Circulating type rapid multi-stage filter pressing system

A circulating and fast technology, applied in the direction of filtration separation, mixer, mixer with rotating stirring device, etc., can solve the problem that the filter residue cannot be purified efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

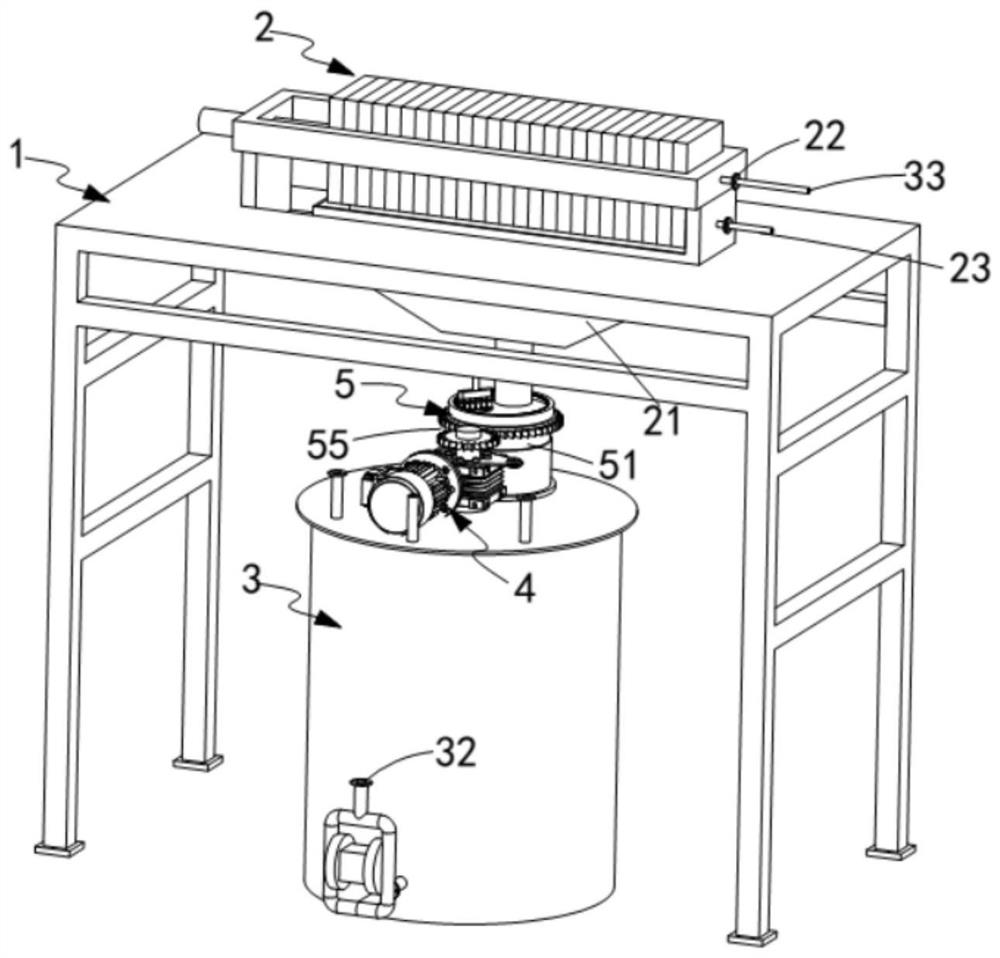

[0054] Such as Figure 1 to Figure 7 As shown, a circulating fast multi-stage filter press system includes support 1, and also includes:

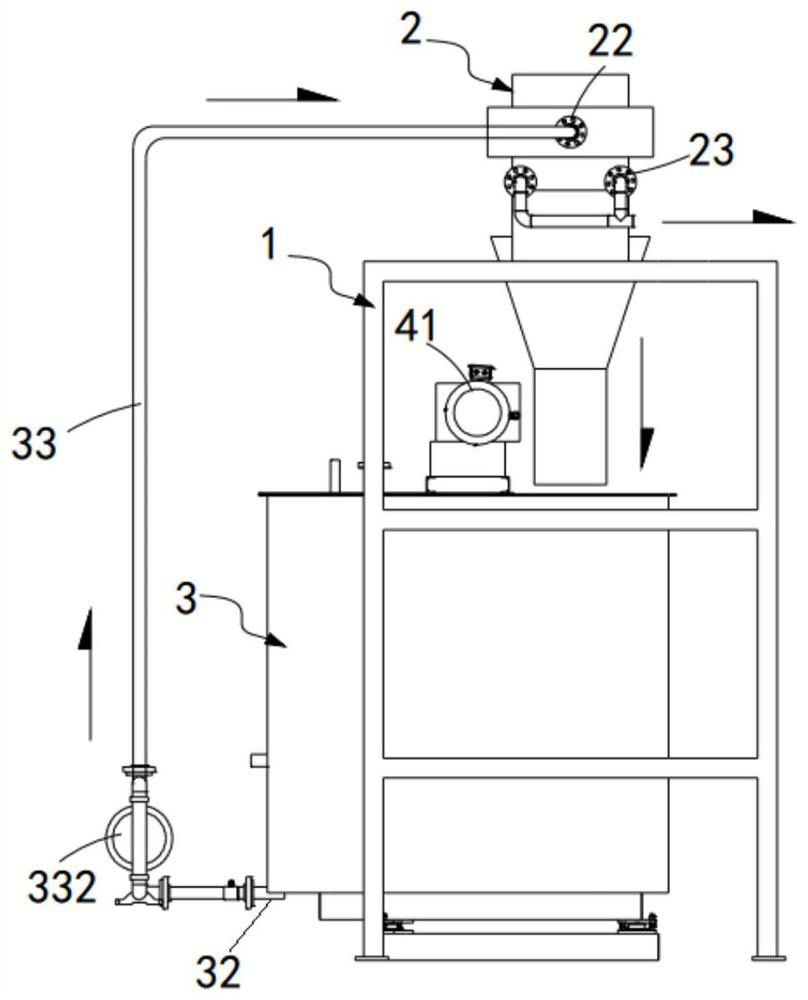

[0055] A filter press device 2, the filter press device 2 is arranged on the top of the support 1, the bottom of which is provided with a slag receiving hopper 21, and one side thereof is provided with a liquid inlet 22;

[0056] A filter residue tank 3, the filter residue tank 3 is arranged directly below the filter press device 2, an opening 31 is arranged on the top, and the opening 31 is arranged facing the slag receiving hopper 21, and a liquid discharge port is arranged on the bottom thereof 32, the liquid discharge port 32 communicates with the liquid inlet port 22 through a connecting pipe 33;

[0057] A stirring mechanism 4, the stirring mechanism 4 is installed on the filter residue tank 3, and the stirring mechanism 4 stirs the filter residue and water in the filter residue tank 3; and

[0058] A material distribution mechanism...

Embodiment approach

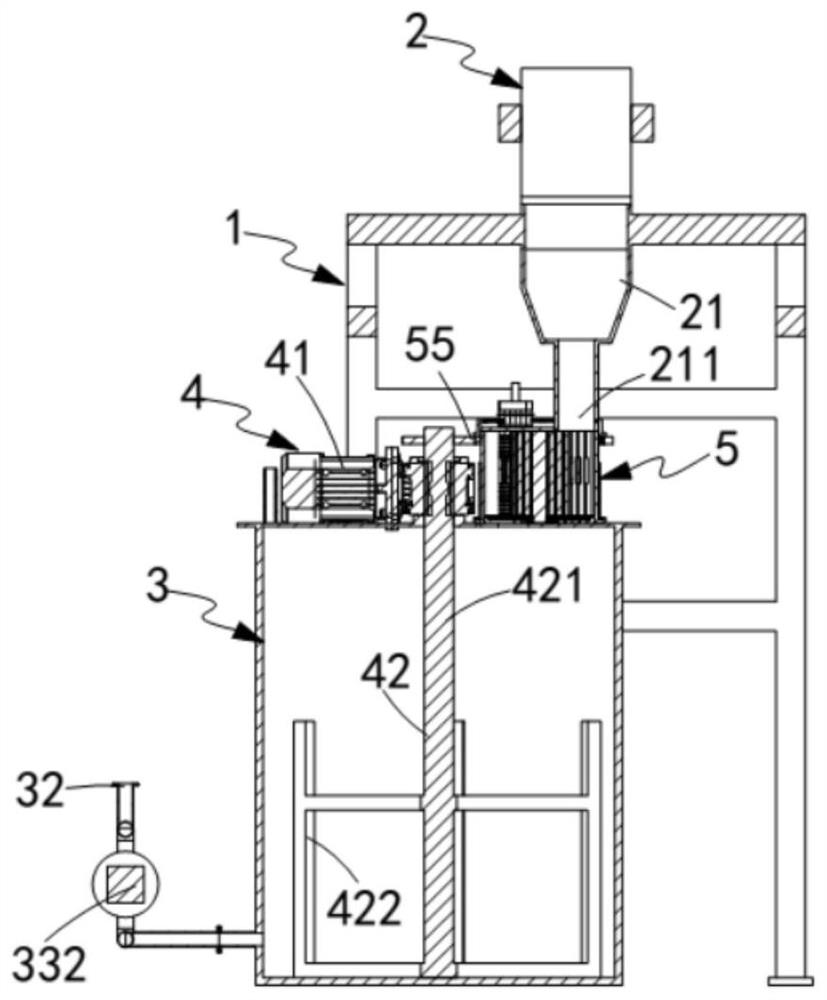

[0063] Such as figure 2 As shown, as a preferred embodiment, the stirring mechanism 4 includes:

[0064] A driving member 41, the driving member 41 is arranged on the top of the filter residue tank 3, which is located on one side of the opening 31; and

[0065] Stirring member 42 , the stirring member 42 is vertically connected to the driving member 41 and is driven to rotate by the driving member 41 .

[0066] Further, the stirring member 42 includes:

[0067] A stirring shaft 421, the stirring shaft 421 is coaxially arranged with the filter residue tank 3, and its top is connected with the driving member 41; and

[0068] The stirring part 422 , the stirring part 422 is integrally provided with the stirring shaft 421 , and is located at the lower part of the filter residue tank 3 .

[0069] In addition, the distributor 51 is in transmission connection with the stirring shaft 421 through a gear transmission unit 55 .

[0070] It should be noted that the rotation of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com