Metal ceramic producing and processing device

A processing device, cermet technology, applied in the directions of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of reducing the service life of the device, the impact of product quality, mixing of different raw materials, etc., to increase bearing capacity, reduce Small moving range, reduced sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

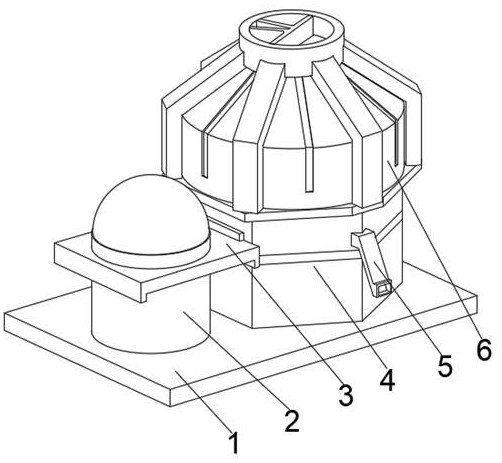

[0040] see Figure 1-6 , the present invention provides a technical solution: a cermet production and processing device, including a bearing plate 1, the top right side of the bearing plate 1 is fixedly connected with a stabilizing seat 4, and the front top of the stabilizing seat 4 is connected with a discharge pipe 5, which is stable The top of the seat 4 is provided with a processing device 6, and the top of the left outer wall of the stable seat 4 is fixedly connected with a solid plate 3, and the middle position of the bottom of the solid plate 3 is provided with a storage tank 2, and the top of the storage tube 2 runs through the solid plate 3 and extends to the outside of the solid plate 3;

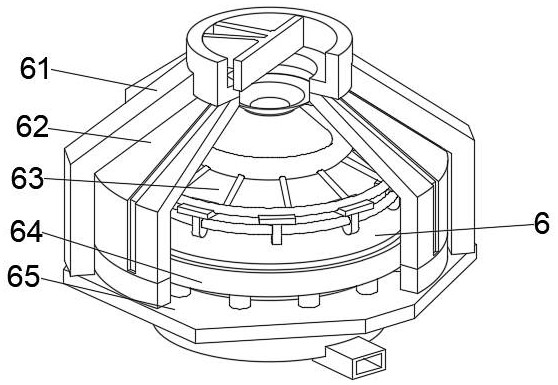

[0041] Processing device 6 comprises dividing plate 65, and the top middle position of dividing plate 65 is provided with communicating mechanism 64, and the bottom of communicating mechanism 64 penetrates dividing plate 65 and extends to the outside of dividing plate 65, and the t...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using a cermet production and processing device, step 1: fix the device, and transfer the storage tank 2 to the processing device 6 through the delivery pipeline Communication, the discharge pipe 5 is communicated with the stable seat 4, and the processing device 6 is connected with the power supply;

[0048] Step 2: Connect the preparation cylinder 62 and the partition plate 65 through the elastic support frame 61, use the pusher of the preparation cylinder 62 to push the internal materials, and communicate the material receiving mechanism 63 with the communication mechanism 64;

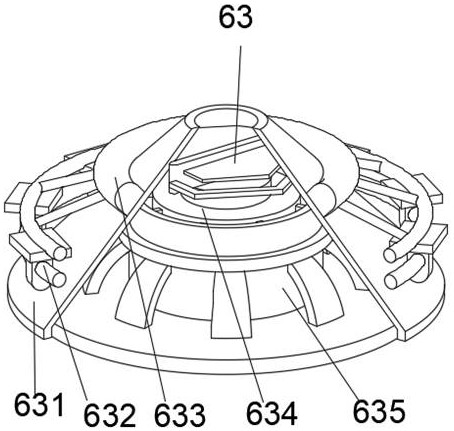

[0049] Step 3: Connect the adjusting frame 633 with the conical housing 631, so that the adjusting frame 633 drives the touch piece 632 to move, and the centralized transportation of materials is carried out through the collecting cavity generated by the rotating piece 634 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com