Water conservancy silt remover

A dredging machine and water conservancy technology, applied in the direction of soil mover/shovel, water/sludge/sewage treatment, mechanically driven excavator/dredger, etc., can solve the blockage and broken of the dredger's mud delivery pipe Shaft winding, affecting the crushing efficiency of the crushing shaft, etc., to improve filtration efficiency, prevent winding, and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

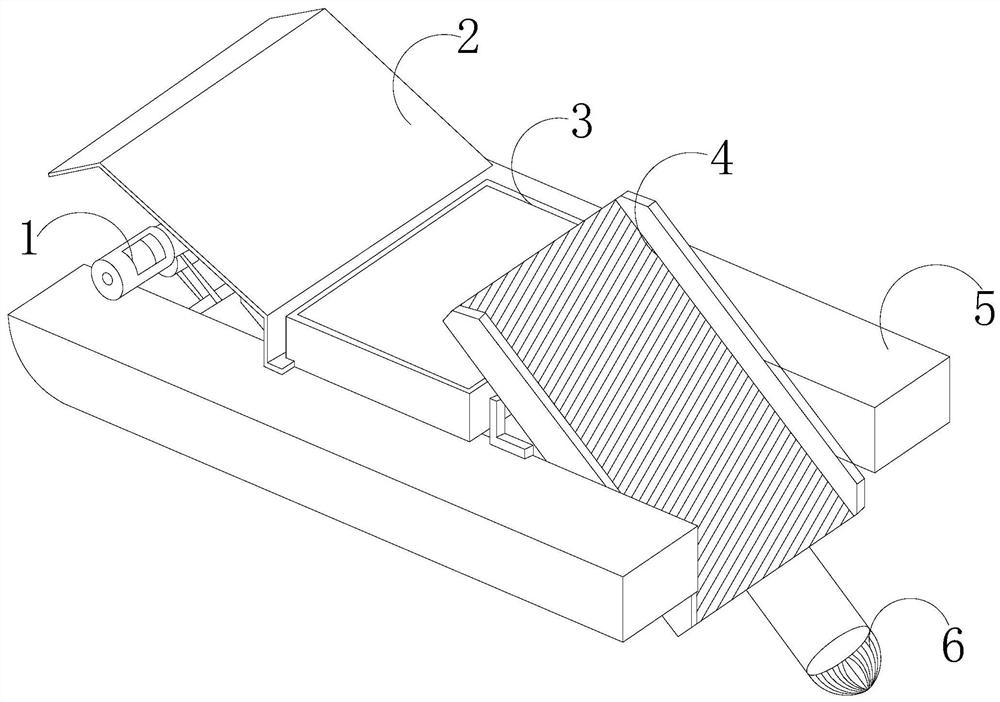

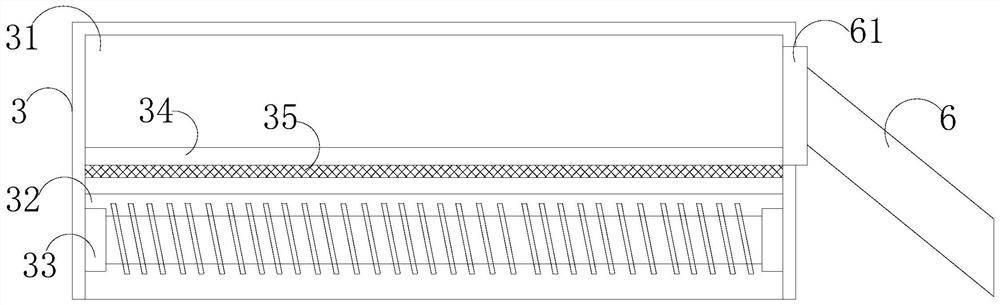

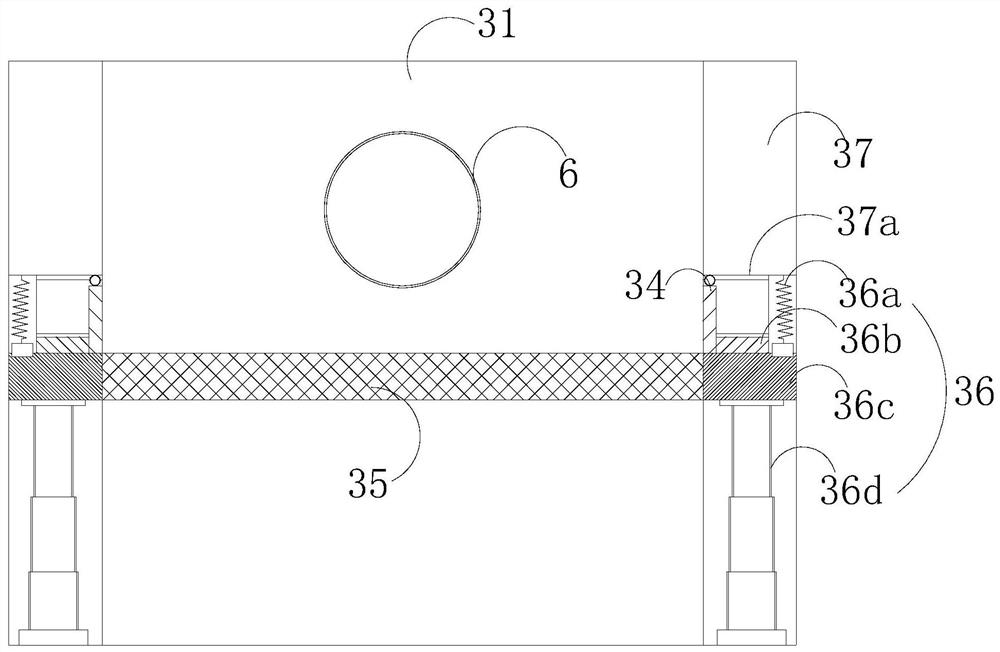

[0026] Such as Figure 1-Figure 6 As shown, the present invention provides a kind of water conservancy desilting machine, and its structure comprises generator 1, baffle plate 2, crushing mechanism 3, mud deflector 4, frame 5, twisting suction head 6, described twisting suction head 6 and crushing Bearings 61 are connected between the mechanisms 3, the frame 5 is hingedly connected with a baffle plate 2, the mud guide plate 4 is mechanically connected to the crushing mechanism 3 on the frame 5, and the crushing mechanism 3 and the twisting suction head 6 Controlled by the generator 1, the twisting suction head 6 and the inside of the crushing mechanism 3 are interconnected, and the crushing mechanism 3 includes a feeding chamber 31, a crushing chamber 32, a crushing shaft 33, a folding plate 34, a filter screen 35, and a lifting device 36 , installation slot 37, the feeding chamber 31 is located at the upper end of the crushing chamber 32, the connection position between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com