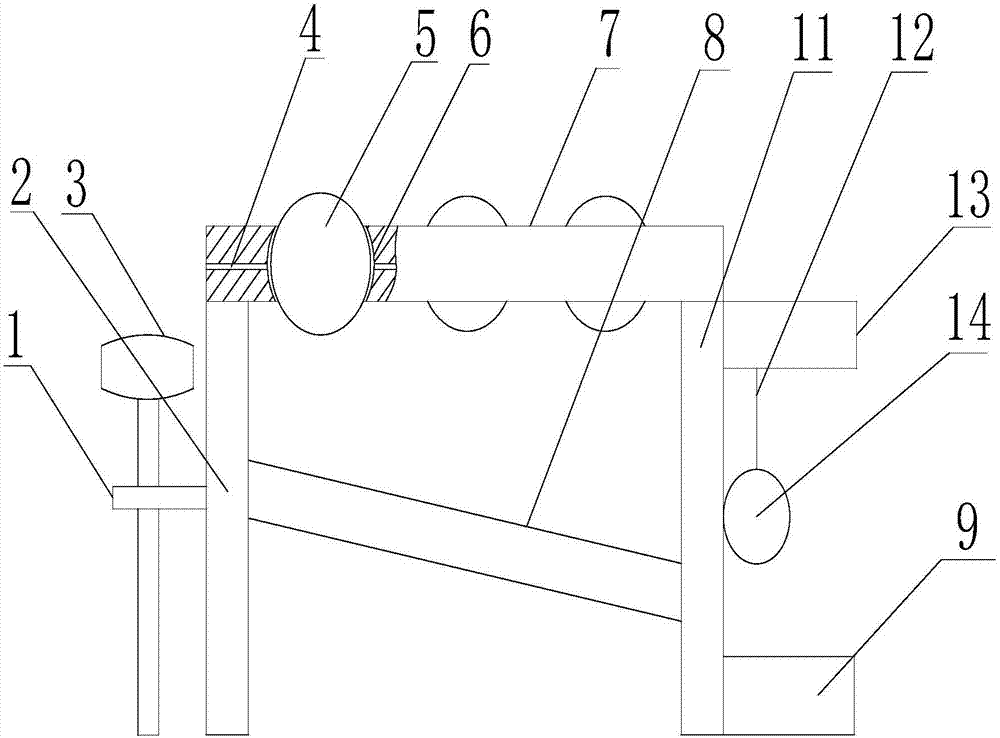

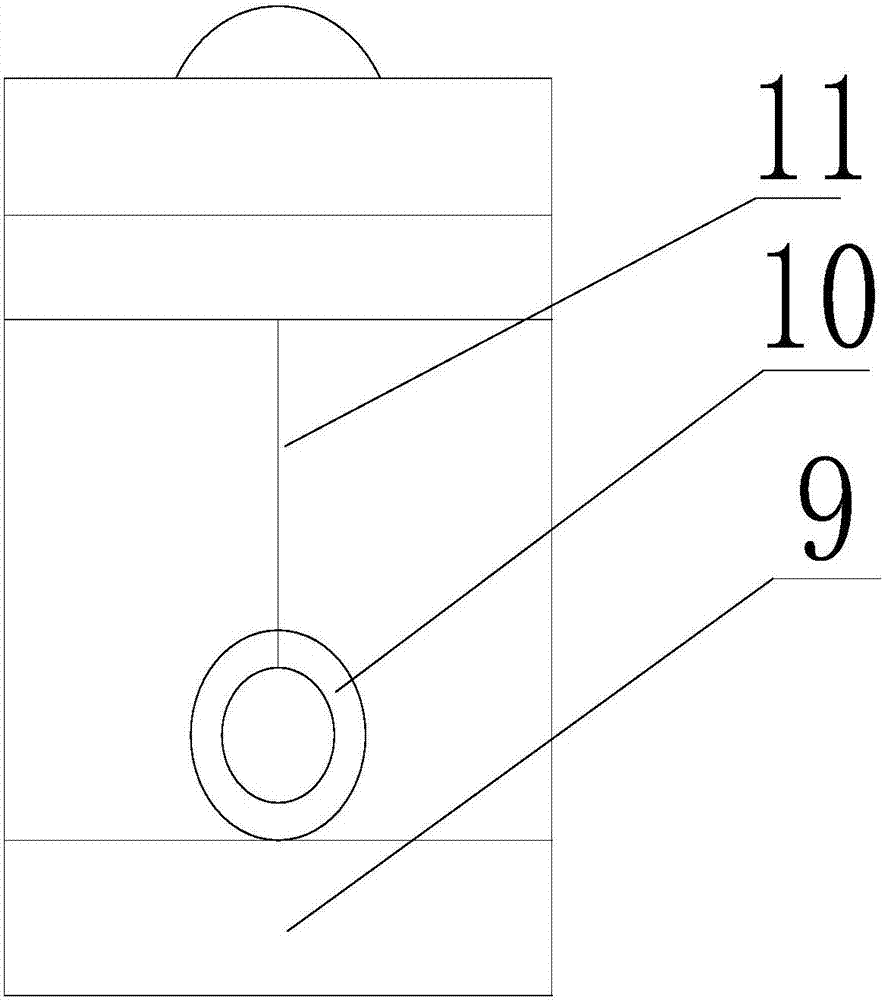

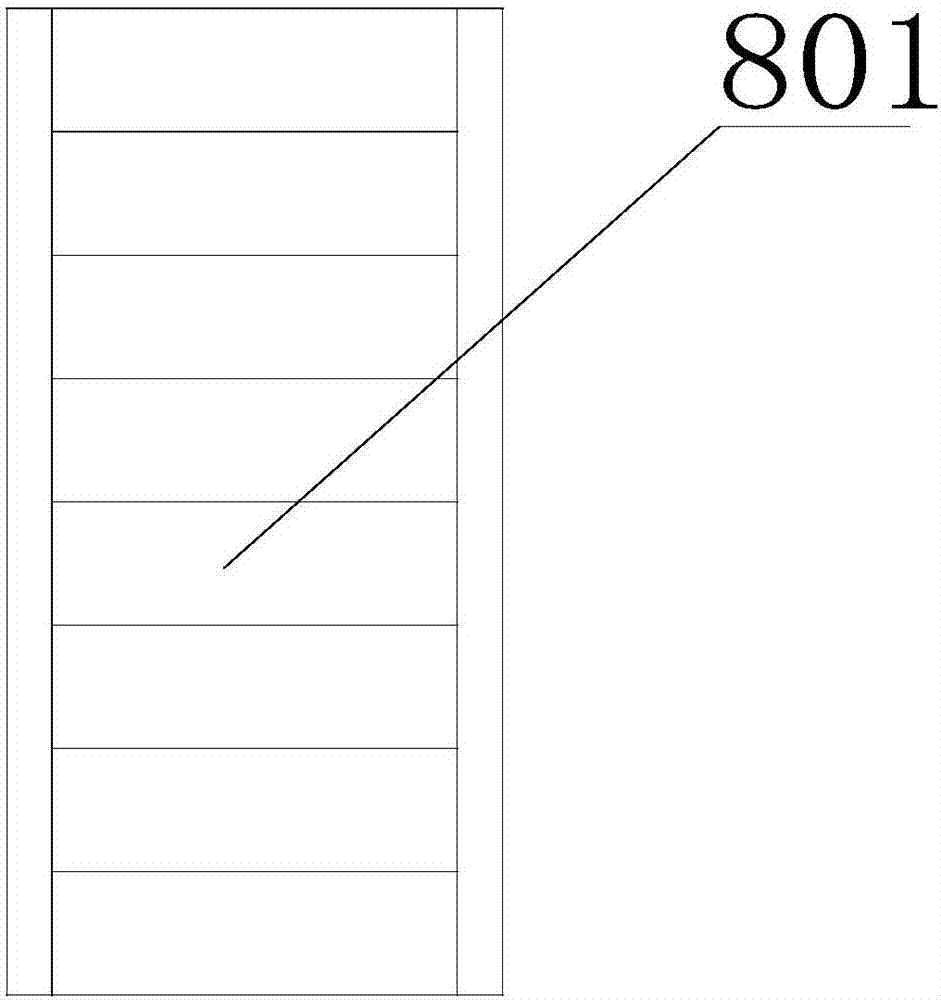

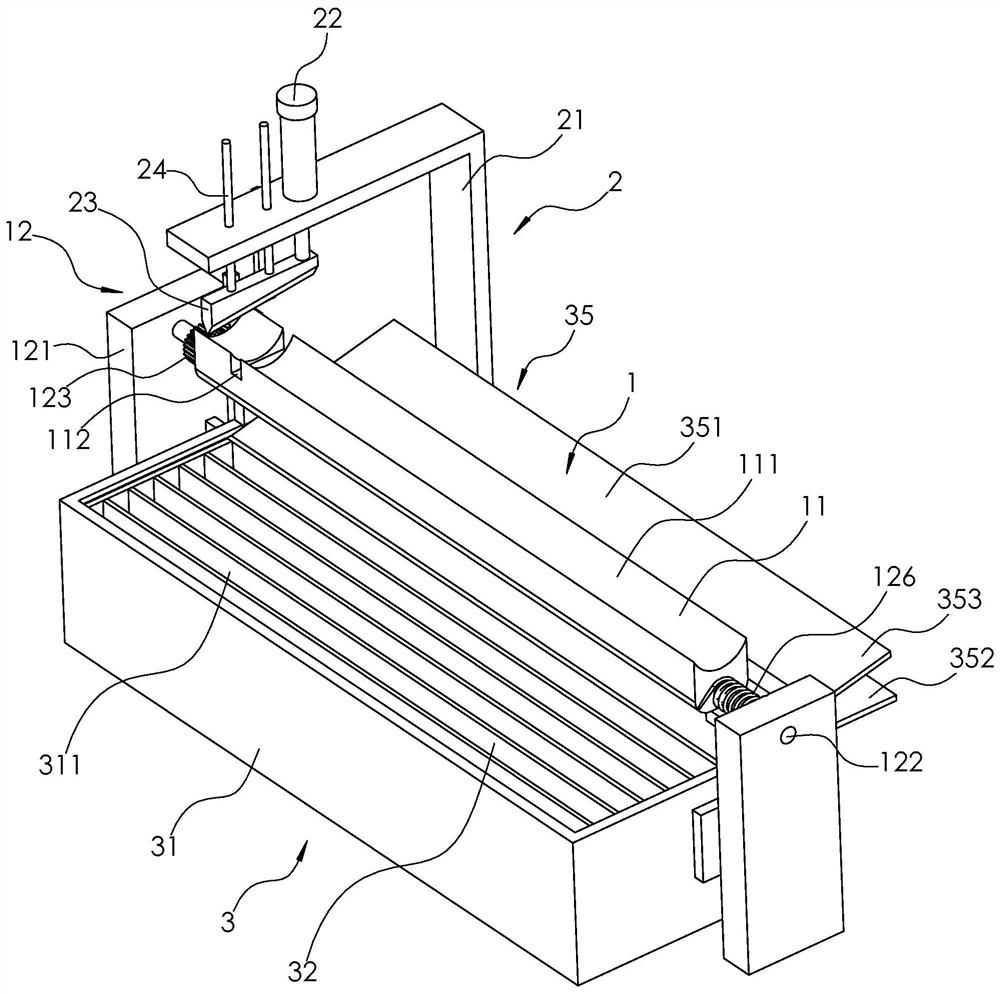

Feeding mechanism in paper cup tapping device

InactiveCN104528333AAchieve dropImprove feeding efficiencyPaper/cardboard wound articlesConveyor partsPulp and paper industryCup feeding

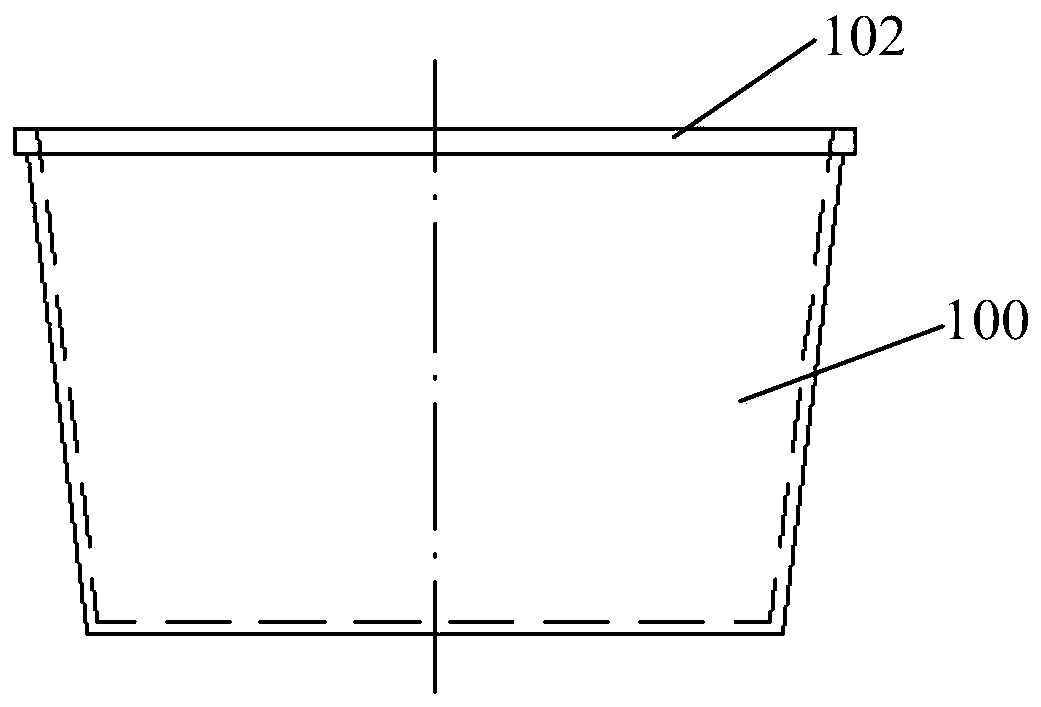

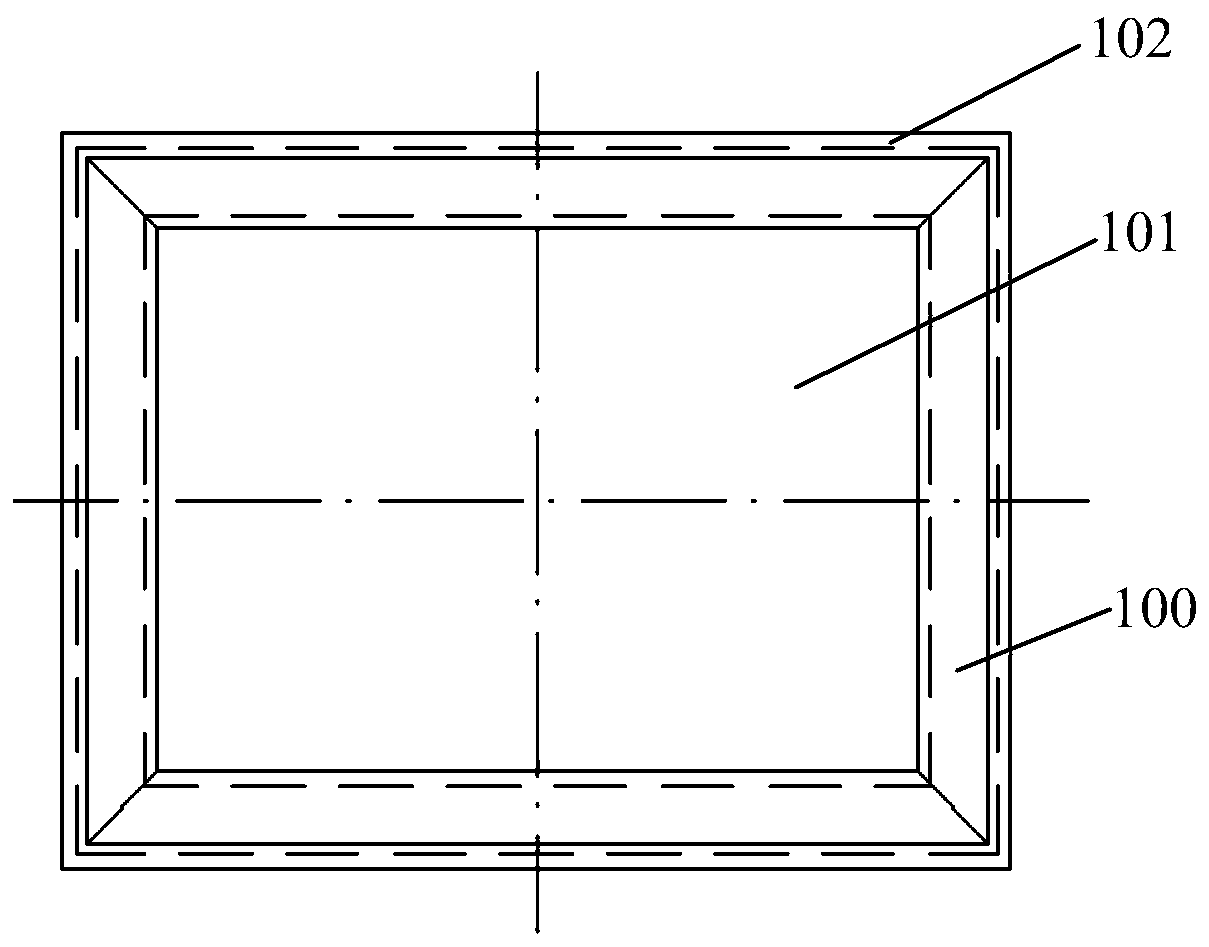

The invention provides a feeding mechanism in a paper cup tapping device, and belongs to the technical field of machinery. The feeding mechanism solves the technical problems that an existing cup feeding device cannot convey paper cups tidily one after the other, and the paper cups need to be tidied manually, so that the production efficiency is low, and the like. The feeding mechanism in the paper cup tapping device is arranged at the tapping device and comprises a cylindrical cup storing barrel and a horizontally arranged mounting plate; the mounting plate is provided with through discharge holes; the lower end of the cup storing barrel is fixedly connected to the upper part of the mounting plate; the cup storing barrel is communicated with the discharge holes; the lower part of the mounting plate is provided with at least three feeding rods; a positioning part used for being clamped at the convex edge of a paper cup opening is formed among the feeding rods; the lower part of the mounting plate is also connected with a turntable; the turntable is linked with a power piece capable of controlling the turntable to intermittently rotate; the part, close to the edge of the turntable, of the turntable is circumferentially and uniformly provided with a plurality of positioning holes for positioning the paper cups by taking the center of the turntable as a datum. The feeding mechanism has the advantages of high feeding efficiency and good guiding effect.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

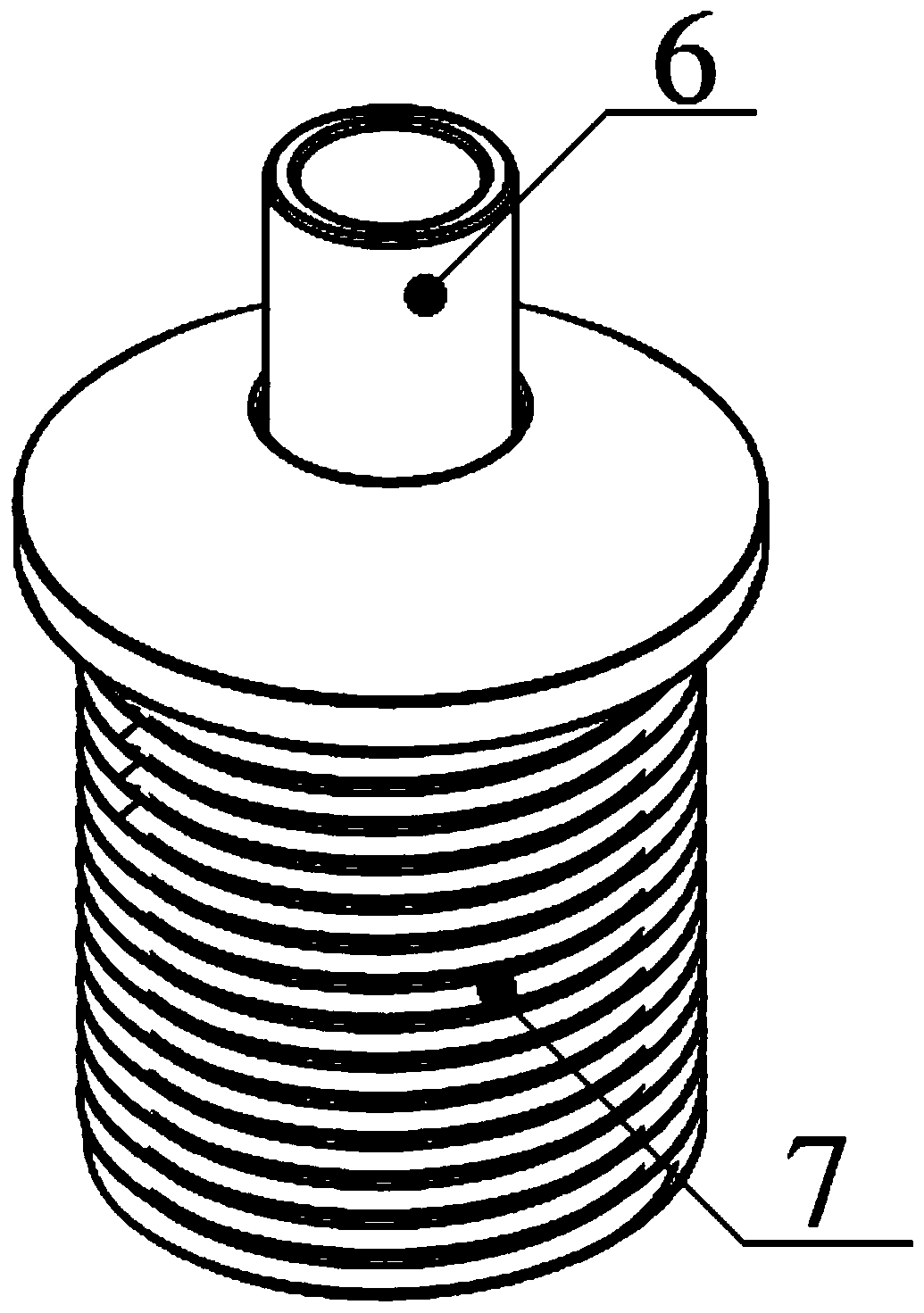

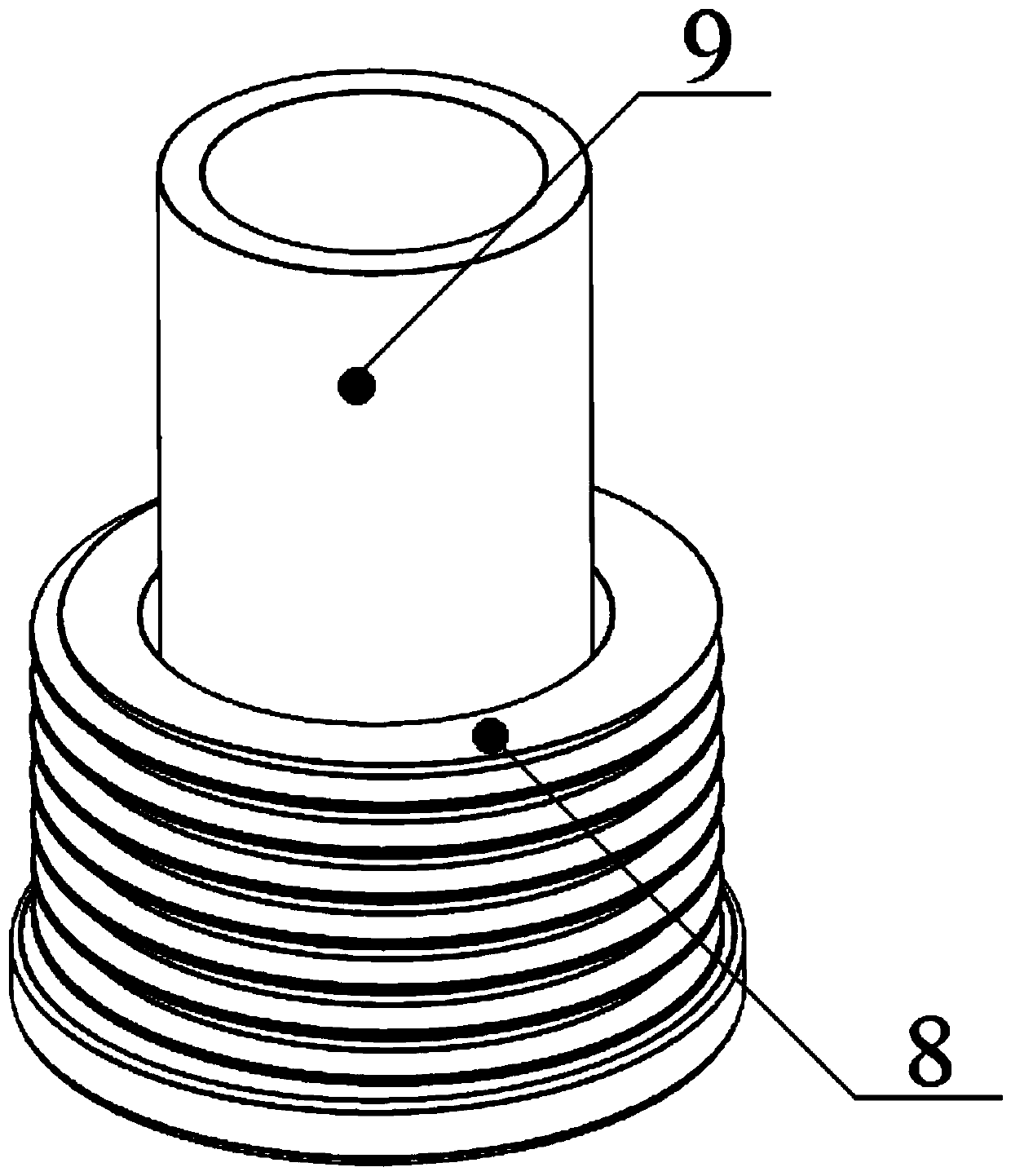

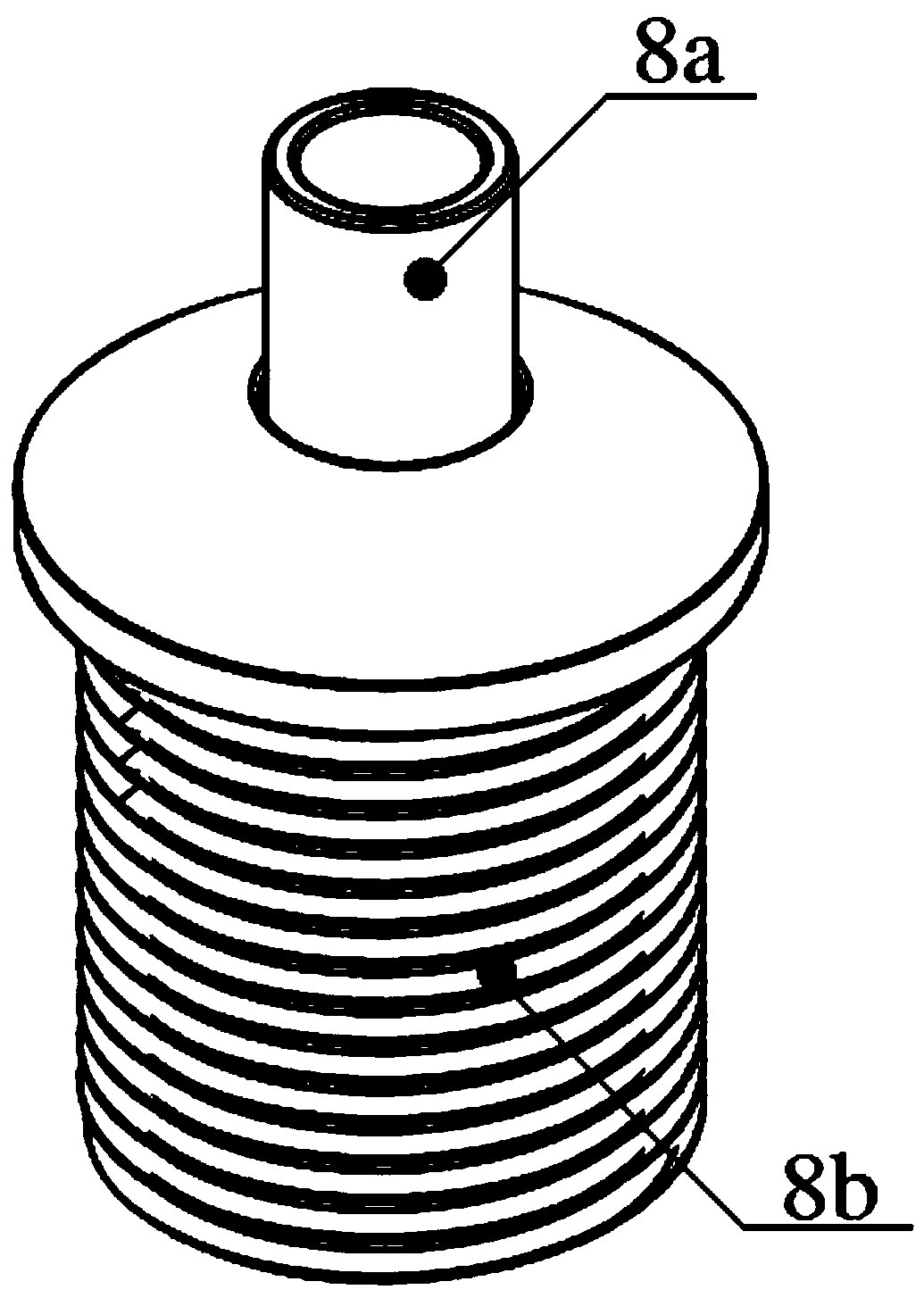

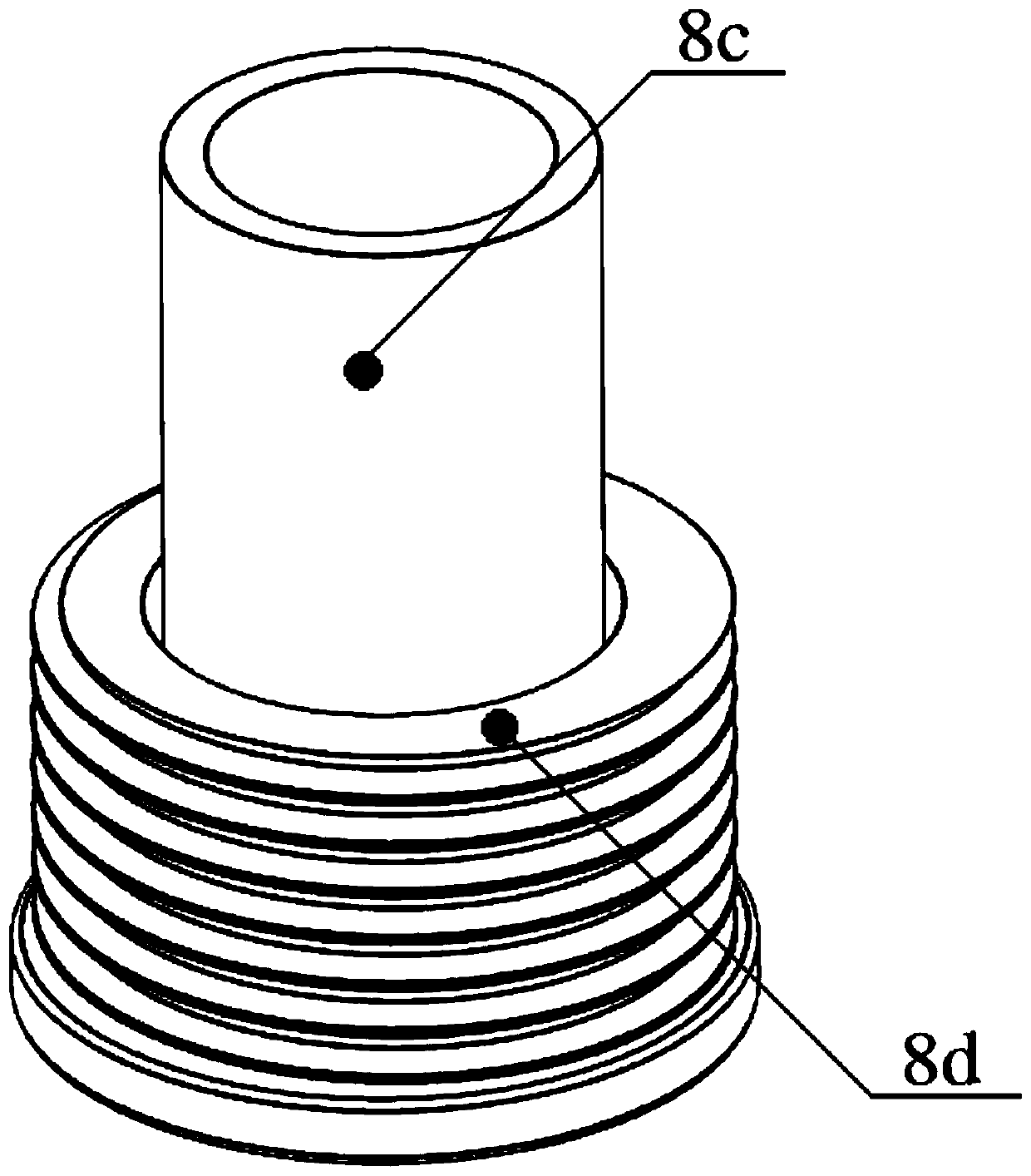

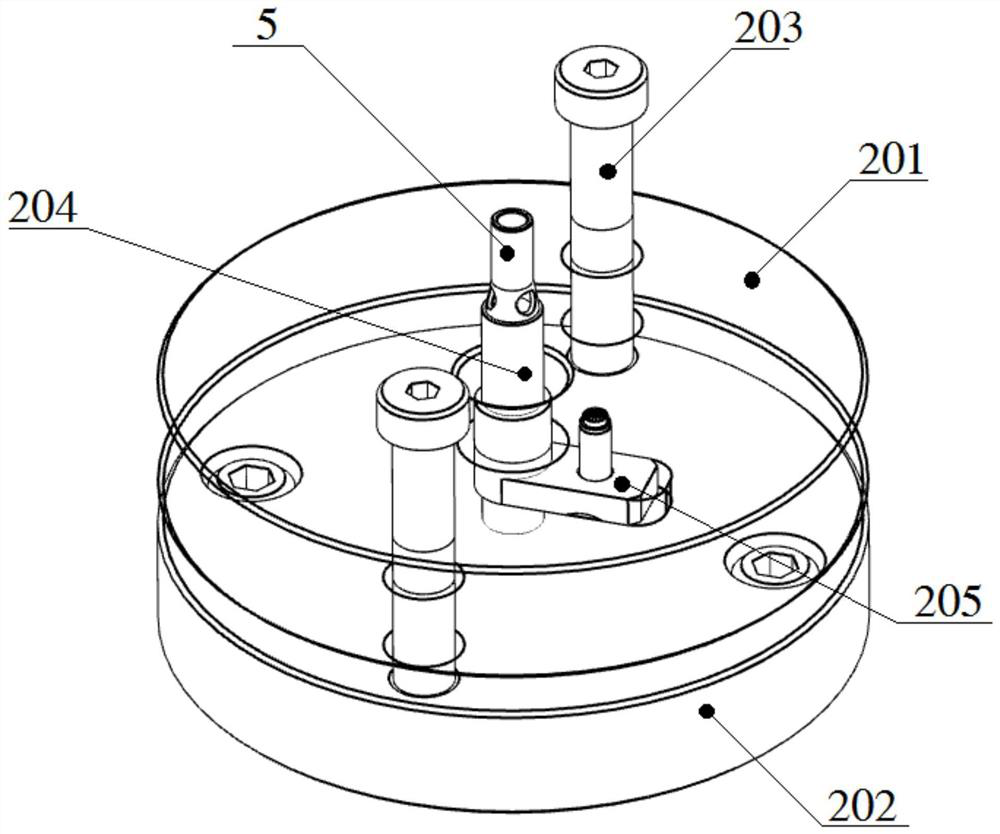

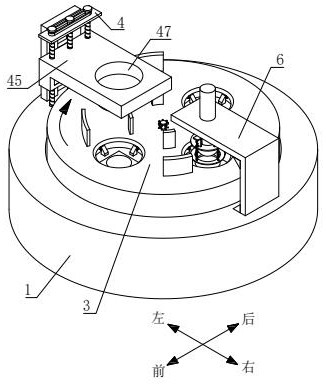

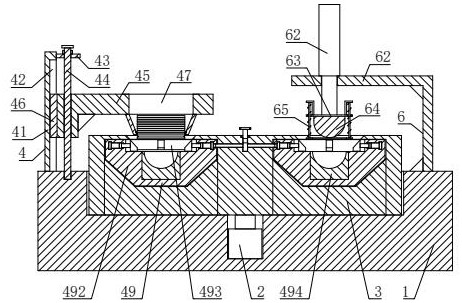

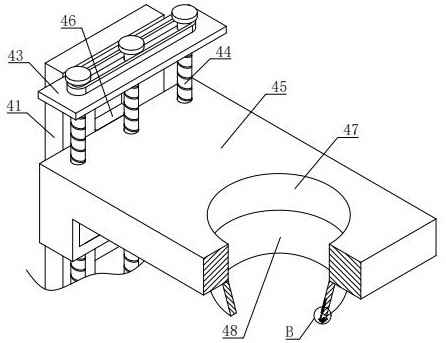

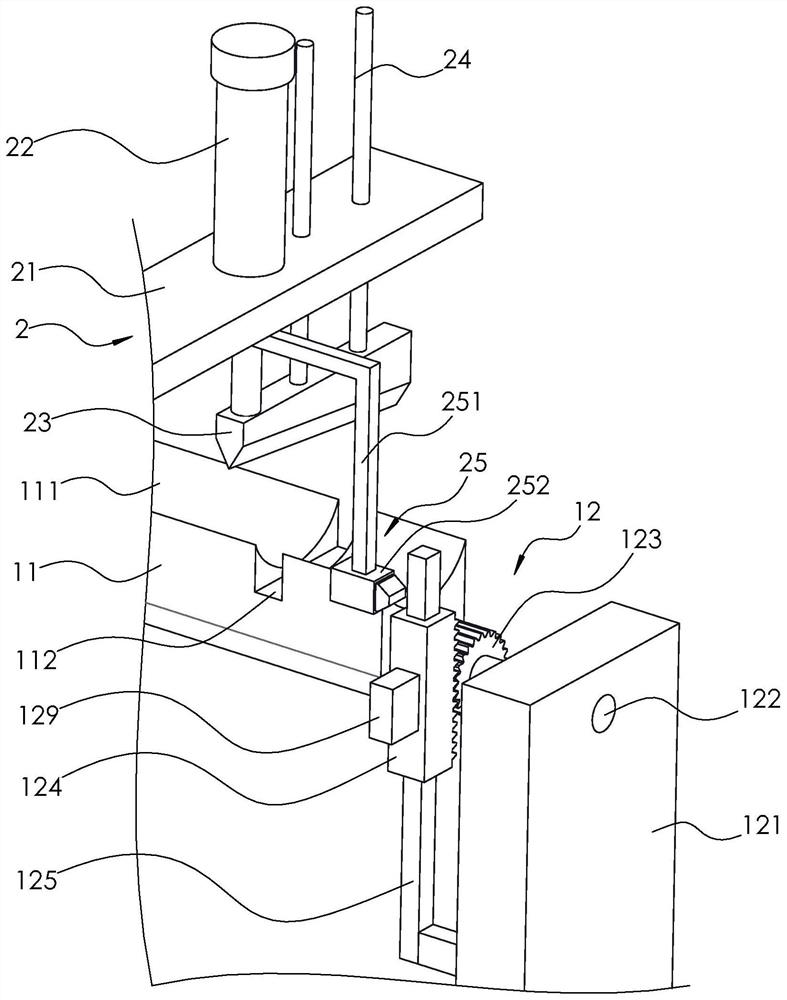

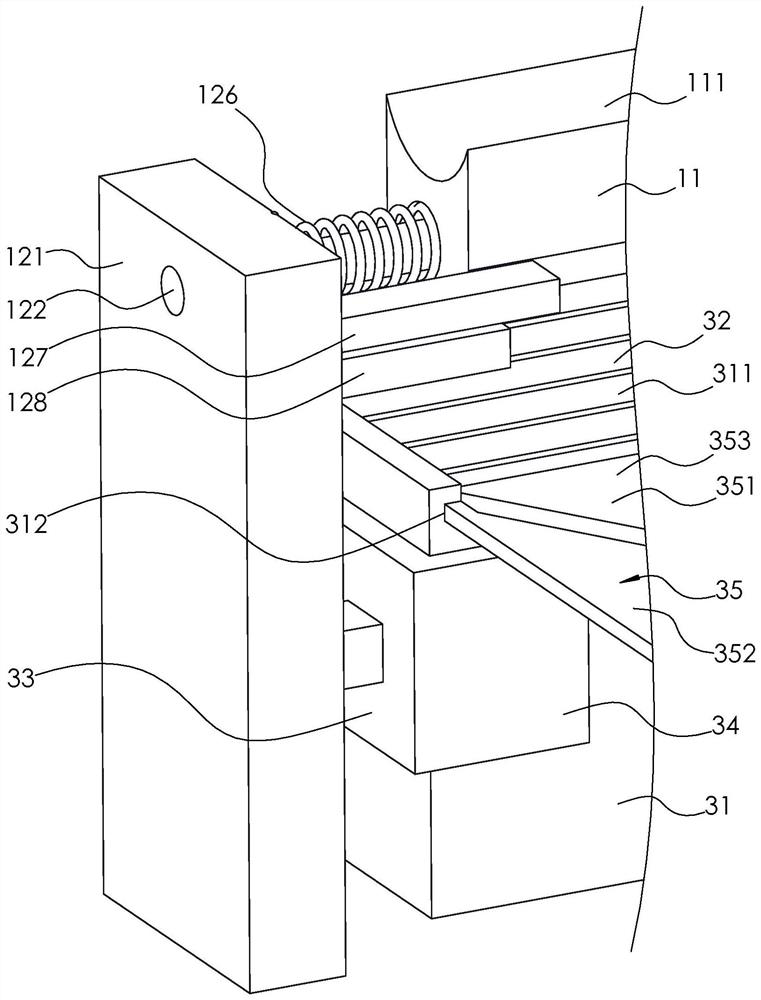

Automatic feeding and copper cap screwing device

ActiveCN111331368AEasy to processAvoid displacementAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention provides an automatic feeding and copper cap screwing device. The automatic feeding and copper cap screwing device comprises a containing tool rotationally arranged on the top surface ofa rotating platform and used for storing a stand column, a shell feeding mechanism is arranged beside the rotating platform, a feeding opening of the shell feeding mechanism is arranged above a rotating track of the containing tool, the shell feeding mechanism is used for receiving a shell and arranging the shell on the stand column in a sleeving mode, a copper cover screwing mechanism is arranged beside the rotating platform, a feeding part of the copper cover screwing mechanism is arranged above the rotating track of the containing tool, a copper cover spring feeding mechanism communicateswith the copper cover screwing mechanism, the copper cover spring feeding mechanism is used for receiving and assembling a copper cover and a spring and conveying the copper cover and the spring to the copper cover screwing mechanism, and the copper cover screwing mechanism is used for assembling the shell, the stand column, the copper cover and the spring together. The automatic feeding and copper cap screwing device has reasonable design and high automation degree, realizes efficient assembly production of the shell, the stand column, the spring and the copper cover, reduces labor intensityof personnel and error rate of manual operation, and improves production efficiency and quality.

Owner:SHAOYANG UNIV +1

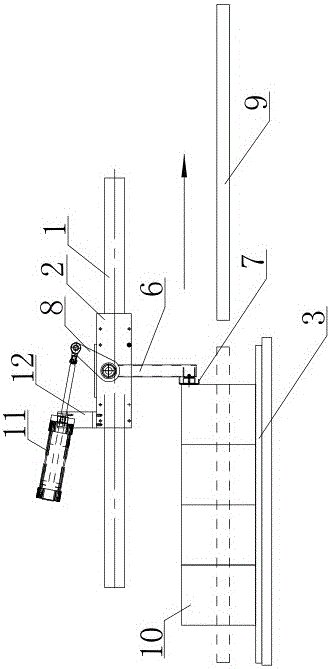

Box stop device

The invention discloses a box stop device. The box stop device comprises a support frame mounted on a frame, wherein a support shaft is fixedly mounted on the support frame, and is coated with a shaft sleeve; the shaft sleeve can rotate on the support shaft, and is fixedly connected with a stop rod; the outer end of the stop rod is fixedly connected with a stop plate; the shaft sleeve is fixedly connected with a swing rod; under the driving of a driving device, the swing rod can drive the shaft sleeve to forwards rotate or reversely rotate on the support shaft; the shaft sleeve forwards rotates on the support shaft so as to urge the stop plate to move to the outer side of a box on a transplantation platform positioned rightly above a stamp plate and to stop the box moving in the return direction of the transplantation platform; and the shaft sleeve reversely rotates on the support shaft so as to urge the stop plate to move to a height higher than the top of the box on the transplantation platform. The box stop device has the advantages of largely simplifying the structure, effectively stopping the box moving in the leaving direction of the transplantation platform and guaranteeing the box to accurately drop on the stamp plate.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

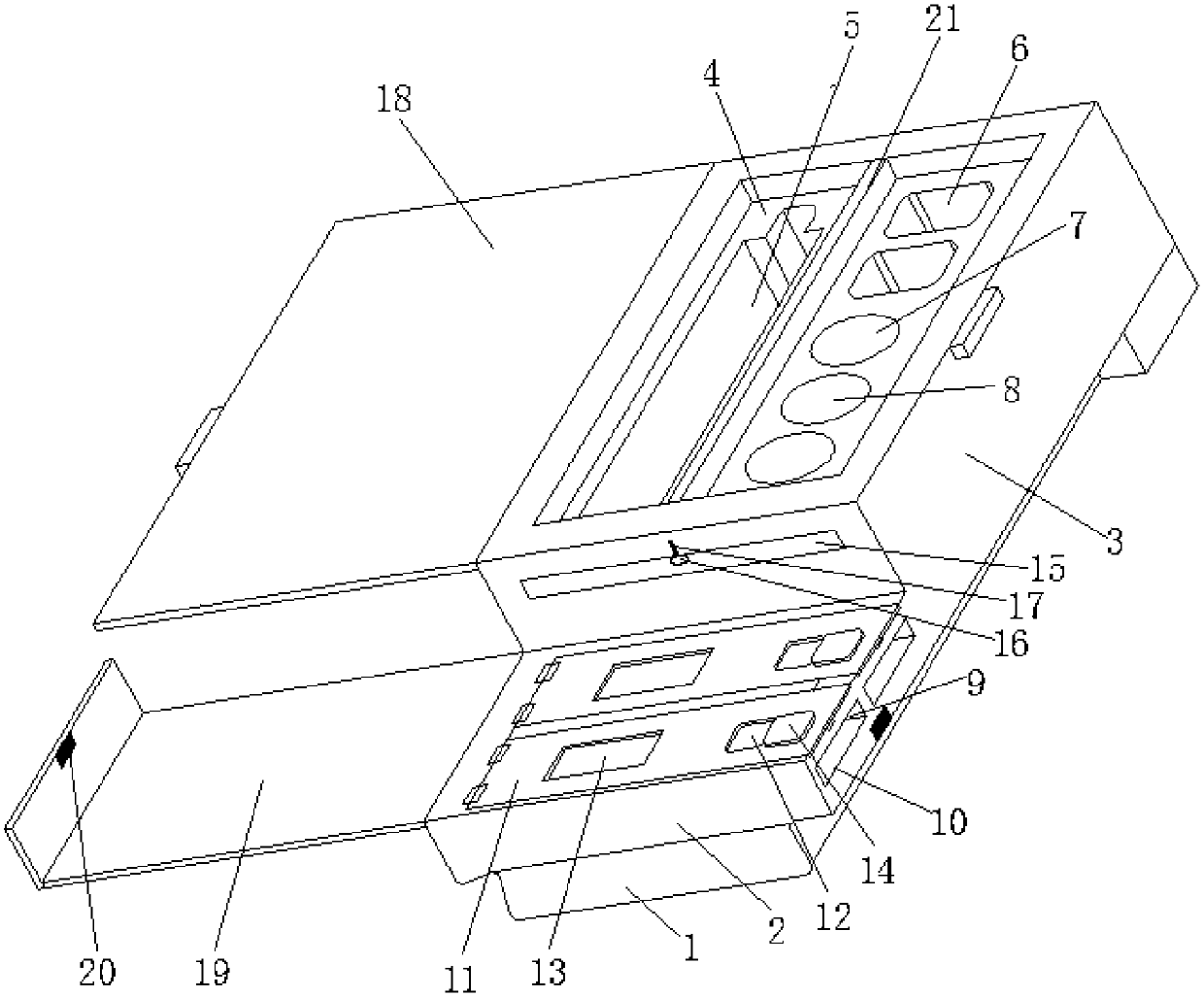

Handheld kit for food detection

The invention creatively provides a handheld kit for food detection. The handheld kit comprises a box body and a box cover, wherein a handheld base is arranged at the bottom of the box body; the box body comprises a detection box and a storage box which are fixedly sequentially connected; the upper end surface of the storage box sinks inwards to form a cavity structure, a placement pad is arrangedin the cavity of the storage box, and a test paper card storage slot, a reagent bottle slot, a sample pipe slot and a dropper slot are formed in the placement pad; a test paper card detection slot sinking inwards is formed in the upper end surface of the detection box, a test paper card insertion hole is formed in the right side wall, corresponding to the test paper card detection slot, of the detection box, a cover plate is arranged on the test paper card detection slot, and a sample feeding hole and an observation hole are formed in the cover plate. The handheld kit is low in environmentalrequirements on field detection, the structures of all parts of the whole box are designed according to a thought for facilitating handheld operation, and the layout of the handheld kit is reasonable.

Owner:天津灵卫科技发展有限公司

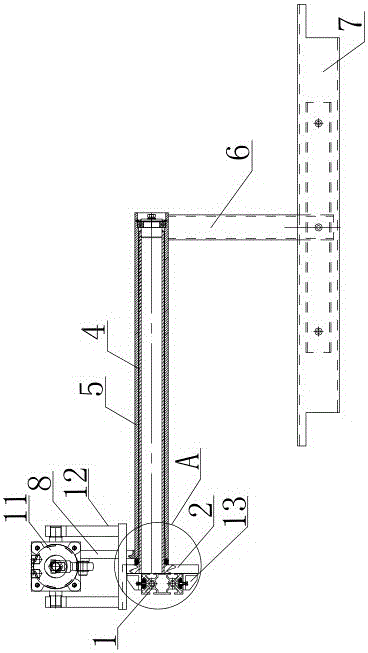

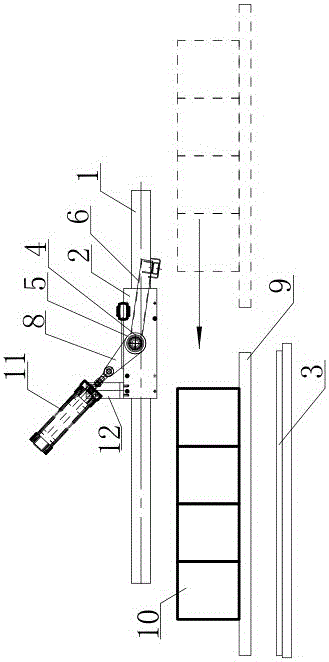

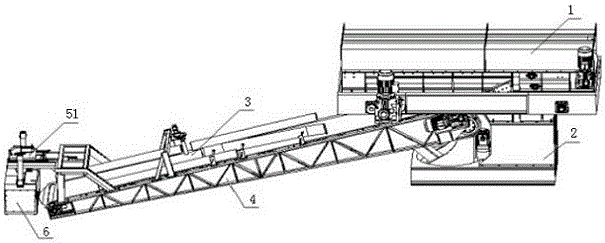

Rocker type automatic truck loading mechanical arm

ActiveCN106809655ASteady fallAccurate dropProgramme-controlled manipulatorStacking articlesEngineeringManipulator

The invention discloses a rocker type automatic truck loading mechanical arm. The rocker type automatic truck loading mechanical arm comprises a mechanical arm and a discharging box arranged at the discharging end of the mechanical arm. A small rack which is connected with the discharging box and is of a rigidity structure is fixedly arranged on the mechanical arm, and the discharging box is connected with the small rack through a universal adjusting device arranged on the small rack. A conveying mechanism is arranged in the mechanical arm, and the discharging end of the conveying mechanism corresponds to the discharging box. The discharging box is flexibly controlled through the universal adjusting device, in cooperation with the movement of the mechanical arm, the discharging box loaded with materials can rapidly and accurately move to any assigned position in a carriage in order, the problem about the blind area of automatic truck loading is solved, stacking is accurate, and the automatic truck loading efficiency is high.

Owner:MIANYANG LANAO HEAVY MACHINERY MFG

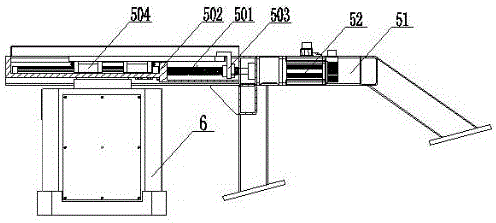

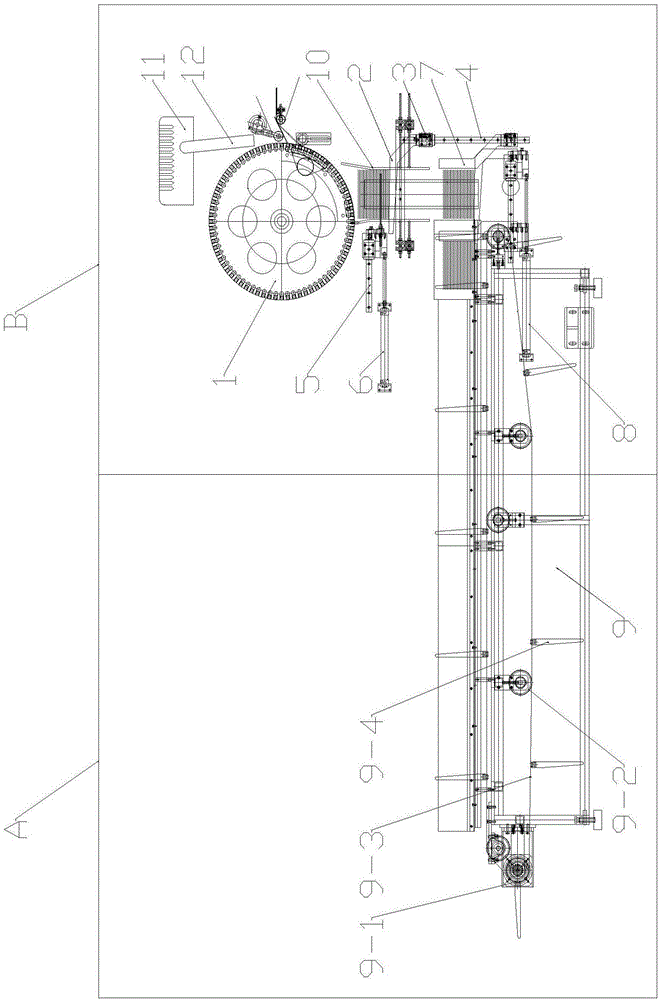

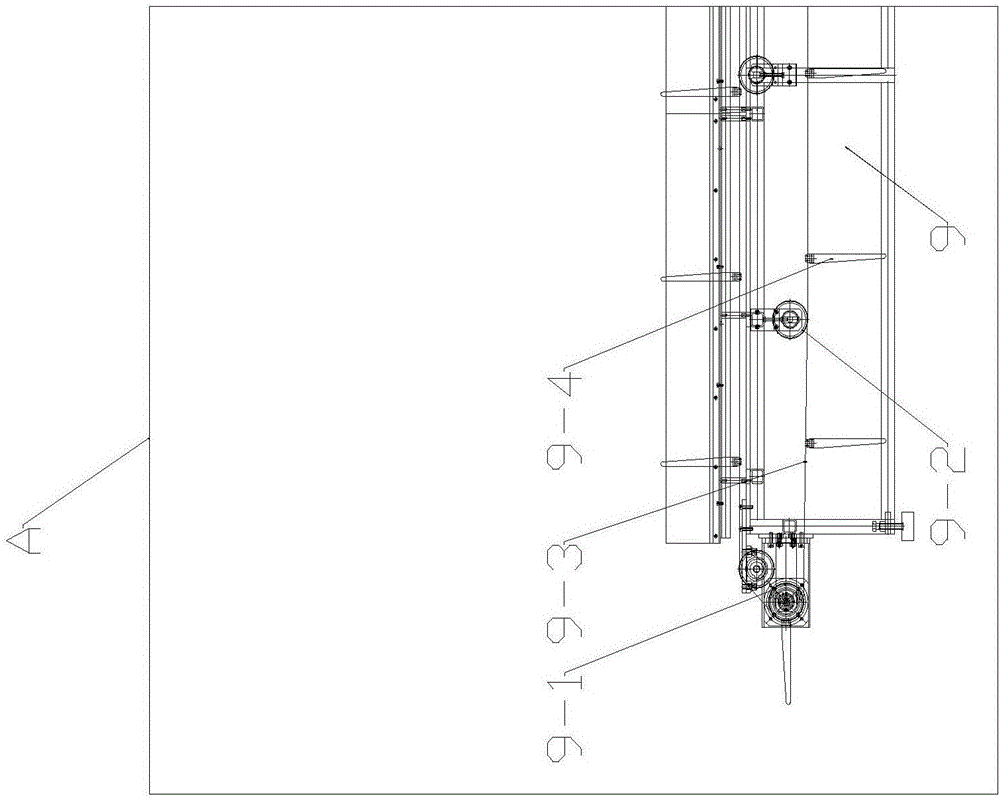

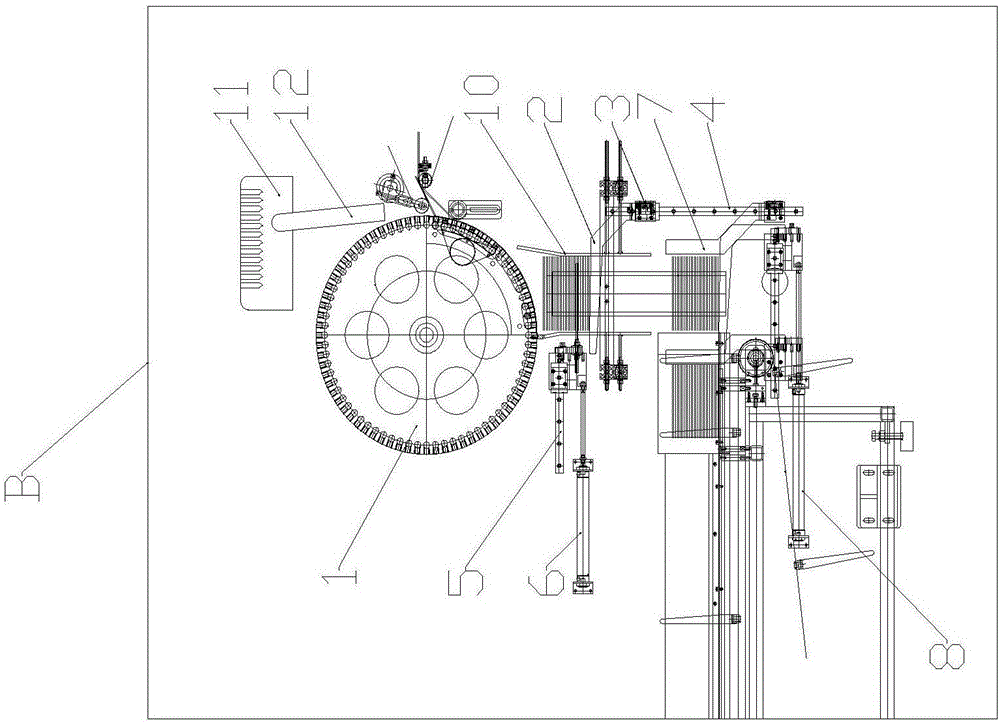

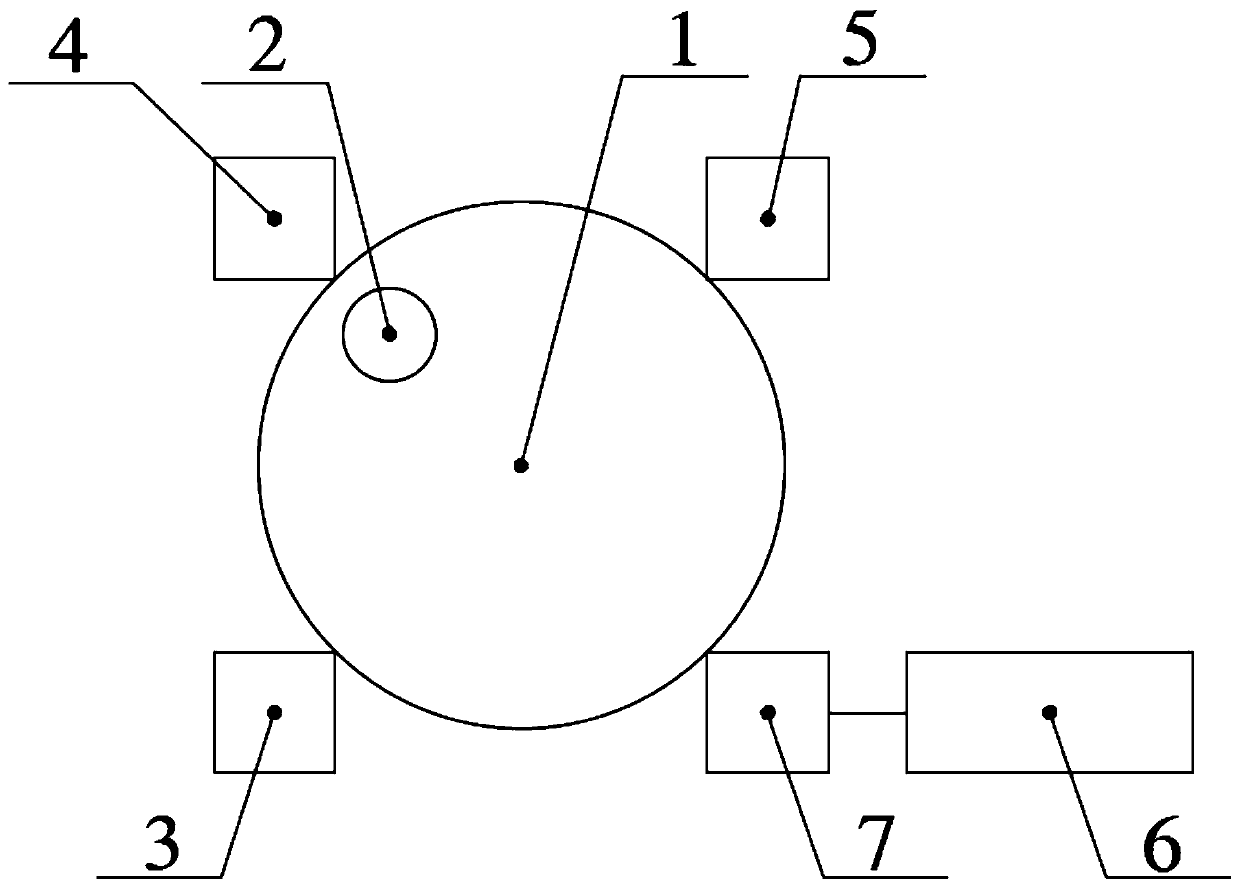

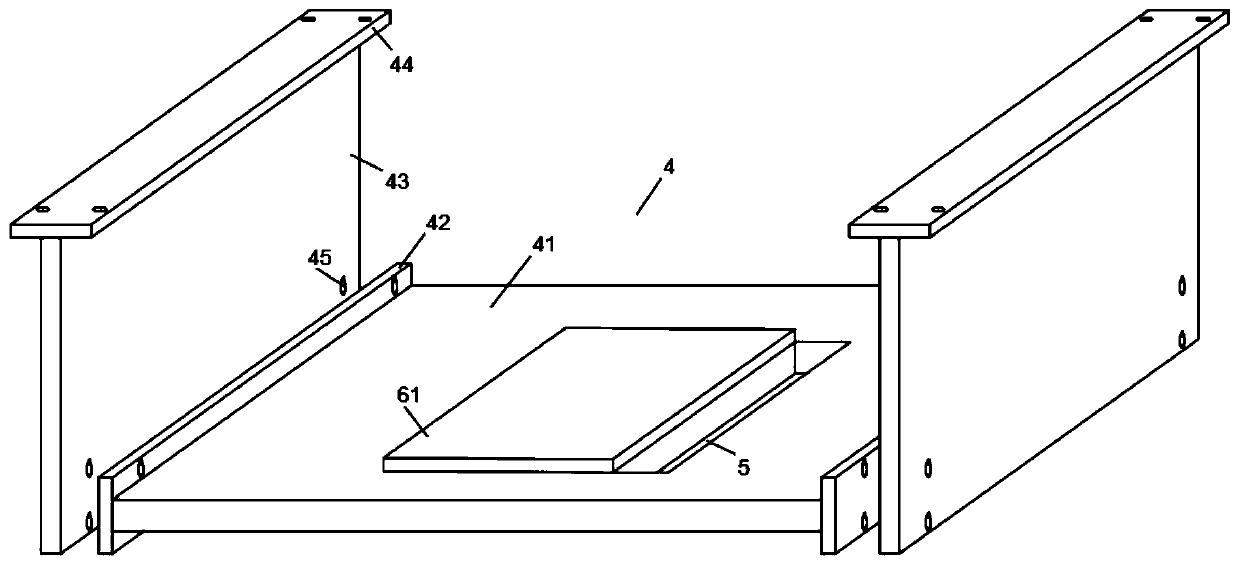

Efficient slice arrangement device used for disposable sanitary product manufacturing equipment

The invention relates to an efficient slice arrangement device used for disposable sanitary product manufacturing equipment. The efficient slice arrangement device comprises a transferring wheel which is used for adsorbing a product to the circumferential surface of the transferring wheel, keeping rotating and enabling the product to change the heading direction via negative pressure release and enter the next procedure, and a sliding plate assembly which consists of a sliding plate, a linear guide rail and a linear motor, wherein the sliding plate is arranged below the transferring wheel and supports an object transferred by the transferring wheel. During actual production, by the adoption of a transferring and slice arrangement structure, the efficient slice arrangement device disclosed by the invention can effectively enhance the function of arranging slices at a high speed and meet the development requirement; the product is clamped and conveyed through a belt, then output at a high speed, and is adsorbed onto the outer surface of the transferring wheel through an air distribution bin of the transferring wheel so as to be tidily arranged on a slice receiving assembly; the product is output through a slice discharging assembly; and after being adsorbed onto a material receiving assembly through the transferring wheel, the product can be tidily arranged and meet the high-speed development requirement.

Owner:江苏昇瑞机械制造有限公司

Metal ceramic producing and processing device

InactiveCN113460723AEasy to collectEasy to seal and storeLoading/unloadingConveyor partsEngineeringMaterials science

The invention discloses a metal ceramic producing and processing device comprising a bearing plate, the right side of the top of the bearing plate is fixedly connected with a stabilizing seat, the top of the front face of the stabilizing seat communicates with a discharging pipe, the top of the stabilizing seat is provided with a processing device, and the top of the outer wall of the left side of the stabilizing seat is fixedly connected with a middle fixing plate; and a storage barrel is arranged in the middle of the bottom of the middle fixing plate. The invention relates to the technical field of ceramic processing. According to the metal ceramic producing and processing device, the fixing area of the metal ceramic producing and processing device can be increased through the bearing plate, the stability of a preparation barrel can be improved through connection of a supporting frame and a partition plate, meanwhile, the interior can be partitioned through the partition plate, therefore material collection is facilitated, through communication between a communication mechanism and a material receiving mechanism, the phenomenon that materials are scattered in the metal ceramic producing and processing device is effectively avoided, so that the phenomenon that last working materials are left in gaps is avoided, the subsequent preparation quality is improved, and adhesion of internal impurities during processing is reduced.

Owner:南通百大石墨设备有限公司

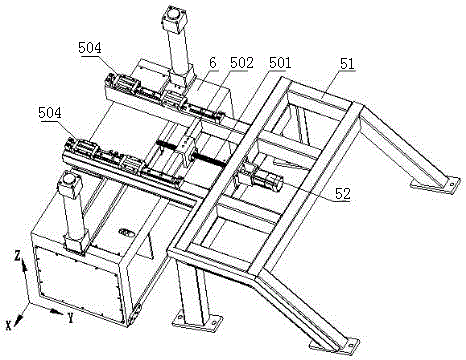

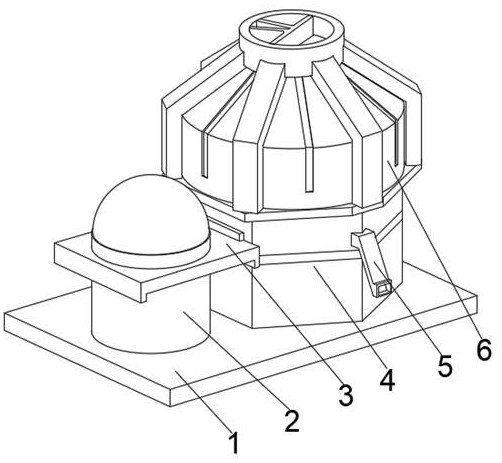

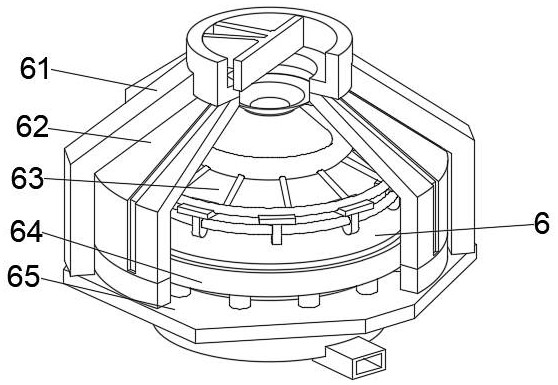

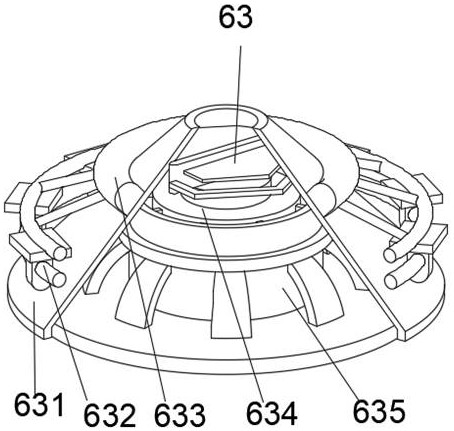

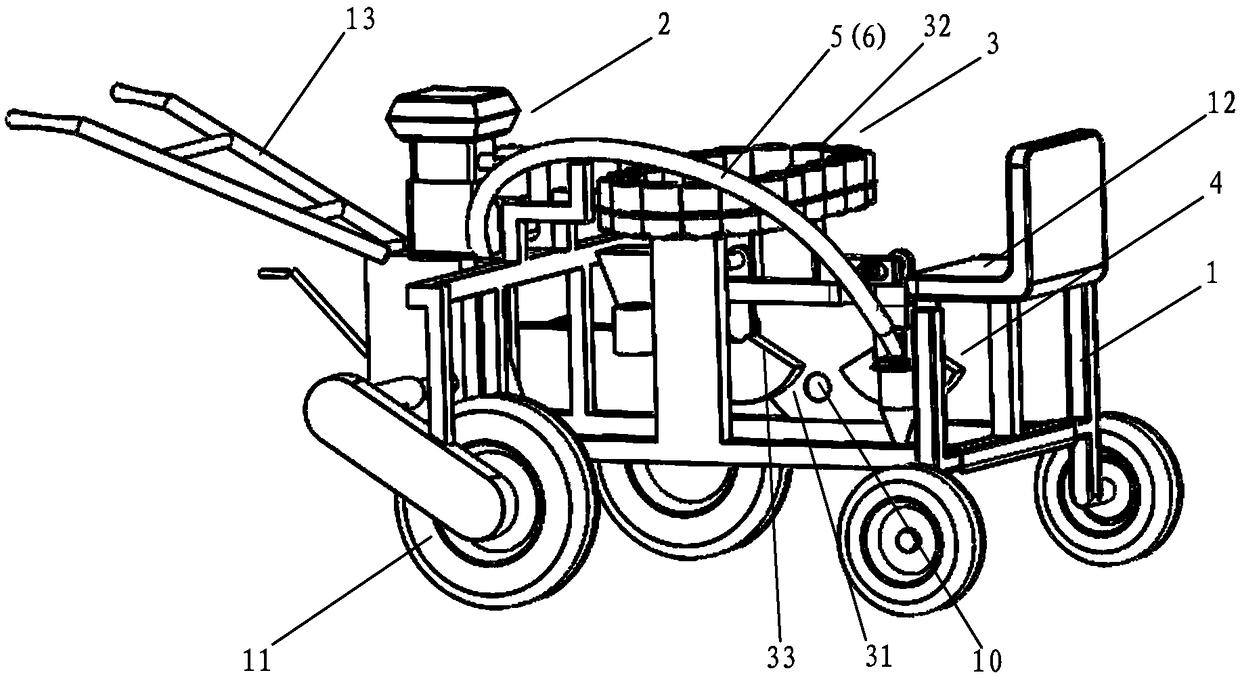

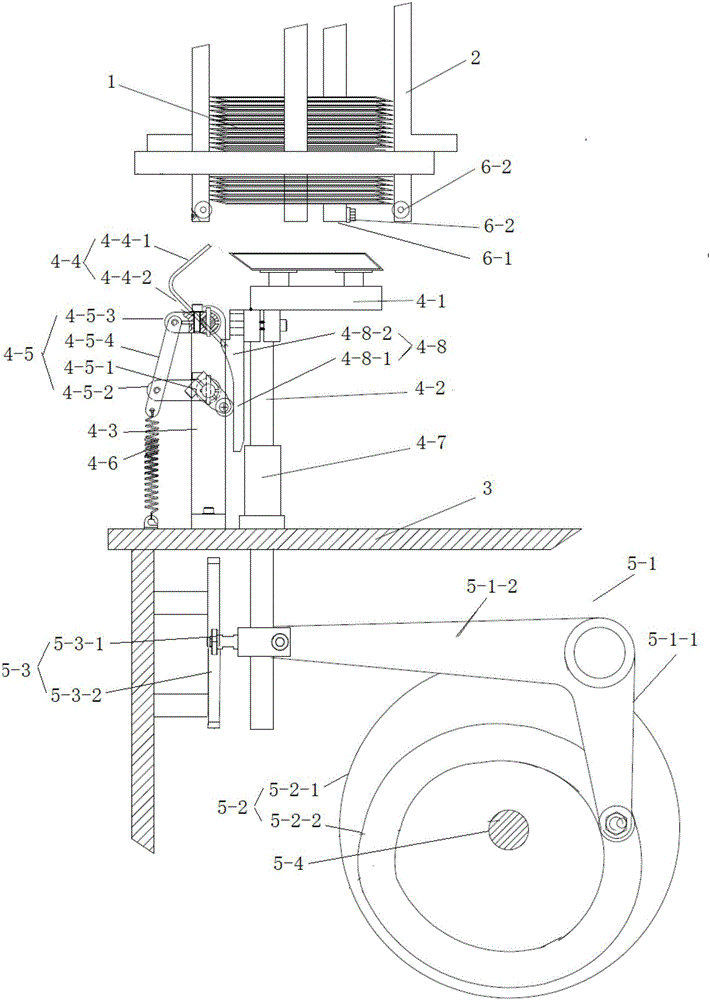

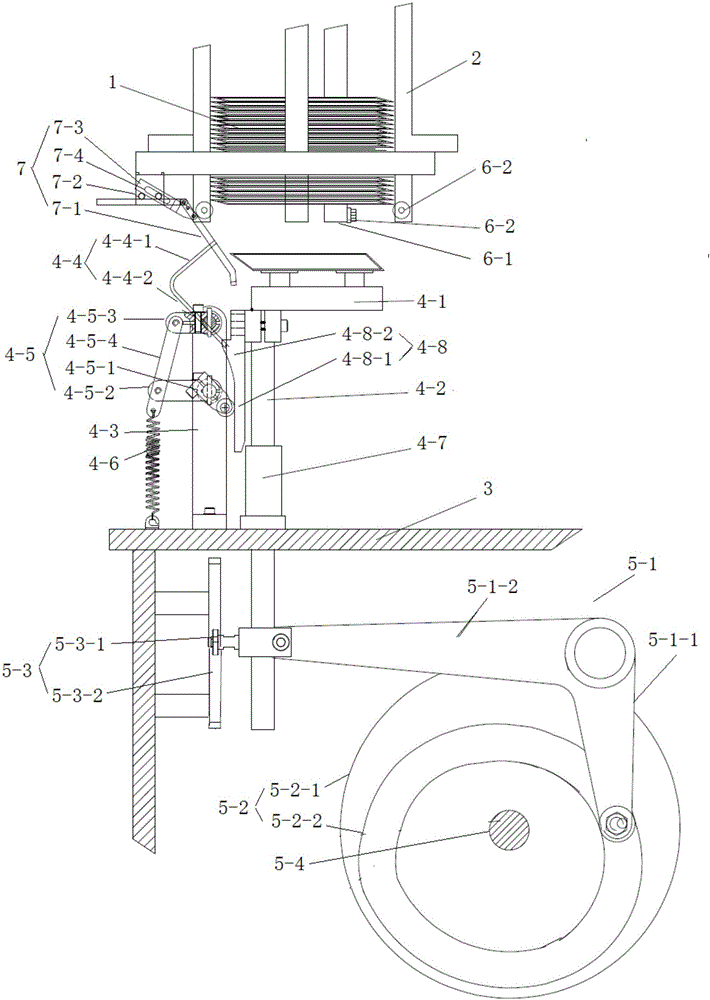

Spinning punch transplanter

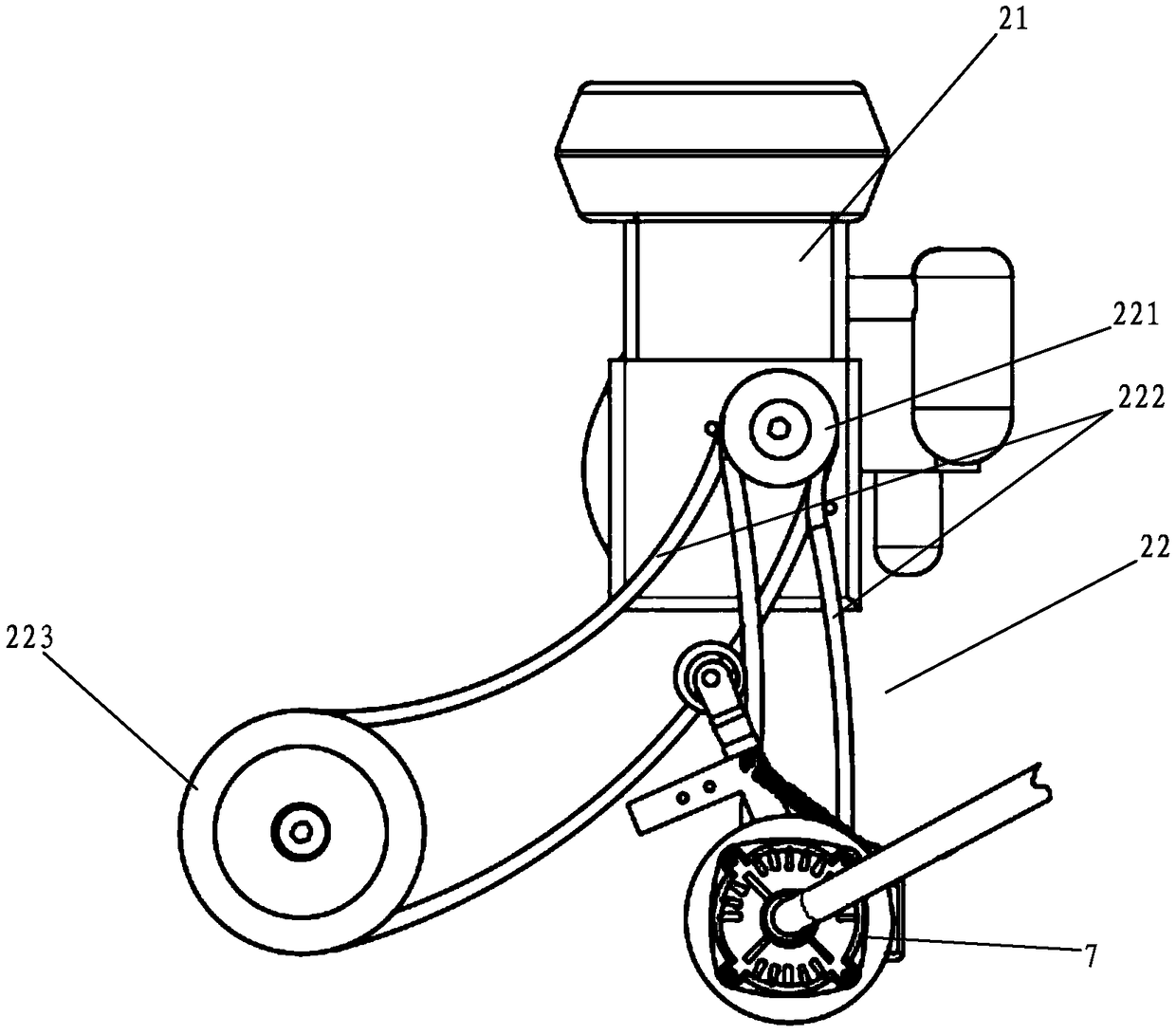

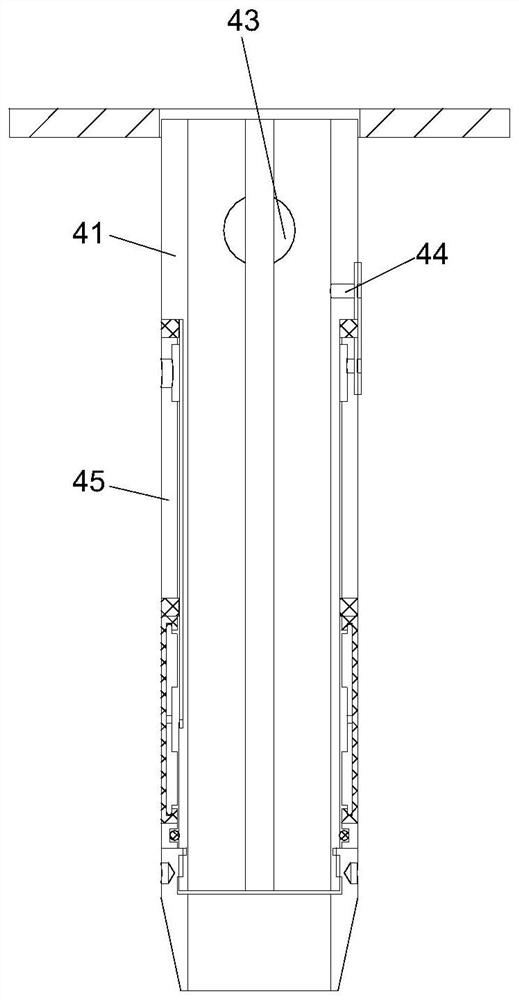

InactiveCN108781612ADedicated to precisionEasy to useTransplantingFurrow making/coveringVehicle frameEngineering

The invention discloses a spinning punch transplanter which includes a frame, a driving device, a seedling dropping device and a punch device, wherein the driving device, the seedling dropping deviceand the punch device are mounted on the frame; wheels are arranged at the bottom of the wheels; the power output of the driving device is connected with the wheels and the power input end of a punch head; the front end of the frame is used for bearing a seat of a seedling dropping people, and handles used for pushing the frame by hands of the people are arranged at the rear end of the frame; a seedling dropping outlet of the seedling dropping device corresponds to the bottom of the punch device, so that seedlings are dropped to caves caved by the punch device. According to the invention, the driving device and the punch device are mounted into a whole by the frame, and the driving device drives the punch device to move to movably cave the furrow slice of a ridging body, so that the spinning punch transplanter has the advantages of simple structure, convenience in use, high working efficiency, safety and reliability.

Owner:SOUTH CHINA AGRI UNIV

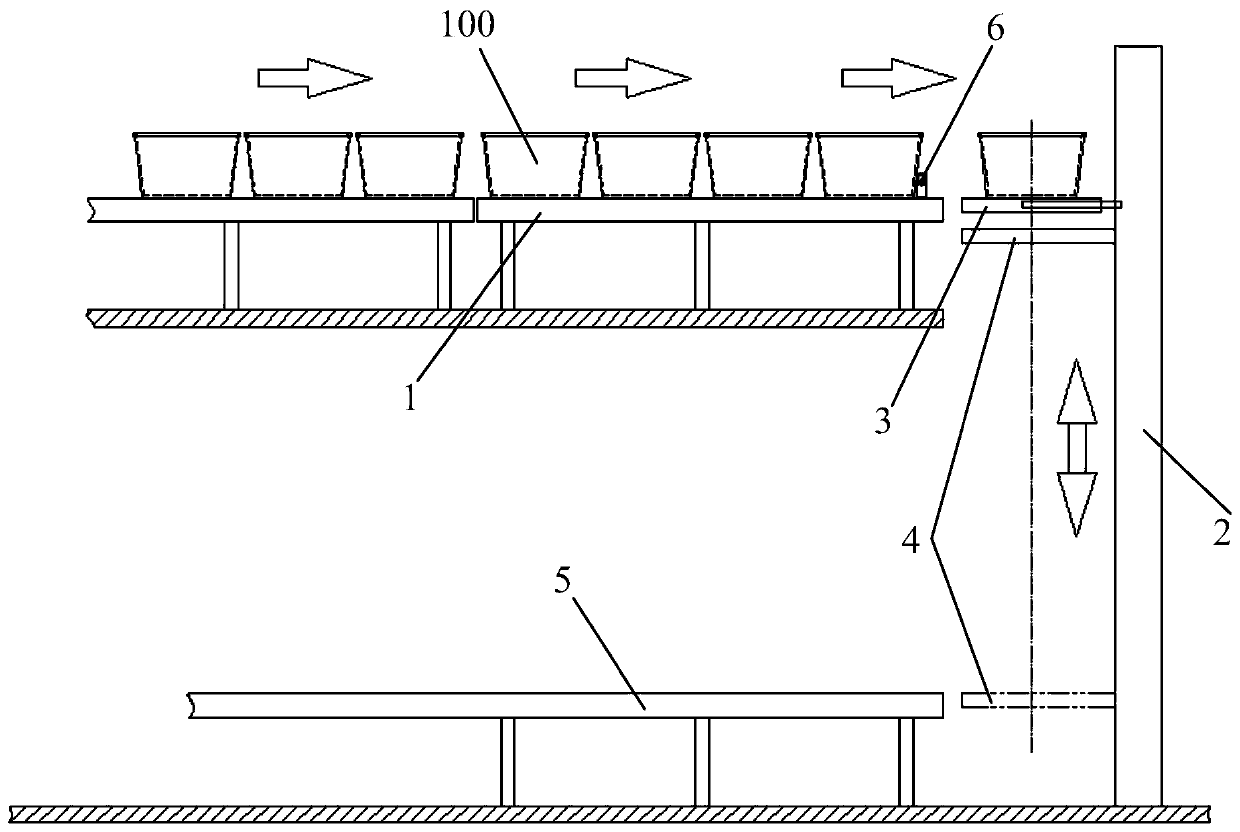

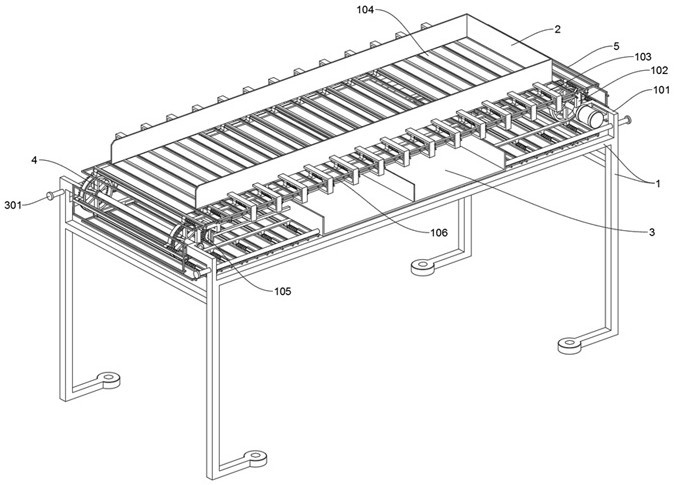

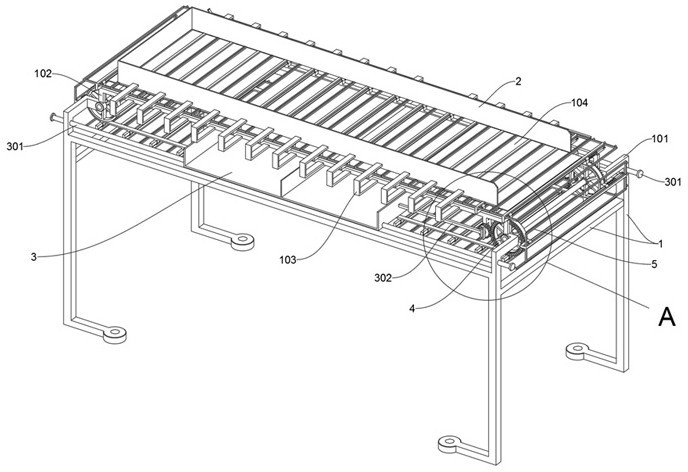

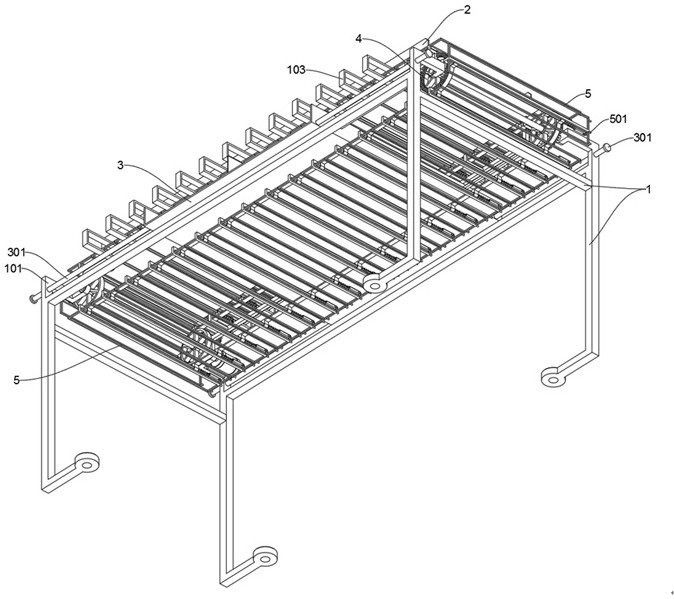

Automatic box stacking system of turnover boxes

InactiveCN110077858ASave manpower and costHigh degree of automationConveyorsStacking articlesElectrical controlSpace elevator

The invention discloses an automatic box stacking system of turnover boxes. The automatic box stacking system involves a stepping conveyor, a reciprocating type elevator, a roller type conveyor, and an electrical control system; a plurality of the turnover boxes to be stacked are arranged on the stepping conveyor at intervals along the starting end to the tail end direction of the stepping conveyor; the reciprocating type elevator is provided with a material receiving mechanism and a cargo carrying table, the material receiving mechanism is in butt joint with the tail end of the stepping conveyor, the cargo carrying table is arranged on the reciprocating type elevator in an up-and-down lifting mode and is positioned right below the material receiving mechanism; the starting end of the roller type conveyor is in butt joint with the cargo carrying table; and the electrical control system is electrically connected with the above-mentioned mechanisms. According to the automatic box stacking system, the problem that the turnover boxes are randomly stacked is solved, the turnover boxes can be effectively stored through the system, the unnecessary labor and cost are saved, further the automation degree of the whole system is improved, and the method has an obvious effect on improving the operation efficiency, saving resources and the like.

Owner:YUNNAN UNIVERSITY OF FINANCE AND ECONOMICS

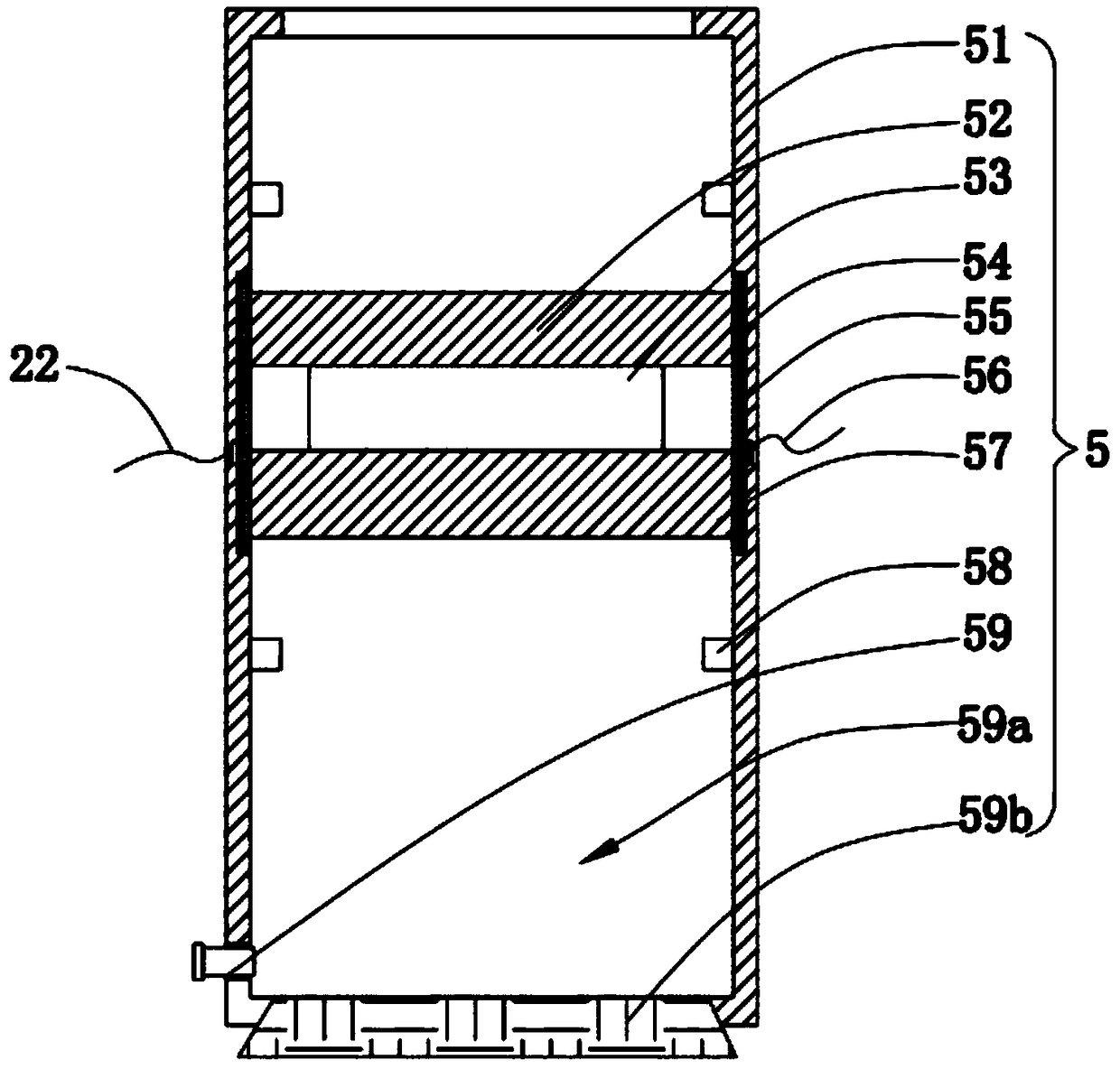

Box opening device and boxing production line with same

InactiveCN105752404AAutomate operationNo human intervention requiredPackagingProduction lineCorrecting paper

The invention relates to a box opening device, in particular to a box opening device applied to a boxing production line and the boxing production line.The box opening device comprises a containing bin used for containing paper boxes, a box suction mechanism used for sucking paper boxes in the containing bin out, a lifting mechanism used for driving the box suction mechanism to ascend and descend, a box opening mechanism located on the box outlet side of the containing bin and used for opening paper boxes when paper boxes in the containing bin are sucked out by the box suction mechanism, and a correcting mechanism used for correcting paper boxes located on the box suction mechanism.Compared with the prior art, when the lifting mechanism drives the box suction mechanism to ascend, paper boxes located on the box outlet side of the containing bin can be sucked out by the box suction mechanism, while when the lifting mechanism drives the box suction mechanism to descend, due to the fact that a linkage part used for driving the correcting mechanism is arranged on the box suction mechanism, the correcting mechanism is driven through the linkage part so as to complete correction of all opened paper boxes, automatic operation that paper boxes are opened from the plane state is achieved without manual intervention, and thus the boxing efficiency of products is improved.

Owner:SHANGHAI SUNGLOW PACKAGING TECHNOLOGY CO LTD

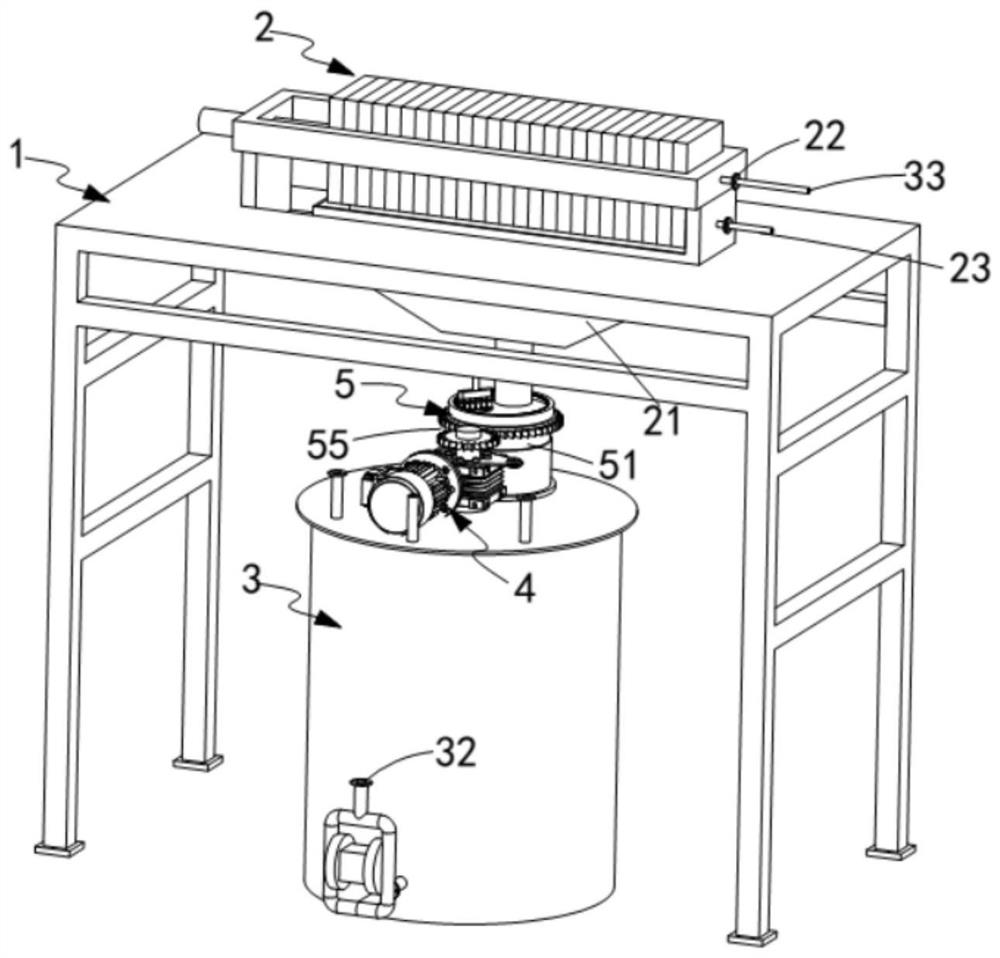

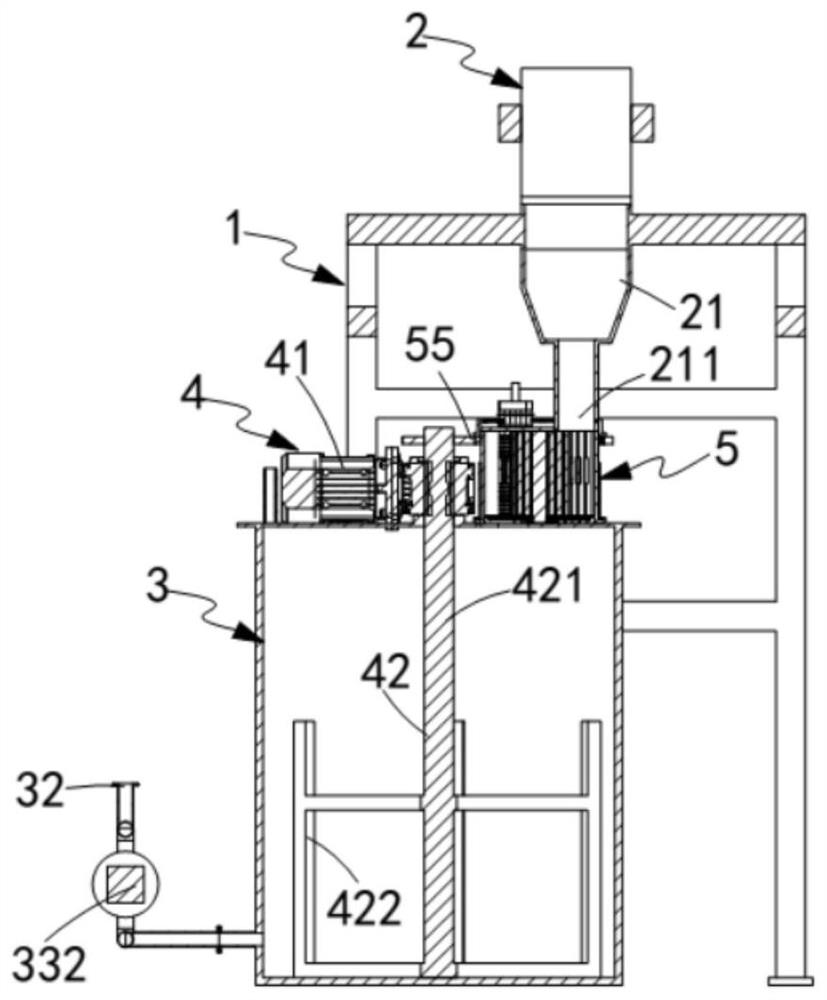

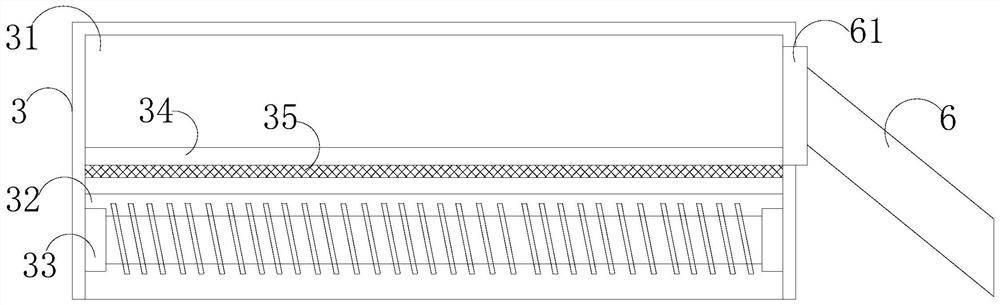

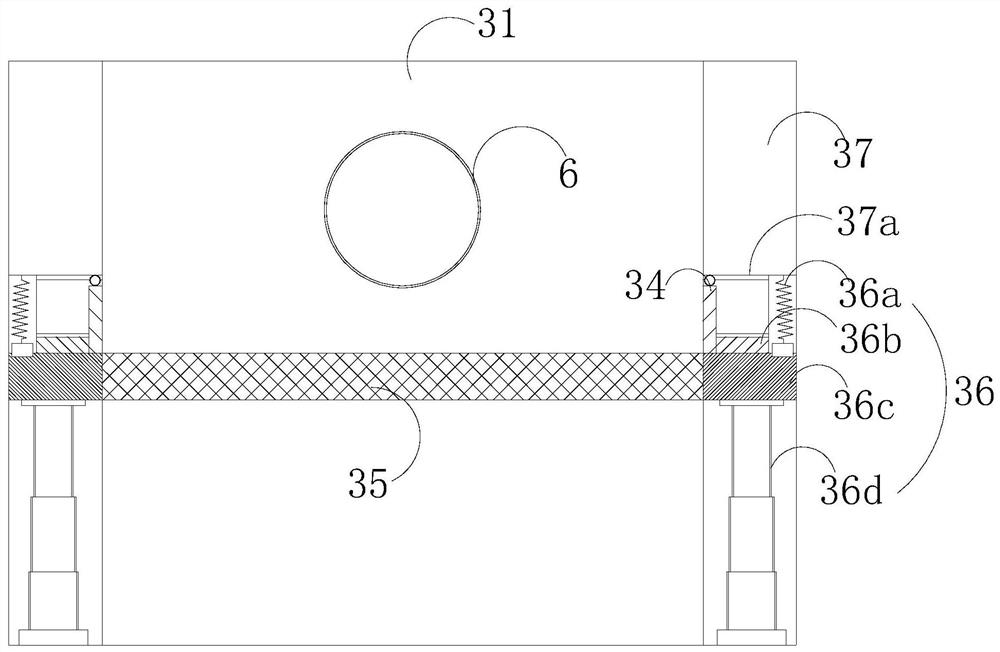

Circulating type rapid multi-stage filter pressing system

InactiveCN112704921ASolve technical problems that cannot be purified efficientlyAvoid clumpingRotary stirring mixersTransportation and packagingControl engineeringProcess engineering

The invention provides a circulating type rapid multi-stage filter pressing system which comprises a filter pressing device, a filter residue tank, a stirring mechanism and a material distributing mechanism, and the material distributing mechanism comprises a rotatably arranged material distributor, a fixedly arranged mandrel, a cover plate covering the top of the material distributor and a liquid adding pipe installed on the cover plate and inserted into the material distributor. The material distributor and the liquid adding pipe are in transmission connection with the stirring mechanism, the material distributor is rotatably arranged around the mandrel, the material distributor comprises a plurality of distributing bins, the distributing bins are separated by partition plates, the stirring mechanism drives the material distributing mechanism to operate, and the material distributing mechanism is arranged between the filter pressing device and the filter residue tank. The stirring mechanism for stirring the filter residue tank is used for driving the material distributing mechanism to operate, the filter residues about to enter the filter residue tank are input in batches through operation of the material distributing mechanism, water is input into filter residues from inside to outside in the input process, the surface layers of the filter residues are prevented from being condensed into balls, and the technical problem that the filter residues cannot be efficiently purified is solved.

Owner:张克军

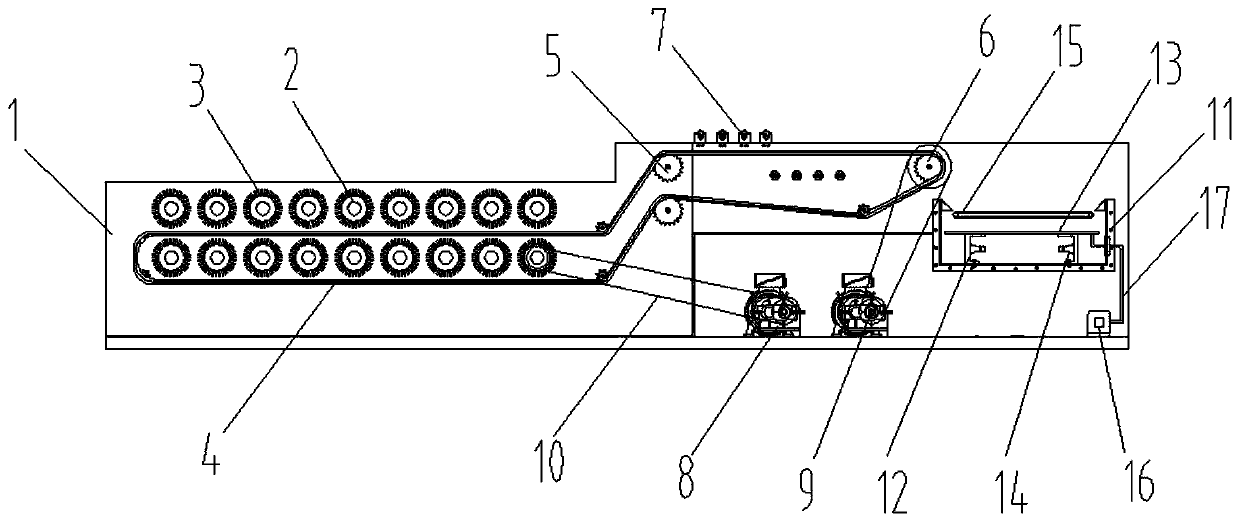

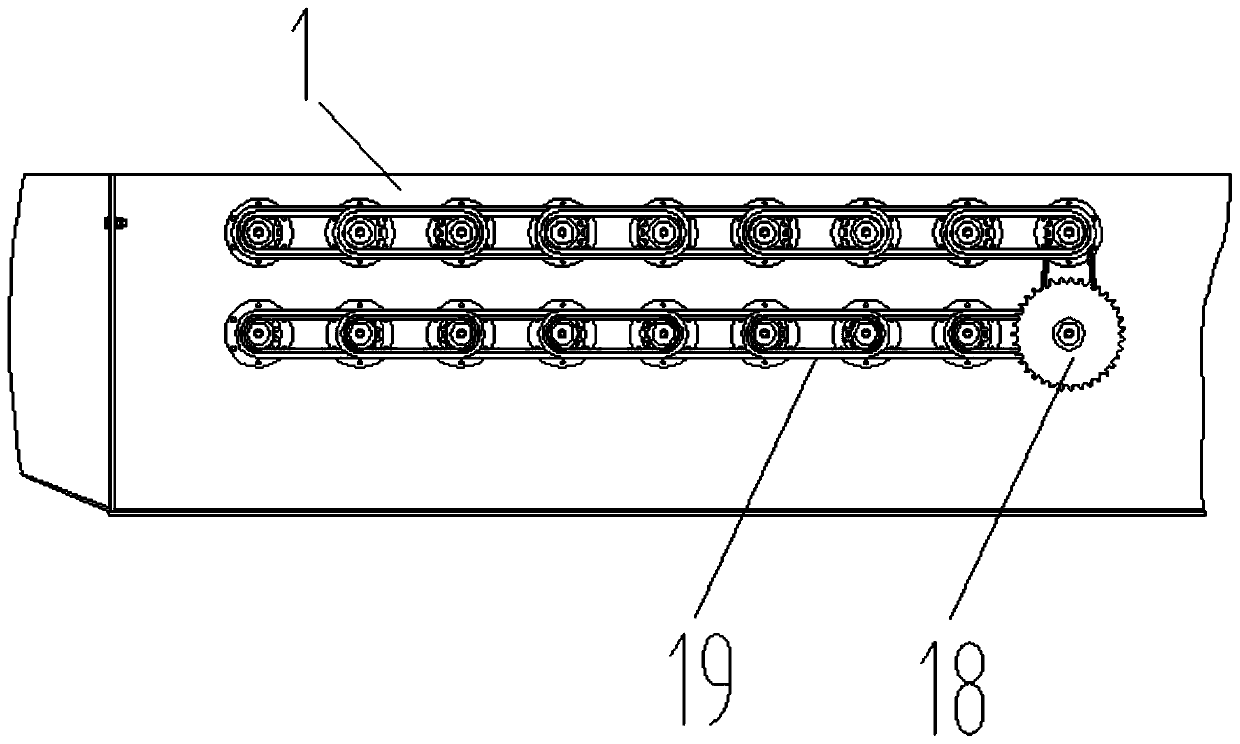

Cleaning device of lotus root cleaning machine

The invention discloses a cleaning device of a lotus root cleaning machine. The cleaning device comprises a mounting frame, brush rollers, a brush, a conveyor belt, a positioning wheel, a power wheel,a high pressure sprinkler, a brush roller motor, a conveyor belt motor, a drive belt, a cleaning water tank, a bracket, a bubble generator, a ultrasonic generator, a ultrasonic conveyor belt, an airpump, an air pipe, a brush power wheel, a roller chain, a bearing seat, a transmission wheel and a limit block. The cleaning device has the beneficial effects that the brush roller has two rows and the conveyor belt passes through between the two rows of brush rollers, so that the outer surface of the lotus root can be in contact with the brush, the brush roller has two rows, and the radiuses of drive wheels rotating on two rows of brush rollers are different. the rotation speeds of the upper and lower rows of brush rollers are different, so that a certain speed difference is generated, whichcan increase a washing area of the lotus root and the brush roller, the cleaning degree of cleaning is increased, the high-pressure spray direction of the high-pressure sprinkler is perpendicular to the direction of the conveyor belt, and the impact force of the water jet is increased to increase the flow rate.

Owner:攸潇潇

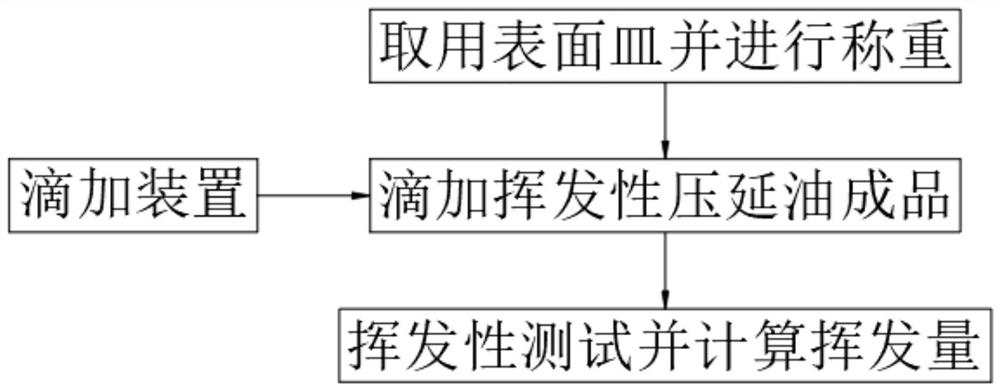

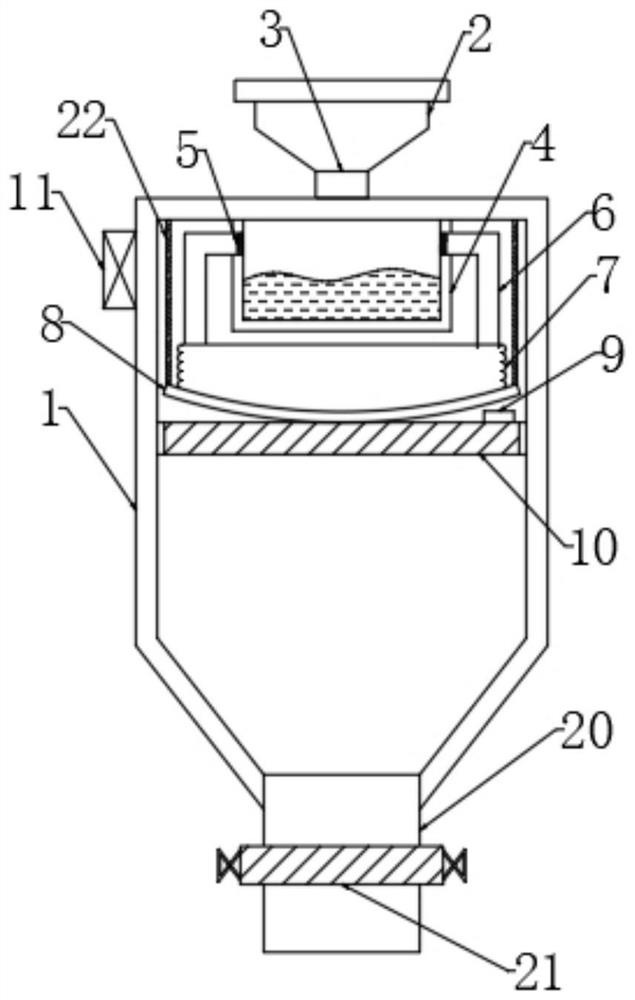

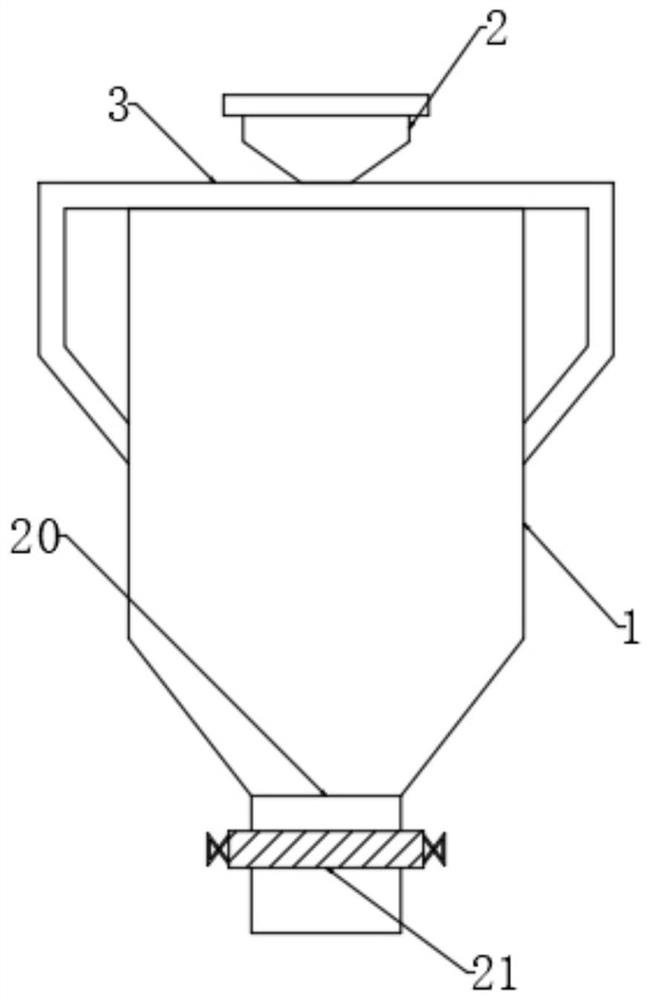

Rolling oil volatility testing method for stainless steel cold rolling

InactiveCN112946248AAccurate dropDropping accuratelyWeighing by removing componentMaterial testing goodsPhysicsPiston

The invention discloses a rolling oil volatility testing method for stainless steel cold rolling, and belongs to the field of rolling oil. The method can realize that an electric push rod is controlled by a driving control terminal to push a moving plate and a rolling wheel to move towards the right side in a dropwise adding process, so that the rolling wheel is in contact with a moving block in the moving process to extrude the moving block to move, a knocking block is driven to knock a containing box, then the containing box vibrates, carbon dioxide dissolved in water is separated out of water and is blown into an expansion air bag through an air guide pipe, then the expansion air bag is swelled, a piston is extruded to move downwards, meanwhile, a control terminal is driven to control an electric valve to be opened, and the piston moves downwards to extrude air in a dropwise adding barrel, the volatile calendering oil drips out through the oil outlet pipe, and the displacement sensor records the movement distance of the piston and feeds back the movement distance to the driving control terminal, and when the displacement amount of the piston reaches the distance of the specified weight, information is fed back to the driving control terminal, so that the electric push rod and the electric valve are closed, and accurate dripping is realized.

Owner:JILIN NORMAL UNIV

Use method of educational interesting toy capable of exercising manipulative ability of children

The invention discloses a use method of an educational interesting toy capable of exercising the manipulative ability of children. The toy comprises a first supporting foot, a second supporting foot, a supporting table and a knocking hammer, the supporting table is located on the tops of the first and second supporting feet, through holes are formed in the supporting table and internally provided with stop pieces, a spring is arranged in the supporting table and connected with the stop pieces, plastic balls are arranged in the through holes and located between the stop pieces, a fixing plate is arranged on the side wall of the first supporting foot, the knocking hammer is inserted in the fixing plate, a sliding plate is arranged between the first supporting foot and the second supporting foot and provided with a groove, a plurality of piano sheets are arranged in the groove, the side face of the second supporting foot is provided with an outlet, a hoisting table and a storage box, the outlet is communicated with the groove, the storage box is located below the outlet, the bottom of the hoisting table is provided with a connection rope, and the connection rope is provided with a buffering ball. Children knock the plastic balls through the knocking hammer, the plastic balls knock the piano sheets to make music, and attention of children is increased.

Owner:成都多元智能文化传播有限公司

Novel chemical material screening machine for chemical engineering

ActiveCN112547303AAchieve decentralizationReduce wasteSievingScreeningStructural engineeringMechanical engineering

The invention belongs to the technical field of screening machines, and discloses a novel chemical material screening machine for chemical engineering. The novel chemical material screening machine comprises a magnetic separation cylinder and a screening cylinder which are sequentially connected from top to bottom, wherein the magnetic separation cylinder and the screening cylinder can independently rotate; the magnetic separation cylinder is obliquely arranged, the two ends of the magnetic separation cylinder are rotationally matched with an upper end cover and a lower end cover correspondingly, a feeding hopper is arranged at the top part of the upper end cover, a material guiding bent pipe is arranged at the bottom part of the lower end cover, and the magnetic separation cylinder communicates with the screening cylinder through the material guiding bent pipe; a magnetic separation device is fixed between the upper end cover and the lower end cover, the magnetic separation device comprises a semi-annular guide plate with an upward opening, fixing bases are welded to the two ends of the semi-annular guide plate, the two fixing bases penetrate through the upper end cover and the lower end cover correspondingly, and a magnetic separation plate is rotatably connected between the two fixing bases; and the magnetic separation device has a self-cleaning function, so that metal chipsattached to the magnetic separation plate can be automatically removed regularly, on one hand, the magnetic separation effect is guaranteed, and on the other hand, material waste is reduced.

Owner:HEBEI CHEM & PHARMA COLLEGE

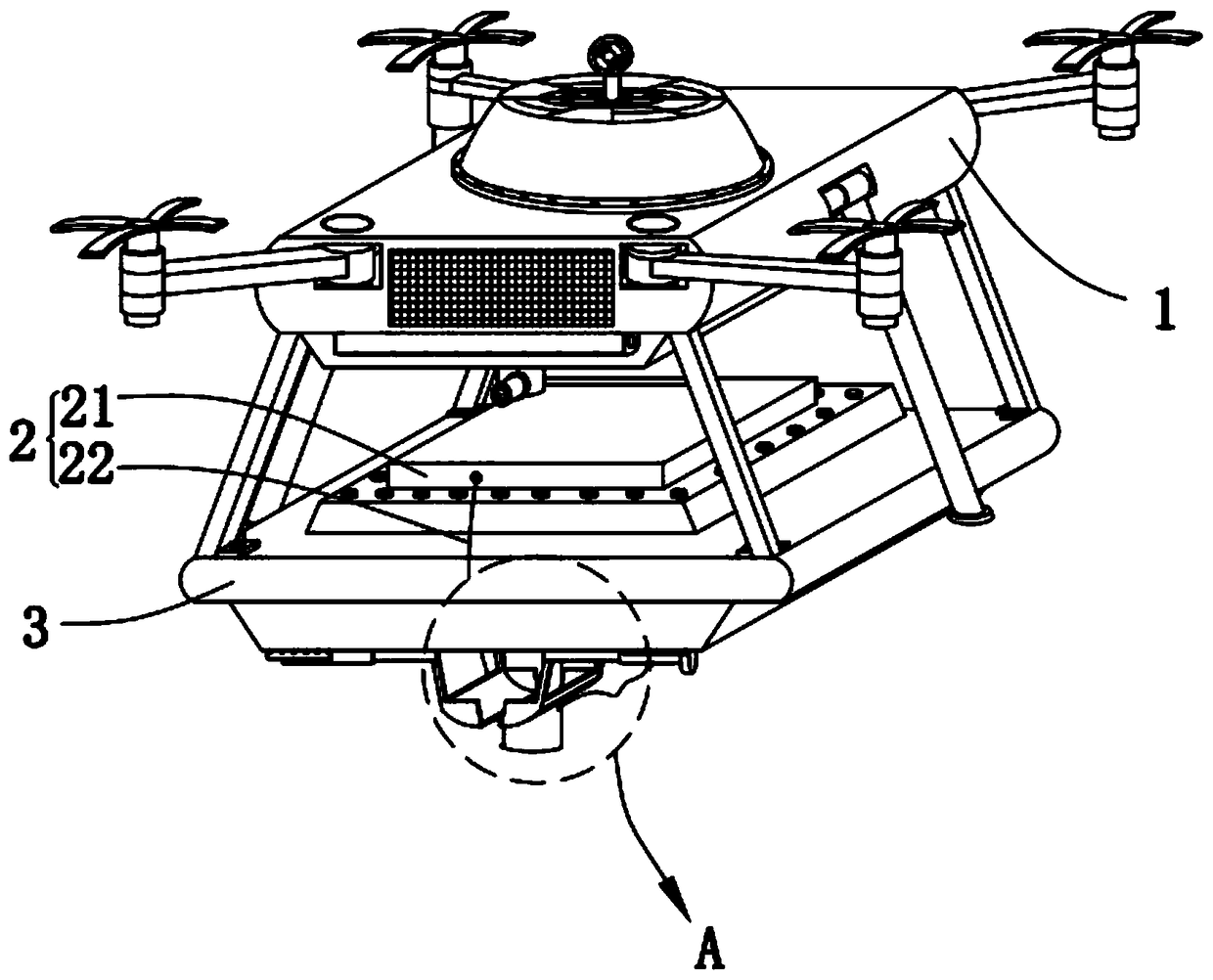

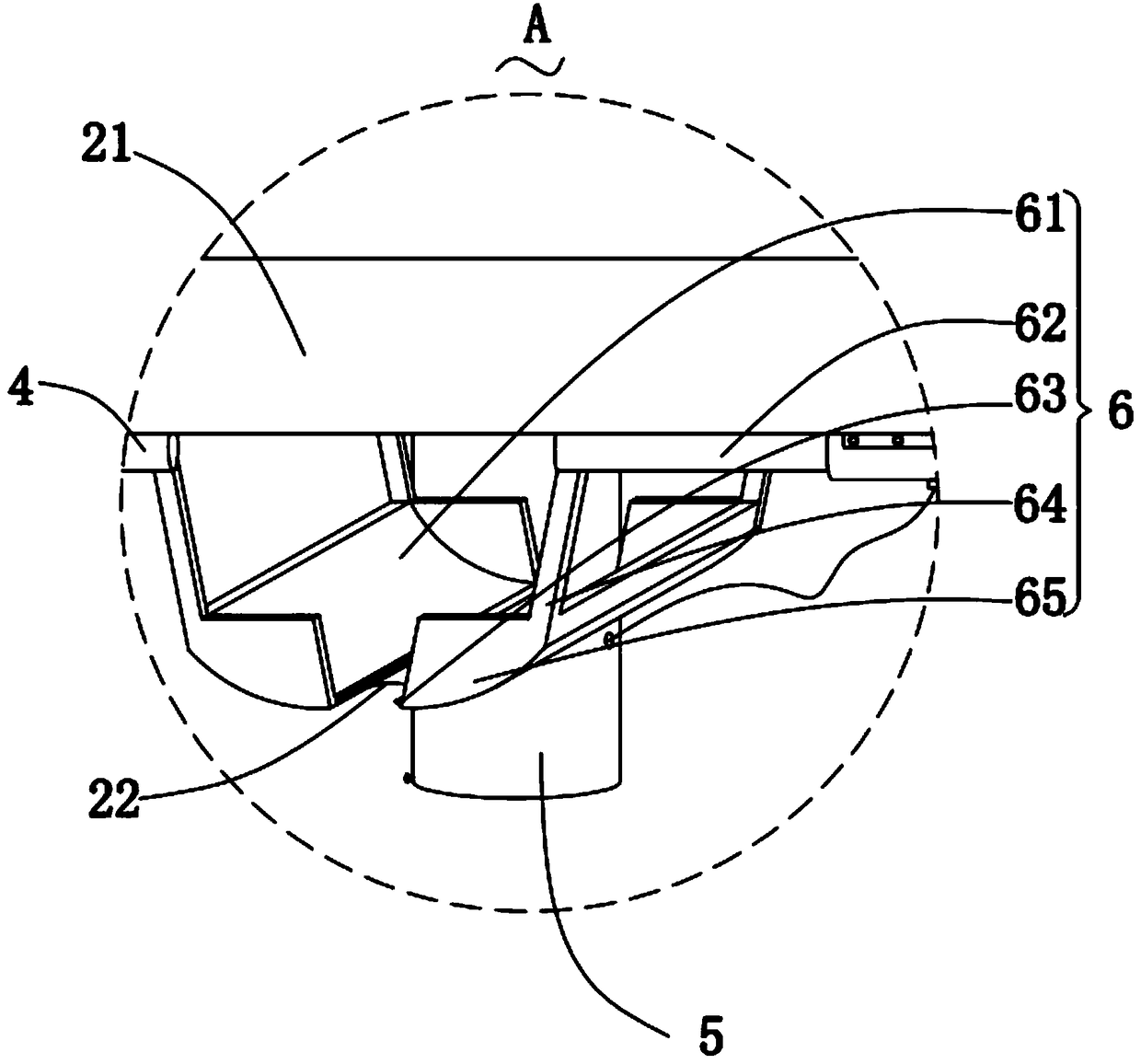

Suspended intelligent fire extinguishing device based on unmanned aerial vehicle

ActiveCN109125985AAccurate dropExtinguish fire accuratelyAircraft componentsFire rescueMaterials preparationHeat conducting

The invention relates to the field of extinguishment, in particular to a suspended intelligent fire extinguishing device based on an unmanned aerial vehicle. The device comprises a body, a power supply mechanism, a fixed plate, a fixed column, a sensing mechanism, a material storage mechanism, a control mechanism, a sliding mechanism and a material preparation mechanism, a box is fixedly connectedwith an electric pushing rod through a connecting rod, heat-conducting fins at the bottom of a cylinder is heated when the body flies, inner nitrogen in a gas chamber is expand, a piston rises, so that a connecting plate, a first power supply line, a second power supply line and a metal sheet are powered off, the electric pushing rod is further powered off, the box is opened, an fire extinguishing bomb accurately falls in a severe area of a fire disaster, fire is rapidly and accurately extinguished, sliders are slidably connected in sliding rails at the bottom of the fixed plate, the slider at the top of the connecting rod slides when the electric pushing rod contracts, the sliders slide a certain position, so that a baffle plate is abutted to a clamping plate, a leaning plate and a bearing plate are separated, fire extinguishing bombs in a material preparation box are thrown out, fire is completely extinguished, and fire extinguishing speed and accurate rate are increased.

Owner:广东云创氢电科技有限公司

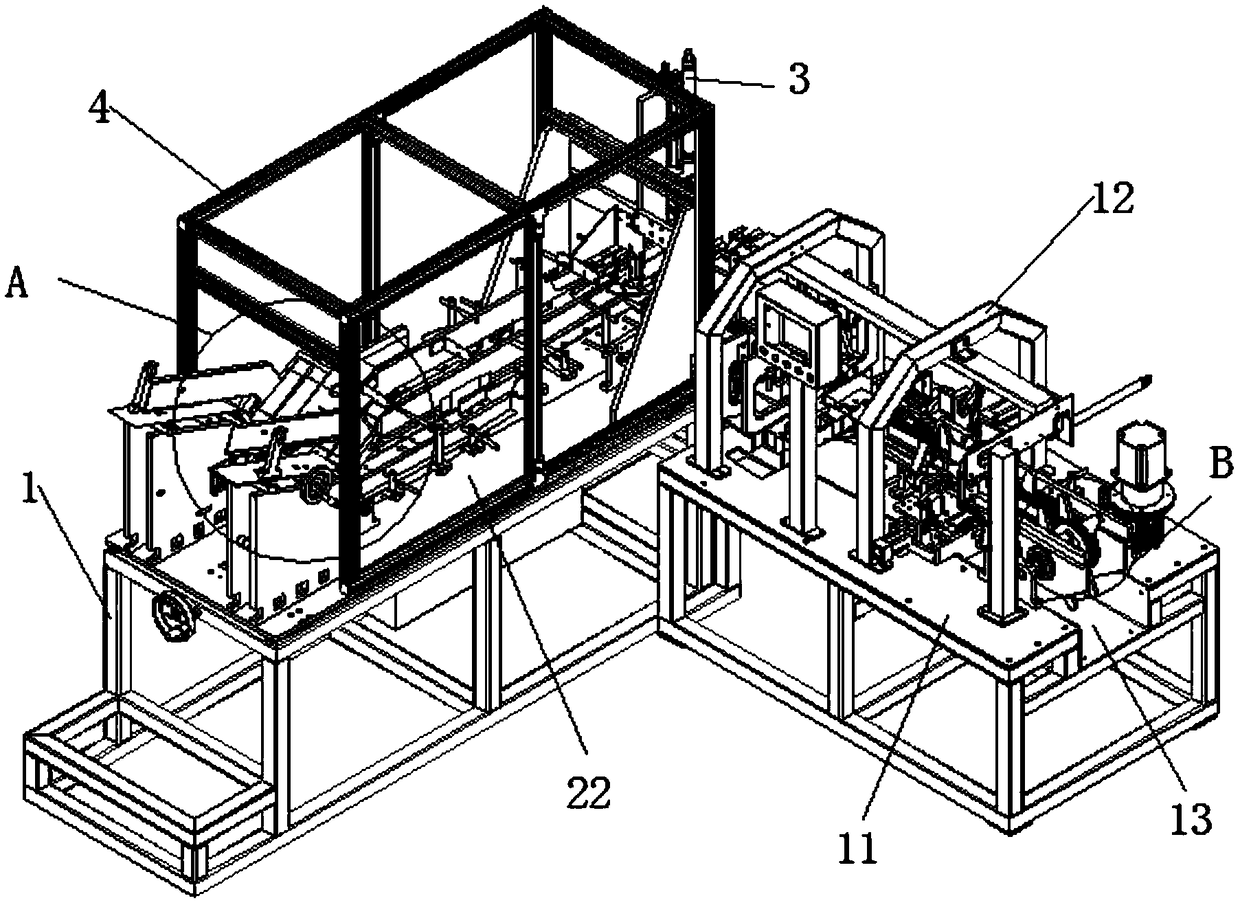

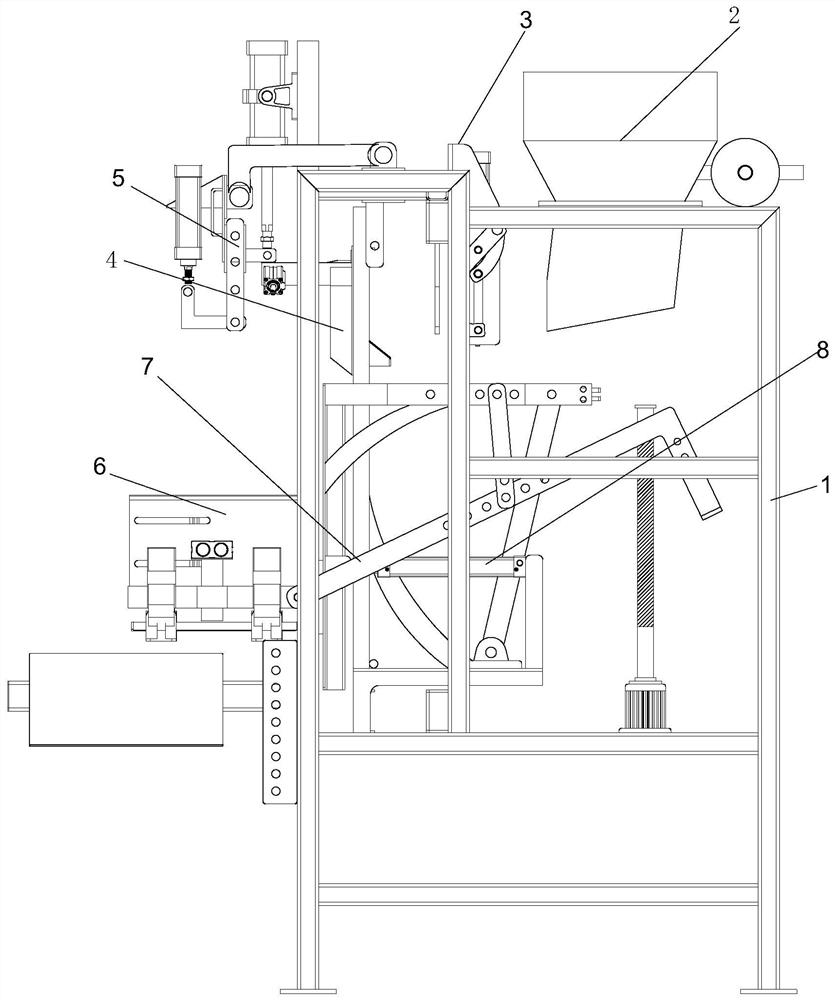

Airplane box folding machine

The invention discloses an airplane box folding machine. The airplane box folding machine comprises a bracket structure, a feeding mechanism, a paper feeding mechanism, a conveying mechanism and an edge folding mechanism; the bracket structure comprises a feeding frame and a box folding frame which are perpendicular to each other and a mechanical arm frame arranged over the box folding frame; theheight of the box folding frame is smaller than that of the feeding frame; the feeding mechanism is arranged over the feeding frame; the paper feeding mechanism is arranged over the feeding frame, located over the conveying mechanism and arranged over the middle of the paper outlet end of the feeding mechanism through a portal frame; the paper feeding mechanism comprises a paper feeding air cylinder arranged on the portal frame and a paper feeding pressing head arranged on an output shaft of the paper feeding air cylinder; the conveying mechanism is transversely arranged in the middle of the box folding frame, and one end of the conveying mechanism is connected with the paper feeding mechanism; and the edge folding mechanism is arranged on the mechanical arm frame and used for conducting box folding operation on raw material paper boards on the conveying mechanism. The box folding machine is good in box folding effect and high in efficiency.

Owner:广东双一智能装备有限公司

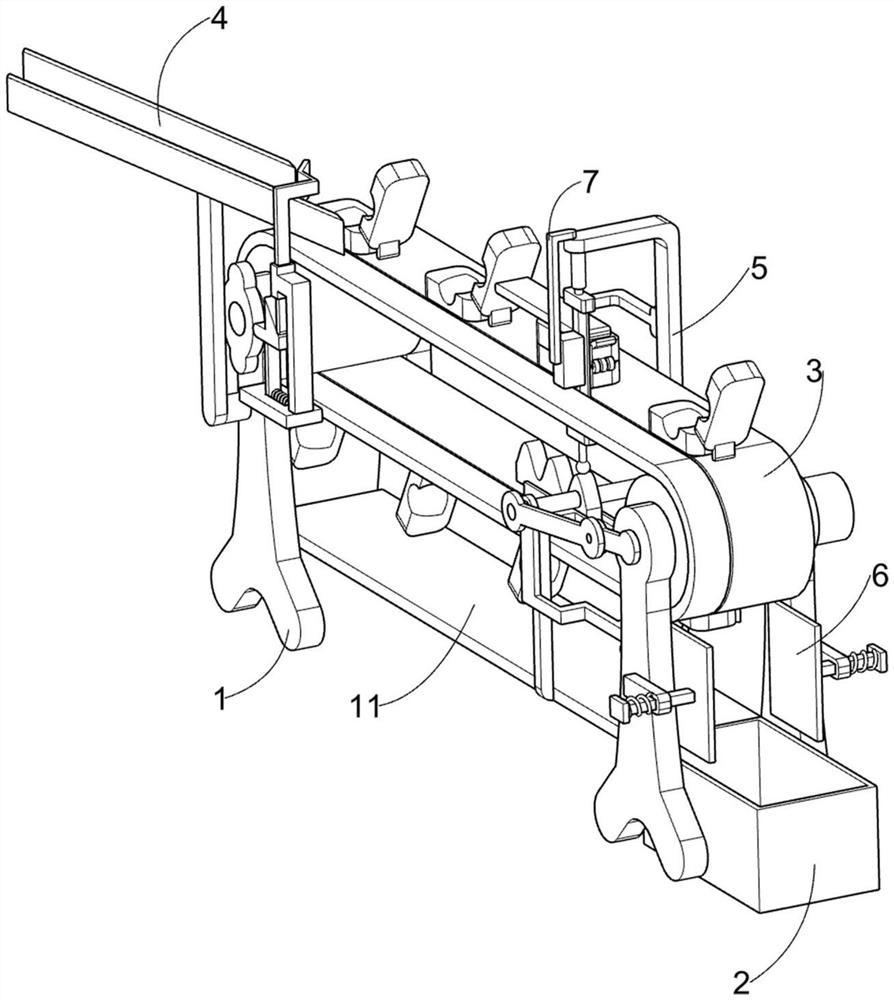

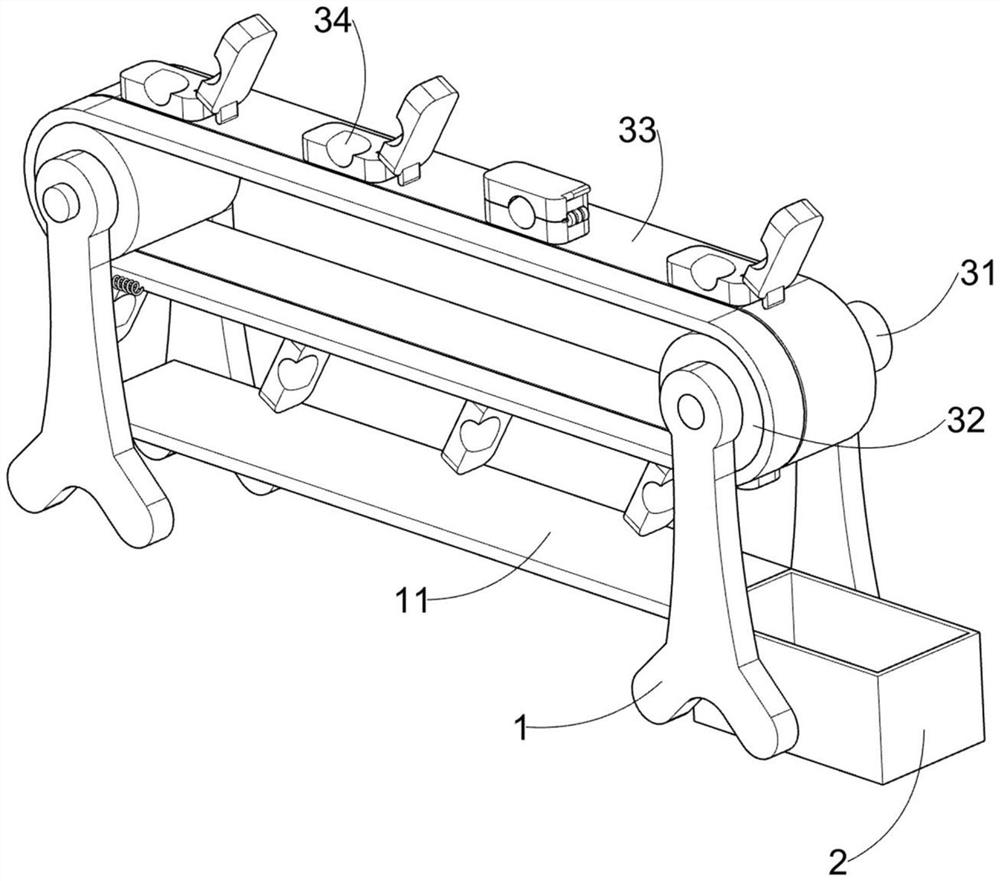

Educational interesting toy mechanism capable of exercising manipulative ability of children

The invention discloses an educational interesting toy mechanism capable of exercising the manipulative ability of children. The mechanism comprises a first supporting foot, a second supporting foot, a supporting table and a knocking hammer, the supporting table is located on the tops of the first and second supporting feet, through holes are formed in the supporting table and internally provided with stop pieces, a spring is arranged in the supporting table and connected with the stop pieces, plastic balls are arranged in the through holes and located between the stop pieces, a fixing plate is arranged on the side wall of the first supporting foot, the knocking hammer is inserted in the fixing plate, a sliding plate is arranged between the first supporting foot and the second supporting foot and provided with a groove, a plurality of piano sheets are arranged in the groove, the side face of the second supporting foot is provided with an outlet, a hoisting table and a storage box, the outlet is communicated with the groove, the storage box is located below the outlet, the bottom of the hoisting table is provided with a connection rope, and the connection rope is provided with a buffering ball. Children knock the plastic balls through the knocking hammer, the plastic balls knock the piano sheets to make music, and attention of children is increased.

Owner:成都多元智能文化传播有限公司

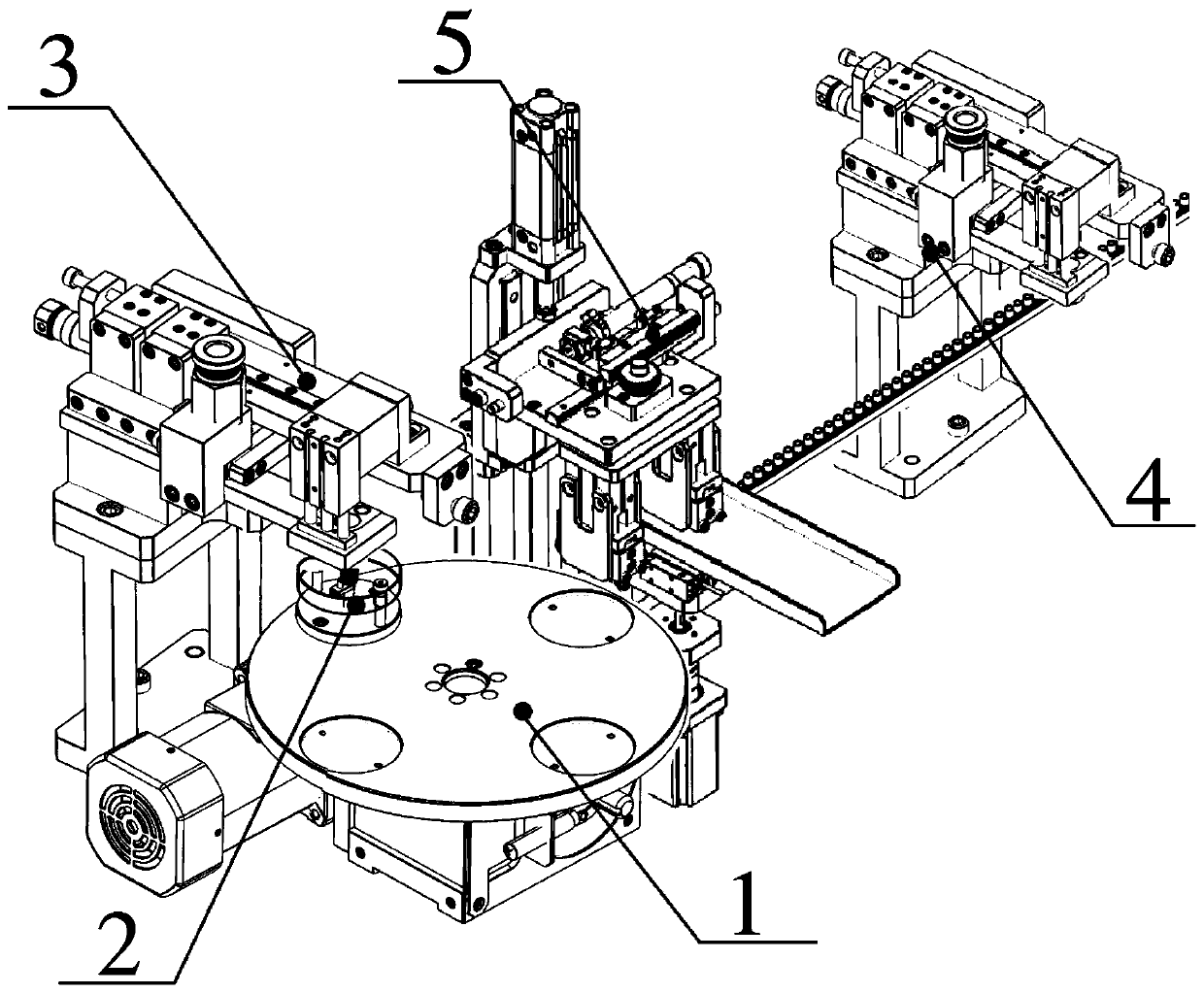

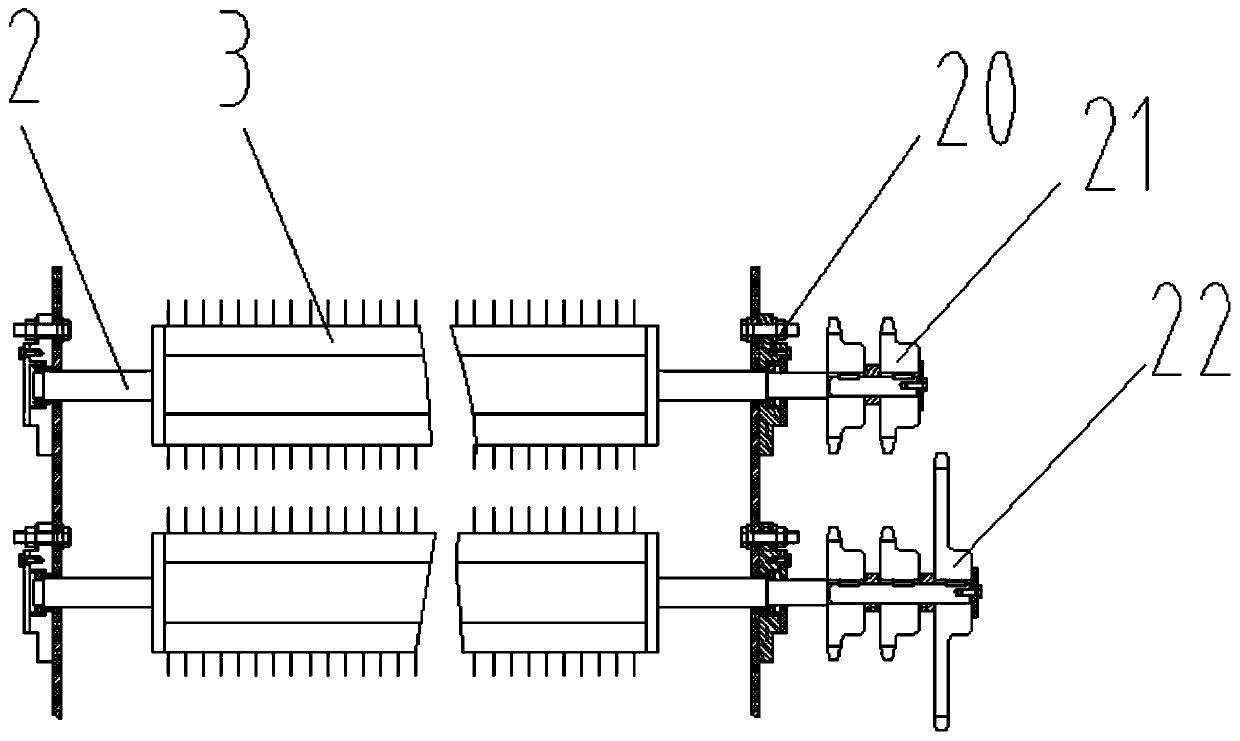

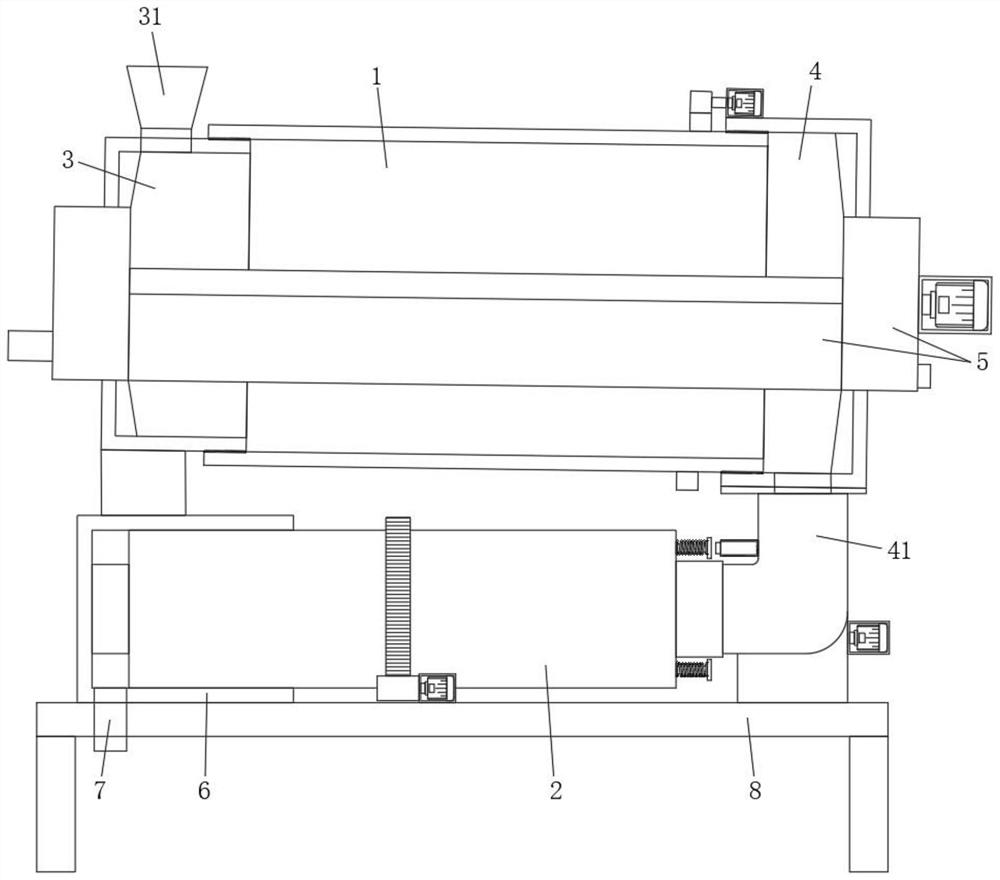

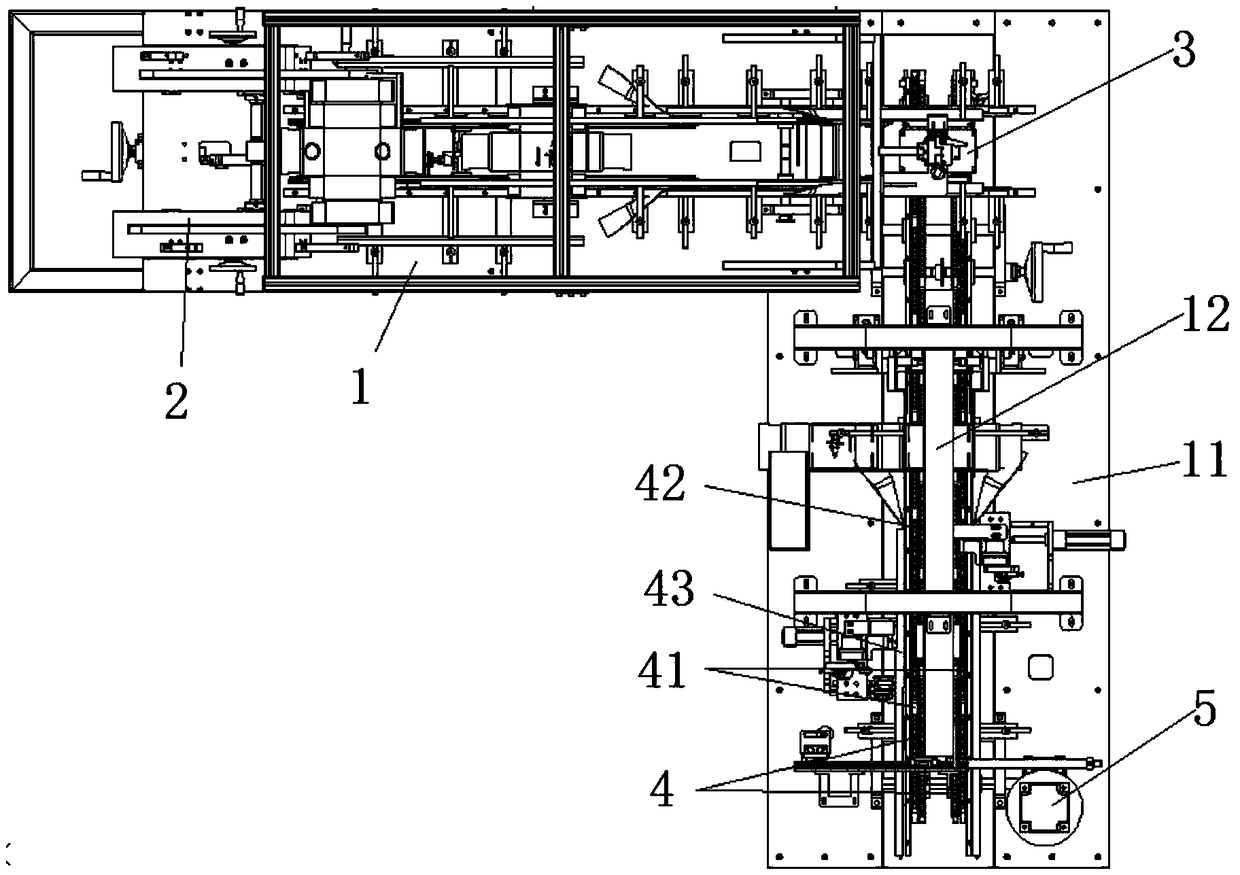

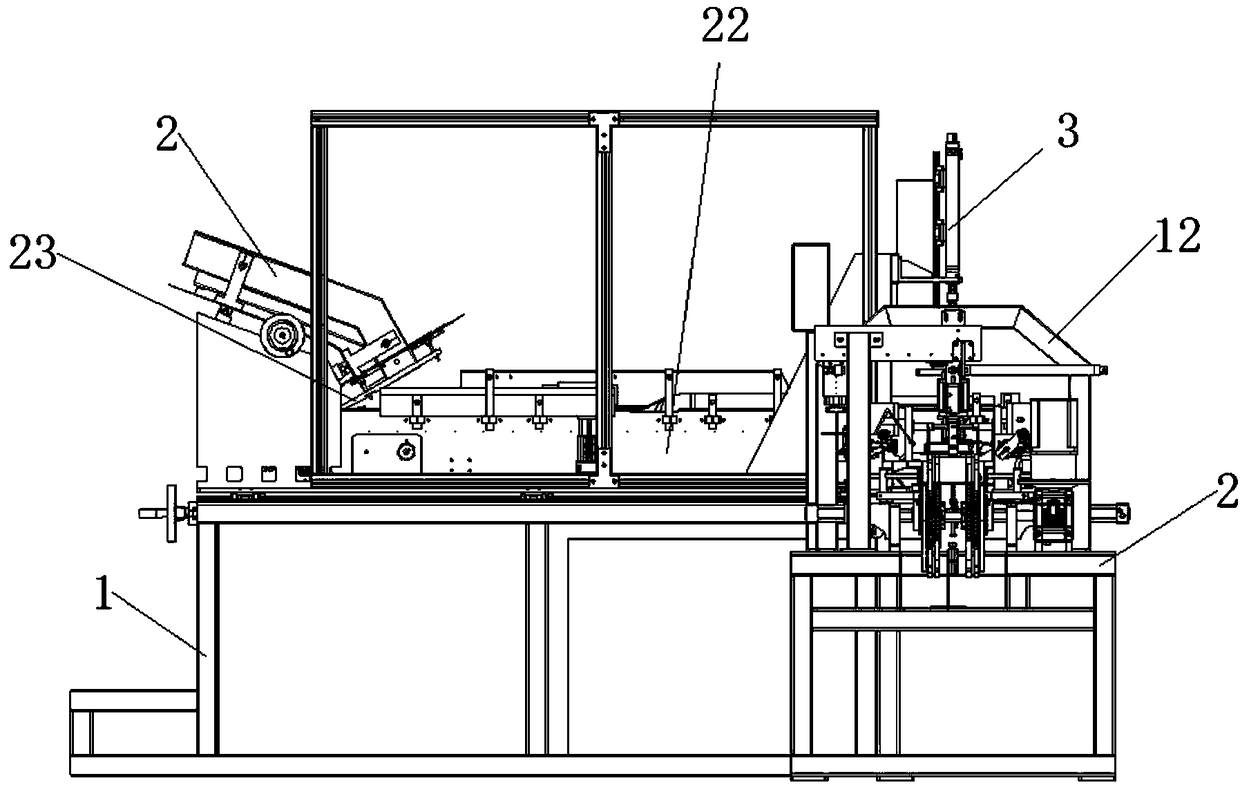

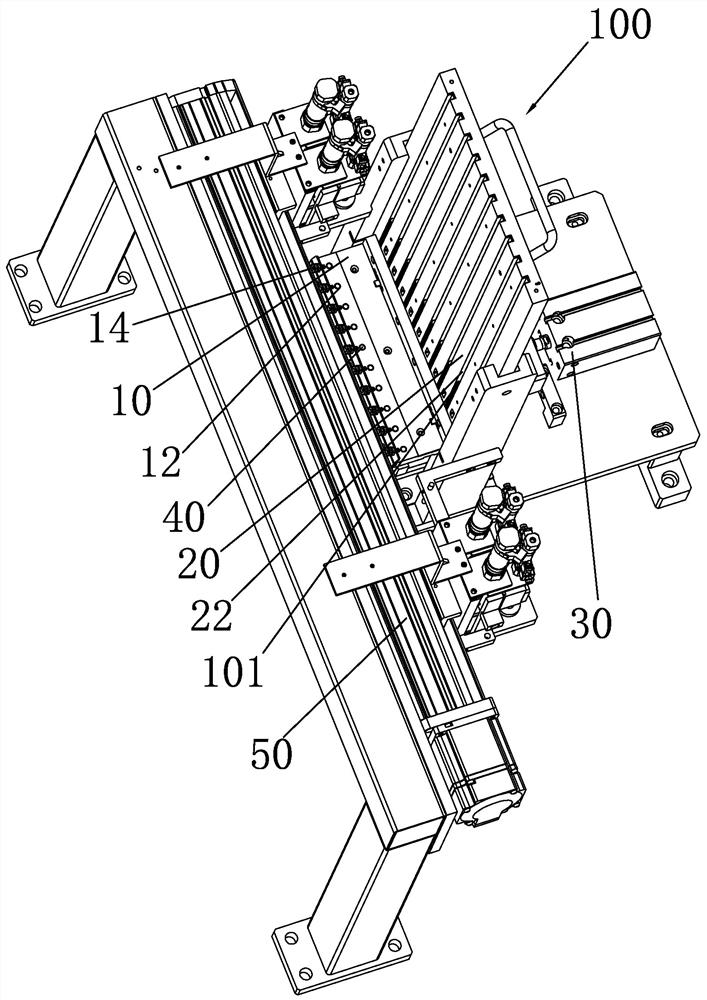

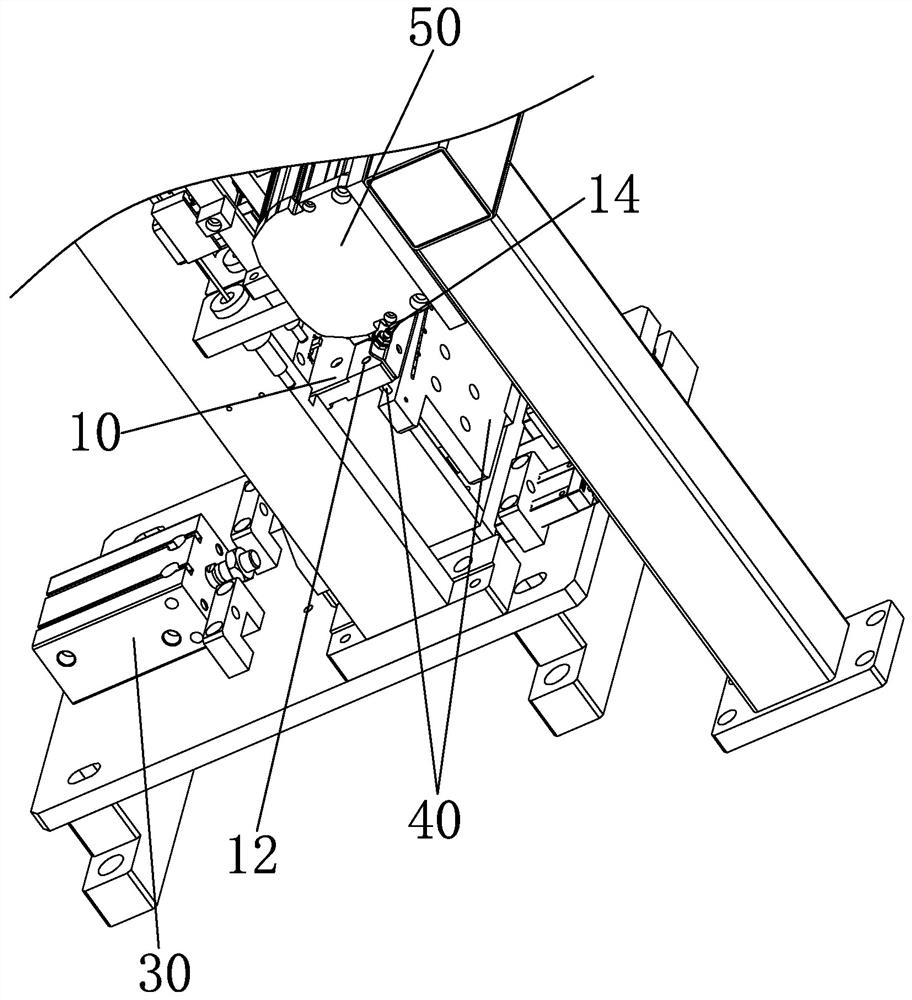

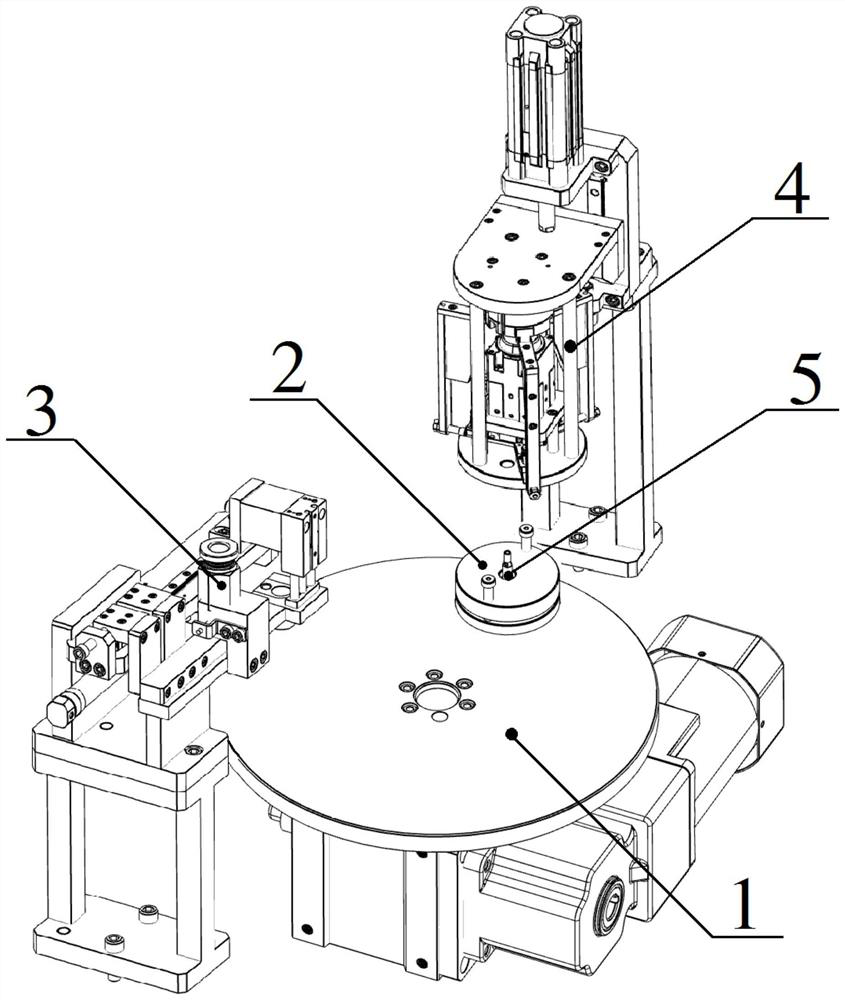

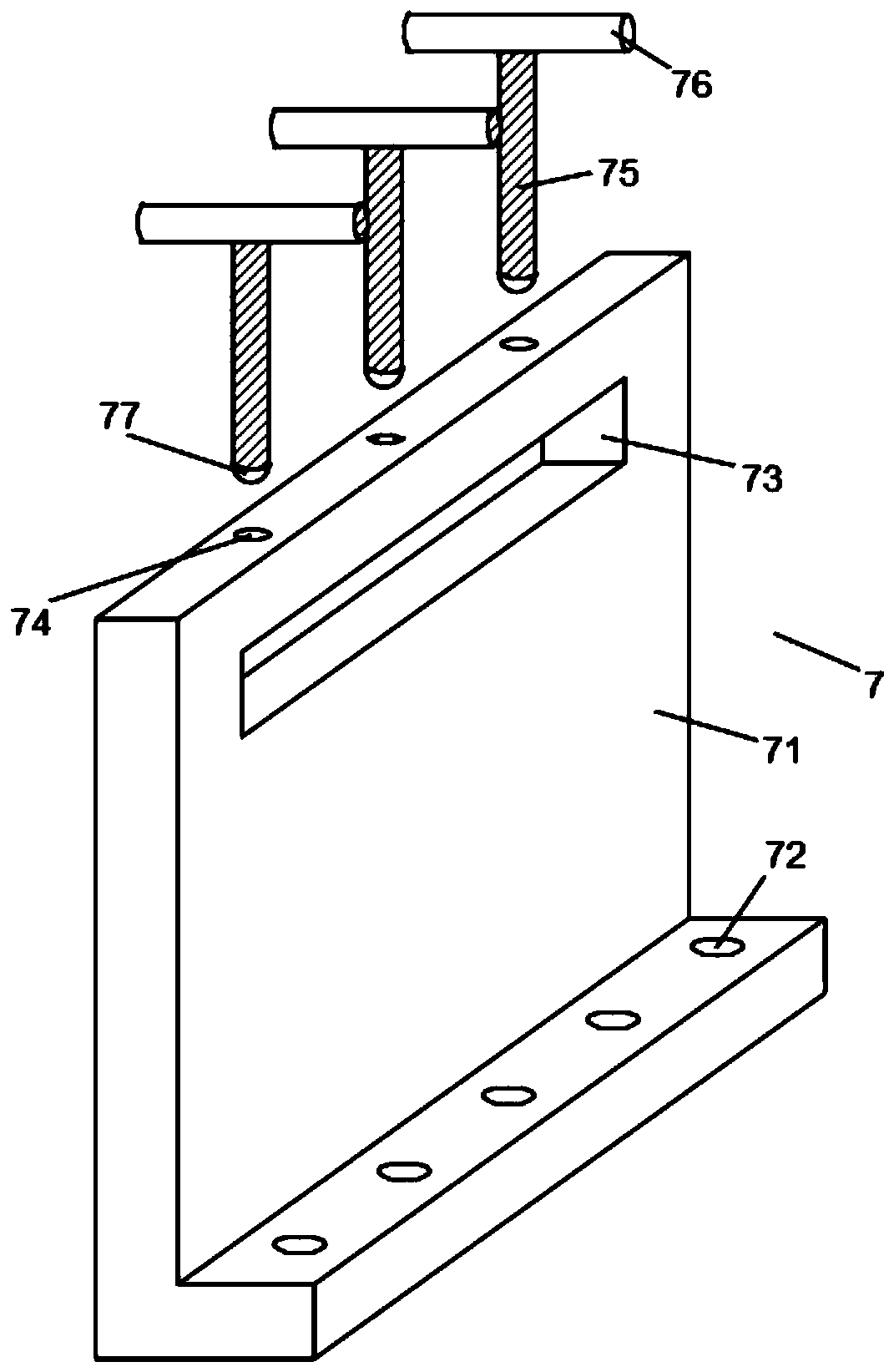

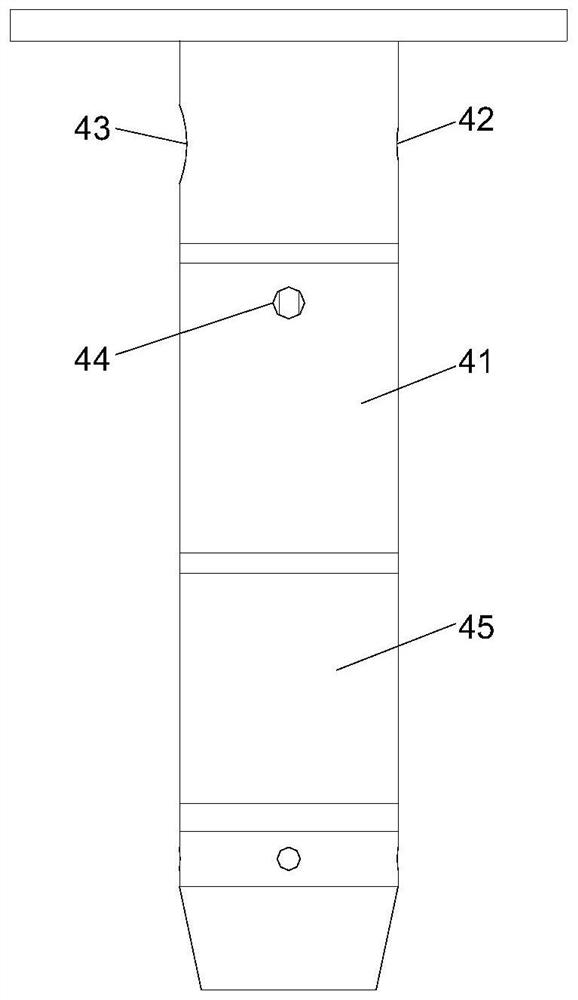

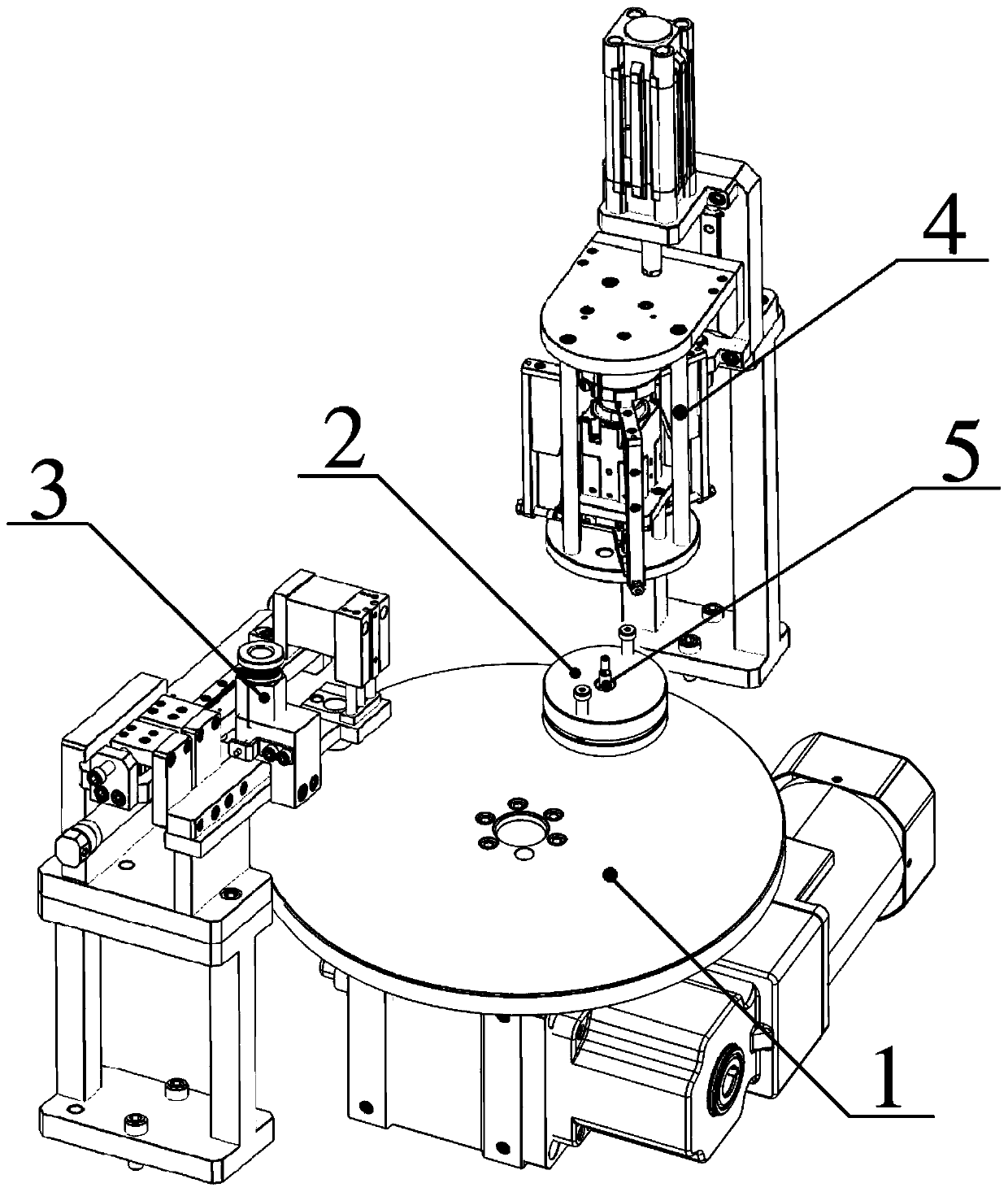

Automatic assembly production line for steel ball stand columns

ActiveCN111331369AEasy to processPrevent movementAssembly machinesMetal working apparatusStructural engineeringSteel ball

The invention provides an automatic assembly production line for steel ball stand columns. The automatic assembly production line comprises a discharging tool, a stand column feeding and oil injectionmechanism, a stand column steel ball filling mechanism, a housing feeding mechanism, a spring copper cover feeding mechanism and a copper cover twisting mechanism, wherein the discharging tool is rotationally arranged on a rotating platform; the stand column feeding and oil injection mechanism is used for receiving the stand columns and injecting oil to the bottoms of the stand columns, and the stand columns are placed in the discharging tool after oil injection; the stand column steel ball filling mechanism is used for filling the stand columns with steel balls after oil injection; the housing feeding mechanism is used for receiving housings and sleeving the stand columns with the housings; the spring copper cover feeding mechanism is used for receiving springs and copper covers and assembling and conveying the springs and the copper covers to the copper cover twisting mechanism; and the copper cover twisting mechanism is used for assembling the stand columns, the housings, the springs and the copper covers into a complete product. The automatic assembly production line is reasonable in design and high in automation degree, and can be used for assembling the steel balls, the stand columns, the housings, the springs and the copper covers, efficient and automatic assembly production of the housings, the stand columns, the steel balls, the springs and the copper covers is achieved, the labor intensity of personnel is relieved, the error rate of the personnel is decreased, and the production efficiency and quality are improved.

Owner:SHAOYANG UNIV +1

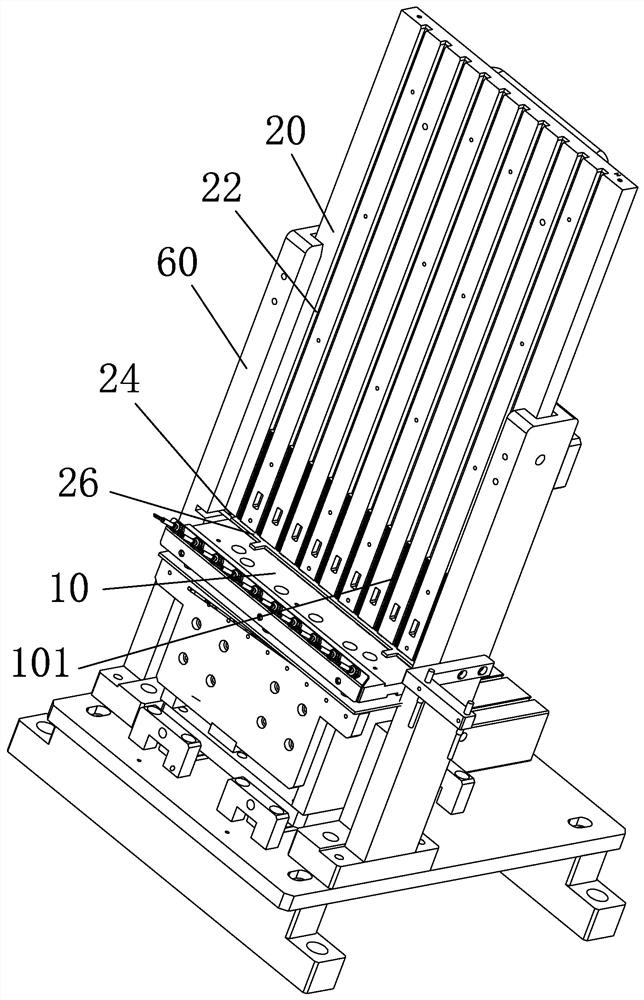

Magnet feeding mechanism of Bluetooth earphone

ActiveCN113542968ASimple structureHigh feed accuracyMetal working apparatusEarpiece/earphone manufacture/assemblyEngineeringMechanical engineering

The invention relates to the technical field of Bluetooth earphones, and discloses a magnet feeding mechanism for Bluetooth earphones, which comprises a base station, a storage rack, a first telescopic driving device, a positioning device and a first transmission unit. At least one first containing hole is formed in the top face of the base table and used for containing the magnet block. The storage rack is located above the base table, containing grooves in one-to-one correspondence with the first containing holes are formed in the storage rack, the containing grooves are formed in the vertical direction, and at least one magnet block can be contained in the containing grooves in the vertical direction; the first telescopic driving device is in transmission connection with the base table so as to drive the first containing hole and the containing groove to be in butt joint or staggered; the positioning device is located at the bottom end of the first containing hole and can attract and position the magnet block in the first containing hole. The first conveying unit is in butt joint with the first containing hole, and the first conveying unit can take away the magnet block in the first containing hole. The magnet feeding mechanism of the Bluetooth headset is high in feeding precision and not prone to making mistakes.

Owner:深圳双十科技股份有限公司

Automatic loading steel ball device

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Illuminating lamp metal shell punch forming device

ActiveCN114682667AImprove stamping effectAvoid offsetMetal-working feeding devicesPositioning devicesStamping processMoulding device

The invention relates to the technical field of lighting lamps, in particular to a lighting lamp metal shell punch forming device which comprises a workbench, an intermittent motor, a supporting base, a discharging part and a punching part. An existing stamping die has the following problems that an aluminum sheet cannot be guided and limited by the stamping die, so that the aluminum sheet cannot be accurately moved into a lower die, and the stamping effect on the aluminum sheet is easily affected; in the stamping process, the aluminum sheet cannot be limited, so that the aluminum sheet is prone to deviation, and the stamping precision of the aluminum sheet is affected. According to the metal plate punching device, a metal plate can be guided through the multiple guide blocks, so that the metal plate accurately falls to the position above the receding groove, and the punching effect on the metal plate is enhanced; in the stamping process of the metal plate, the metal plate can be pressed and fixed, so that the metal plate is prevented from deviating in the stamping process, and then the stamping precision can be improved.

Owner:江苏烨明光电有限公司

Water conservancy silt remover

InactiveCN112832313AAffect normal operationAvoid entanglementSludge treatmentMechanical machines/dredgersCrusherGeotechnical engineering

The invention discloses a water conservancy silt remover. The silt remover structurally comprises a generator, a baffle, a crushing mechanism, a mud guide plate, a rack and a cutter suction head, wherein a bearing is connected and arranged between the cutter suction head and the crushing mechanism, the baffle is hinged to the rack, the mud guide plate and the crushing mechanism are mechanically connected to the rack, the crushing mechanism and the cutter suction head are controlled by the generator, and the cutter suction head is interconnected with the interior of the crushing mechanism. According to the silt remover, a filter screen is arranged in a feeding cavity, when silt is sucked in the cutter suction head, impurities in the silt are filtered through the filter screen firstly, the impurities, particularly plastic impurities, in the silt are separated into the feeding cavity, the situation that normal operation of the crushing mechanism is affected due to the fact that the plastic impurities are prevented from entering the crushing cavity, and a crushing shaft is prevented from being wound.

Owner:郑素花

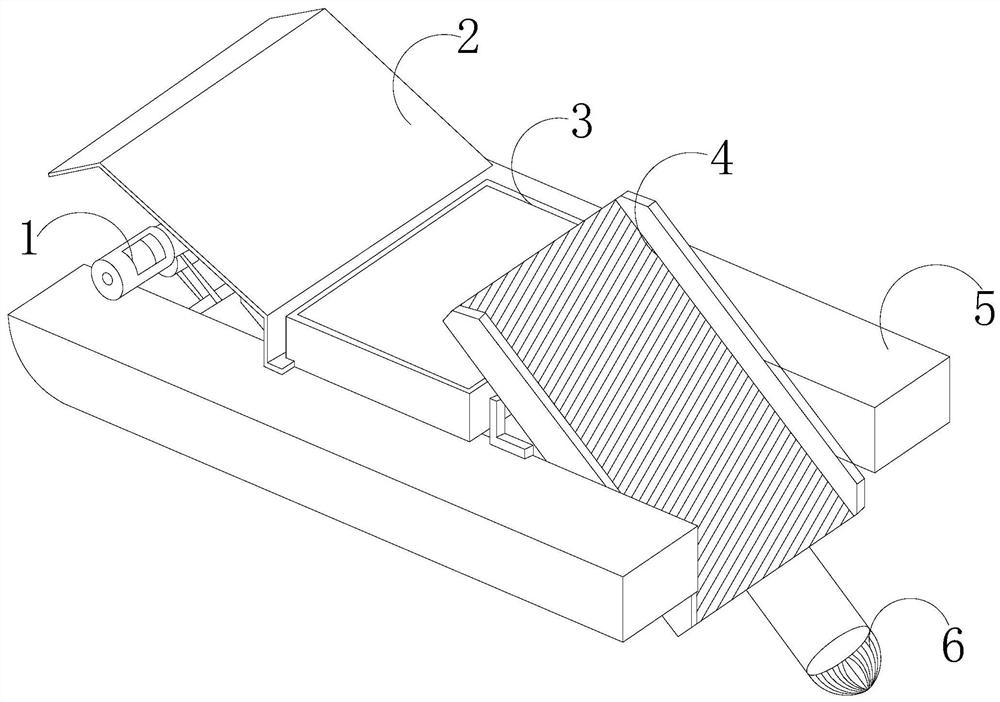

Bevel cutting device for processing beauty blender

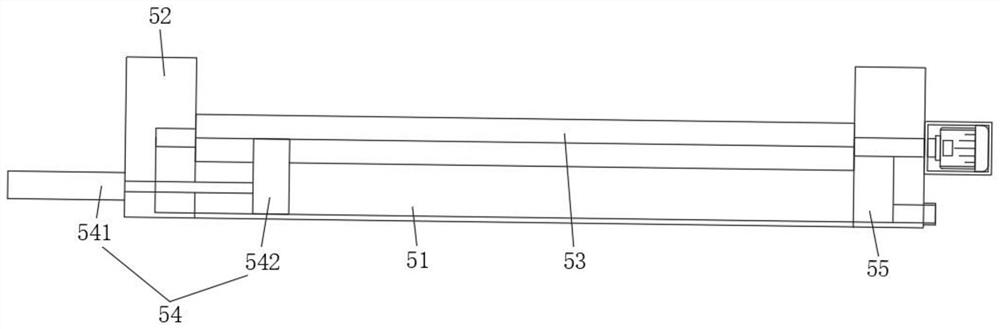

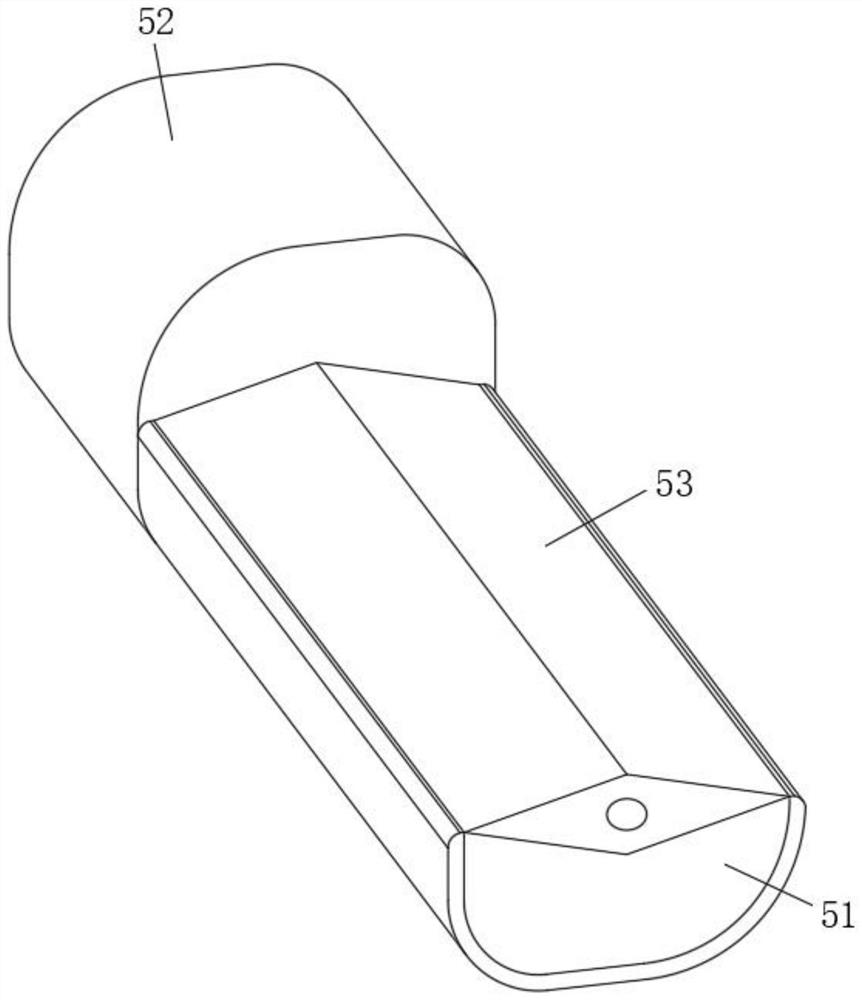

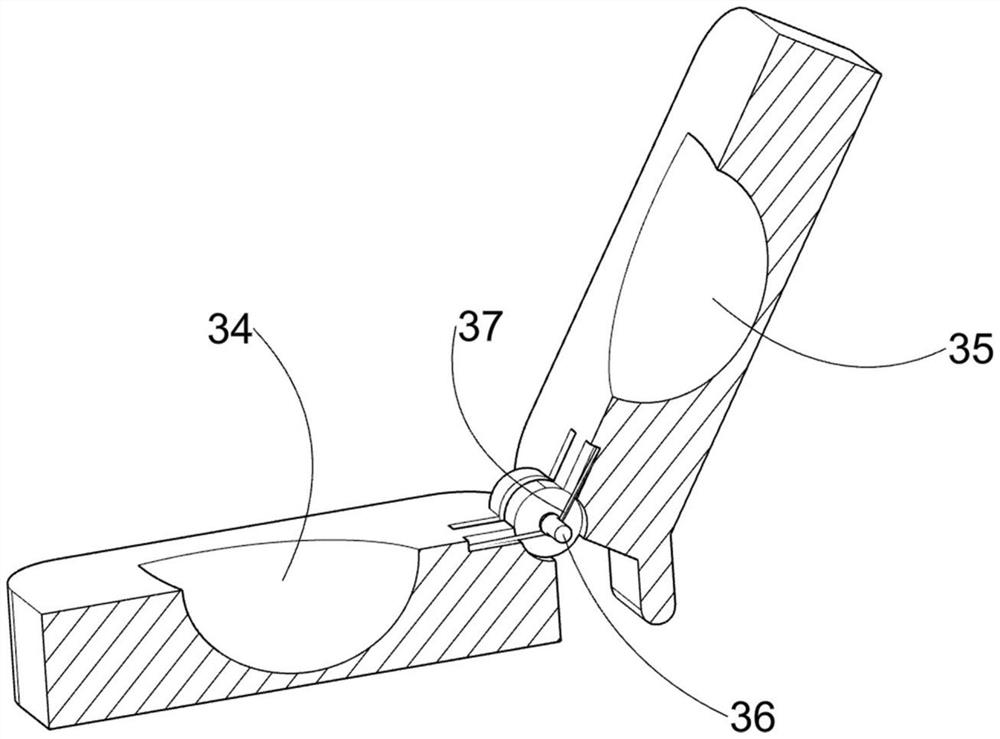

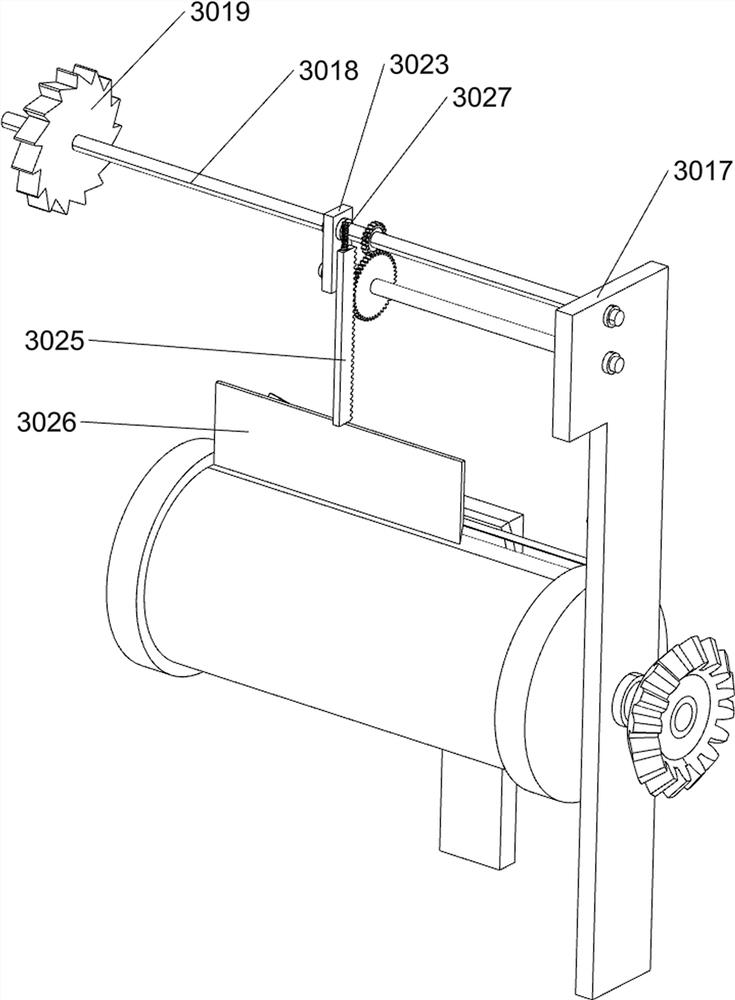

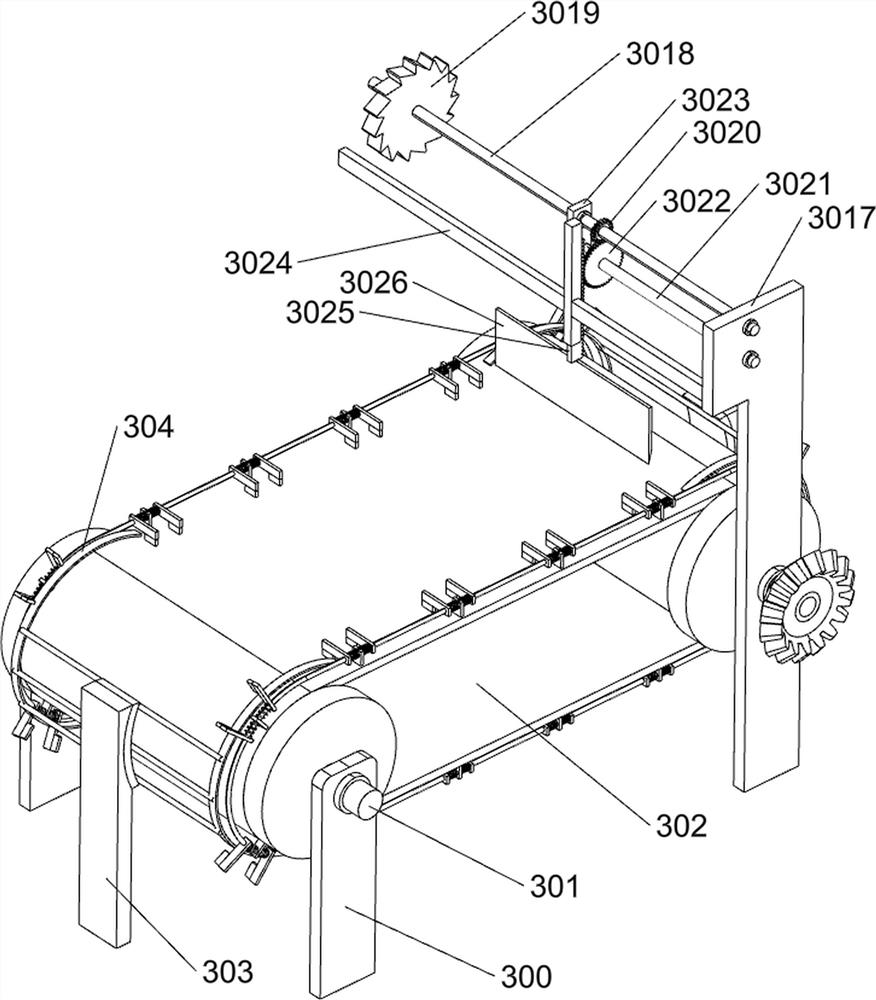

PendingCN113021446AContinuous automatic cuttingAccurate dropMetal working apparatusEngineeringKnife blades

The invention relates to a cutting device, and particularly relates to a bevel cutting device for processing a beauty blender. The bevel cutting device comprises a rack, a supporting plate, a box, a transmission mechanism, a material leaking mechanism and the like; the supporting plate is arranged in the rack; the box is arranged on one side of the supporting plate; and the rack is provided with the mold transmission mechanism and the material leaking mechanism. According to the bevel cutting device, through mutual cooperation of the mold transmission mechanism, the material leaking mechanism, a cutting mechanism and a cleaning mechanism, the material leaking mechanism enables the beauty blender to continuously fall onto a first mold block, then the beauty blender on the first mold block are conveyed through a belt, then the cutting mechanism cuts the beauty blender, then a sponge block can wipe away redundant beauty egg leftover materials left on a blade, and the effect of continuously and automatically cutting the beauty blender is achieved.

Owner:余甜甜

Coke guide device for petroleum coke processing production

The invention discloses a coke guide device for petroleum coke processing production, relates to the technical field of guide conveying devices, and solves the problems that most of existing conveying devices cannot directly screen materials, so that the materials can be loaded or stored after being additionally screened and classified subsequently, and the use is troublesome and inconvenient. The coke guide device for petroleum coke processing production comprises a supporting frame. The supporting frame comprises L-shaped supporting plates, the whole supporting frame is formed by symmetrically welding four L-shaped ground contact supporting rods, the four L-shaped supporting plates are symmetrically welded to the top ends of the four L-shaped supporting plates, two wheel shafts are rotationally installed between the four L-shaped supporting plates in a front-back symmetrical mode, and the left end sections and the right end sections of the two wheel shafts are symmetrically sleeved with four chain wheels. According to the coke guide device, coke particles can be screened according to the size in the coke conveying process, the trouble of follow-up coke screening and classifying is omitted, the coke discharging post-treatment step is simplified, and use is convenient and efficient.

Owner:SHENGLI OILFIELD SHENGXIN ANTISEPSIS

Wire winding machine discharging device

The invention relates to the technical field of mesh belt machining, and particularly relates to a wire winding machine discharging device. The wire winding machine discharging device comprises a supporting mechanism, a cutting mechanism and a collecting mechanism; the supporting mechanism comprises a containing table for containing steel wires obtained after wire winding and an overturning assembly for driving the containing table to overturn on the vertical face; the cutting mechanism is located at the position of the containing table; the collecting mechanism comprises a collecting box located below the containing table, a plurality of partition plates arranged in the collecting box and a sliding assembly movably arranged on the upper side of the collecting box; a box opening of the collecting box is arranged upwards, the interior of the collecting box is divided by the partition plates into a plurality of collecting cavities sequentially arranged in the horizontal direction, and the arrangement direction of the collecting cavities is perpendicular to the length direction of the steel wires; and the sliding assembly is provided with a first inclined face used for guiding the steel wires into the collecting cavities. By means of the wire winding machine discharging device, the machining efficiency of the steel wires can be improved.

Owner:杭州亿成金属网带有限公司

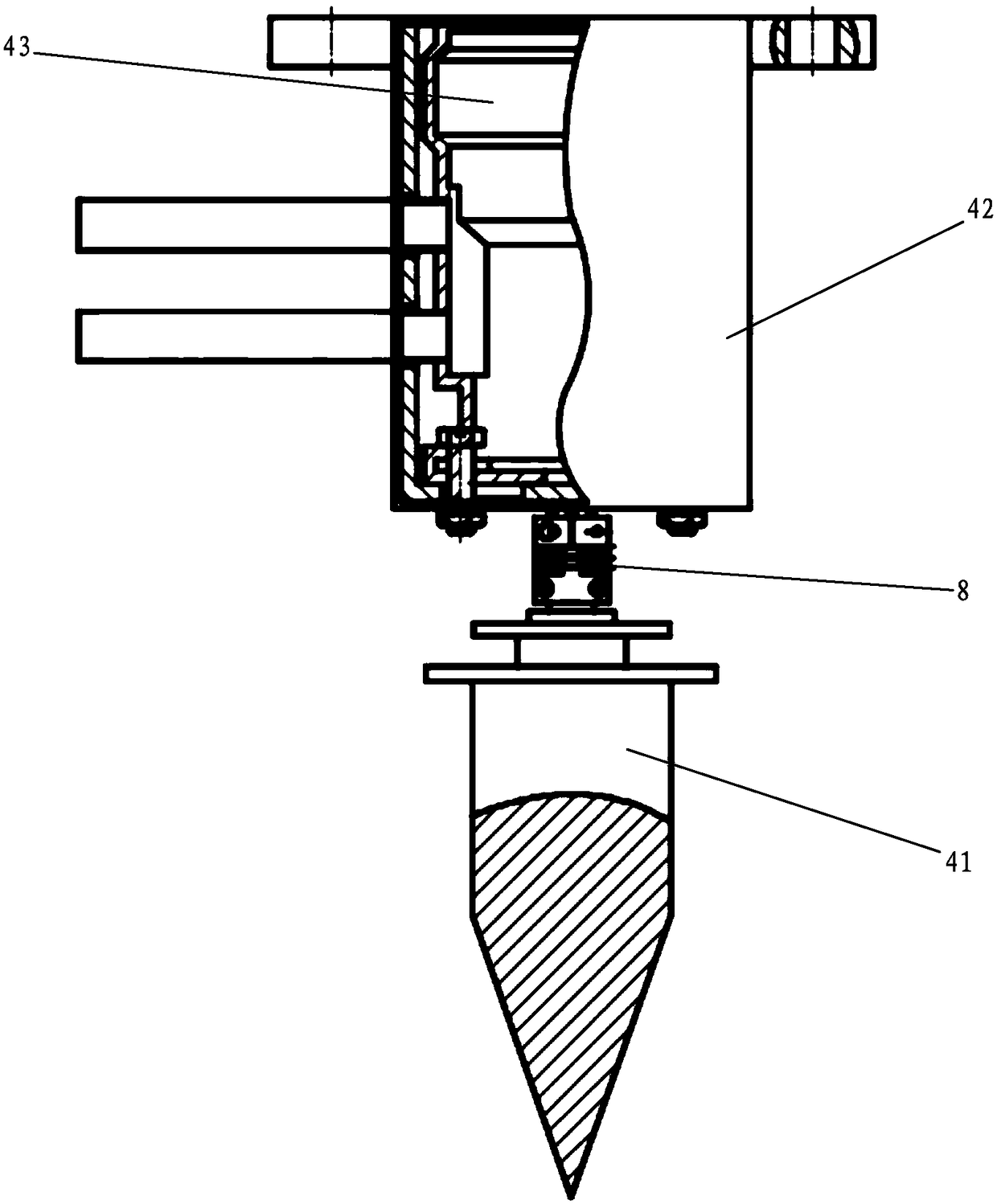

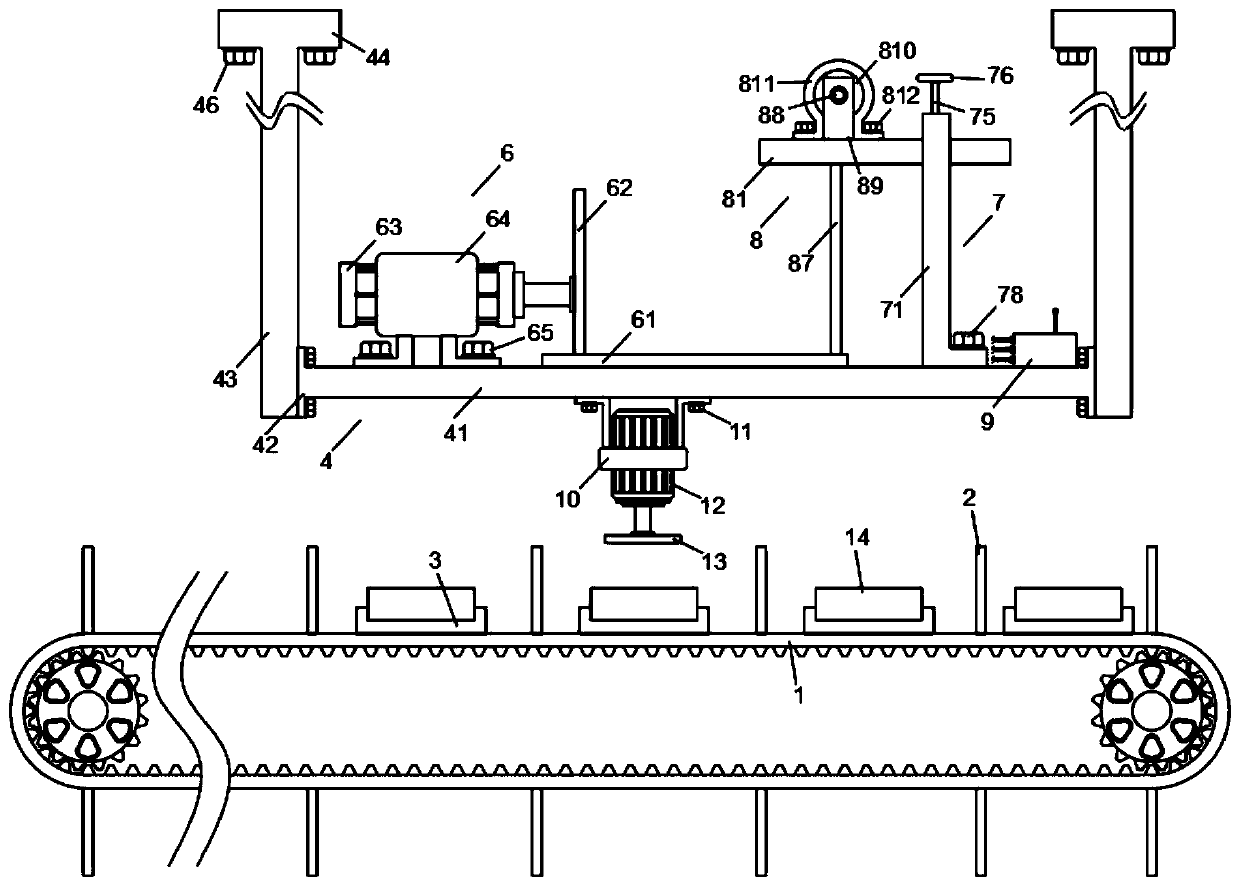

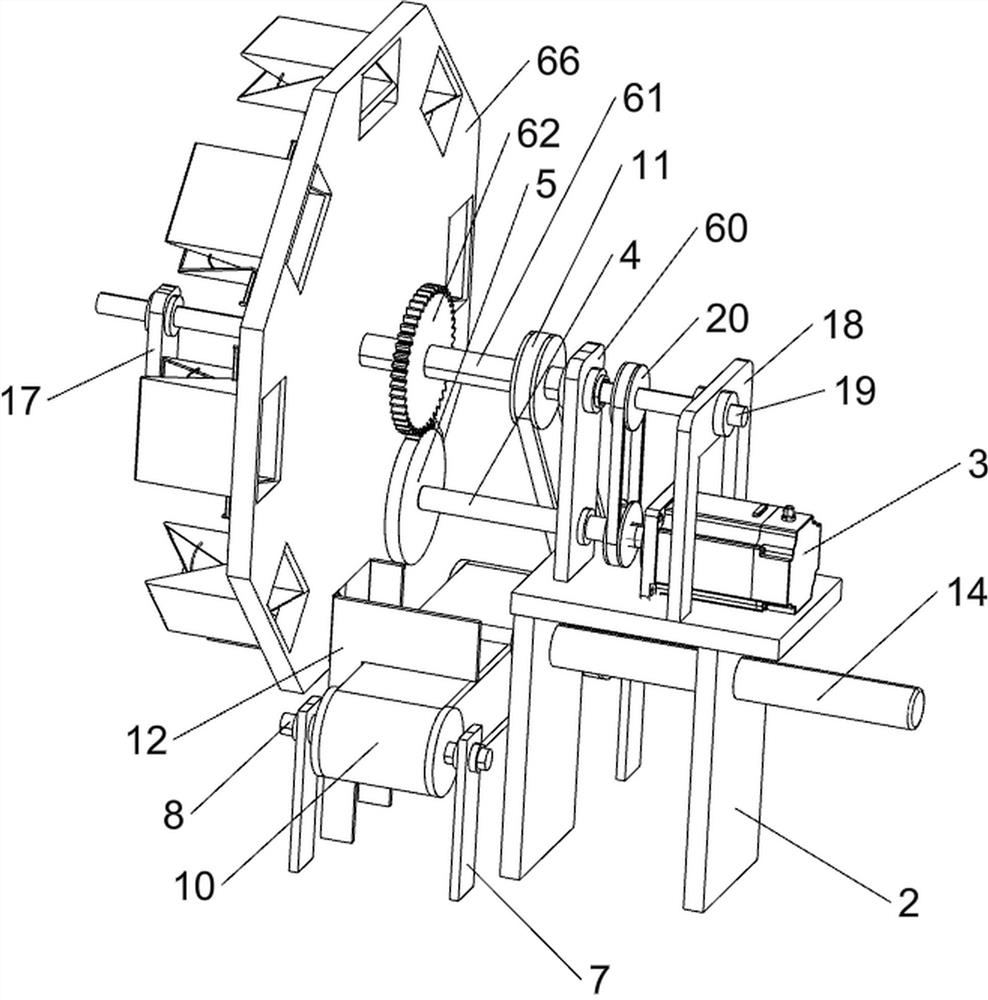

Automatic clay billet cutting and feeding device for ceramic production line

PendingCN110978249AAccurate dropAvoid wasteful situationsFeeding arrangmentsAuxillary shaping apparatusProduction lineStructural engineering

The invention discloses an automatic clay billet cutting and feeding device for a ceramic production line. The device comprises a conveying belt, wherein a plurality of partition boards are fixedly connected with the outer wall of the conveying belt, a limit seat is fixedly connected with the conveying belt outer wall between every two adjacent partition boards, a die is embedded in each limit seat, and a load-bearing mechanism is arranged above the conveying belt. A controller controls the conveying belt, a pushing mechanism and a cutting mechanism to work, so that materials can accurately fall in the dies in the limit seats on the conveying belt between the adjacent partition boards, and the condition of material waste is avoided; and besides, by means of interpenetration connection anddetachable connection of the limit mechanism and the cutting mechanism, the position of a cutter on a placement plate is convenient to adjust, and cutting size of the materials is convenient to adjust.

Owner:醴陵市和泰陶瓷制造有限公司

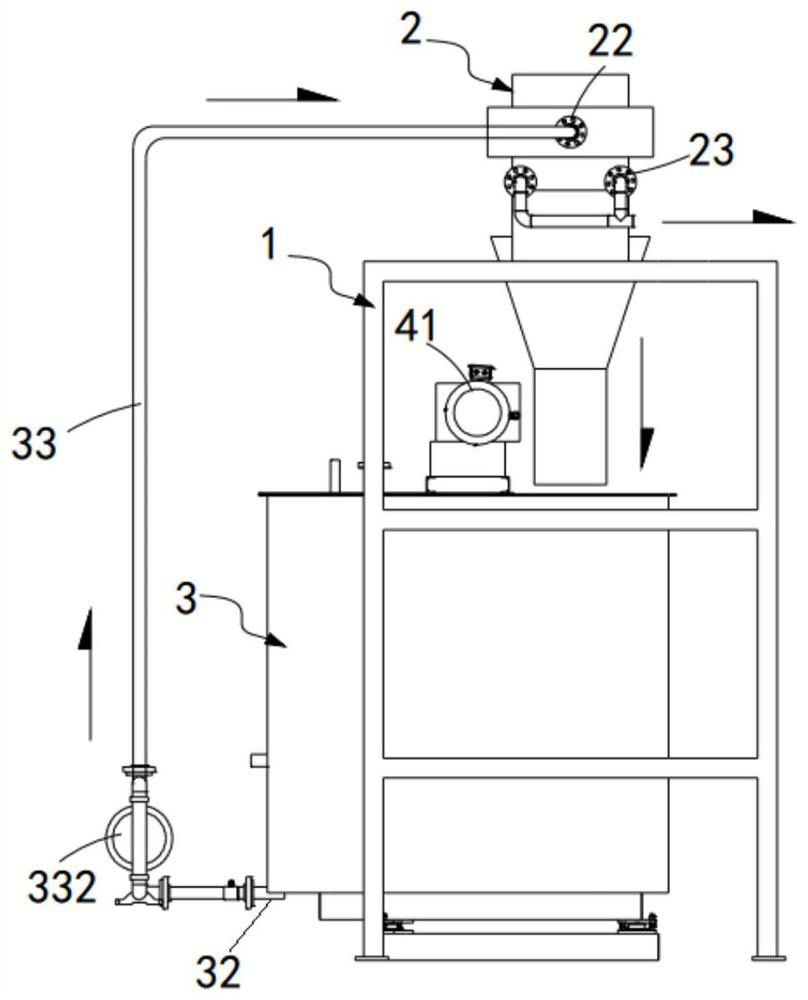

Intelligent valve port packaging machine and control system thereof

InactiveCN114013762ASolve the problem of packaging dustSolve the fragileConveyor partsPackaging machinesControl systemControl engineering

The invention discloses an intelligent valve port packaging machine and a control system thereof. The intelligent valve port packaging machine comprises a sending bin arranged on a rack, the sending bin is communicated with a discharging pipe, a discharging device is arranged between the discharging pipe and the sending bin, and an ultrasonic device and a bag supporting assembly are further arranged on the rack. The ultrasonic device is located above the bag supporting assembly, and the ultrasonic device and the bag supporting assembly are both arranged on the side, away from the discharging device, of the discharging pipe. The bag supporting assembly is connected with a lifting assembly, a bag pushing assembly is further arranged on the rack and pushes material bags placed on the bag supporting assembly, and the bag pushing assembly and the lifting assembly are both arranged on the side, away from the belt conveyor, of the bag supporting assembly. According to the intelligent valve port packaging machine and the control system thereof, the discharging device solves the problems that leakage occurs during discharging and discharged rubber is prone to being damaged, the bag supporting assembly enables material bags to accurately fall on a belt conveyor, and the practicability and accuracy of the device are improved.

Owner:常州新力天合粉体设备有限公司

An industrial noodle packaging box equipment

The invention relates to a box packing device, in particular to a box packing device for industrial noodles. The technical problem to be solved is to provide an industrial noodle packaging box equipment that can accurately drop the bread into the packaging bag, has high working efficiency and is easy to operate. An industrial noodle packaging box equipment, comprising: a bottom plate, the top side of the bottom plate is fixedly connected with a first support; a servo motor, the servo motor is installed on the top of the first support; a first rotating shaft, the first support A rotating shaft is connected to the output shaft of the servo motor through a coupling. The invention achieves the effect that the bread can be accurately dropped into the packaging bag, and the work efficiency is high, and the operation is easy. People only need to continuously place the prepared bread on the first conveyor belt, and the first conveyor belt will drive the bread forward intermittently. Move, and push the bread to the packaging bag on the outside of the fixed part and the movable part through the push plate.

Owner:新乡市口口妙食品有限公司

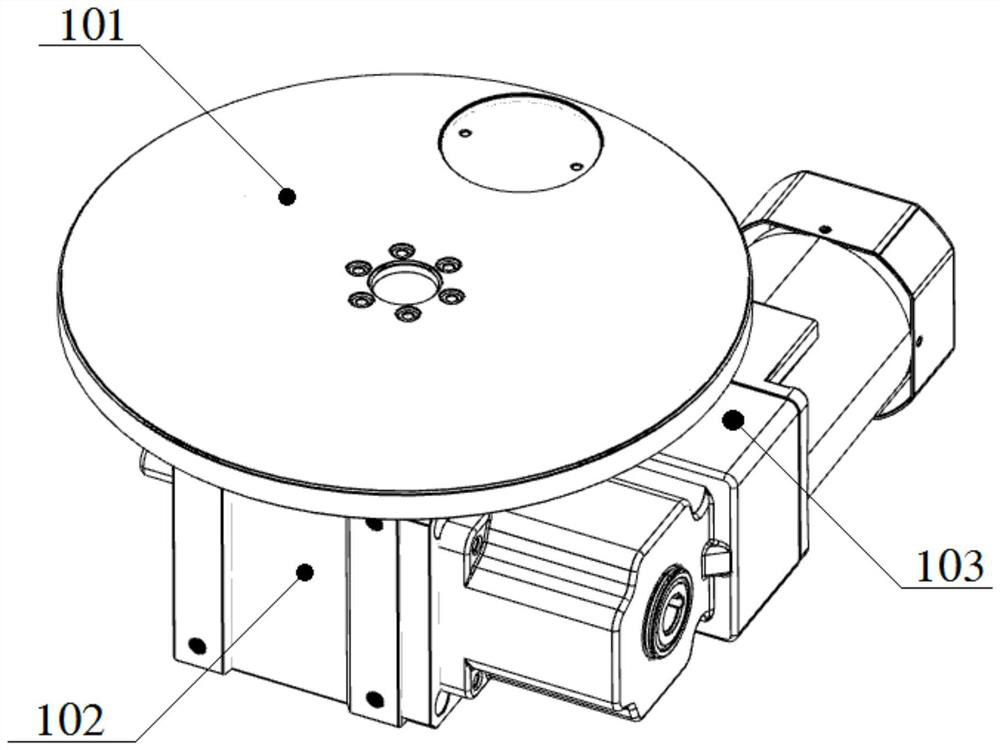

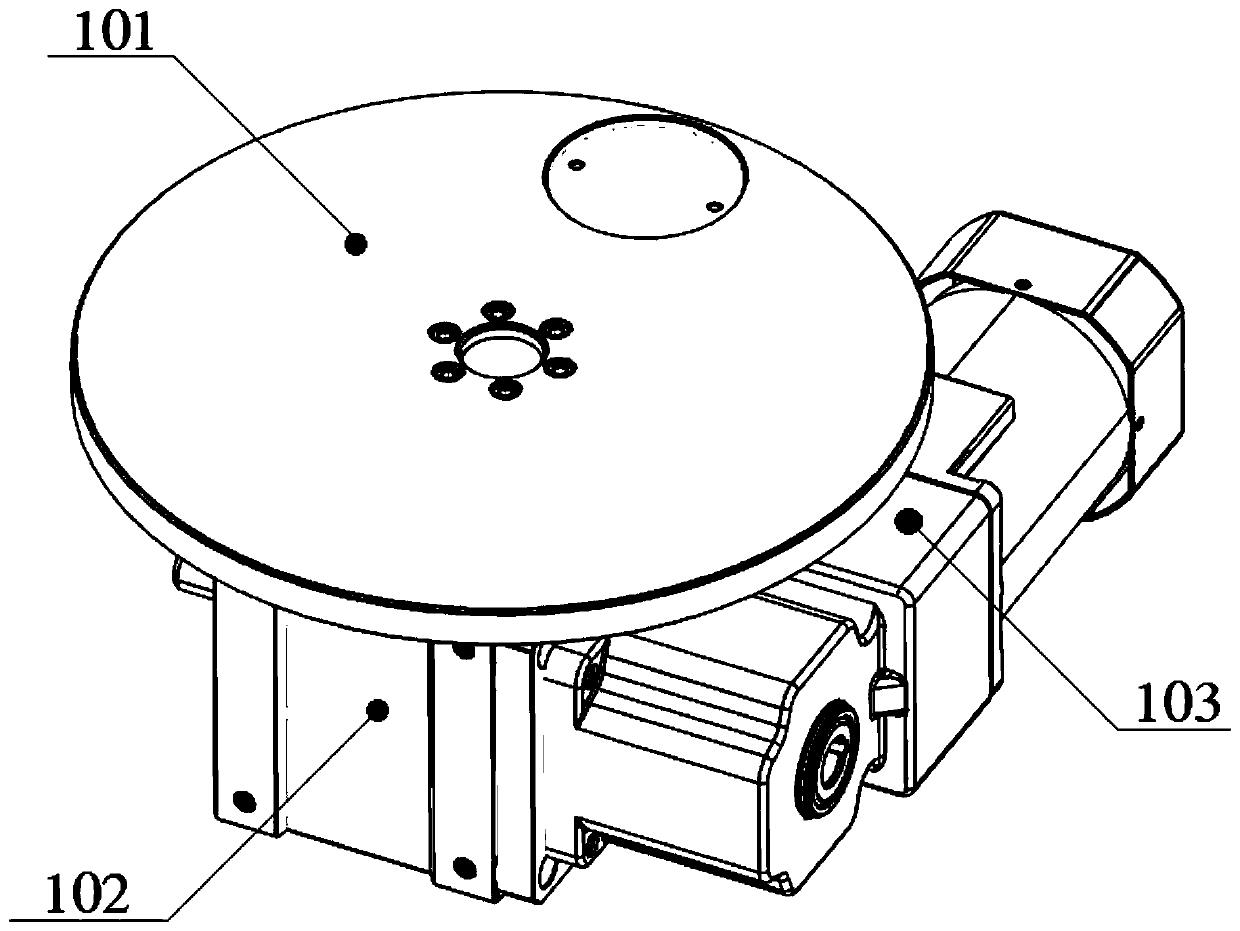

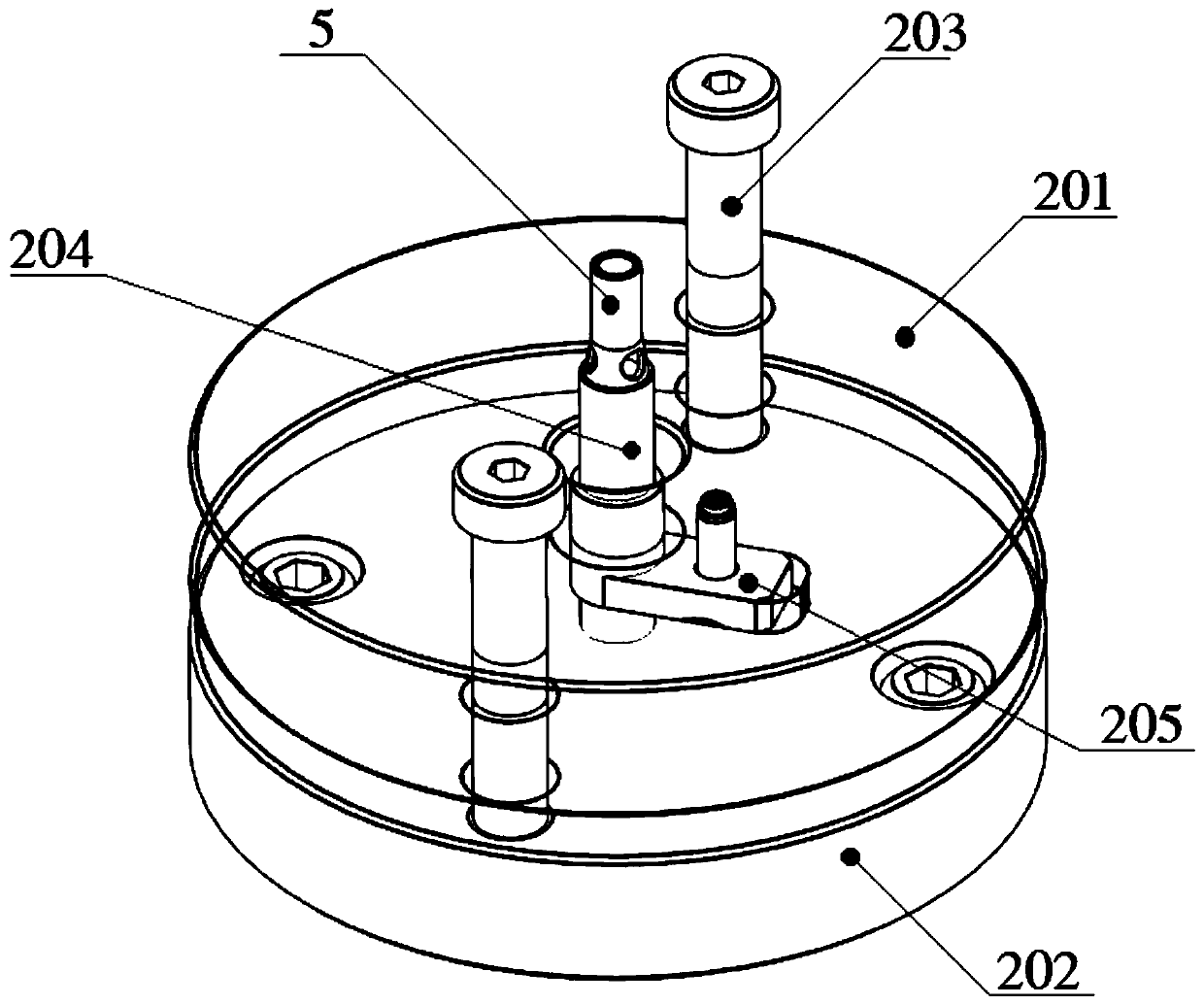

Automatic steel ball filling device

ActiveCN111390521AEasy to processPrevent movementMetal working apparatusStructural engineeringSteel ball

The invention provides an automatic steel ball filling device which comprises a rotating platform, a stand column feeding and oil filling mechanism and a stand column steel ball filling mechanism. Therotating platform, the stand column feeding and oil filling mechanism and the stand column steel ball filling mechanism are arranged on the same plane. A storing tool is arranged on the top face of the rotating platform in a rotating manner and used for storing a stand column. The stand column feeding and oil filling mechanism is arranged beside the rotating platform. A blanking opening of the stand column feeding and oil filling mechanism is formed above a rotating track of the storing tool. The stand column feeding and oil filling mechanism is used for receiving a stand column and filling oil to the stand column. The stand column steel ball filling mechanism is arranged beside the rotating platform. A feeding part of the stand column steel ball filling mechanism is arranged above the rotating track of the storing tool. The stand column steel ball filling mechanism is used for filling steel balls to the stand column. The automatic steel ball filling device is reasonable in design, and high in automation degree, the whole process of stand column feeding, oil filling, transferring and steel ball filling can be achieved efficiently with high quality, the labor intensity of operatorsis effectively reduced, and the production efficiency is improved.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com