Patents

Literature

35results about How to "Fluid discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

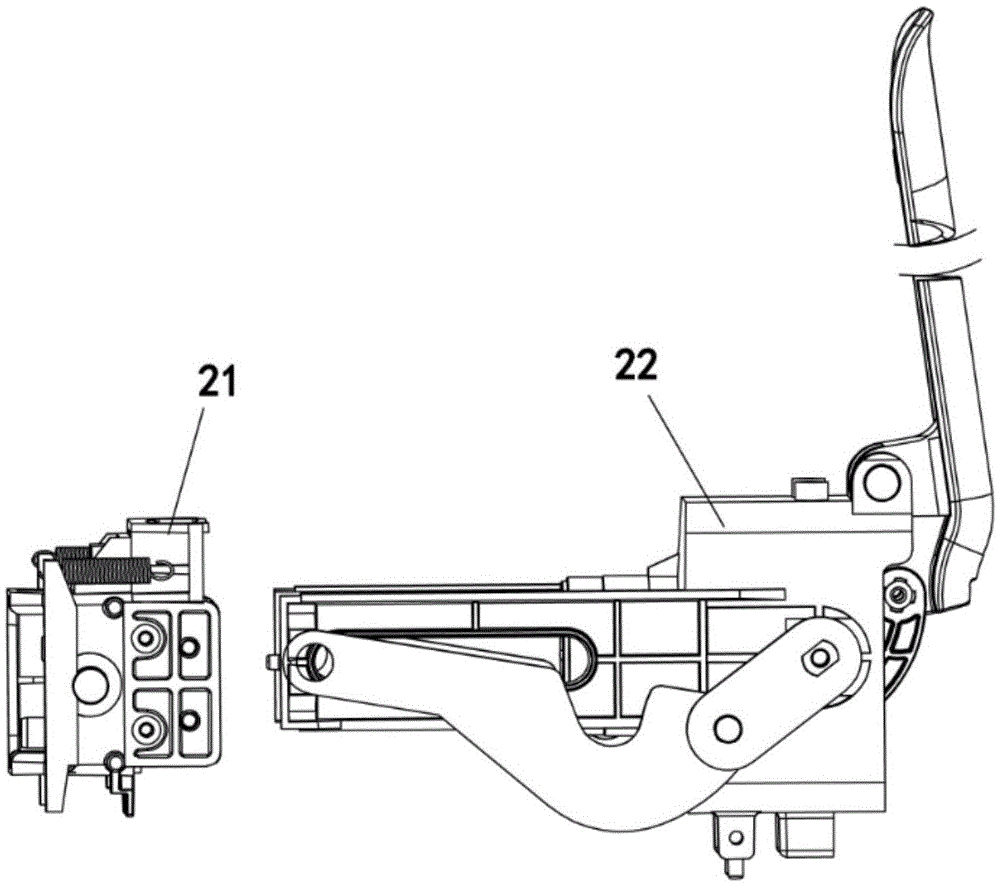

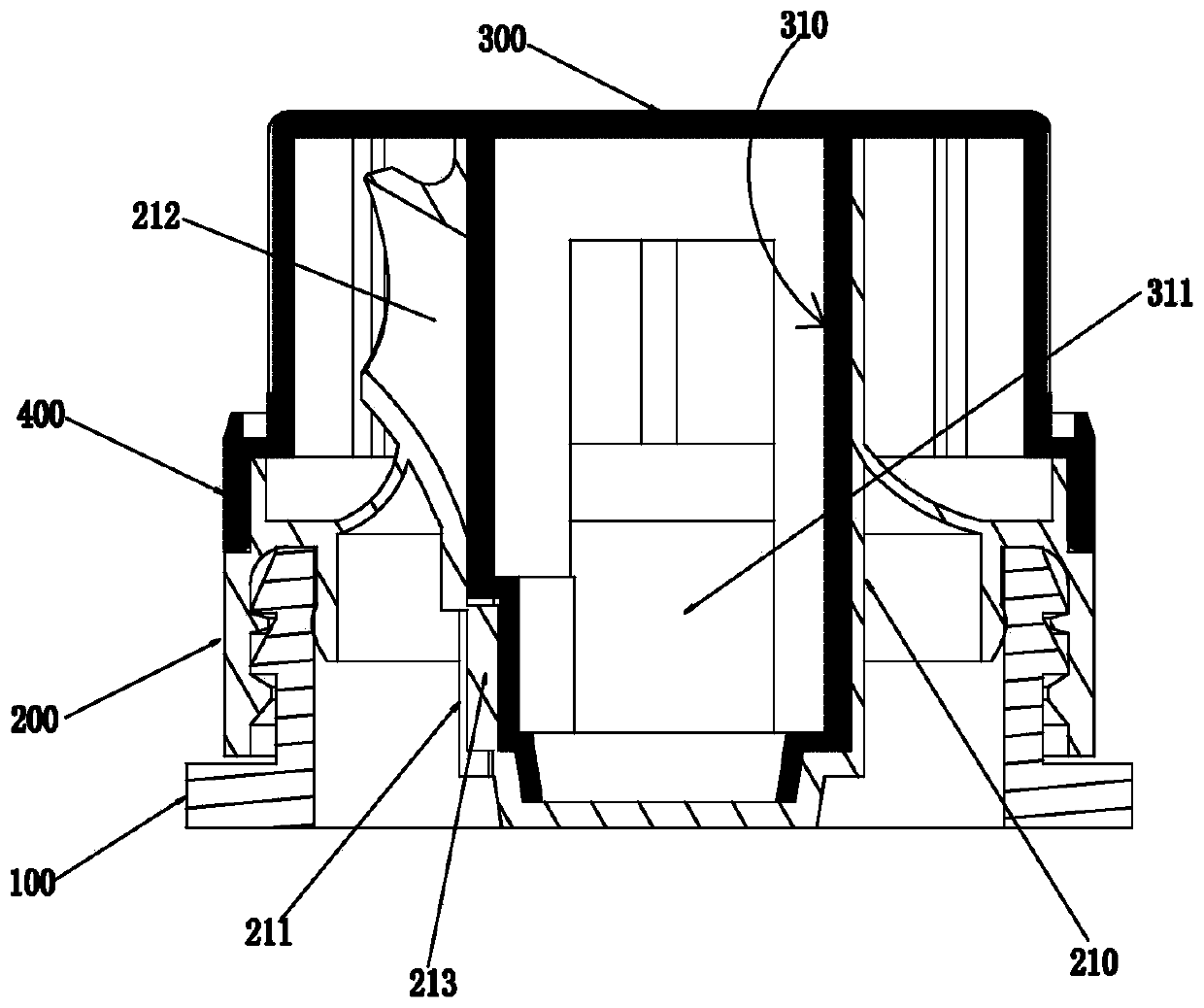

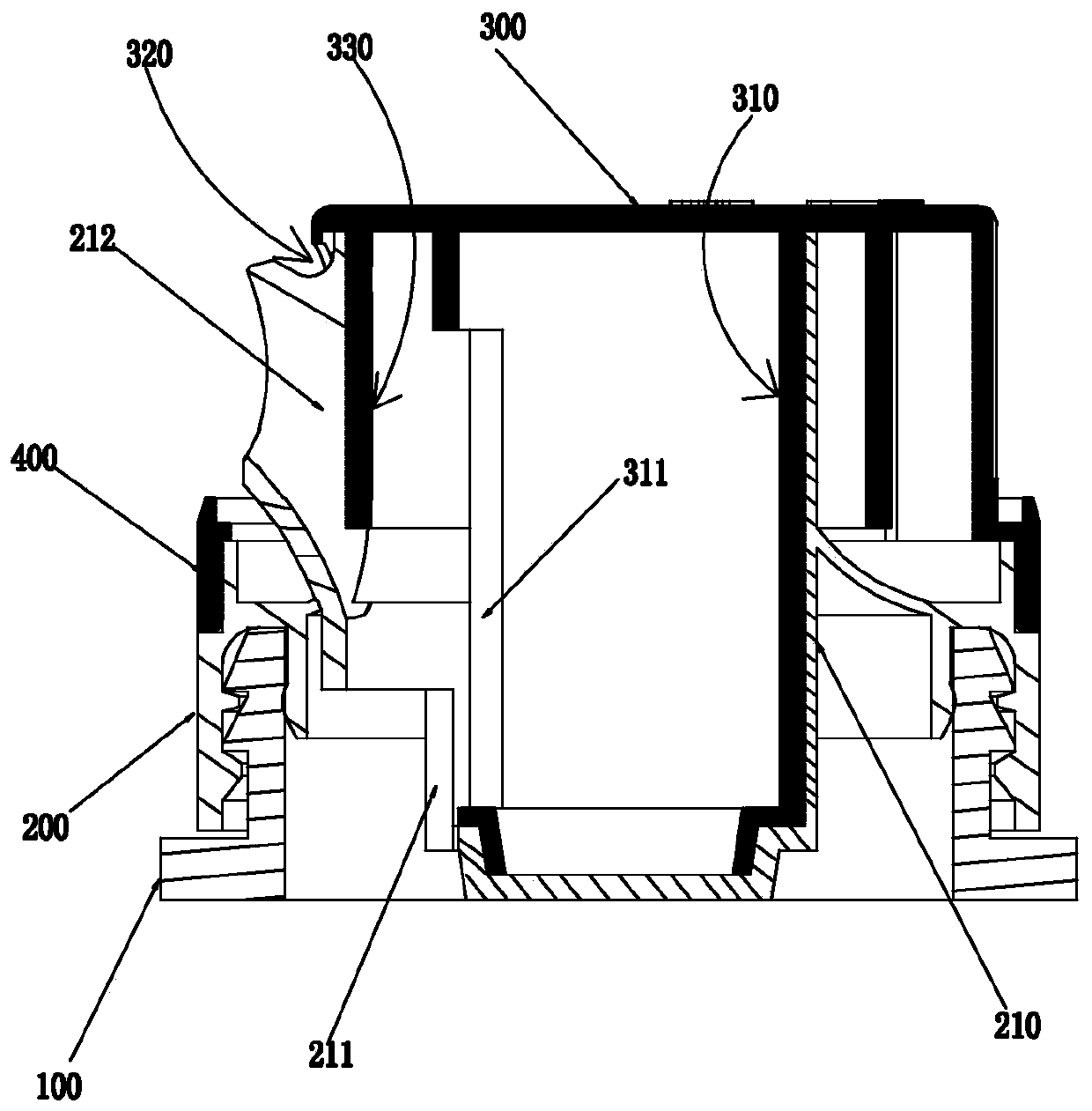

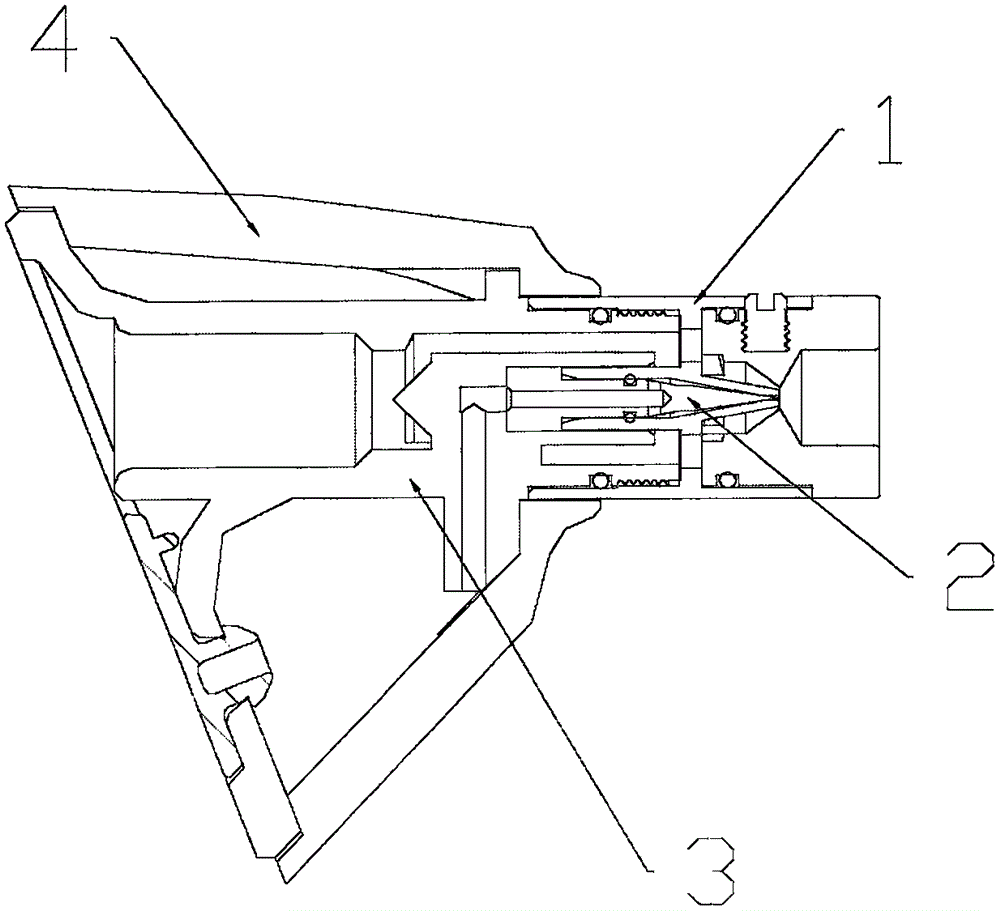

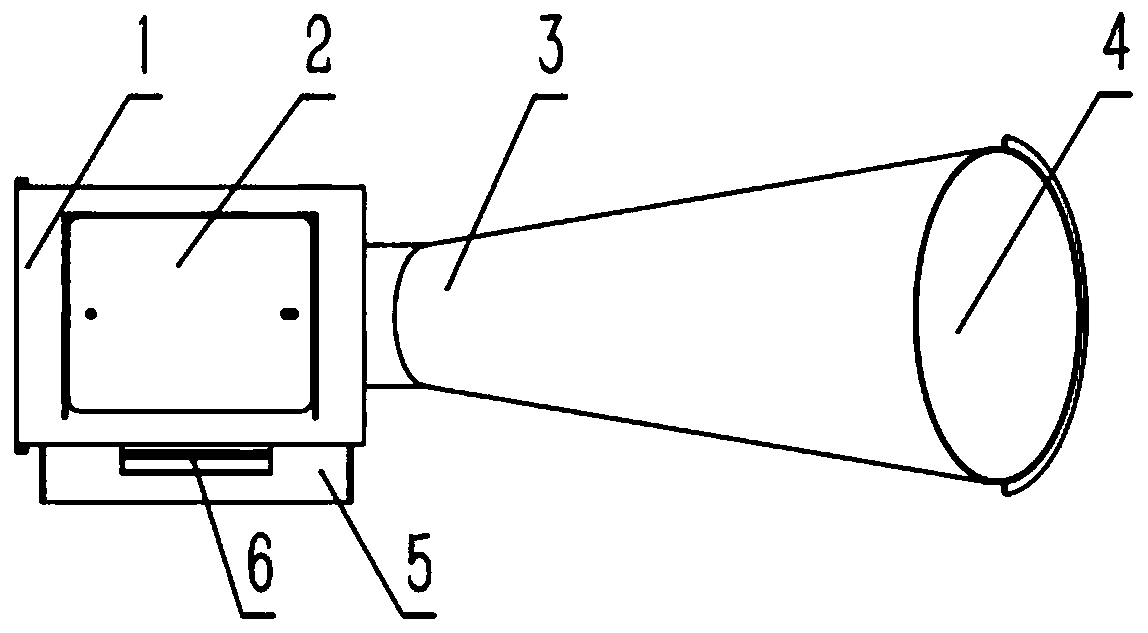

Brewing device for office machines

The invention discloses a brewing device for office machines. The brewing device can be well positioned when capsules are fed, the capsules can drop fast by the aid of gravity after coffee brewing, and the brewing device is convenient to operate and high in reliability. A closed space is provided during the brewing process, and coffee quality is ensured; a good passage is provided for coffee liquid to flow out, and outflowing is smooth. The brewing device comprises a housing, a drive mechanism and a brewing mechanism disposed inside the housing. The brewing mechanism comprises a front brewing chamber and a rear brewing chamber. The front brewing chamber is fixed to the housing. The rear brewing chamber is driven by the drive mechanism to move horizontally. The front brewing chamber is connected with a capsule push plate through an elastic part. A feed hole is provided with a guide channel in the same shape as the edge of a capsule upper cover. Two sides of the housing are provided with capsule positioning blocks facing to each other. Opposing faces of the two capsule positioning blocks are provided with arc rail grooves in the vertical direction and arc guide faces in the horizontal direction. One side, close to the front brewing chamber, of each arc rail groove is also provided with a projection.

Owner:NINGBO MEROL COFFEE MACHINE

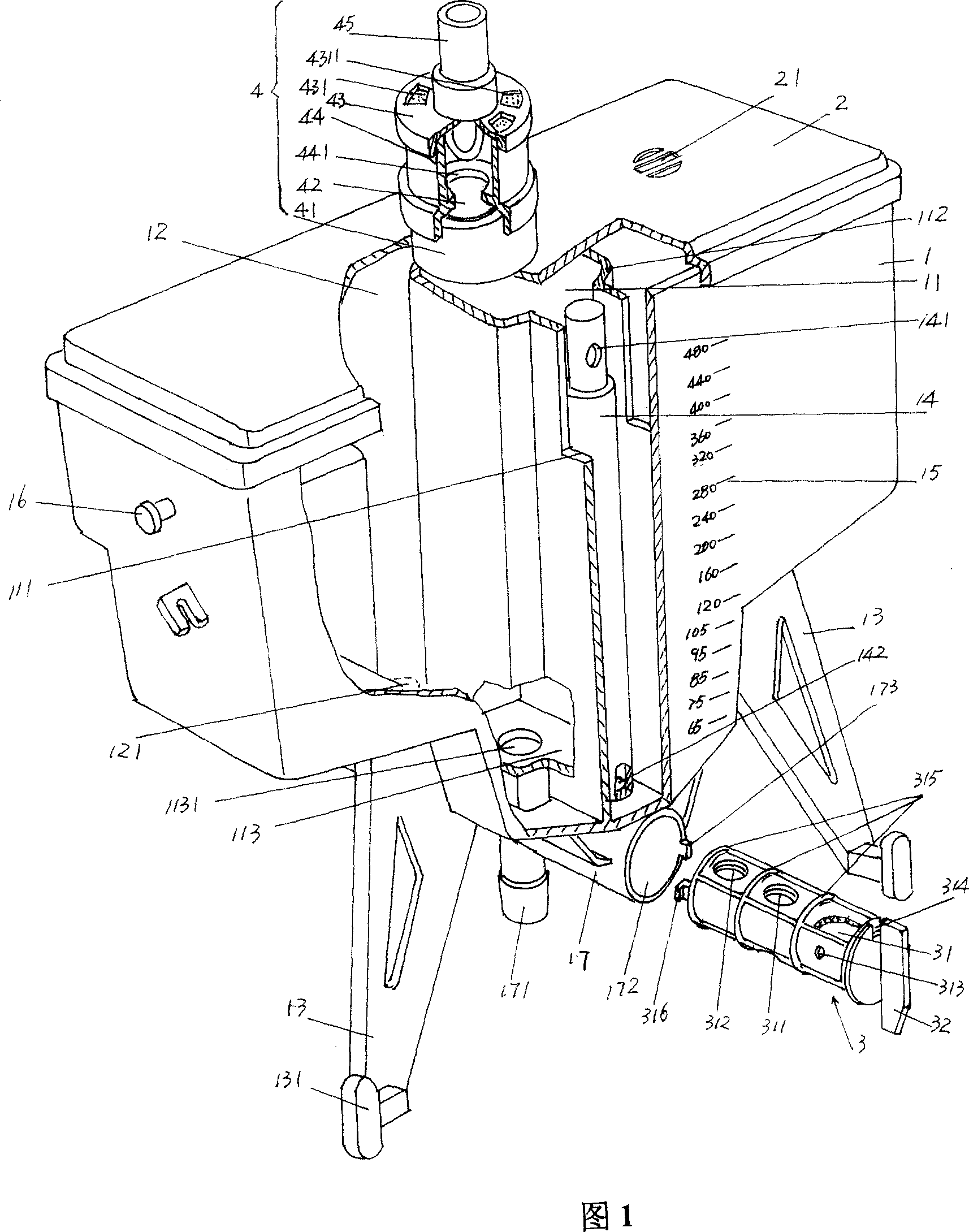

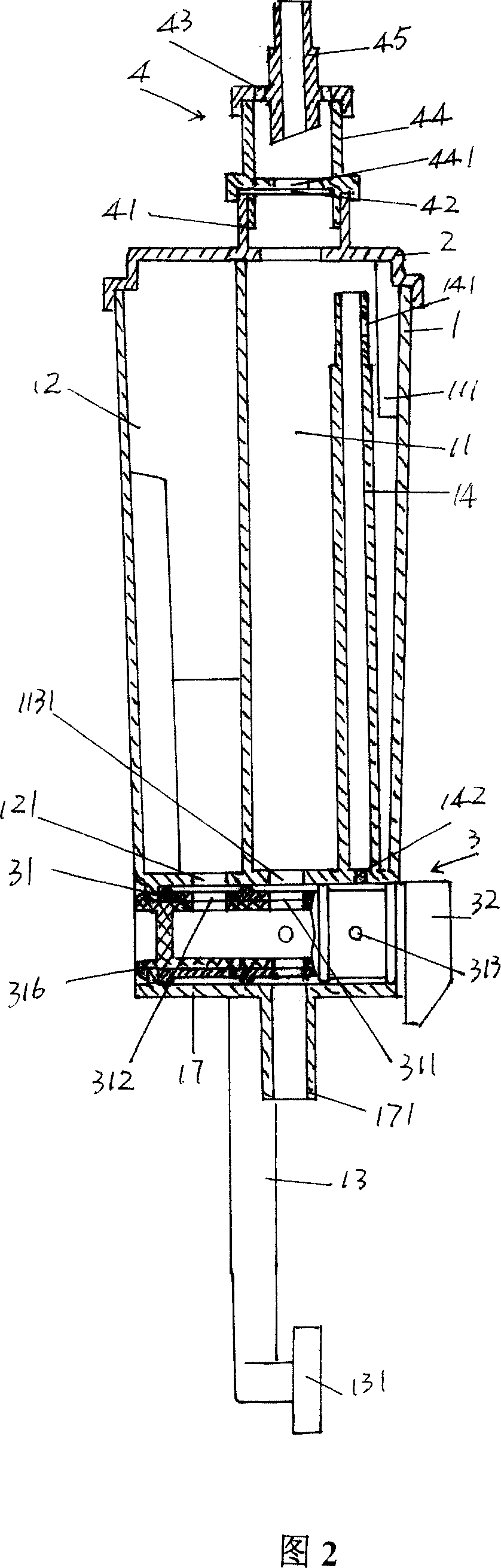

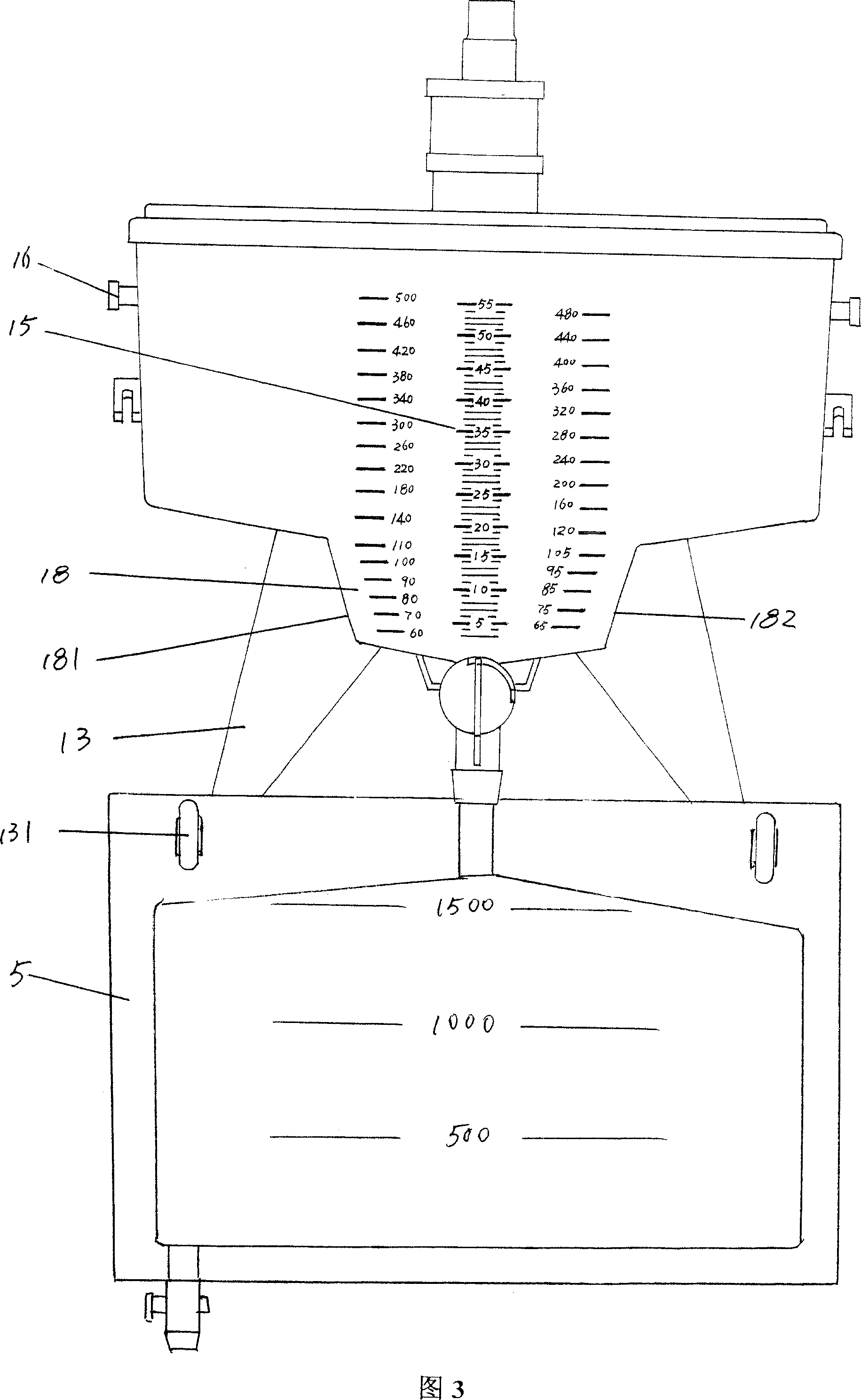

Medical semi-automatic drain liquid metering and storing apparatus

InactiveCN100998540AConducive to exhaustionAccurate measurementVolume measurement and fluid deliveryPharmaceutical containersSemi automaticEngineering

A semi-automatic metering accumulator of drainage fluid for medical purpose is composed of a box body, a box cover with the guide and anti-reflux mechanism of drainage fluid, a panel with a longitudinal metering scale, and a drainage fluid discharging valve. Said box body has a big fluid storage cavity, a cylindrical small fluid storage cavity, and a tubular over-flow cavity arranged vertically in said small fluid storage cavity.

Owner:常熟市神灵医用器材有限公司

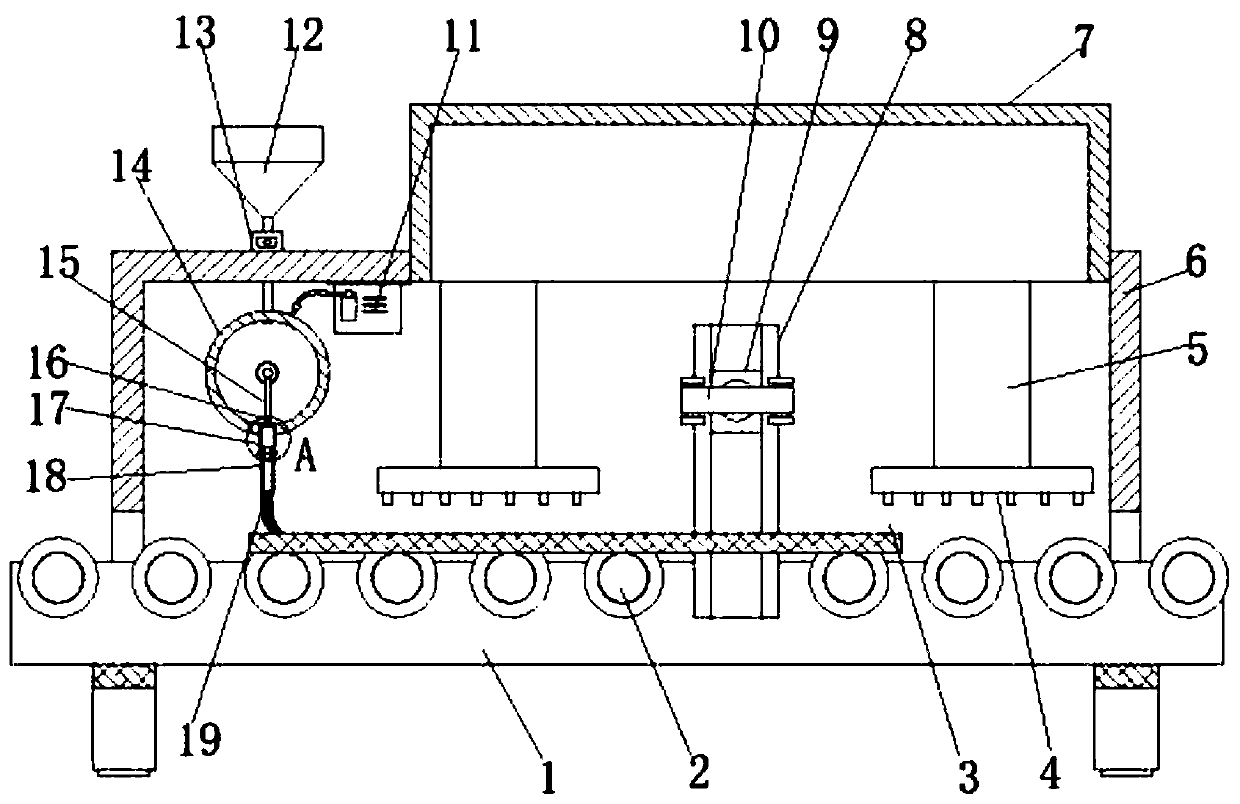

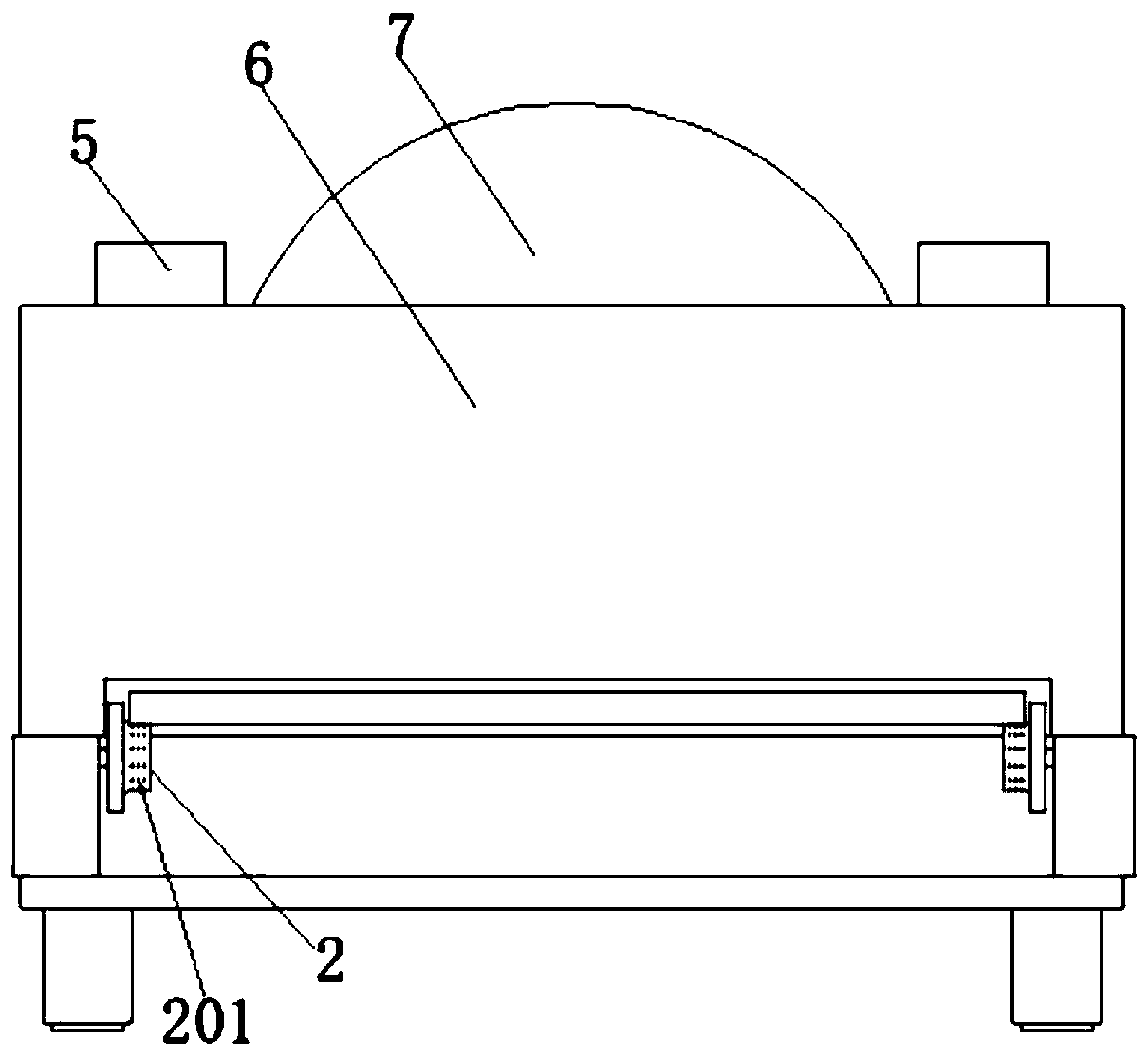

Plate painting device for wood processing

ActiveCN110918365AAvoid environmental pollutionPrevent deviationSpraying apparatusPretreated surfacesBristleSprayer

The invention belongs to the technical field of plate painting, and particularly relates to a plate painting device for wood processing. The device aims to solve the problem that an existing multi-sprayer paint spraying machine can conduct painting conveniently, but a paint body is easy to pause and solidify, sprayers are blocked, and accordingly missing painting is caused or the thickness is notuniform. The device comprises a conveying rack composed of two mutually parallel bearing plates, a box body is fixed to the top end of the conveying rack, and a pressure-resistant spraying tank whichis internally provided with a cavity and is of a cylindrical structure is fixed between the inner walls of the two opposite sides of the box body. Drain pipes which are distributed at equal intervalsare inserted in the portions, close to the bottom end, of the outer peripheral wall of the pressure-resistant spraying tank. Second connecting pipes are inserted into the bottom ends of the drain pipes, and the bottom ends of the connecting pipes communicate with a same brush plate. According to the device, paint can be slowly extruded out from a liquid discharge hole in the bottom, then the surface of a passing plate body is painted through bristles, and the phenomena that traditional paint atomization easily causes blockage of the sprayers and the environment is polluted are avoided.

Owner:江苏瑞构新型材料有限公司

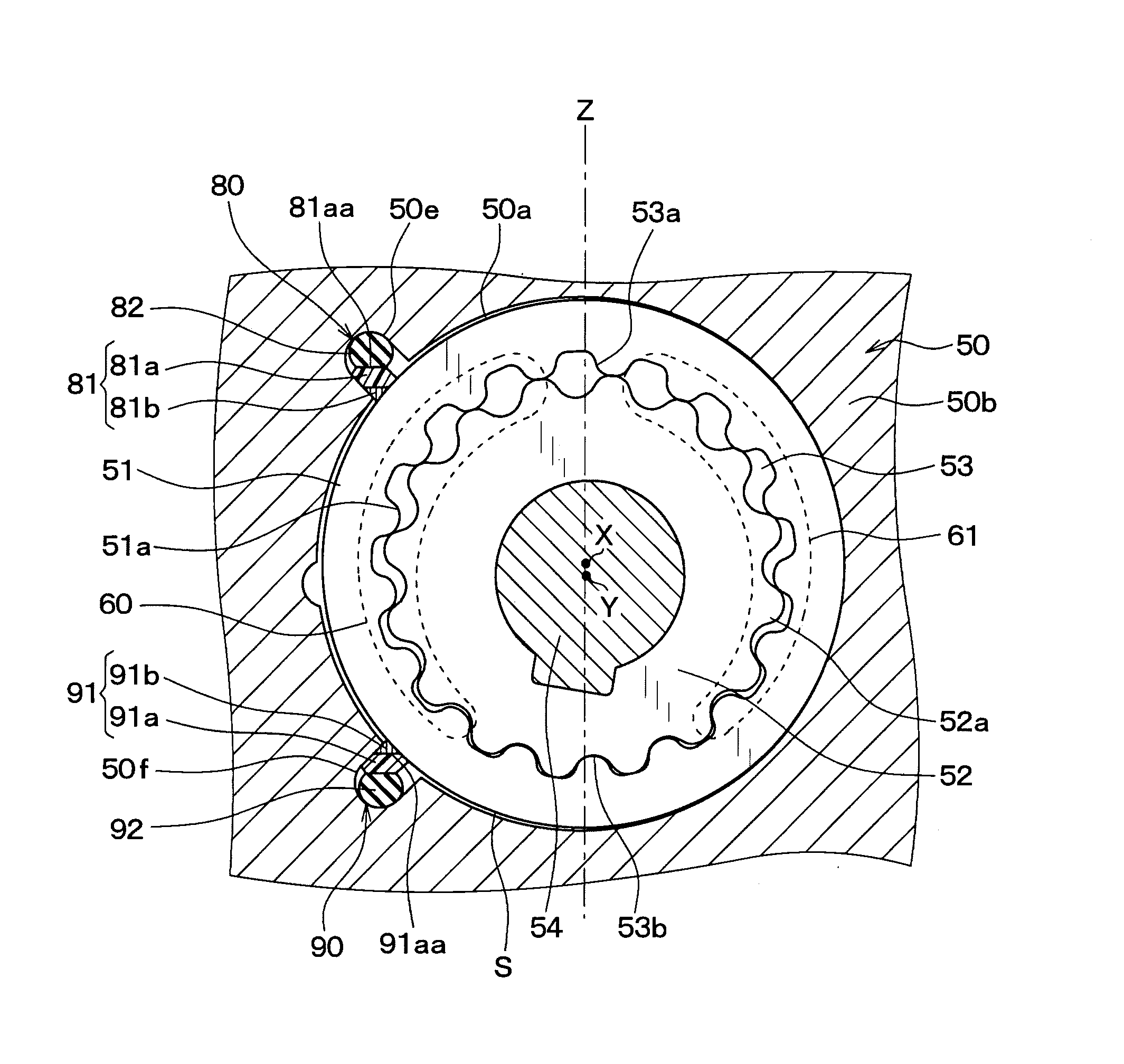

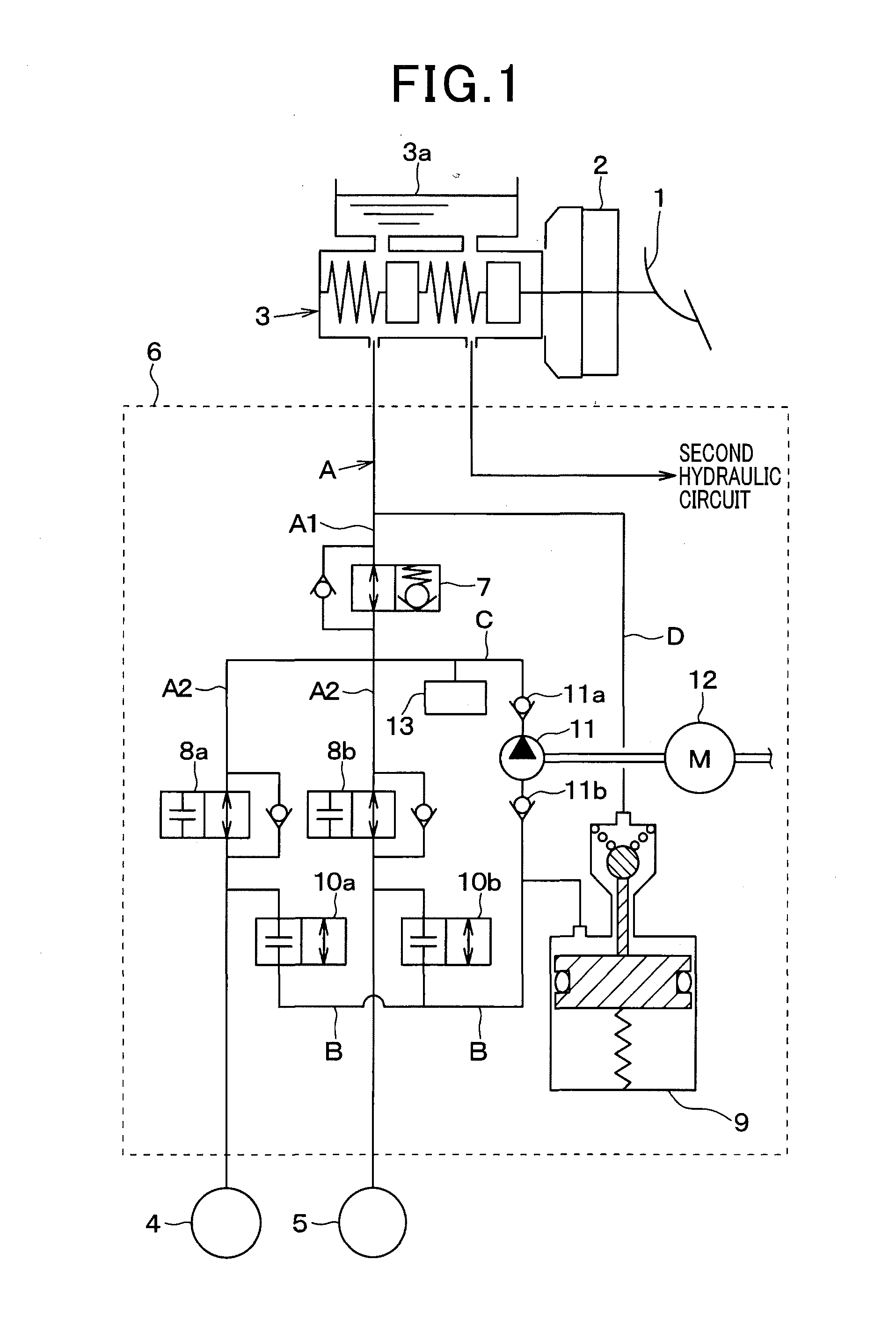

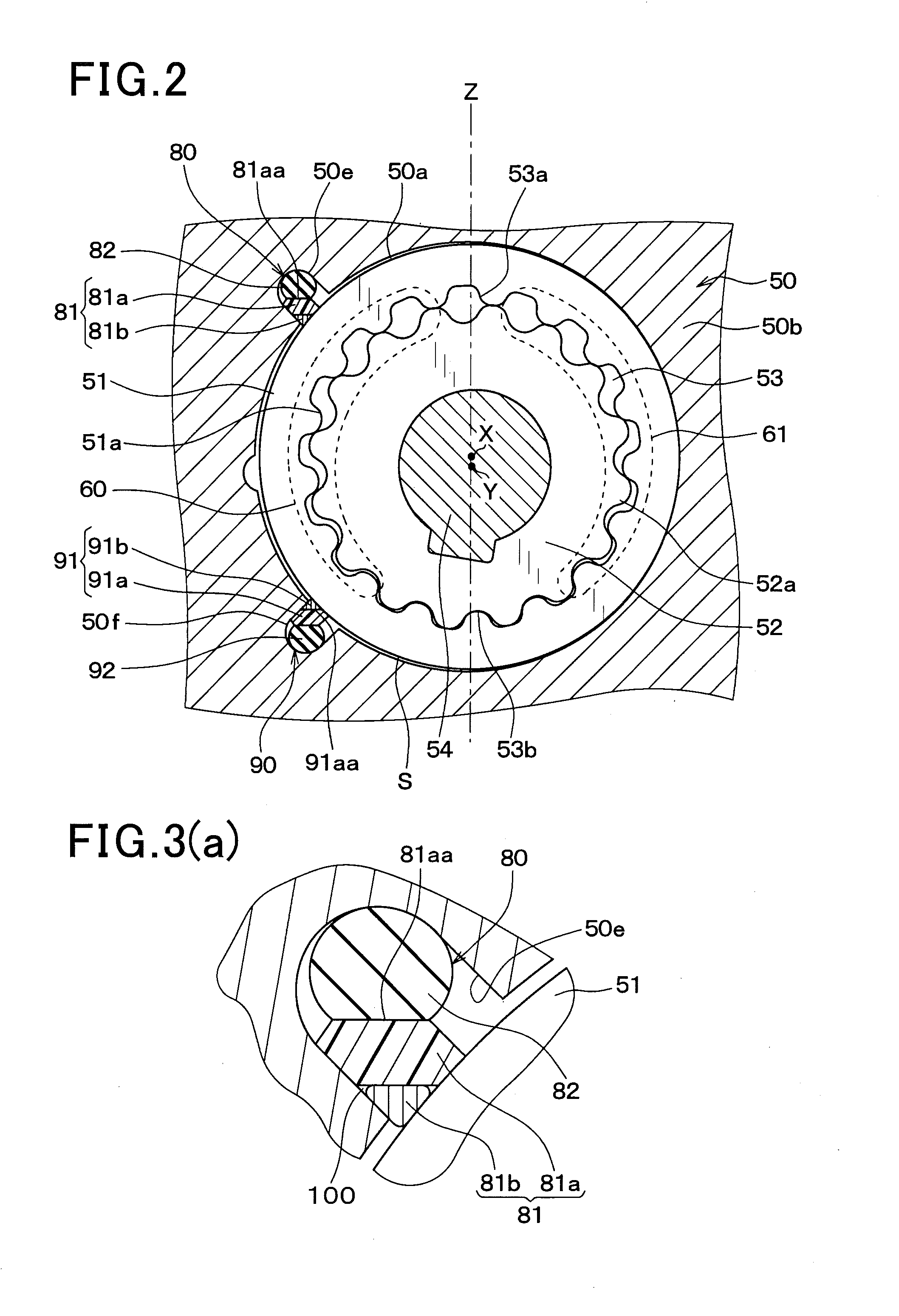

Rotating pump

InactiveUS20150226212A1Minimizing risk of breakageIncrease pressureOscillating piston enginesEngine of counter-engagement typeRotary pumpEngineering

A rotating pump includes an outer and an inner rotor disposed in a casing with a gap between the casing and the outer rotor. The rotating pump also includes a first and a second sealing member in the casing to define a low-pressure region and a high-pressure region within the gap. Each of the first and second sealing members is made up of a seal functioning portion and an elastically pressing portion. The seal functioning portion includes a resinous member and a deformation-suppressing member. The resinous member contacts the outer rotor and a low-pressure side inner surface of the casing to establish a difference in pressure between the low-pressure region and the high-pressure region. The deformation-suppressing member works to stop the resinous member from deforming undesirably. This minimizes the risk of breakage of the resinous member and enables the rotating pump to discharge the fluid at an increased pressure.

Owner:ADVICS CO LTD

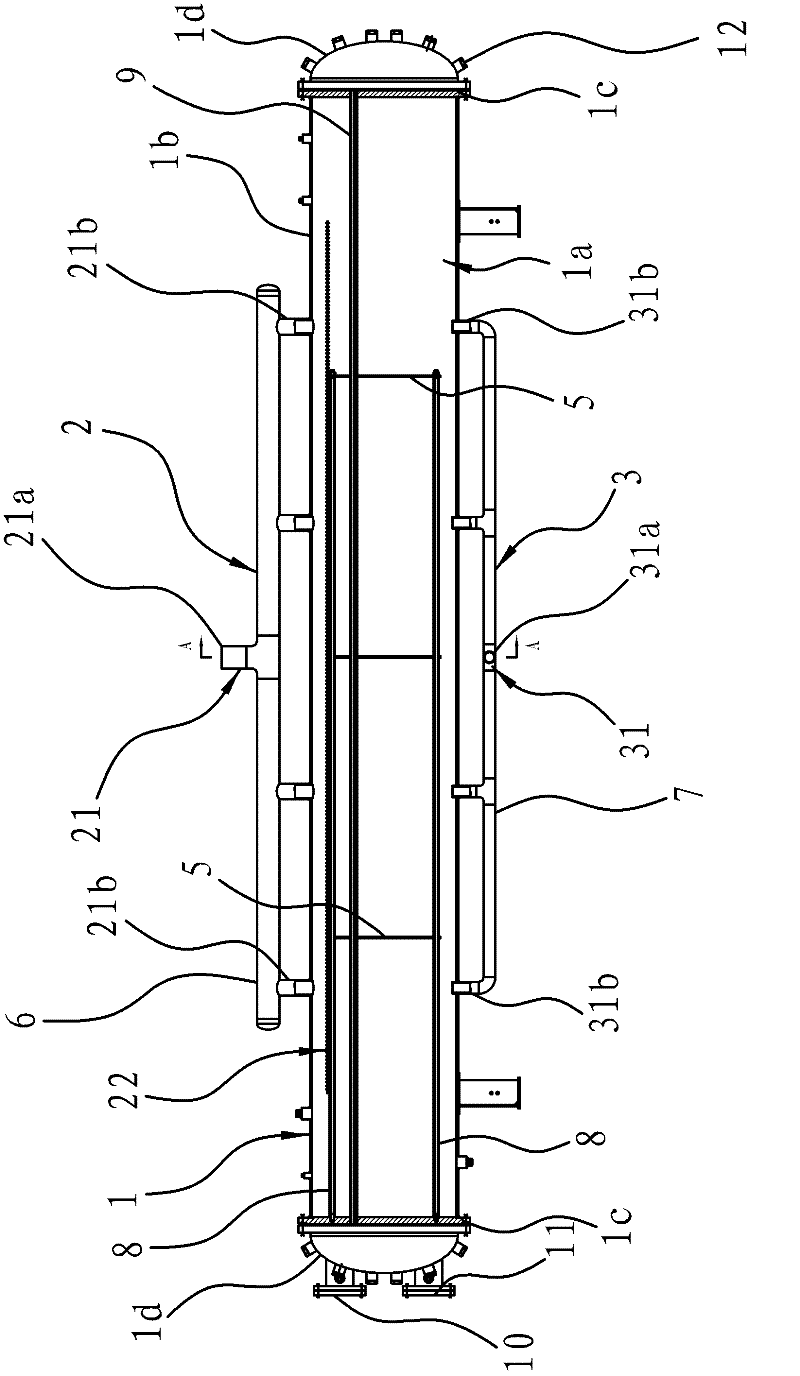

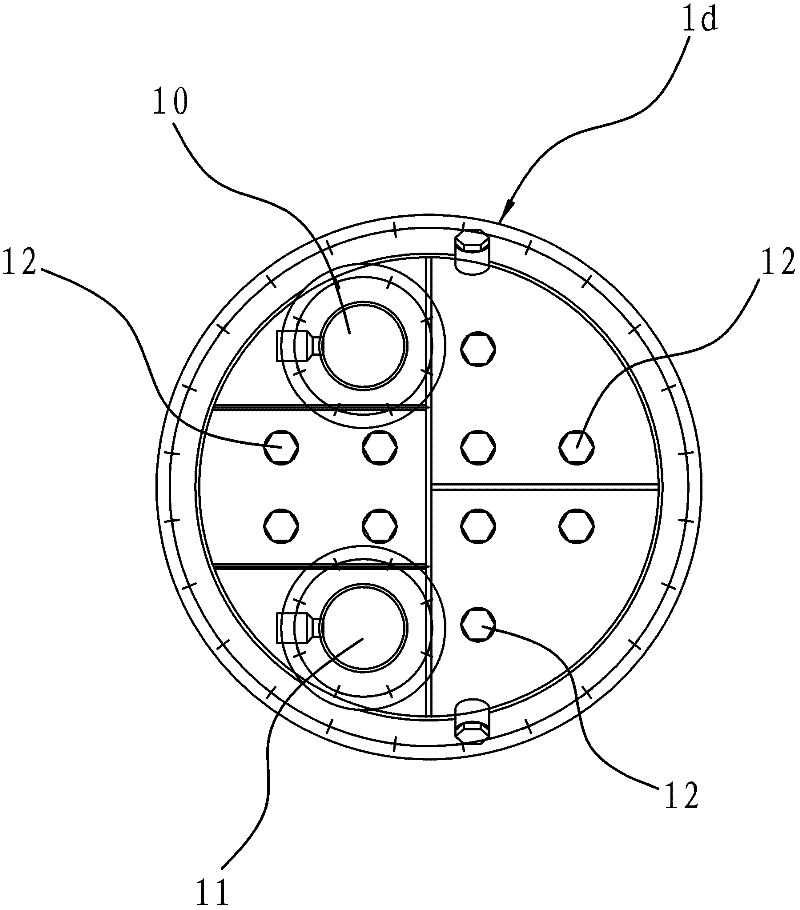

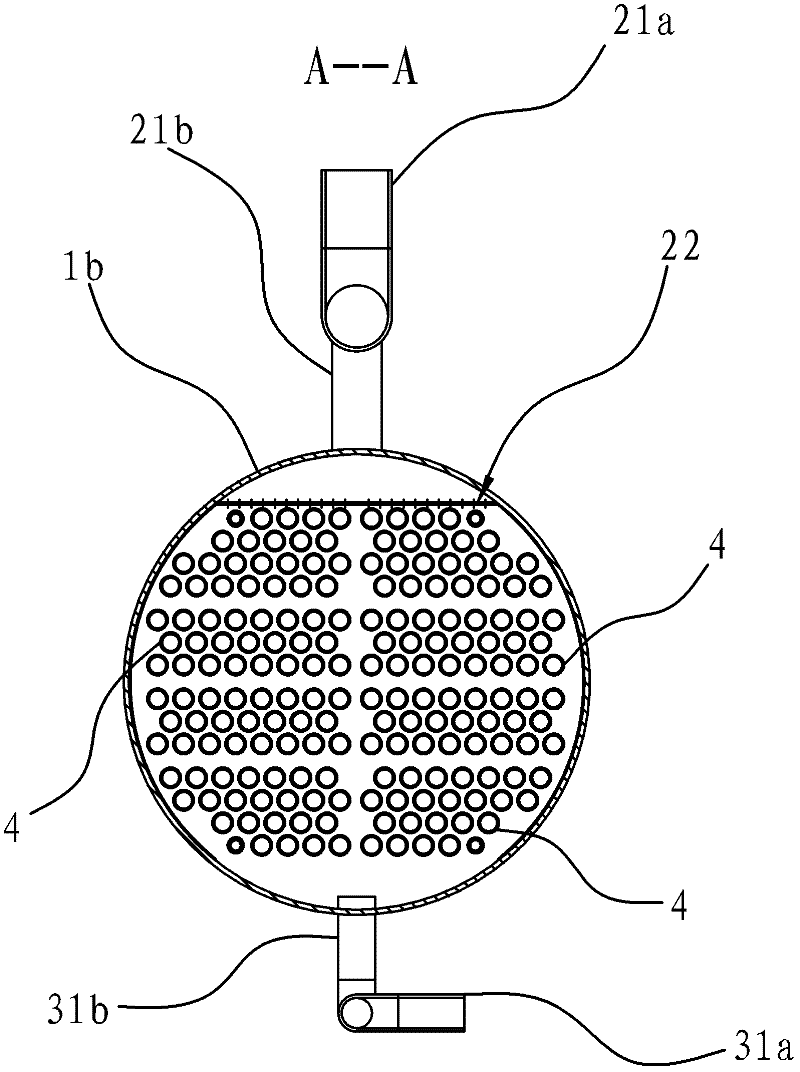

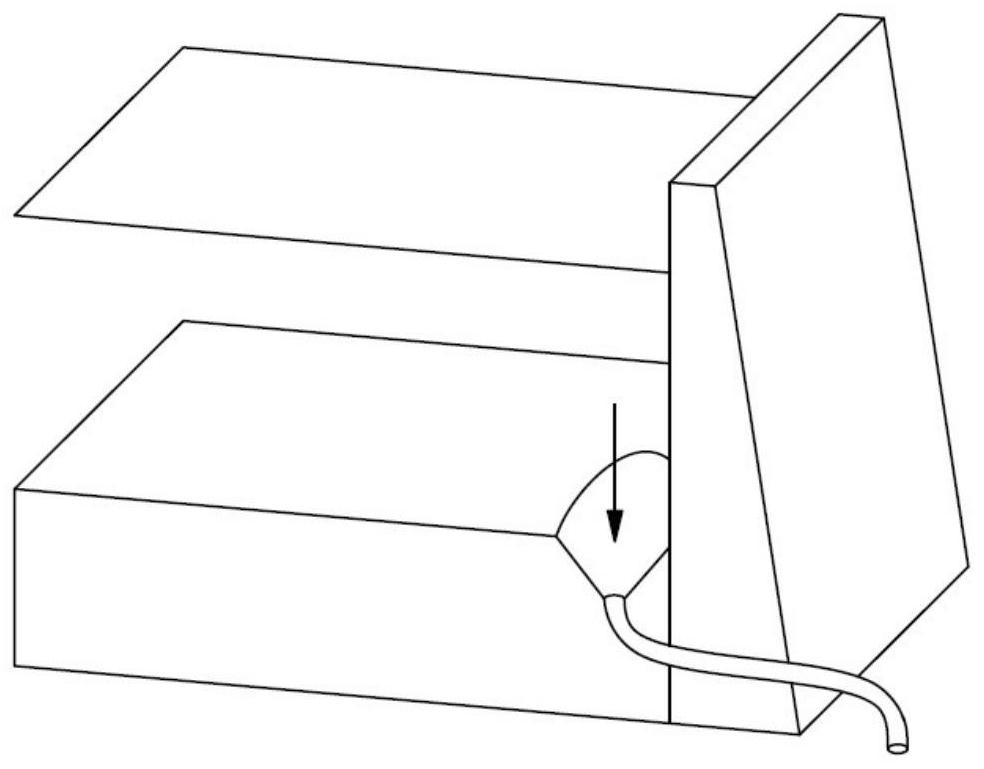

Condensing device

InactiveCN102384695AGuaranteed heat transfer efficiencyImprove heat transfer efficiencyEvaporators/condensersCorrosion preventionEngineeringSewage

The invention provides a condensing device belonging to the technical field of the refrigeration equipment. The condensing device solves the problems of high cost, bad descaling effect and the like owing to the application of the scaler in the existing sewage source heat exchanger to the ship refrigerating system. The condensing device comprises a condenser body having an inside cavity, and an air inlet mechanism and a liquid outlet mechanism which are arranged at the upper-side air inlet and the lower-side liquid outlet of the body, respectively, wherein a plurality of heat exchange pipes for exchanging heat with a gaseous medium entering the body and a supporting plate for supporting the heat exchange pipes are arranged within the cavity of the body; a plurality of projections and / or pits are formed on the inner walls of the heat exchange pipes; and the projections and / or pits are distributed in the axial direction of the heat exchange pipes and in smooth transition with the pipe walls on both sides thereof. The condensing device has the advantages of high descaling property, high heat exchange efficiency and the like.

Owner:温岭市钱江化工机械有限公司

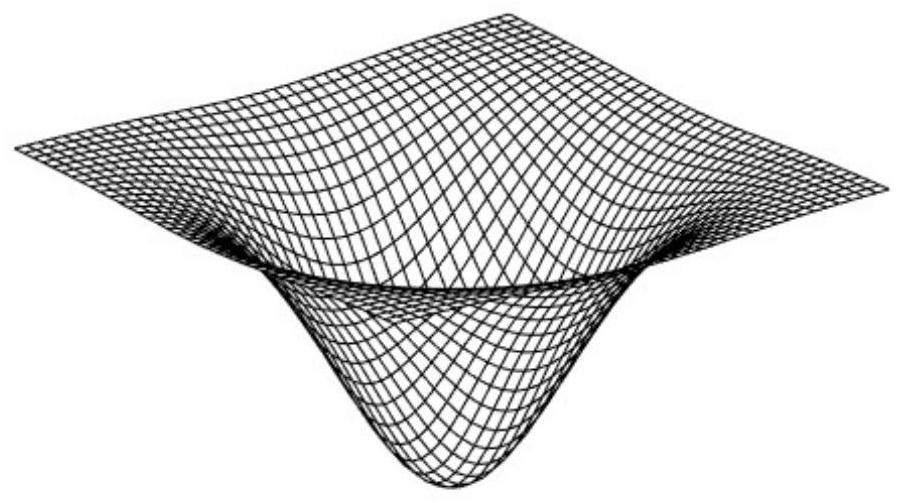

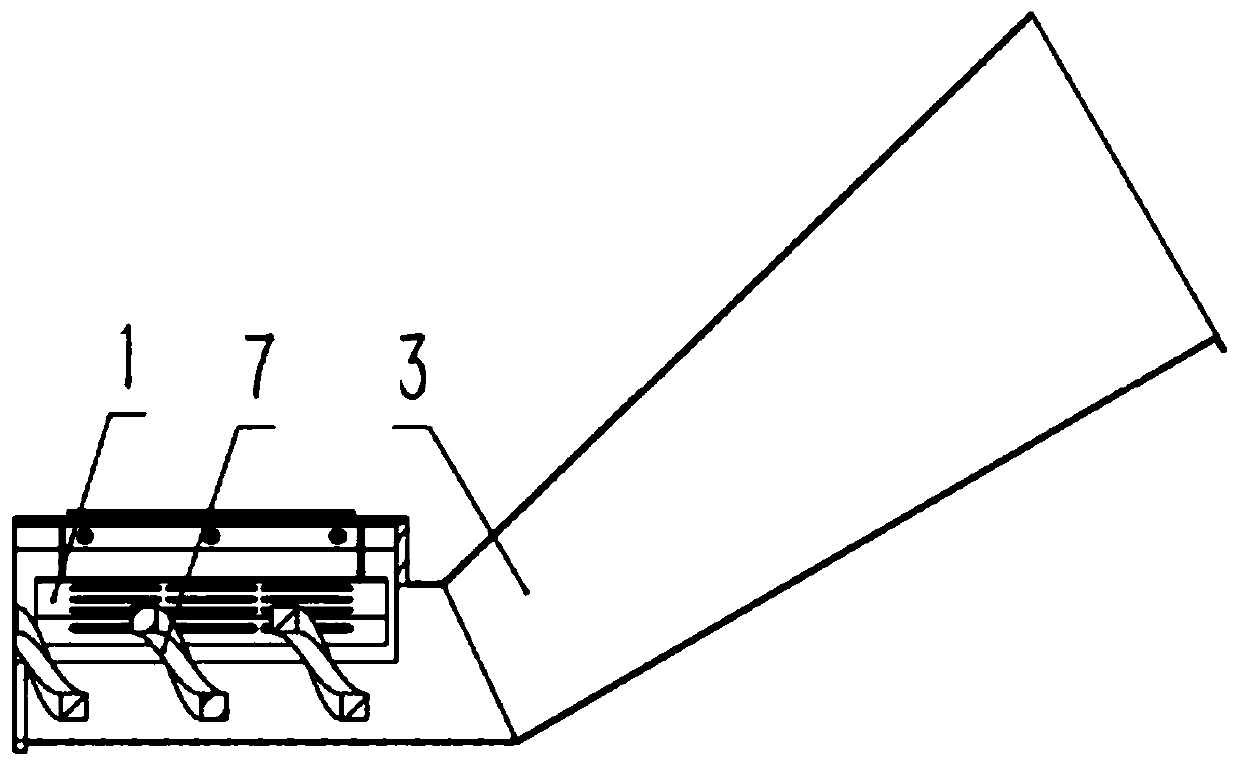

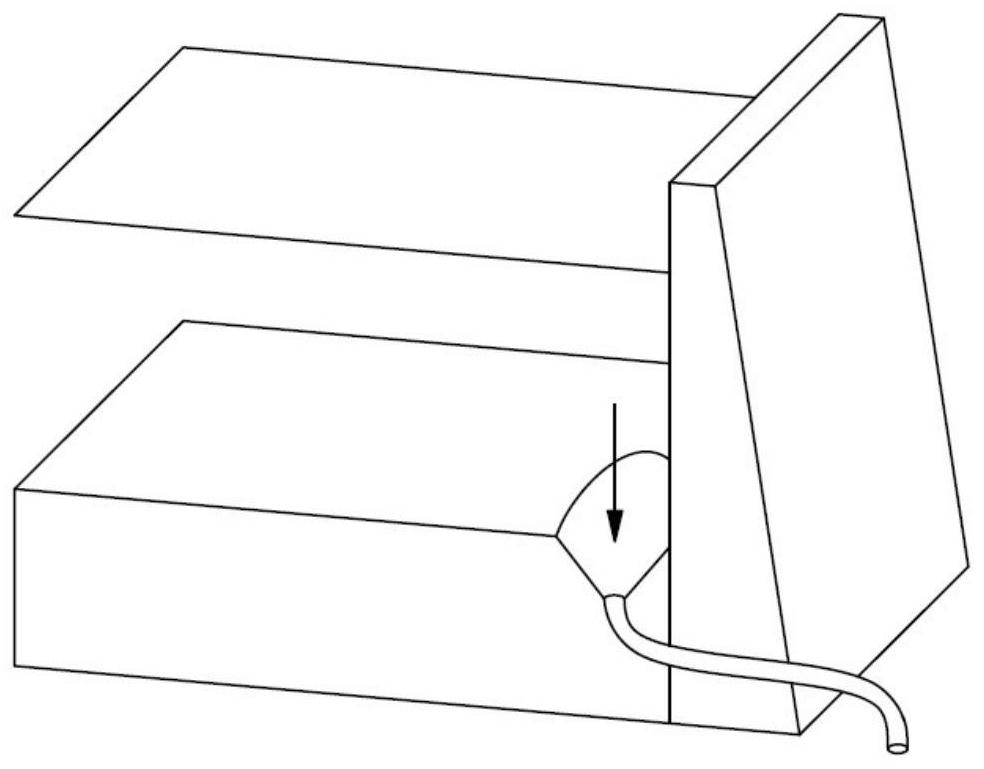

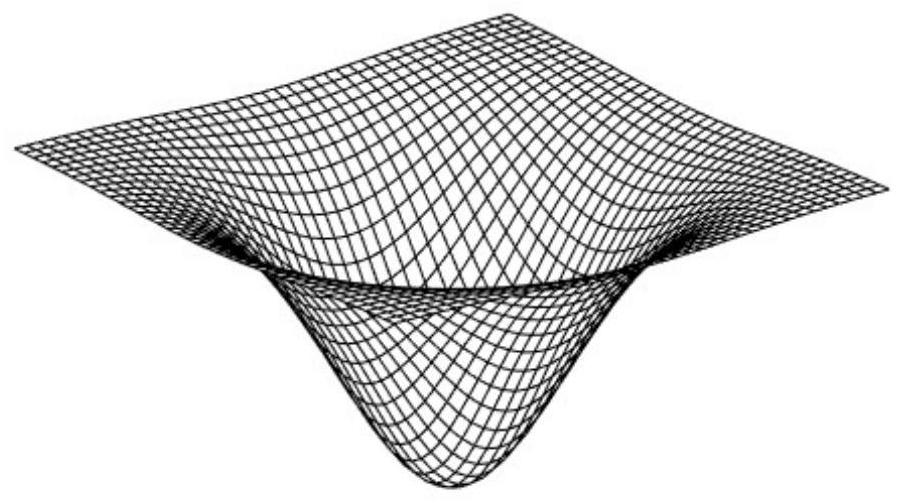

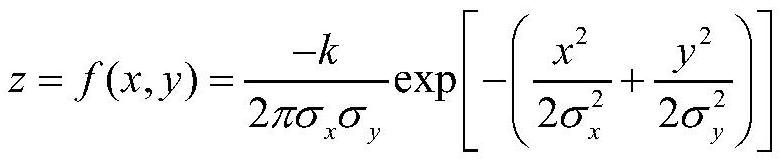

Reservoir sand discharging device based on normal curved surface funnel

The invention discloses a reservoir sand discharging device based on a normal curved surface funnel, and belongs to the technical field of water conservancy projects. The device comprises a sand inlet funnel and a sand conveying pipeline; the sand inlet funnel is located in a sediment accumulation area in a reservoir, the sand conveying pipeline is laid on a reservoir riverbed, the bottom of the sand inlet funnel is connected with one end of the sand conveying pipeline, and the other end of the sand conveying pipeline penetrates out of the bottom of a dam; and the appearance of the sand inlet funnel is in a bivariate normal curved surface shape, the shape of the sand conveying pipeline is in an anti-hyperbolic tangent curve shape, and a valve is arranged on the sand conveying pipeline. When the device runs, the valve on the sand conveying pipeline is opened, and under the action of water pressure in the reservoir, water flow carries sediment to be discharged into the downstream of the reservoir through the sand discharging pipeline. The normal curved surface shape of the sand inlet funnel and the hyperbolic tangent shape of the sand conveying pipeline can effectively solve the problem that a sand inlet and the interior of the pipeline are prone to being blocked, and the sand discharging efficiency is remarkably improved.

Owner:ZHEJIANG UNIV

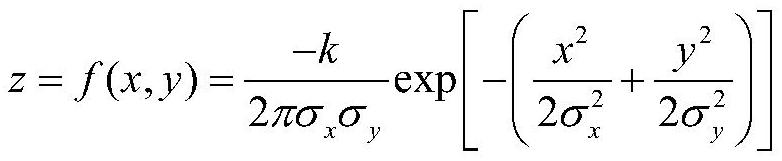

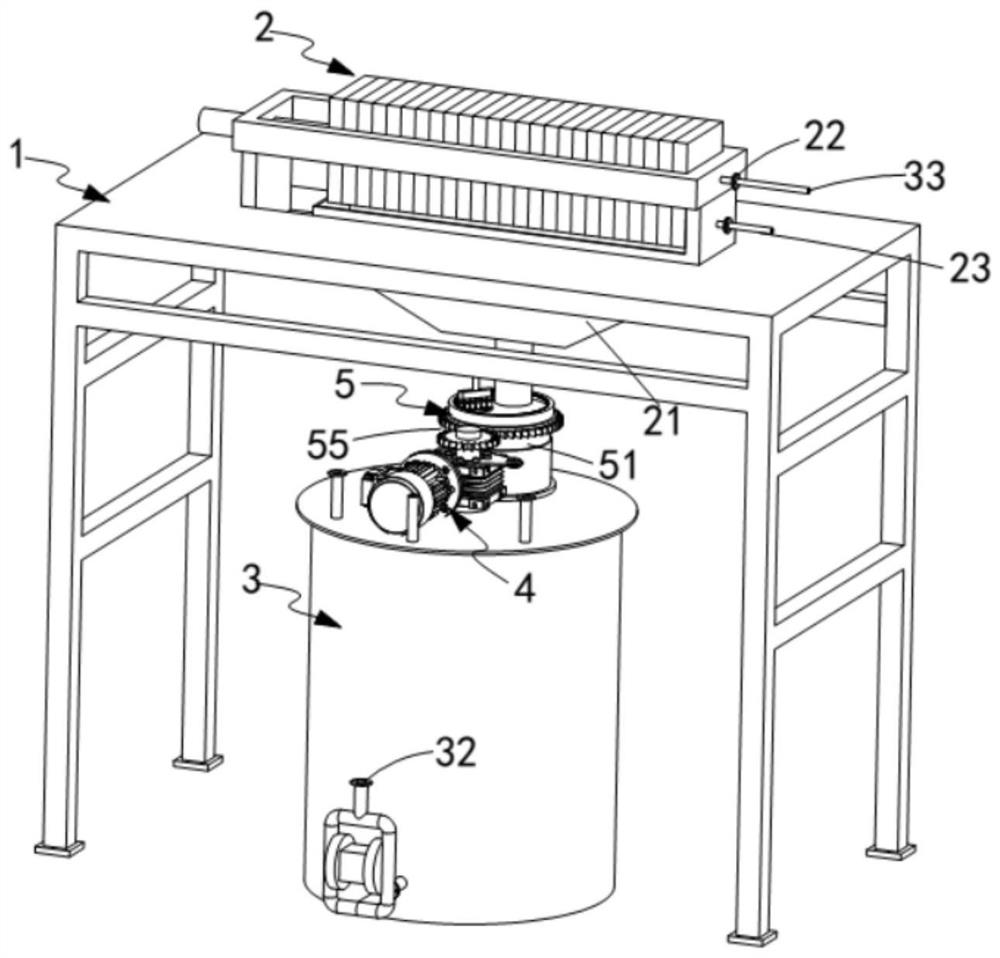

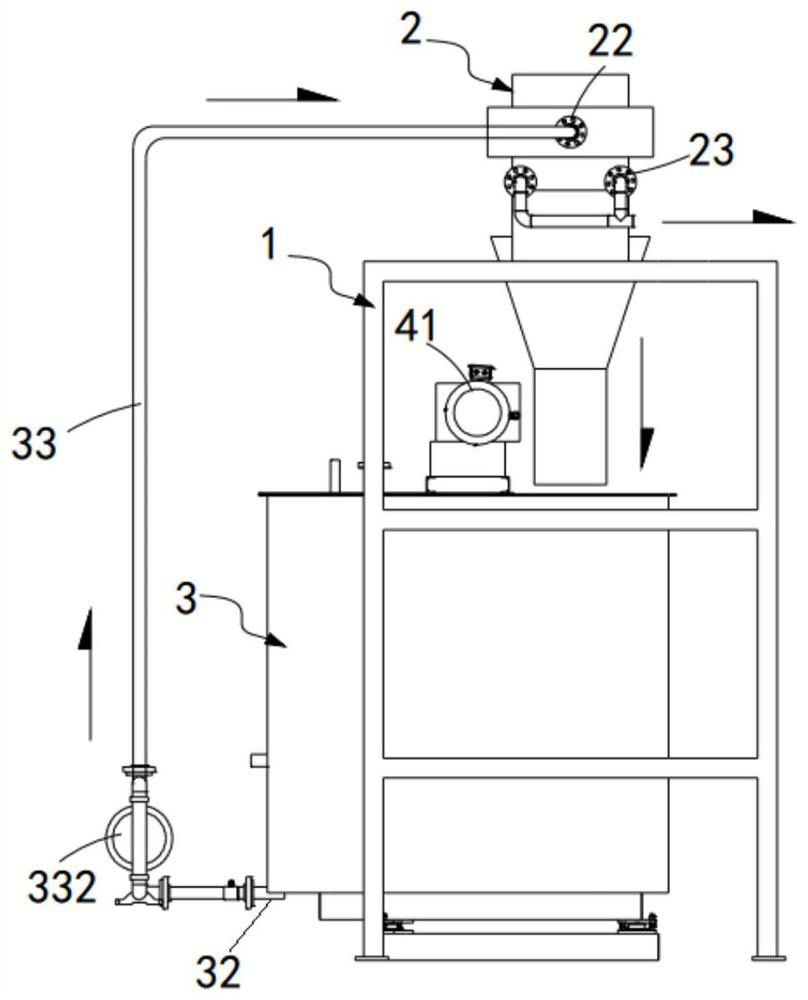

Circulating type rapid multi-stage filter pressing system

InactiveCN112704921ASolve technical problems that cannot be purified efficientlyAvoid clumpingRotary stirring mixersTransportation and packagingControl engineeringProcess engineering

The invention provides a circulating type rapid multi-stage filter pressing system which comprises a filter pressing device, a filter residue tank, a stirring mechanism and a material distributing mechanism, and the material distributing mechanism comprises a rotatably arranged material distributor, a fixedly arranged mandrel, a cover plate covering the top of the material distributor and a liquid adding pipe installed on the cover plate and inserted into the material distributor. The material distributor and the liquid adding pipe are in transmission connection with the stirring mechanism, the material distributor is rotatably arranged around the mandrel, the material distributor comprises a plurality of distributing bins, the distributing bins are separated by partition plates, the stirring mechanism drives the material distributing mechanism to operate, and the material distributing mechanism is arranged between the filter pressing device and the filter residue tank. The stirring mechanism for stirring the filter residue tank is used for driving the material distributing mechanism to operate, the filter residues about to enter the filter residue tank are input in batches through operation of the material distributing mechanism, water is input into filter residues from inside to outside in the input process, the surface layers of the filter residues are prevented from being condensed into balls, and the technical problem that the filter residues cannot be efficiently purified is solved.

Owner:张克军

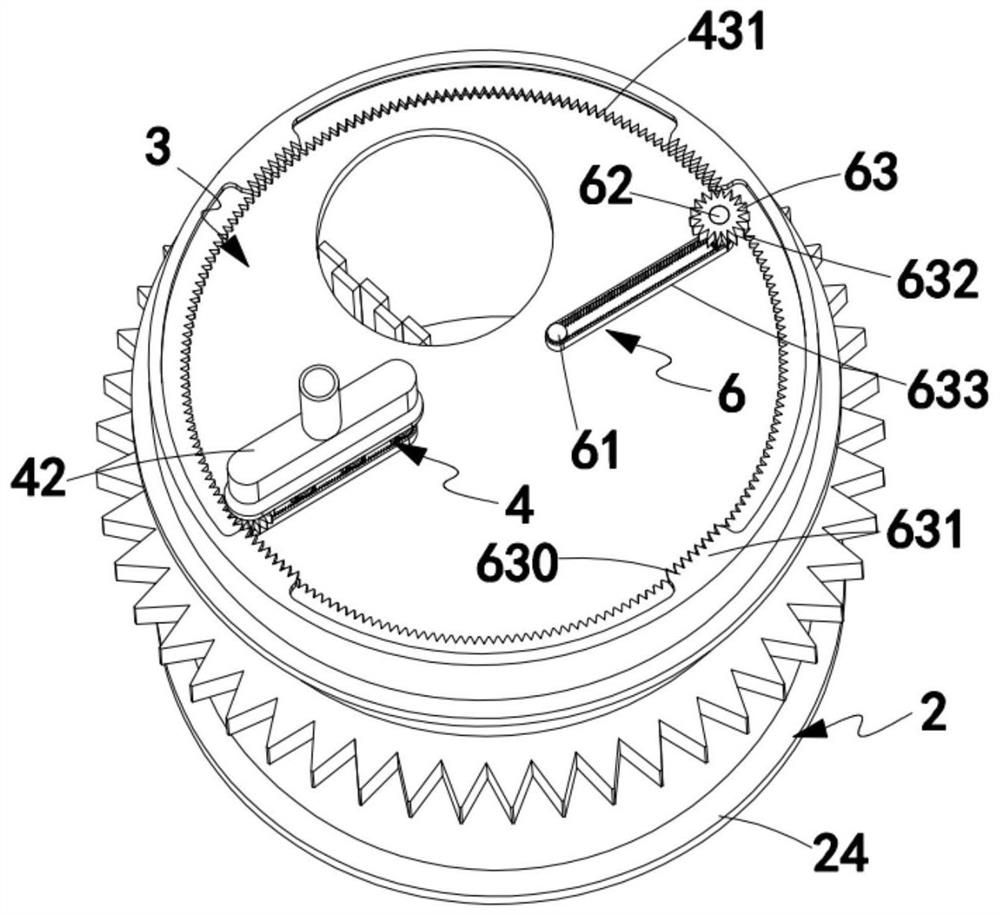

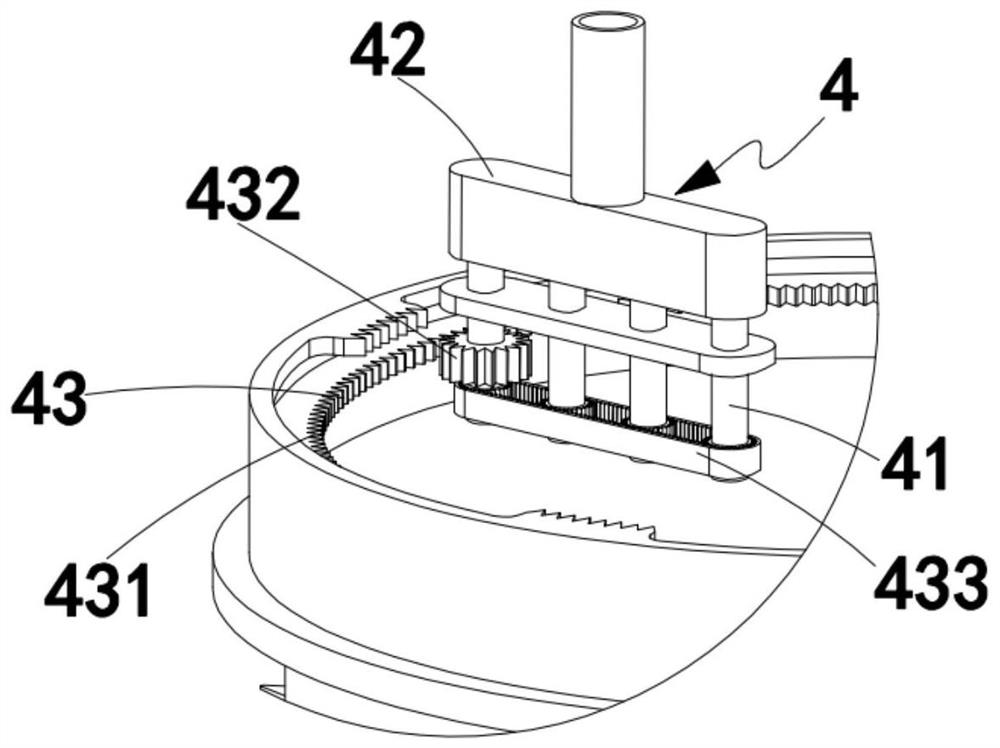

Rapid flow dividing and self-cleaning material dividing mechanism

InactiveCN112452013ASolve the technical problem of reducing the purification effectAvoid clumpingTransportation and packagingMixing methodsMaterial distributionIndustrial engineering

The invention provides a rapid flow dividing and self-cleaning material dividing mechanism which comprises a mounting plate, a material distributing barrel, a liquid adding assembly and a sweeping assembly, filter residues obtained after filter pressing are conveyed in batches through a material distributing area in the material distributing barrel, and in the conveying process, water is input into the filter residues, so that the filter residues are moisturized from inside to outside; in addition, the opening in the partition plate in the material distributing barrel is set to be opened in ahorizontal drawing mode, when a liquid adding pipe moves to the opening, the opening is opened, after the liquid adding pipe passes through, the opening is immediately closed, after the material distribution work is completed in the material distributing area, the outer side wall in the material distributing area is cleaned in time through the sweeping assembly, and the technical problem that thepurification effect is reduced due to the fact that filter residues in the material distributing area are gradually accumulated in the material distribution process is solved.

Owner:张克军

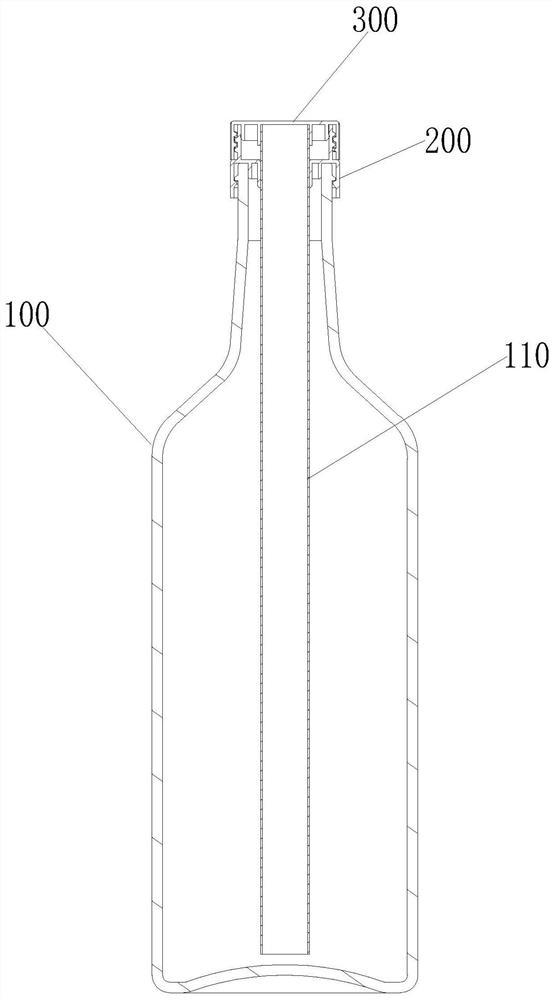

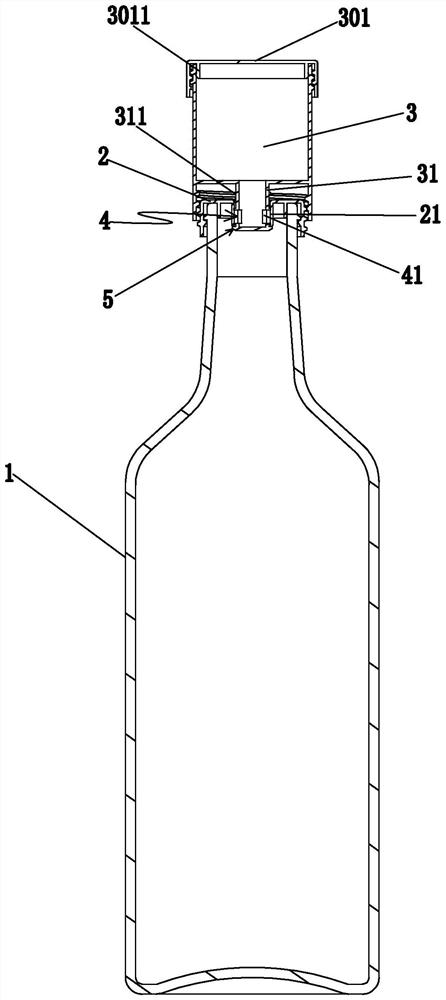

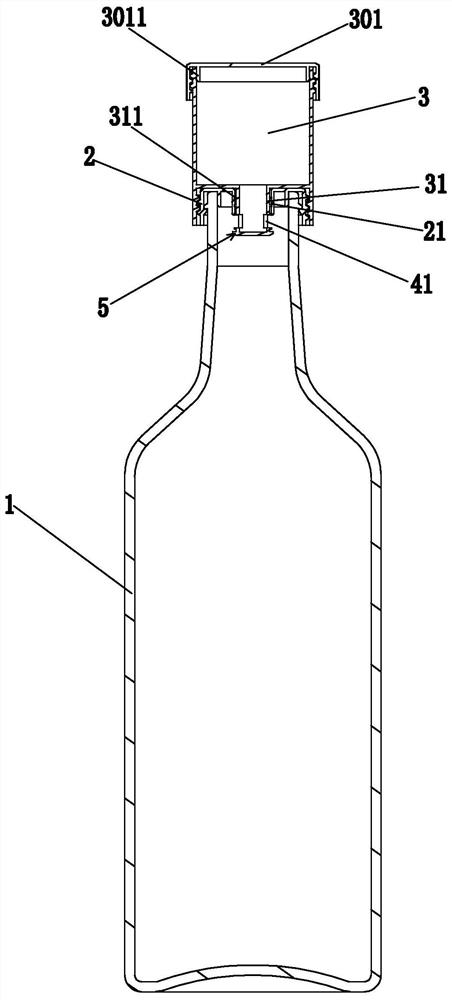

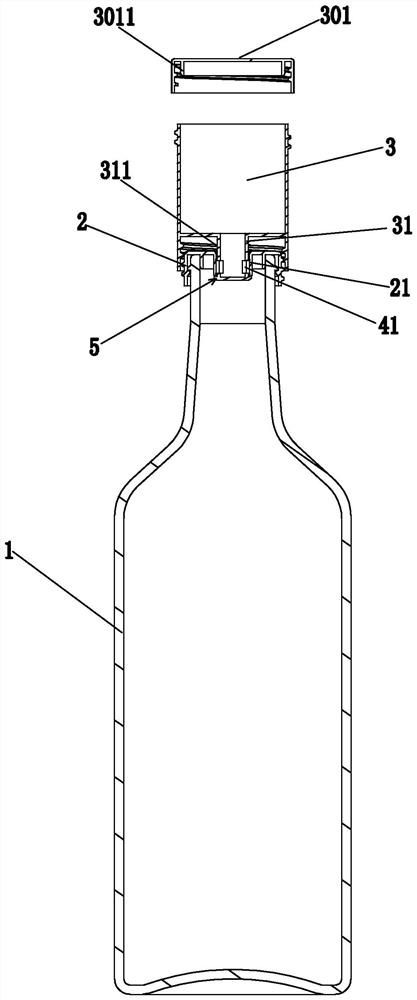

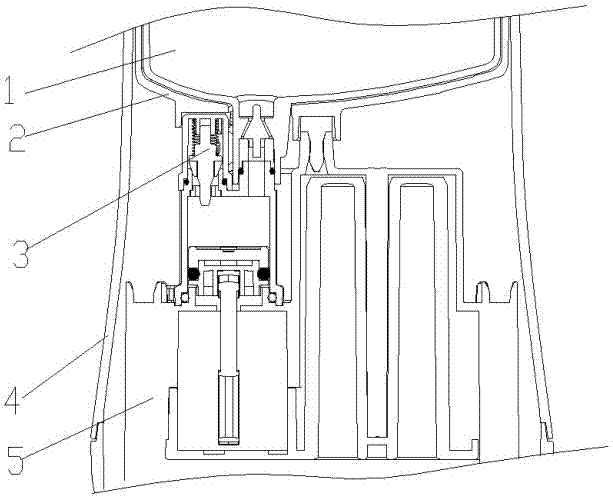

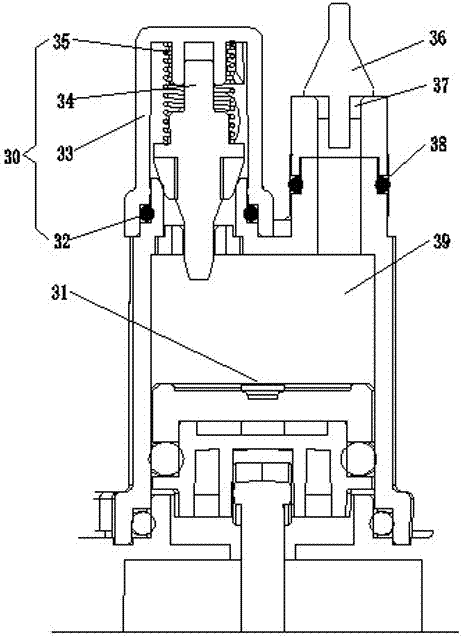

Inner cap assembly convenient to use

The invention discloses an inner cap assembly convenient to use. A reset structure is arranged in an inner cavity of a seal sleeve; when the upper end of a liquid discharge pipe sleeve suffers an external force so as to jack the rest structure, and the external force is removed, the reset structure automatically jacks the liquid discharge pipe sleeve to reset, so that a first liquid inlet and a second liquid inlet are in a staggered sealed plugging state switched from an aligned conducting state; meanwhile, a liquid discharge control valve capable of being opened along with the inclining of the liquid discharge pipe sleeve is arranged at a position, located between a liquid outlet and the second liquid inlet, in a liquid discharge cavity; and when in use, the external force is needed to act on the liquid discharge pipe sleeve so as to align and conduct the first liquid inlet and the second liquid inlet, and meanwhile, a container and the liquid discharge pipe sleeve need to be inclined. Therefore, by adopting the technical scheme provided by the invention, the overall inner cap assembly is ensured to be at a sealed state before and after use, is low in cost due to a concise structure and less parts, is convenient to operate since the inner cap assembly is opened by utilizing the rest structure or automatically closed, and has the characteristic of smoothness in discharging liquid at the same time.

Owner:ZHONGSHAN HUABAOLE DAILY NECESSITIES IND CO LTD

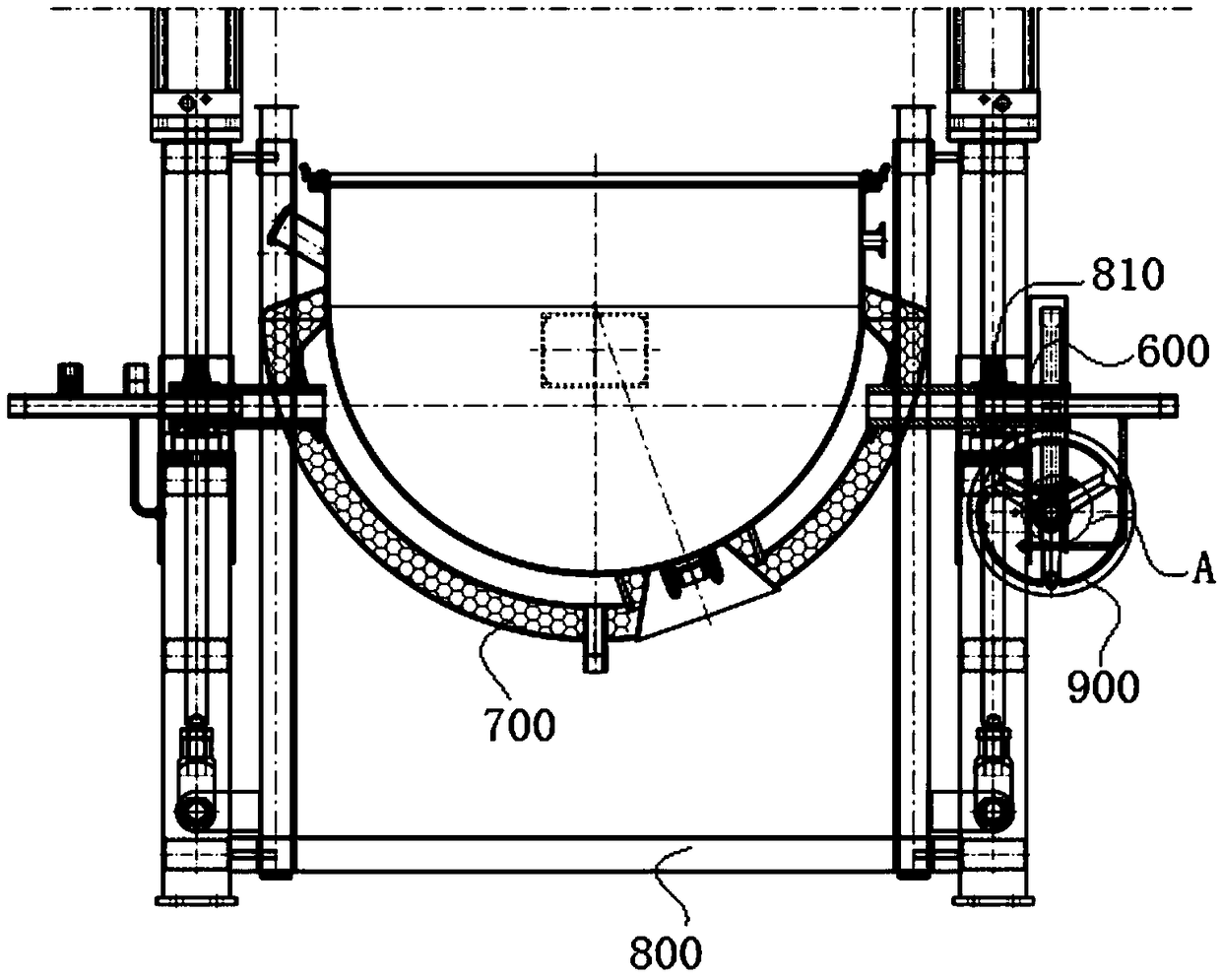

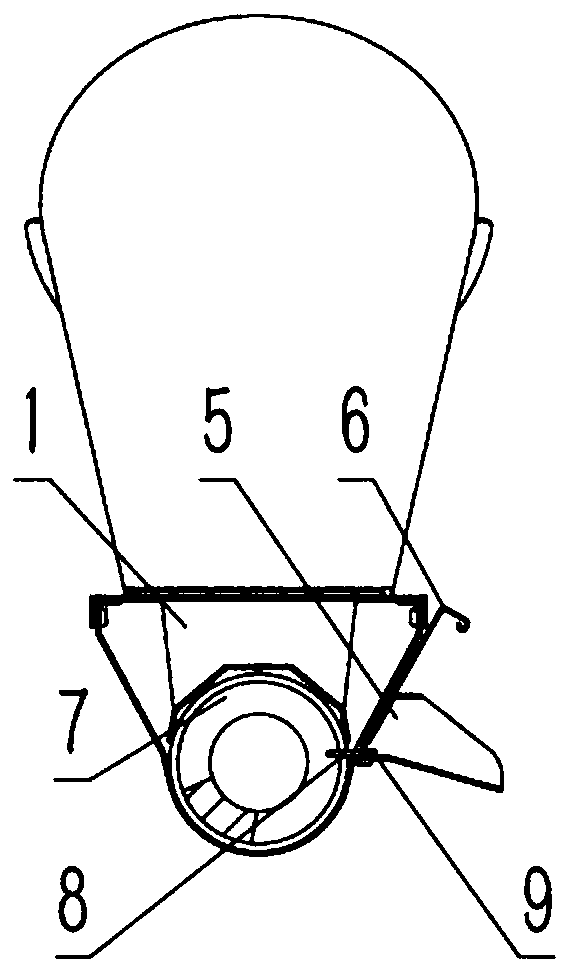

Positioning locking device for tilting sandwich pot

PendingCN109172367AReduce operational difficulty and riskGuaranteed smooth progressPharmaceutical product form changeEngineeringTurbine

The invention discloses a positioning locking device for a tilting sandwich pot, including a turbine disposed on a rotating shaft, wherein a worm is arranged below the turbine and matches the worm, the worm is rotatably arranged on one side of the bracket, a cyclone gear is arranged on the polished rod of the worm, a positioning mounting lever is arranged on the bracket and on the upper side of the cyclone gear, positioning chucks matched with the cyclone gear are rotatably arranged on the positioning mounting lever, and a hand wheel capable of driving the cyclone gear to rotate at the same time is arranged at one end of the worm. The invention has the beneficial effects that when the concentrated liquid is poured into the sandwich pot, the inclination angle of the sandwich pot can be effectively positioned, the operation difficulty and the risk of the operator are reduced, and the smooth progress of the liquid discharge process is ensured.

Owner:SHANGHAI UNIWIN PHARMA MACHINERY

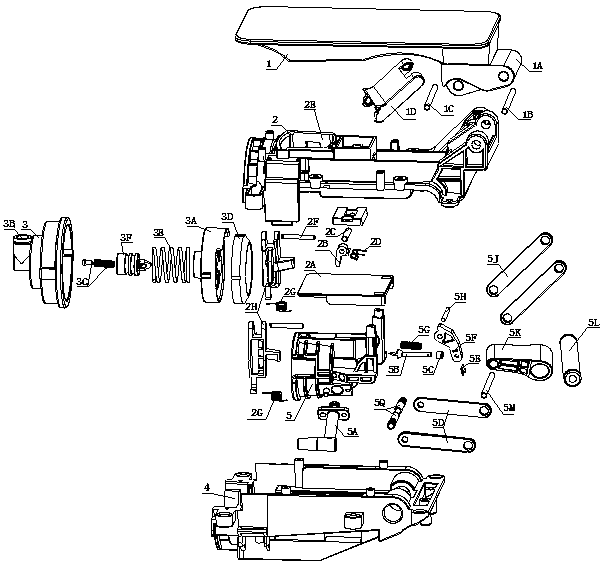

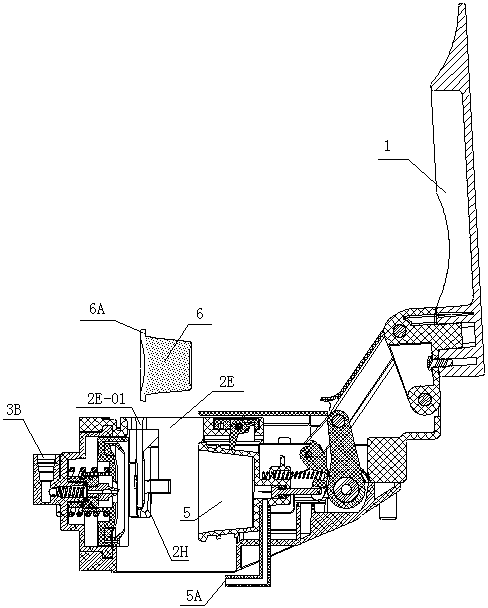

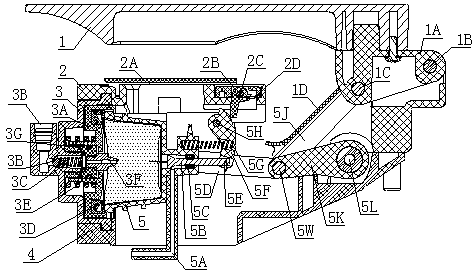

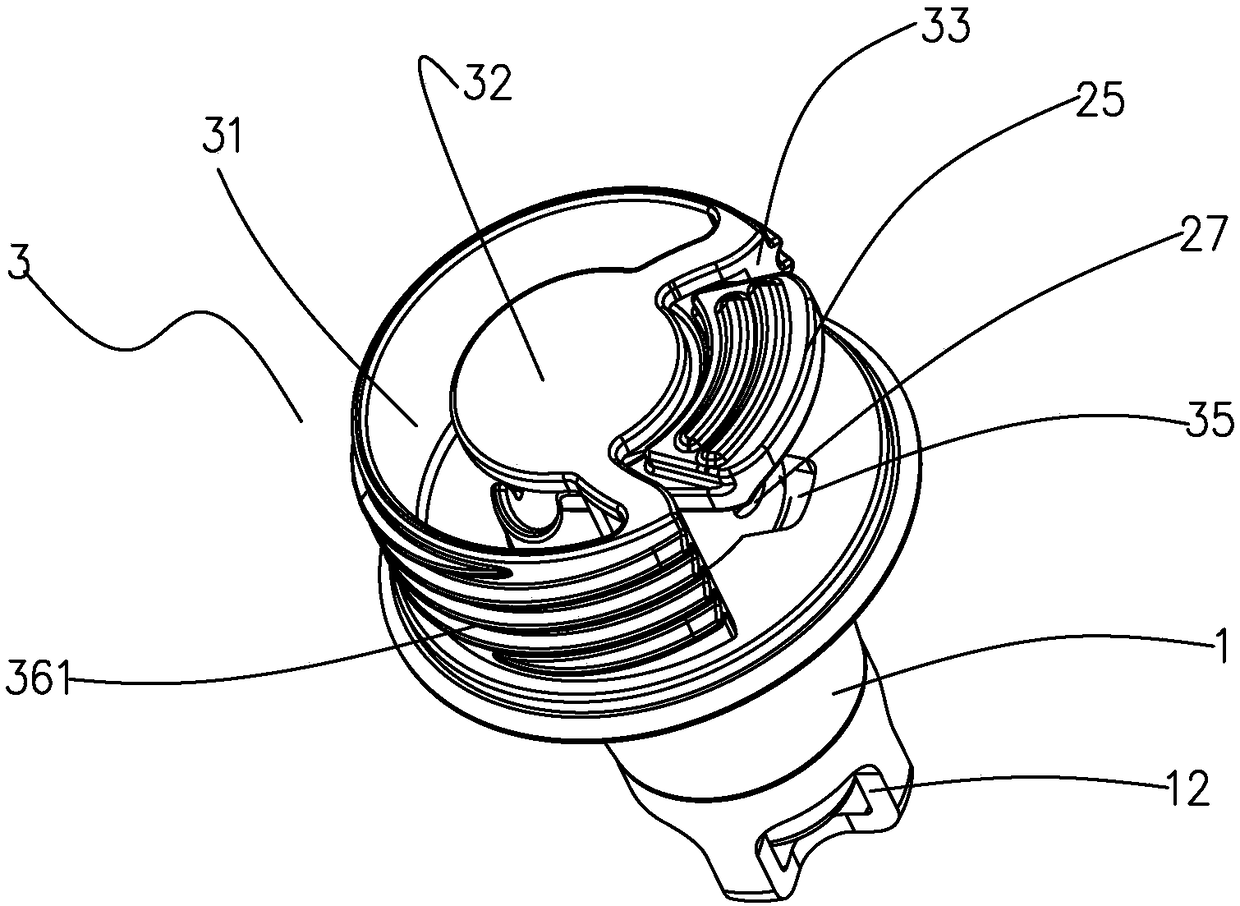

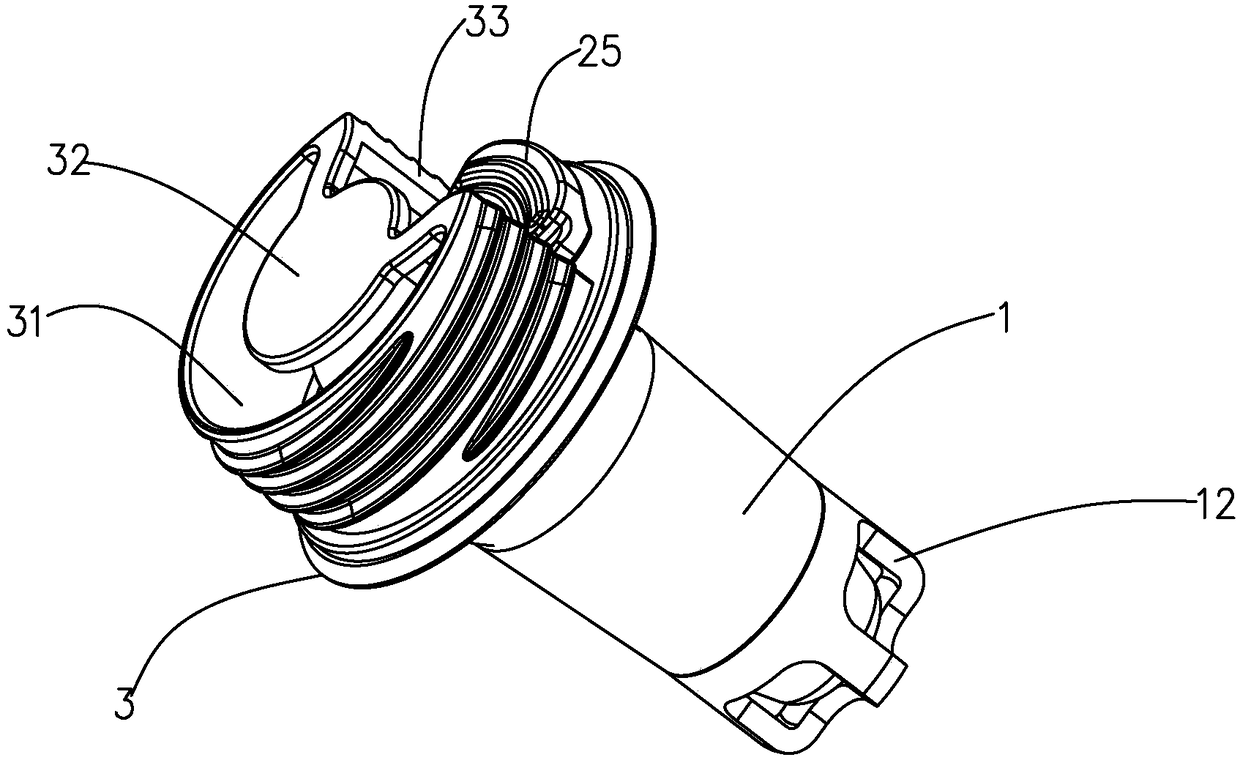

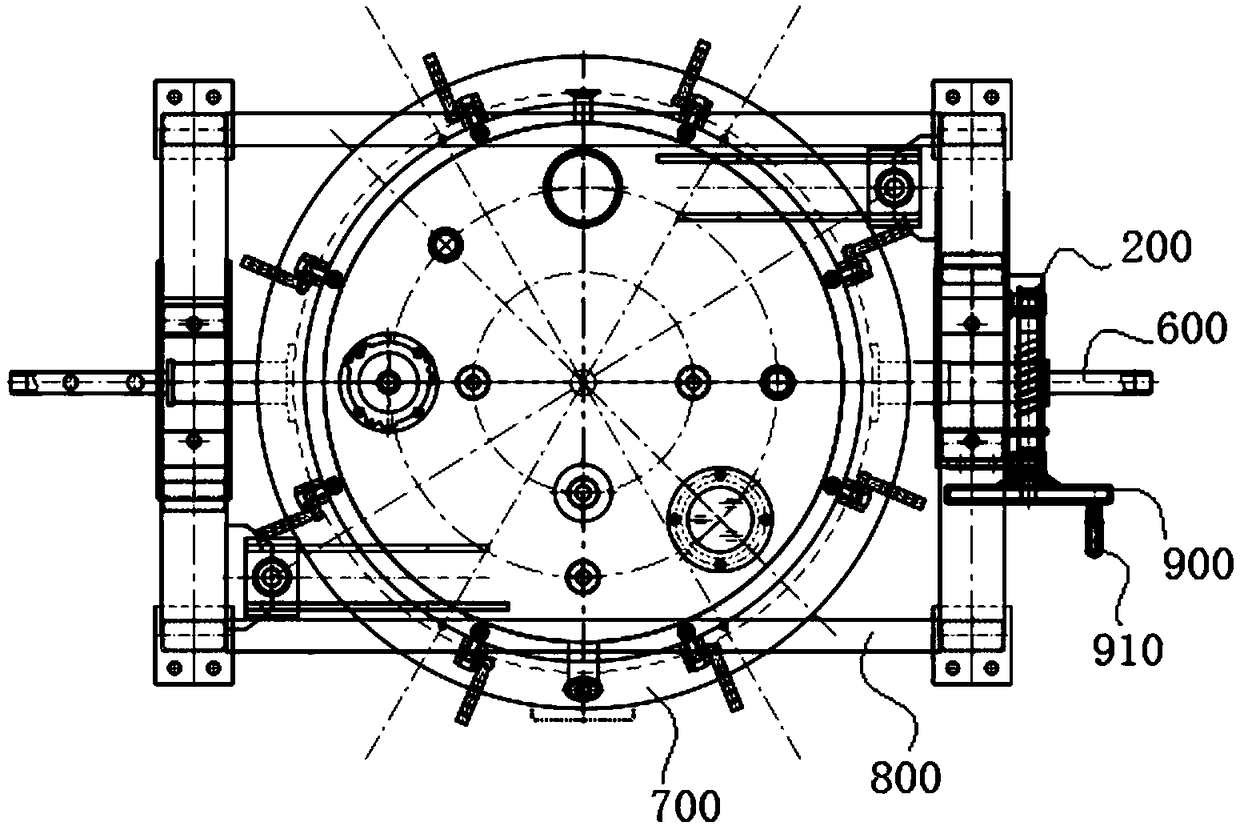

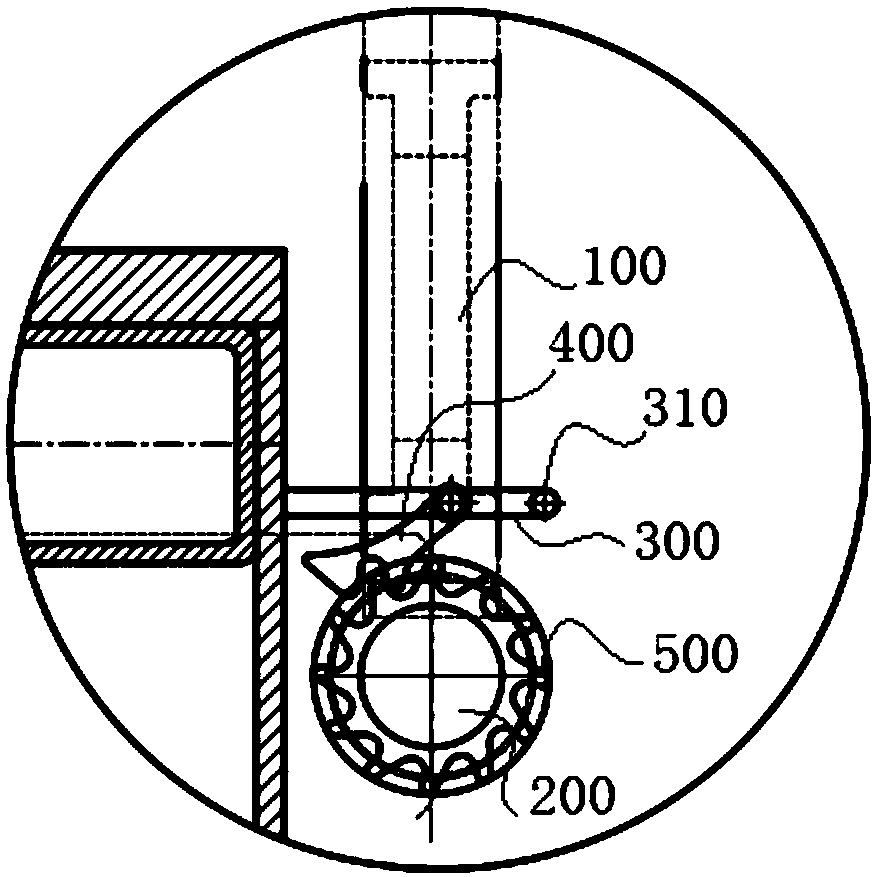

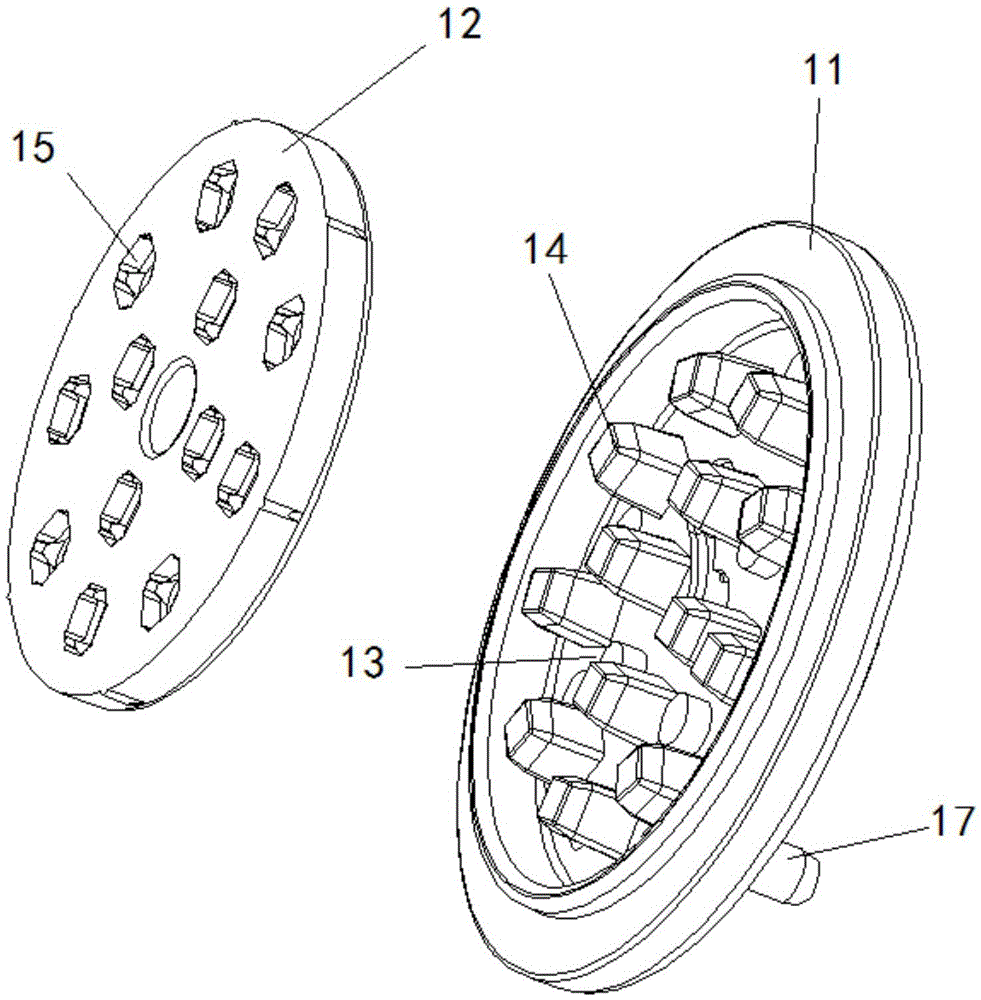

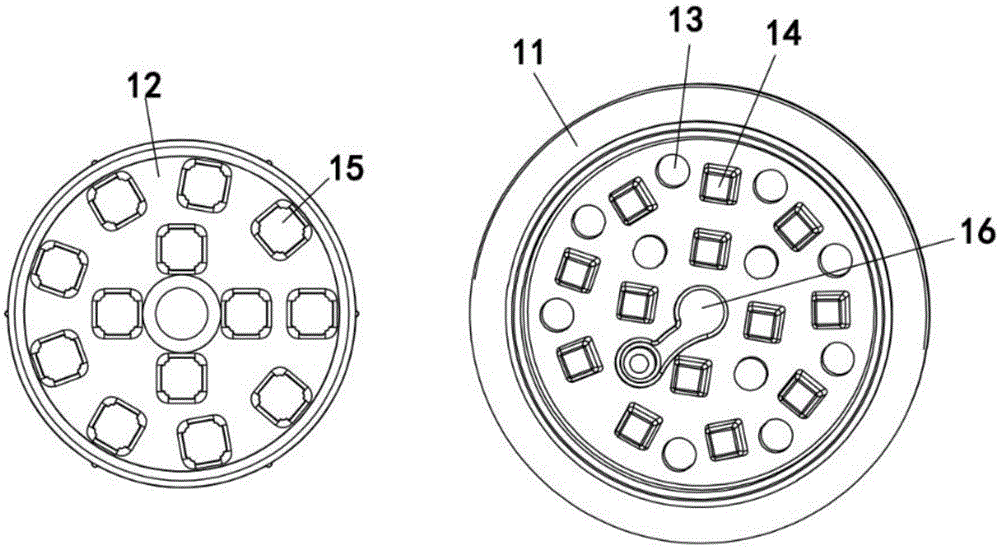

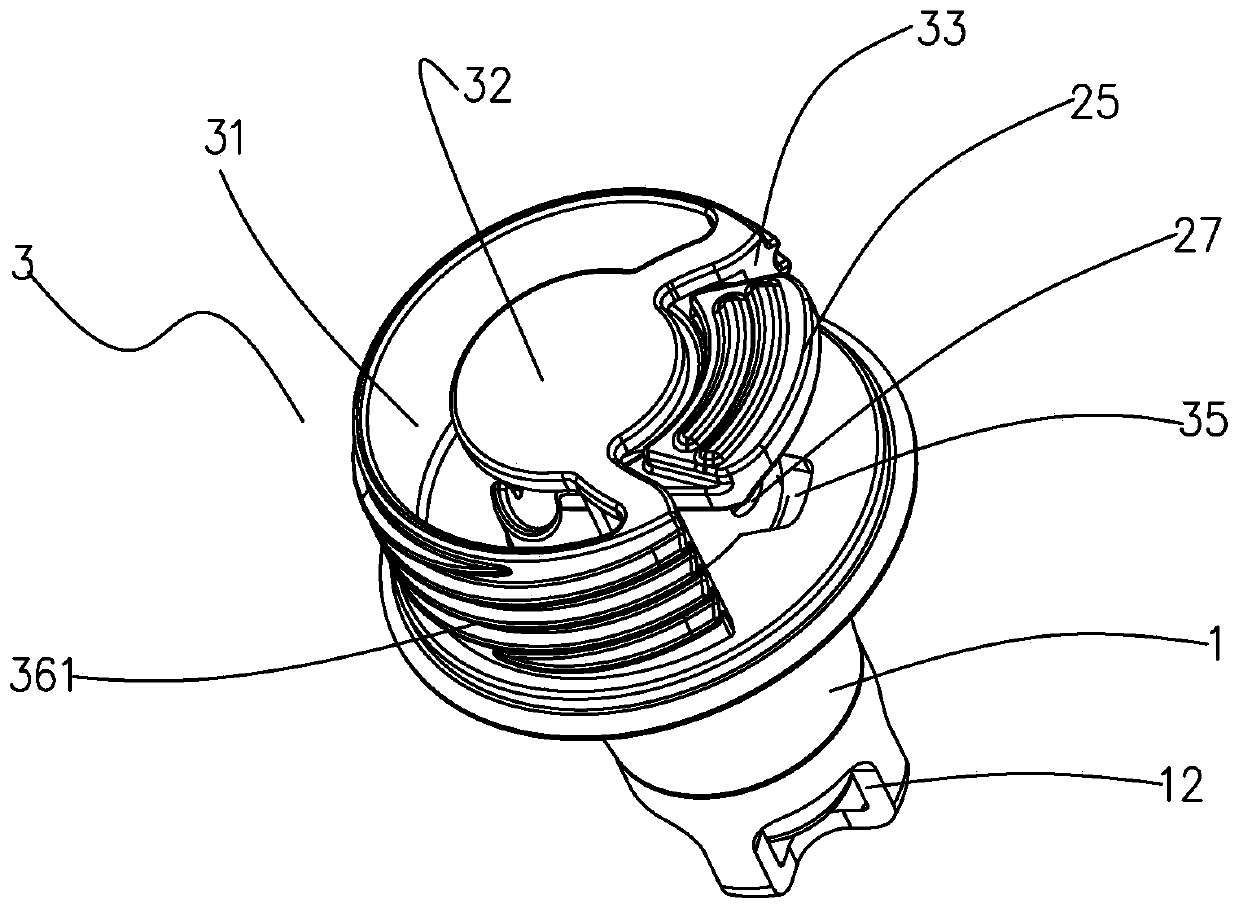

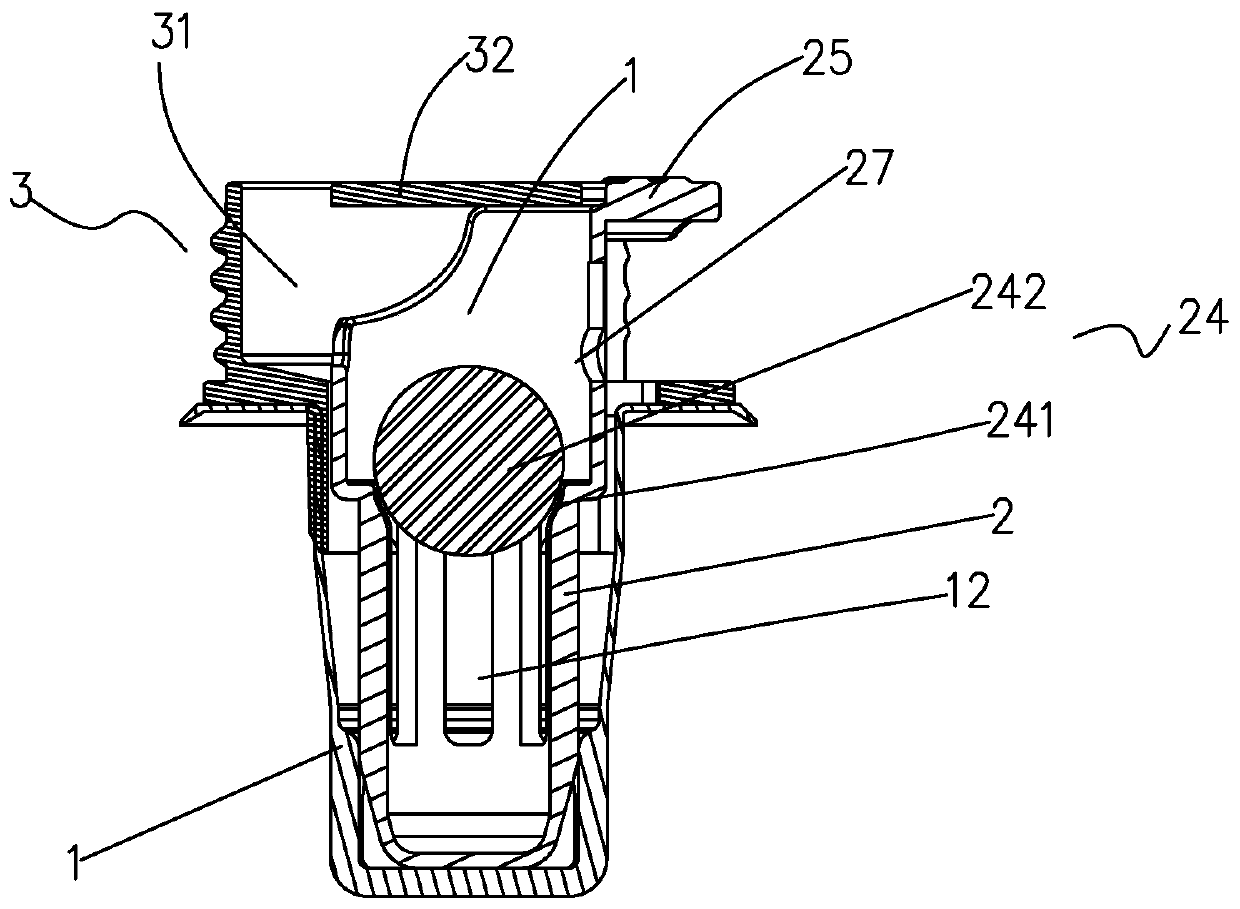

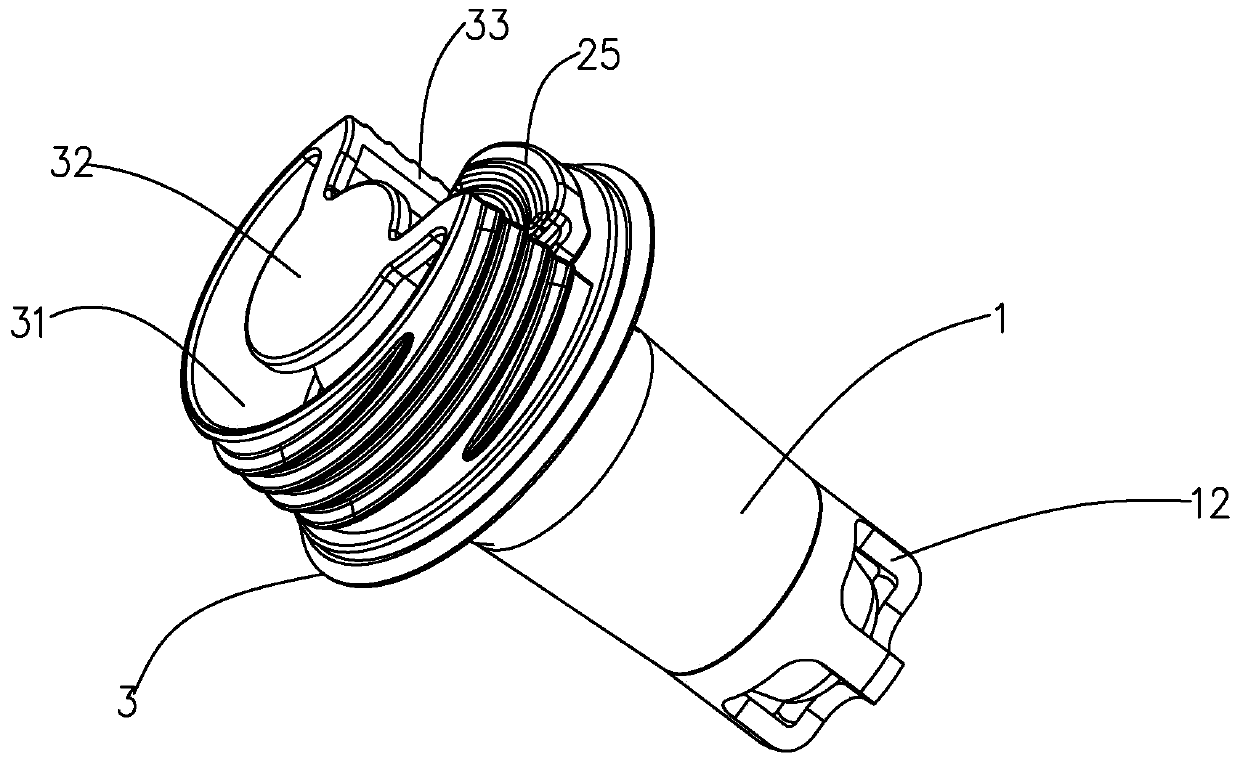

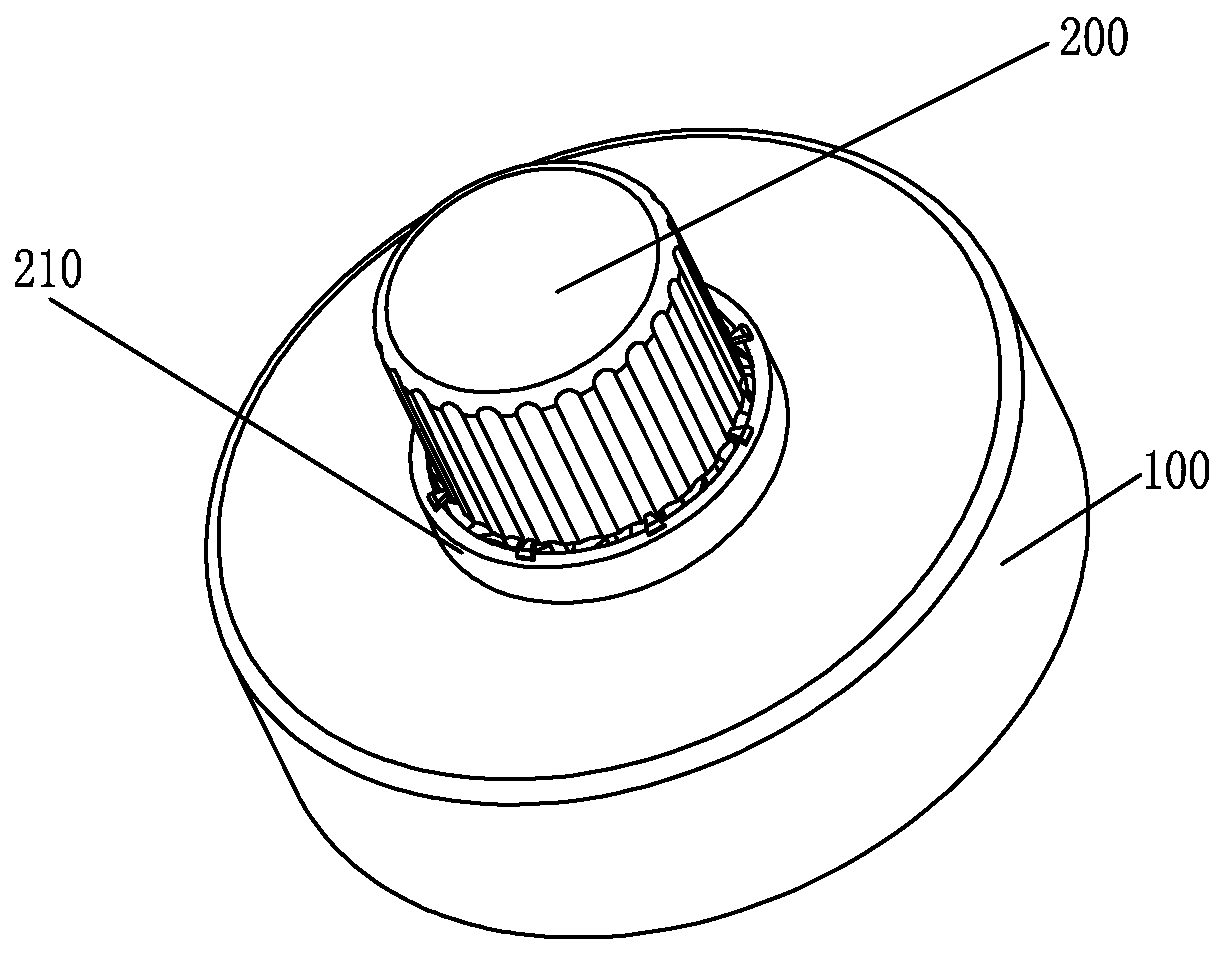

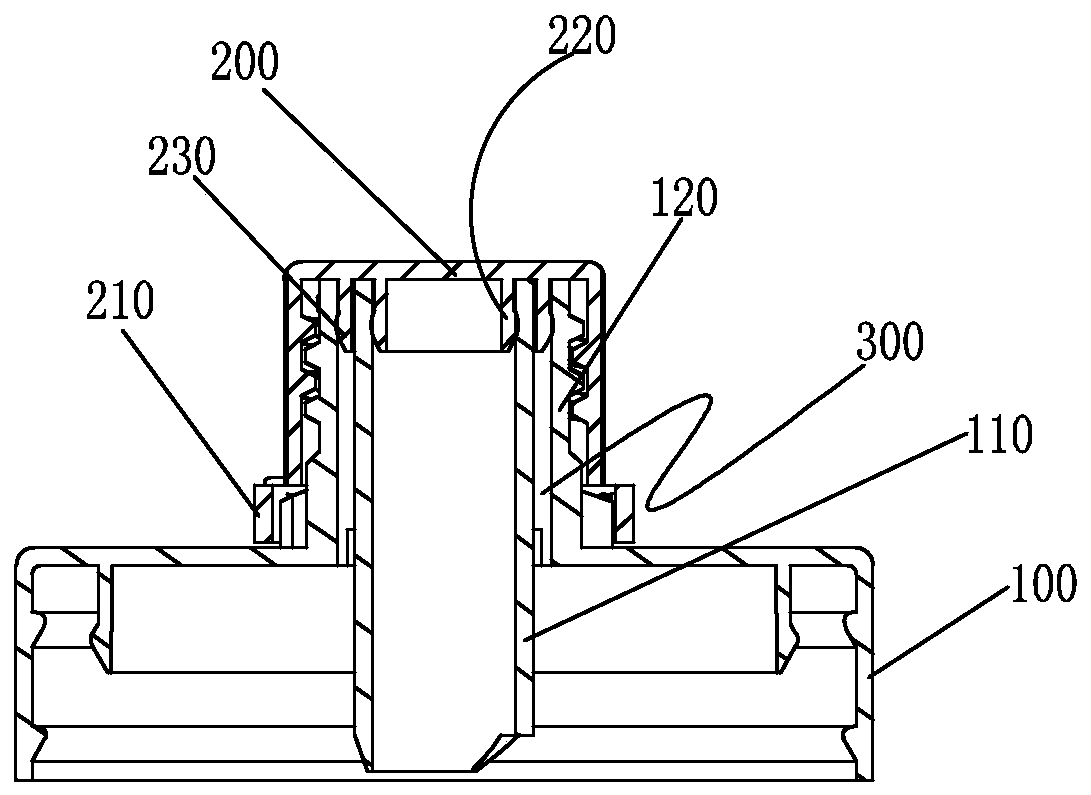

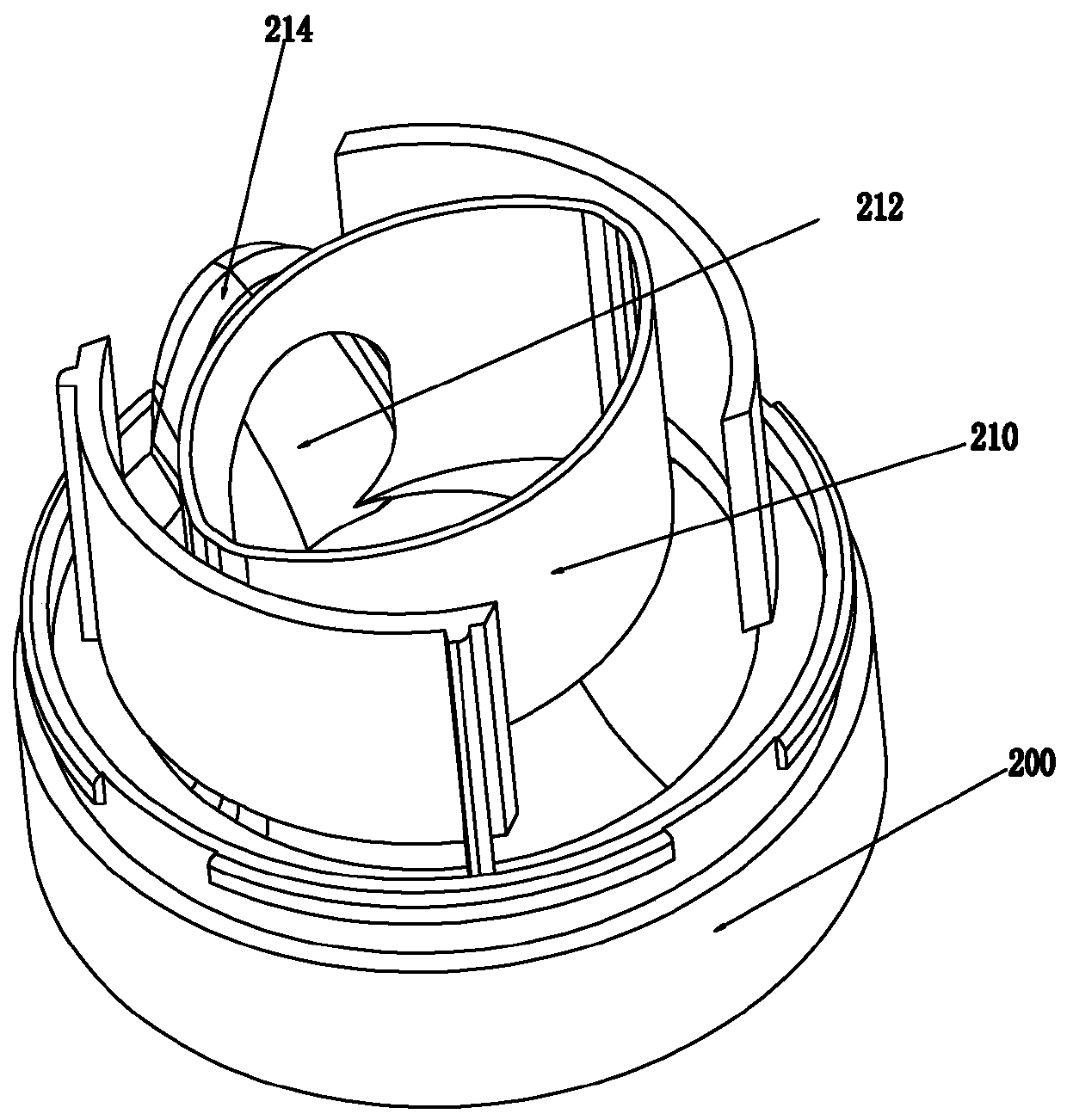

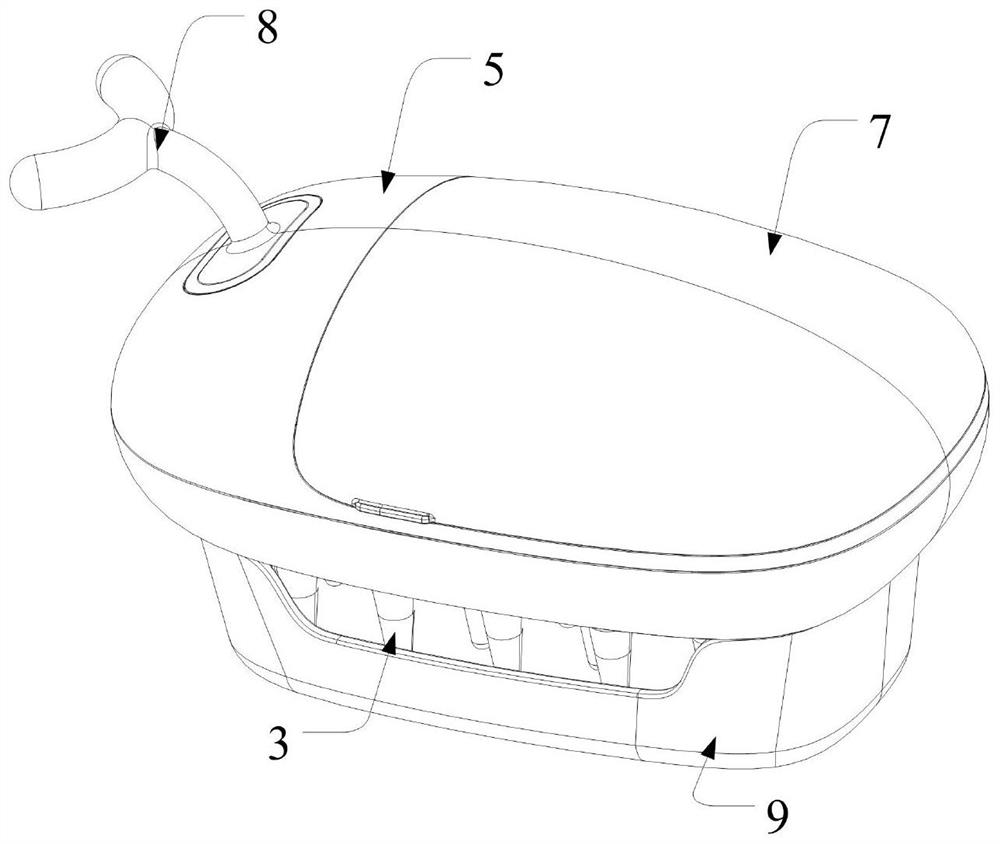

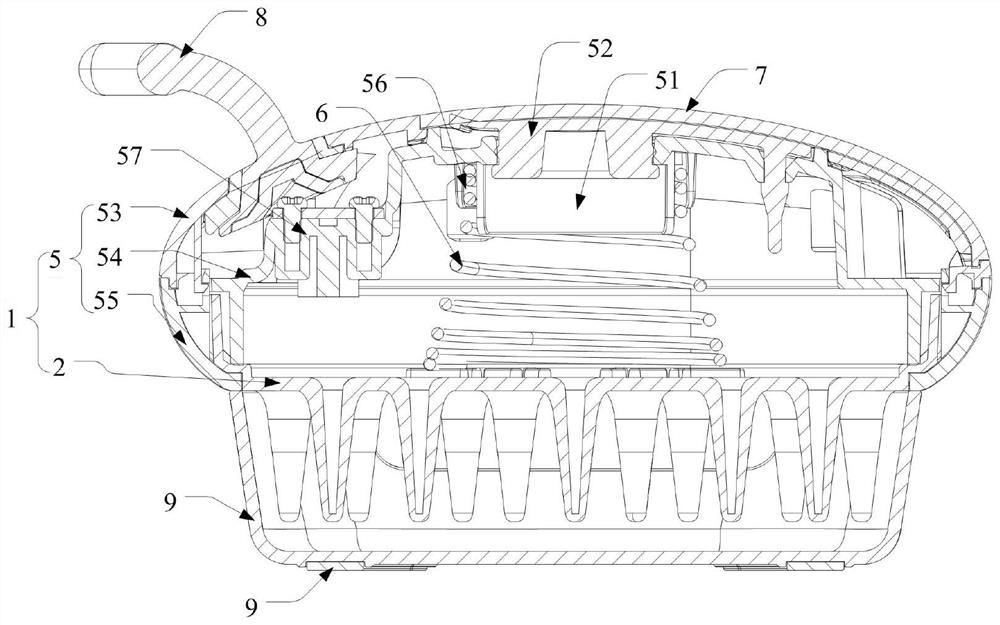

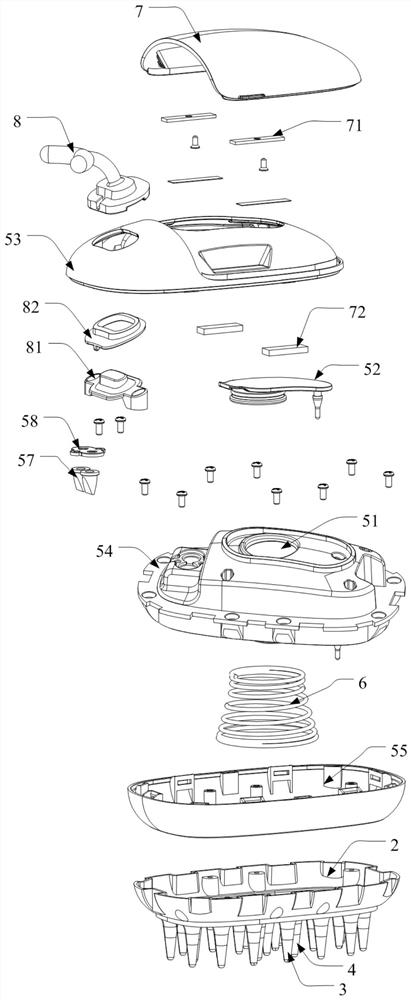

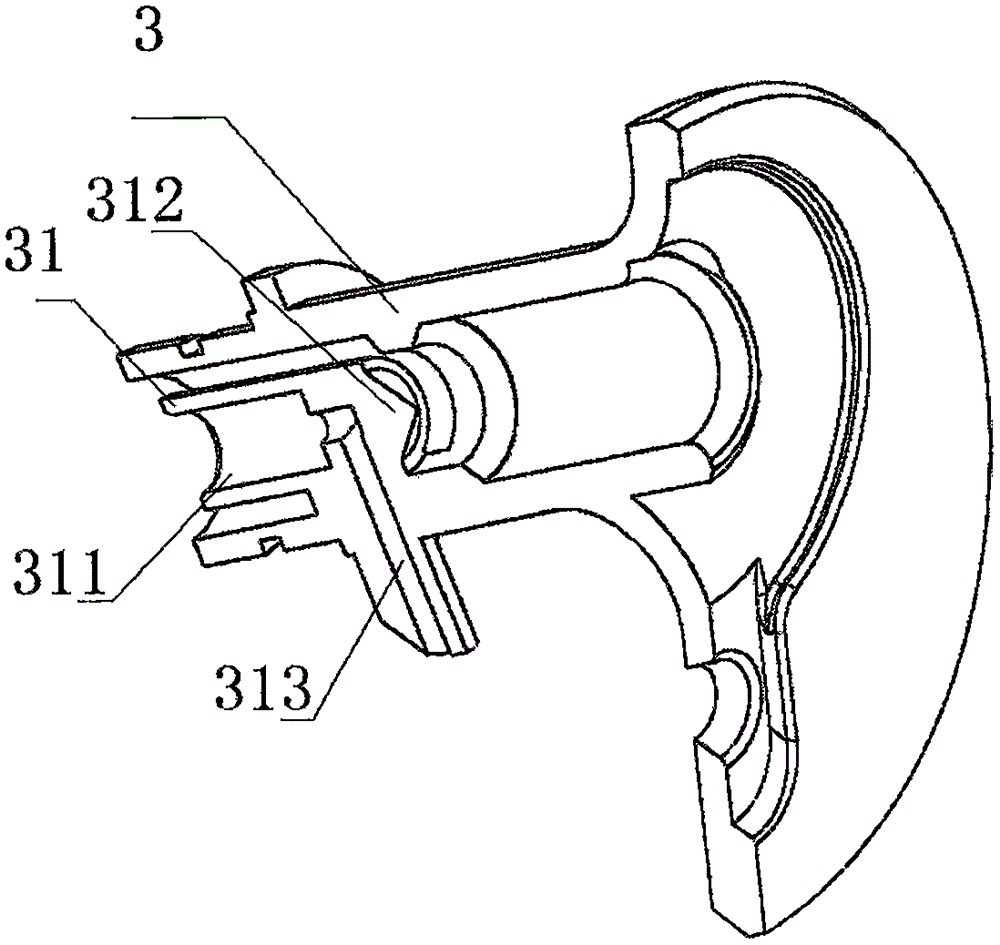

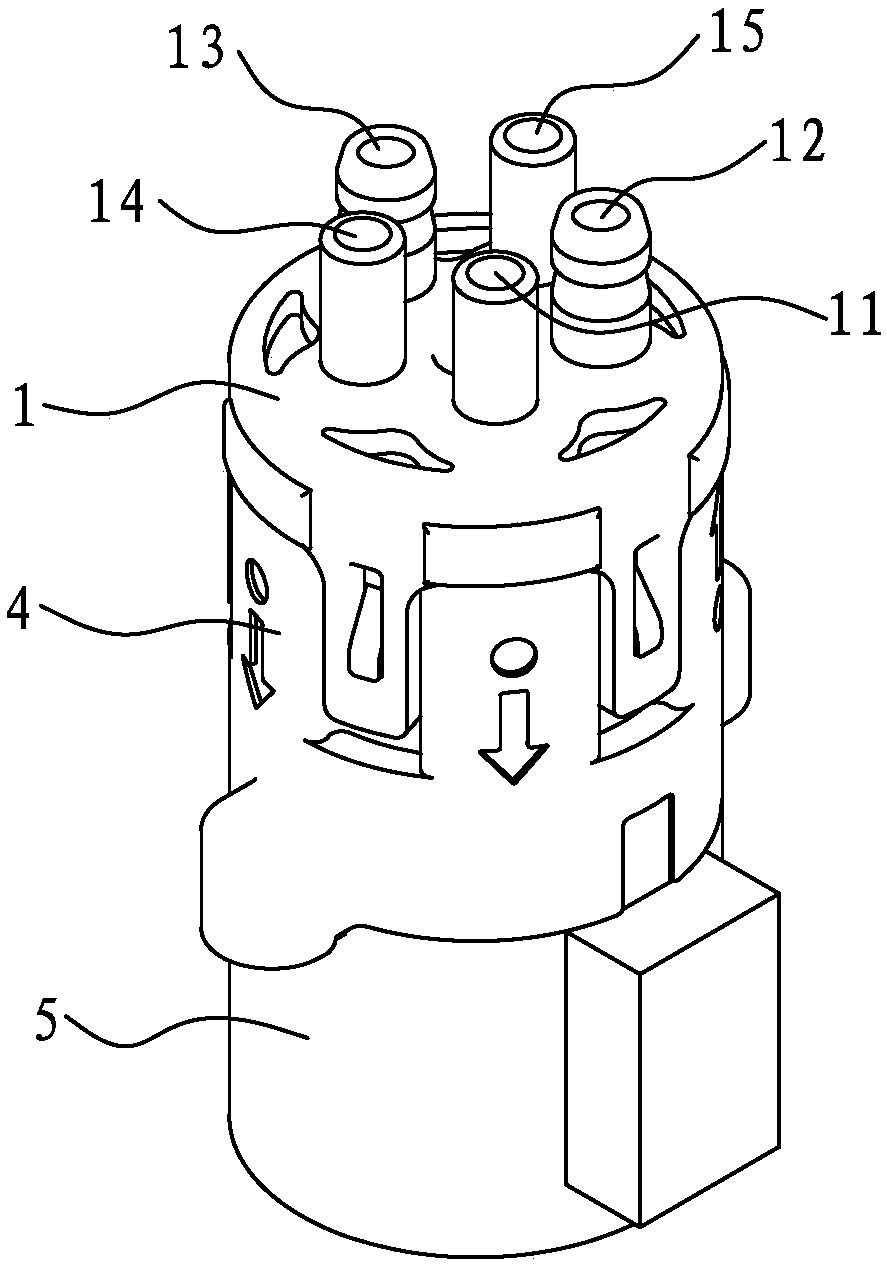

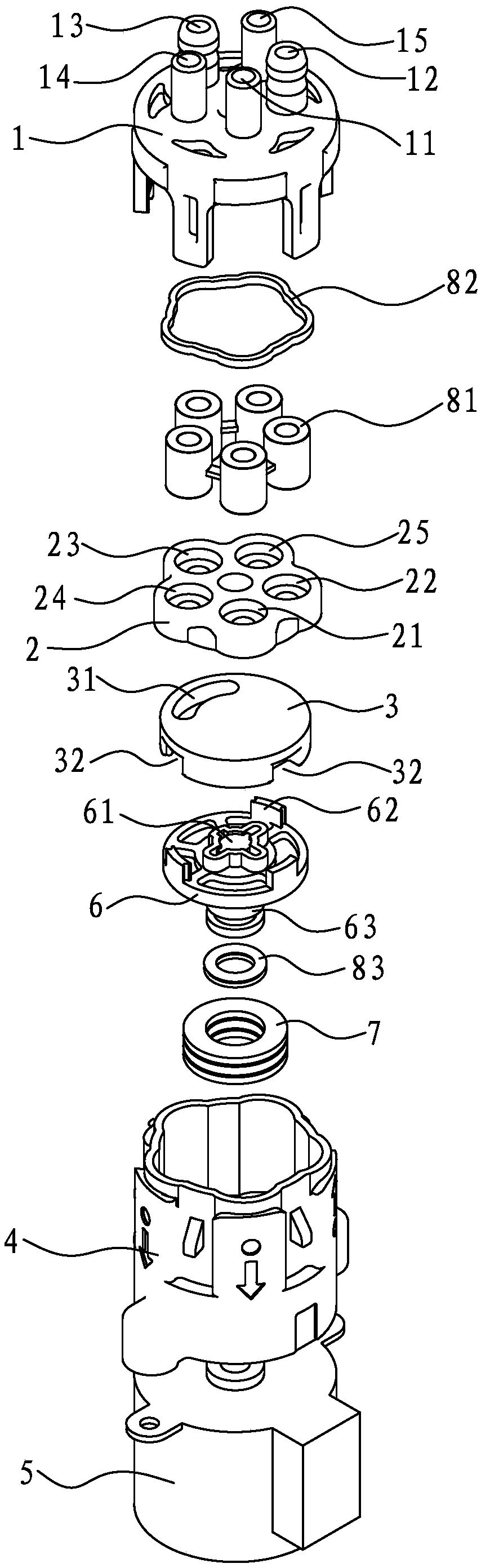

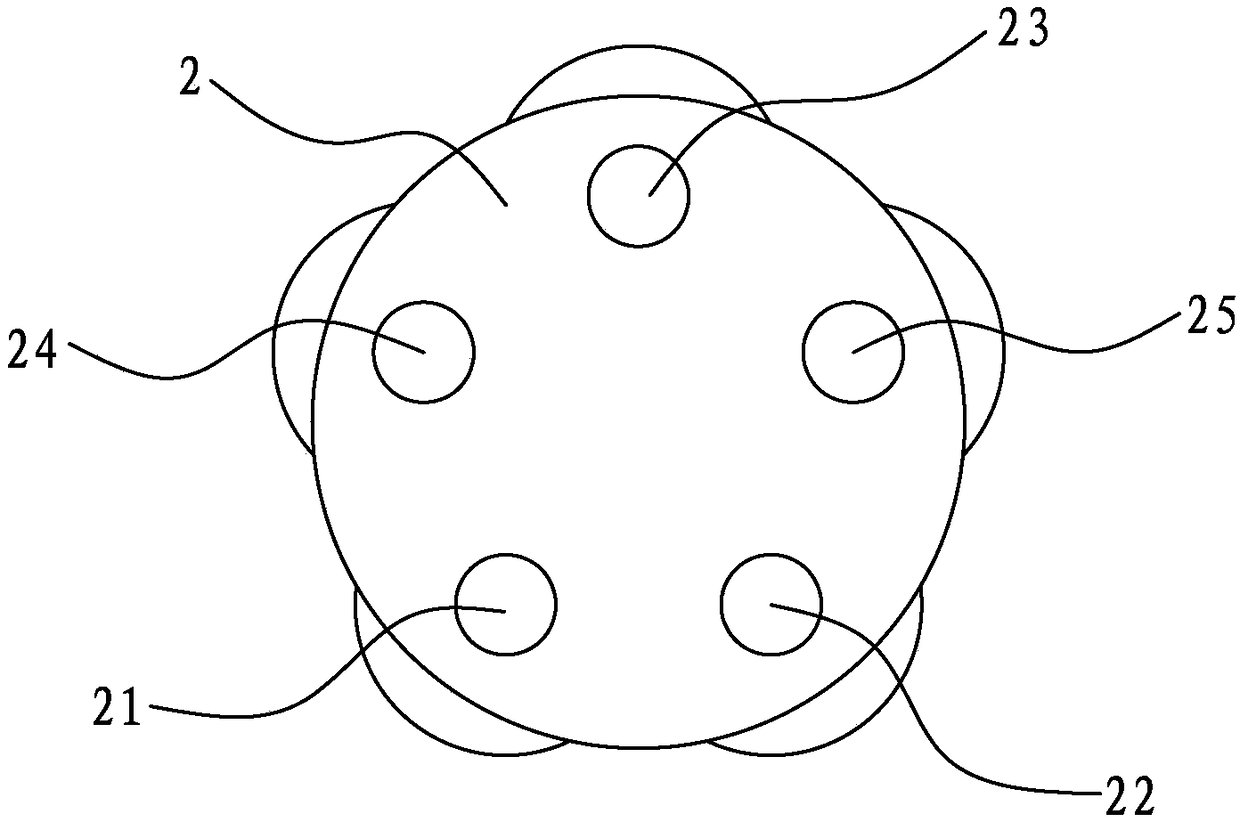

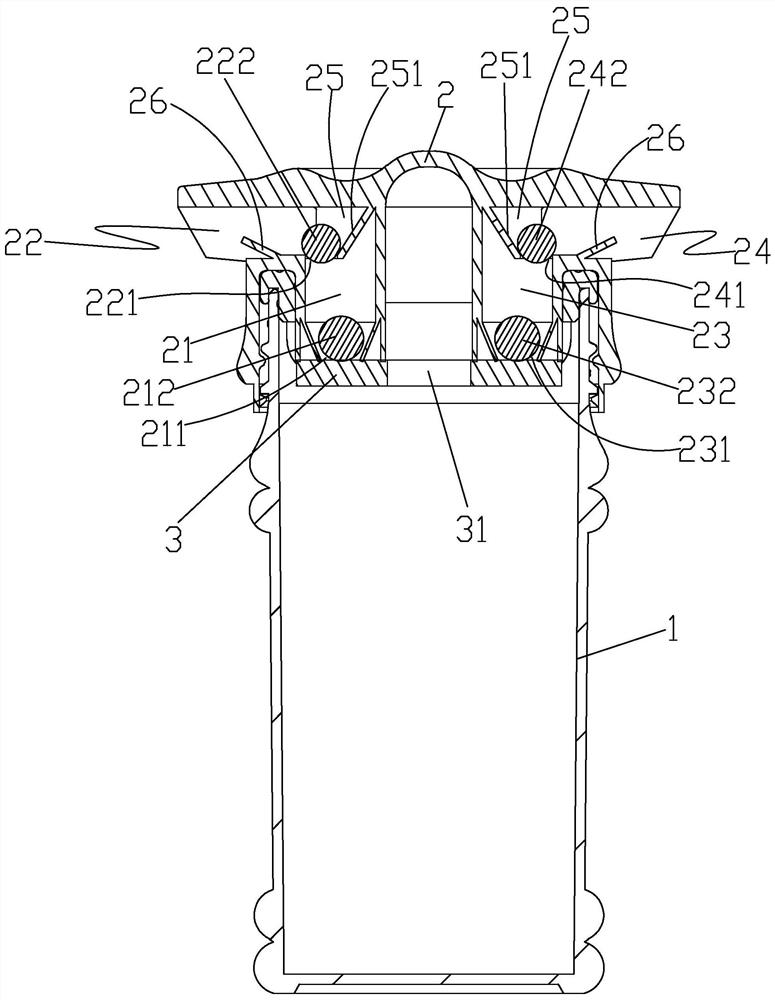

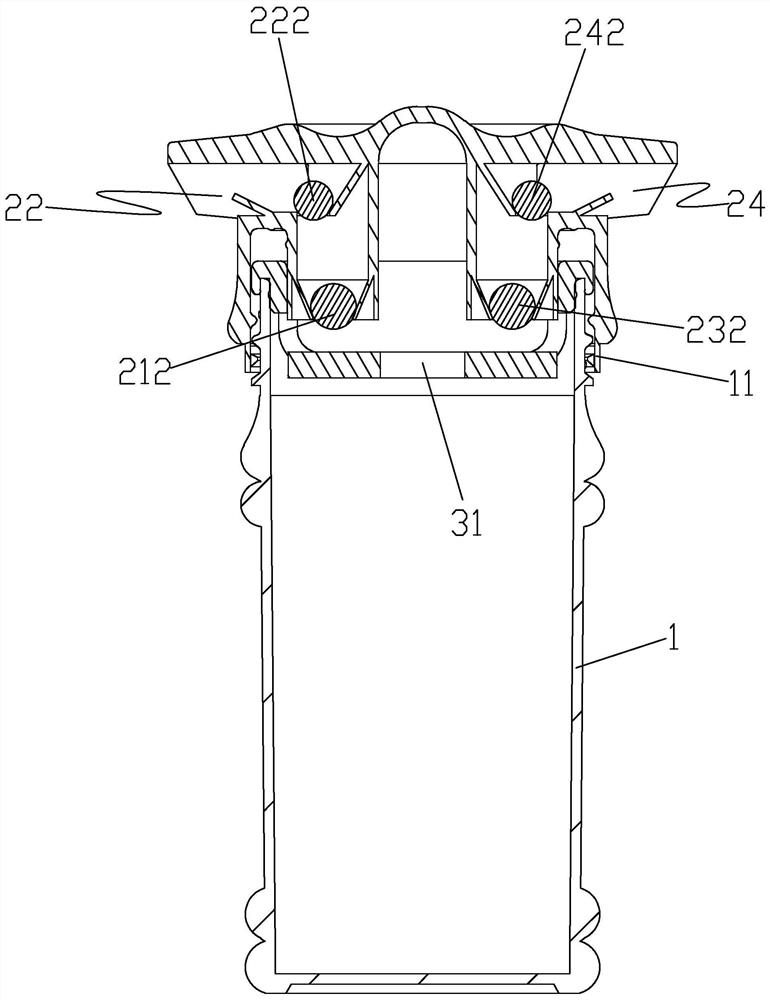

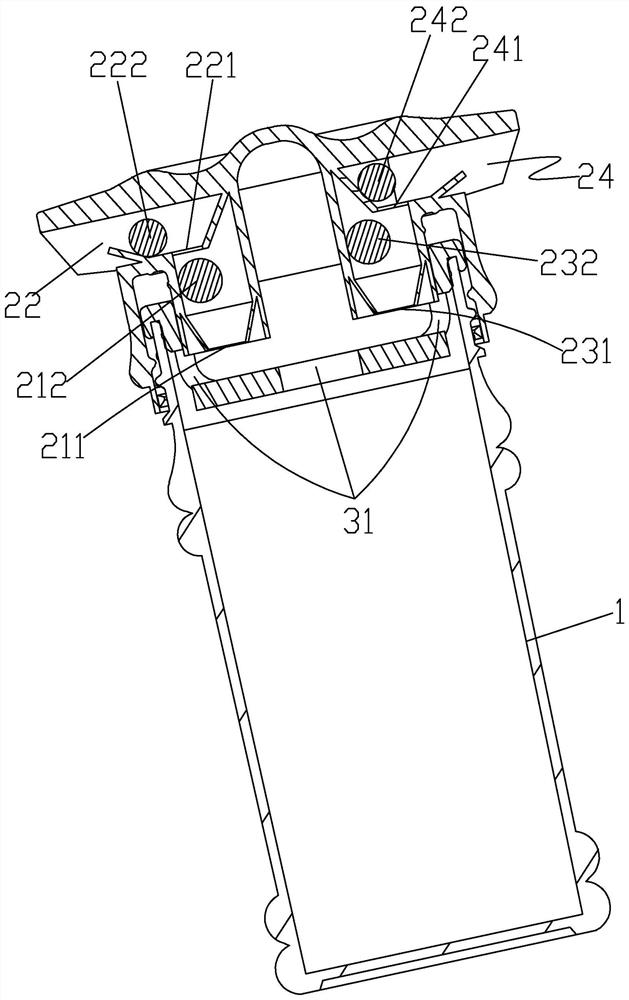

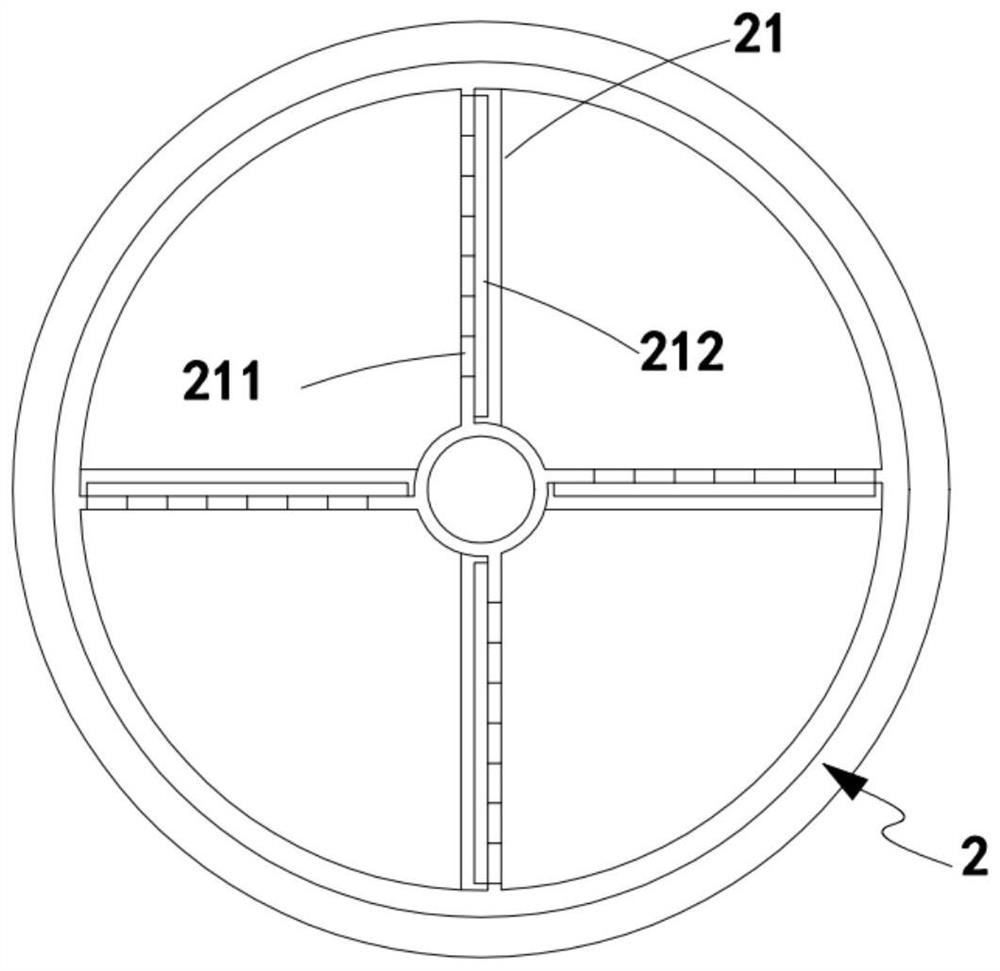

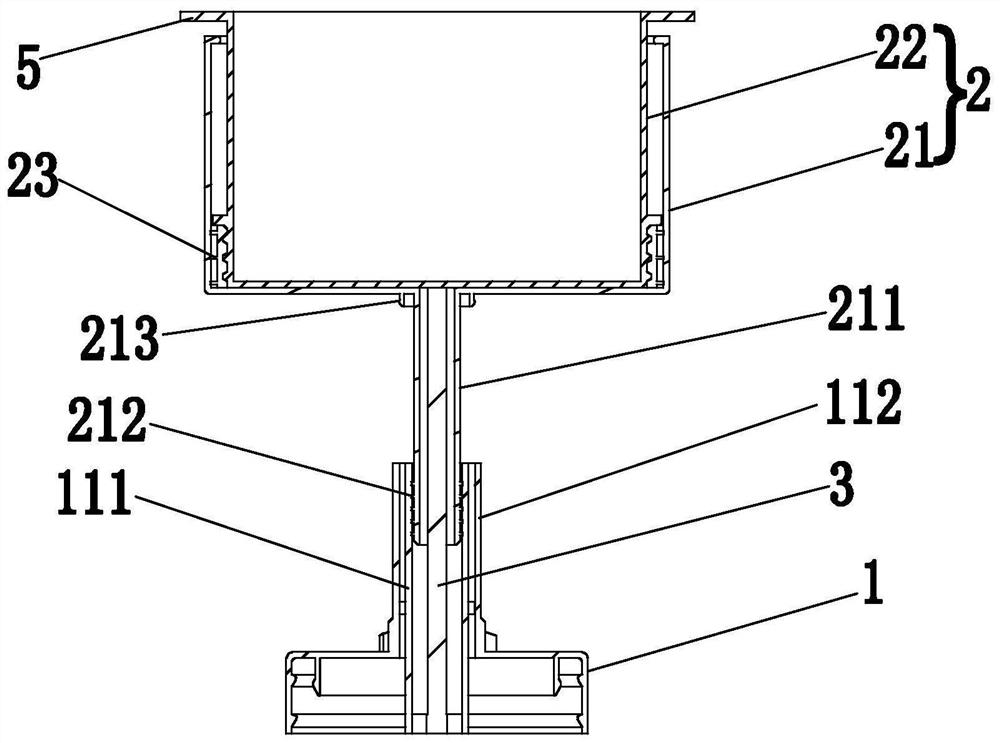

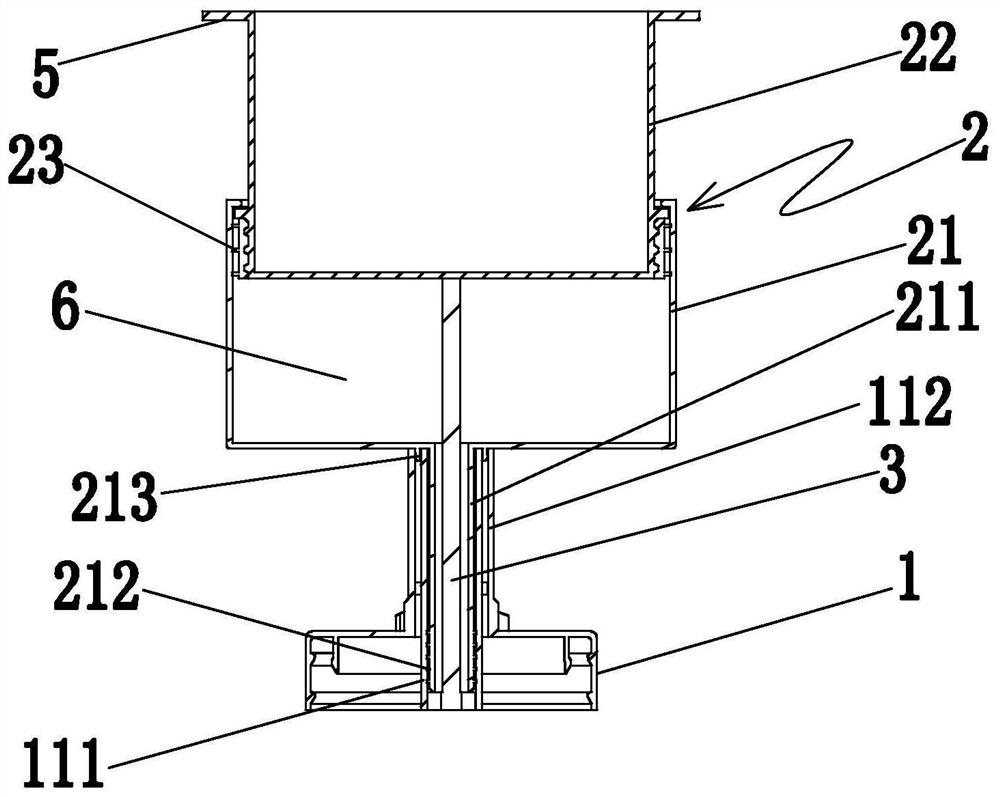

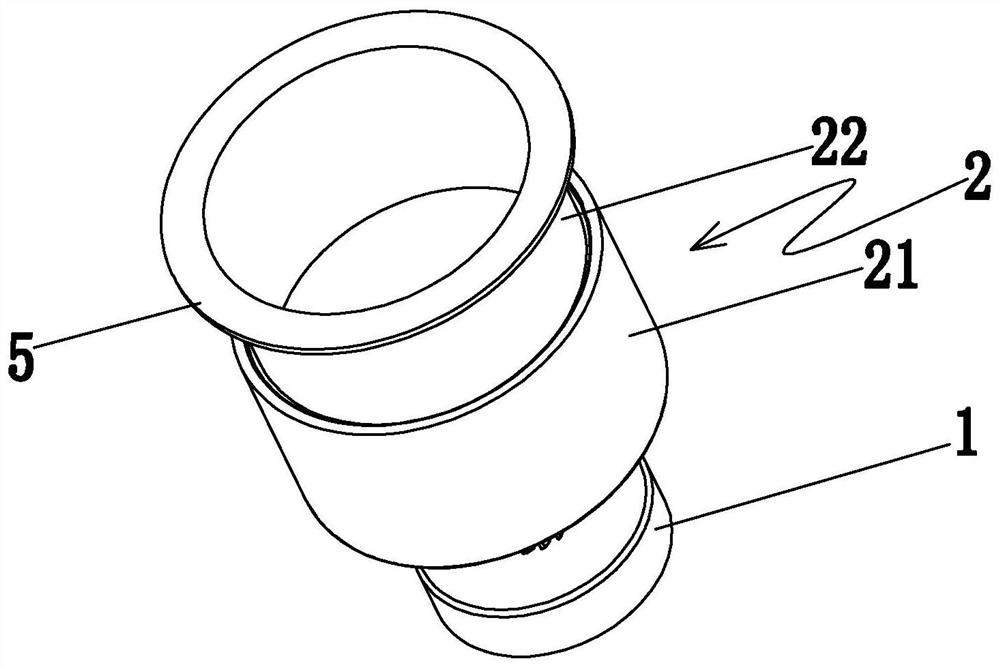

Filtering assembly and capsule coffee making device

InactiveCN105455648ASimple production processThe production process is simpleBeverage vesselsEngineeringManufacturing technology

The invention relates to the technical field of coffee machines, in particular to a filtering assembly. The filtering assembly comprises a filtering screen provided with a plurality of filtering holes. A plurality of bosses are further arranged on the filtering screen. The filtering assembly further comprises a screen cover matched with the filtering screen. The screen cover is provided with a plurality of assembly holes matched with the bosses in shape and in position. The bosses are inserted into the assembly holes in a one-to-one correspondence mode so that the screen cover can be connected with the filtering screen in a matched mode. Besides, gaps exist between the assembly holes and the bosses after the assembly holes and the bosses are rotationally assembled, and the bosses will be higher than the plane of the screen cover. The invention further provides a capsule coffee making device using the filtering assembly. The filtering assembly has the advantages of being simple in manufacturing technology and small in hole diameter, and large making pressure can be provided while it can be guaranteed that coffee liquid output is smooth.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

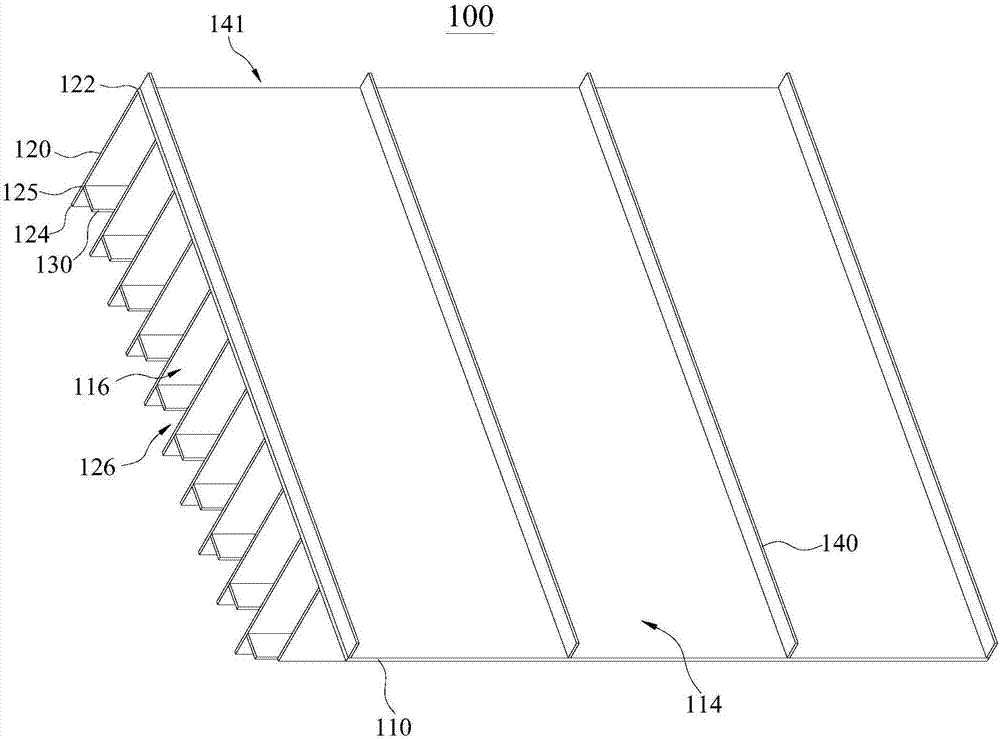

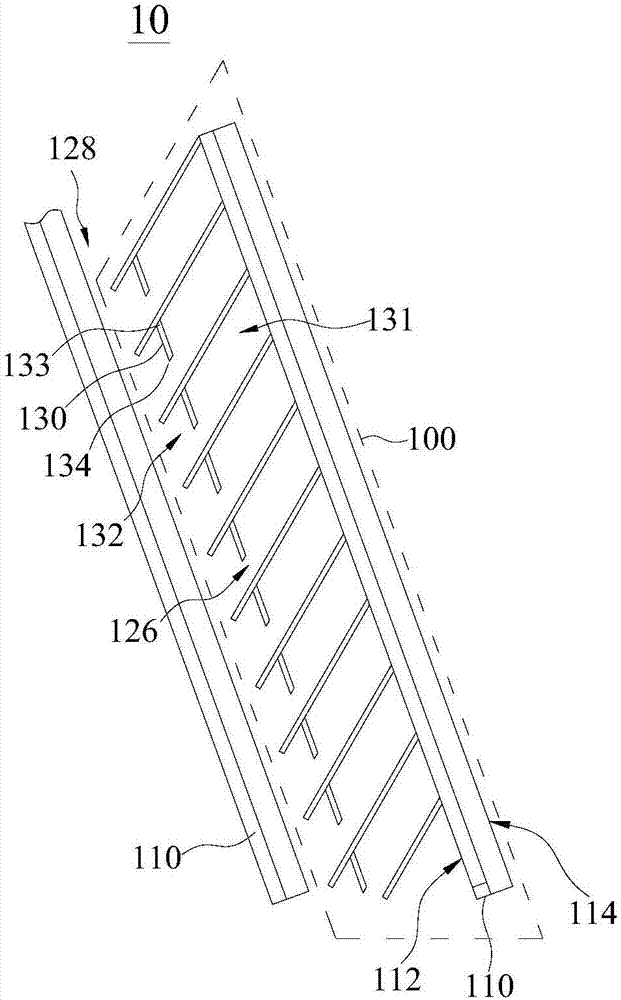

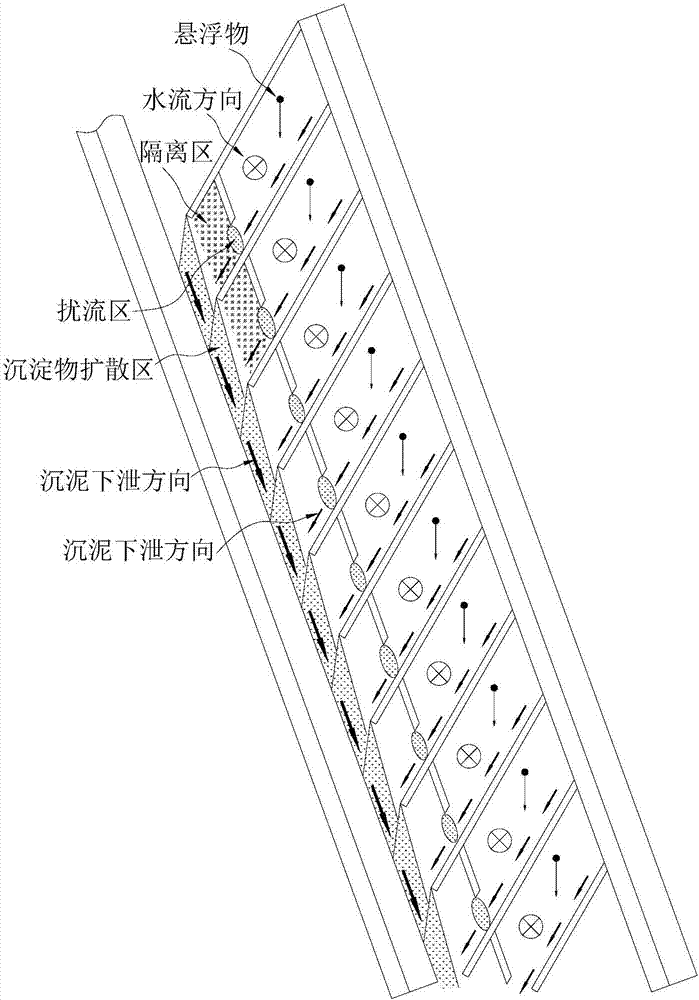

Lateral flow inclined tube sedimentation separator and sedimentation tank

InactiveCN106943776AReduce adverse effectsReduce areaTreatment involving sedimentationSedimentation settling tanksEngineeringSediment

The invention provides a lateral flow inclined tube sedimentation separator and a sedimentation tank. The lateral flow inclined tube sedimentation separator comprises at least one sedimentation separation unit, wherein the sedimentation separation unit comprises an inclined plate, a plurality of alar plates arranged at intervals and a plurality of webs. The inclined plate is provided with a guide surface for guiding sediment to move down and a mounting surface arranged opposite from the guide surface. Each alar plate is provided with a first end and a second end which are opposite from each other, and the first end is connected to the mounting surface. Each alar plate is provided with a connecting part located between the first end and the second end. Each web is provided with a first edge and a second edge which are opposite from each other, the first edge is connected to one of two connecting parts, and a second gap for the passage of sediment is reserved between the second edge and the other one of the two connecting parts. Formed isolating areas ensure that both a sediment diffusion area and a muddy water area in a sediment discharge chute are far from a turbulent flow area, moreover, the water of the turbulent flow area is clean water, consequently, muddy water is prevented from adversely influencing sedimentation separation carried out in a sedimentation separation operation area when disturbed by turbulent flow, and thereby the capability of sedimentation and clarification can be improved.

Owner:刘文义 +1

Inner cap assembly convenient to use

The invention discloses an inner cap assembly convenient to use. The inner cap assembly comprises a sealing sleeve, a liquid outlet pipe sleeve and a connecting seat. Through an action on the liquid outlet pipe sleeve, a sealed state in which a first liquid inlet opening and a second liquid inlet opening are staggered can be changed into a state in which the first liquid inlet opening is communicated with the second liquid inlet opening; and a liquid outlet control valve which can be opened as the liquid outlet pipe sleeve tilts is arranged at the position, in a liquid outlet chamber and between a liquid outlet opening and the second liquid inlet opening. When the inner cap assembly is used, an external force is needed to be applied to the liquid outlet pipe sleeve so that the first liquidinlet opening is communicated with the second liquid inlet opening; after the external force is removed, the liquid outlet pipe sleeve is automatically reset and the first liquid inlet opening and the second liquid inlet opening are staggered to form the sealed state. Therefore, the inner cap assembly ensures that the whole is in good sealed state before and after use, can avoid overflowing caused by falling down and has the characteristics of hygiene and convenience for preservation.

Owner:ZHONGSHAN HUABAOLE DAILY NECESSITIES IND CO LTD

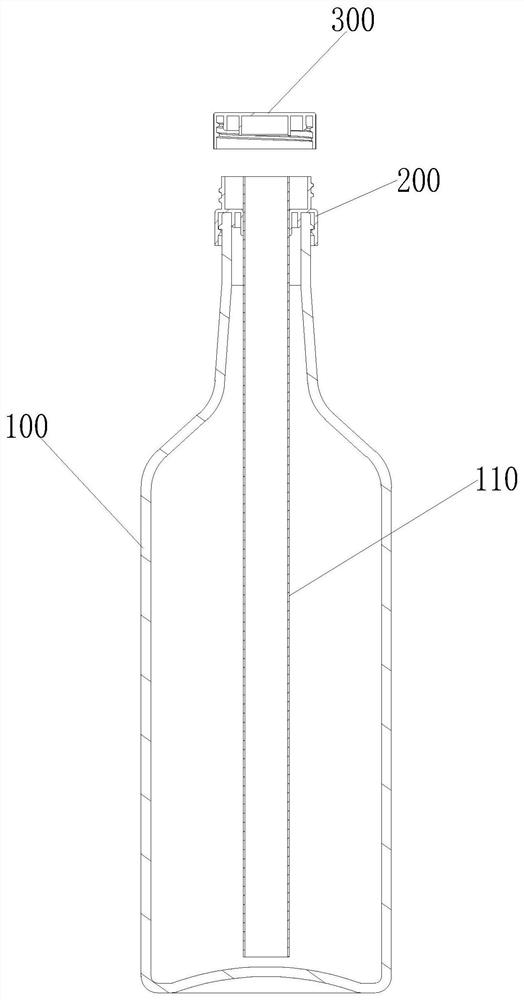

Auxiliary pouring cover assembly

PendingCN111071618AEasy to pourSimple structureClosuresVenting meansStructural engineeringPressure balance

The invention discloses an auxiliary pouring cover assembly. The auxiliary pouring cover assembly comprises a base used for being connected with an opening of a container. A liquid outlet pipe communicating an inner cavity of the container with the outside is arranged on the base. The two ends of the liquid outlet pipe are open and hollow. The lower portion of the liquid outlet pipe extends towards the inner cavity of the container. The upper portion of the liquid outlet pipe is exposed relative to the upper end face of the base. The upper portion of the liquid outlet pipe is detachably / destructively connected with an upper cover / sealing piece covering an upper opening of the liquid outlet pipe. The cover assembly further comprises an air inlet structure used for feeding air into the innercavity of the container. In the using process, a user can act on the upper cover and the air inlet structure to open to form an air inlet channel between the air inlet structure, the inner cavity ofthe container and the liquid outlet pipe, that is, enables the pressure of the inner cavity of the container and the external pressure to be balanced and then can enable liquid filled into the inner cavity of the container to be poured out from the liquid outlet pipe by acting on the container. Thus, the auxiliary pouring cover assembly has the characteristics of being smooth in liquid outlet andconvenient to use. Moreover, through arrangement of a liquid pumping device and a quantifying cavity, the auxiliary pouring cover assembly has the quantitative pouring function.

Owner:李红彪

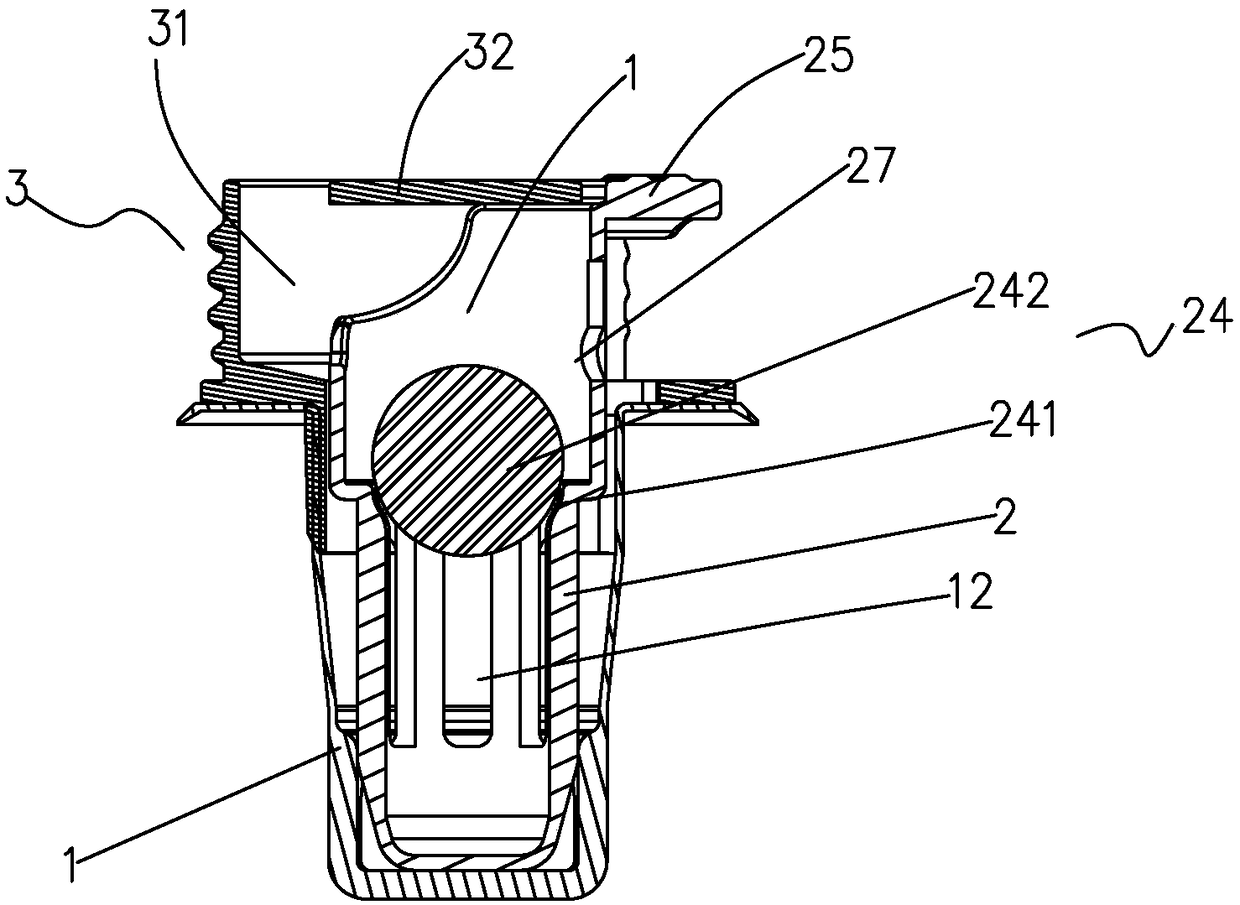

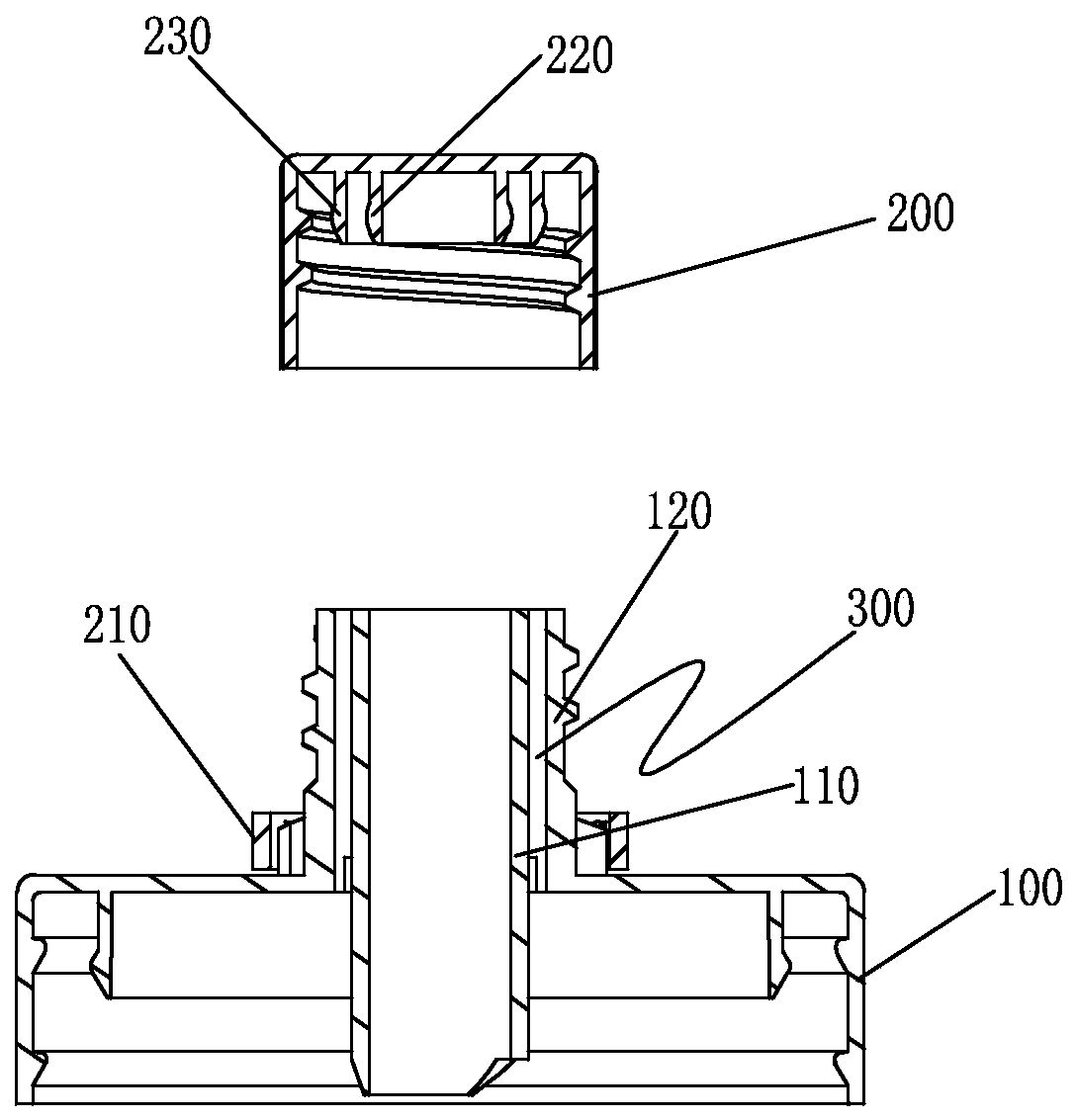

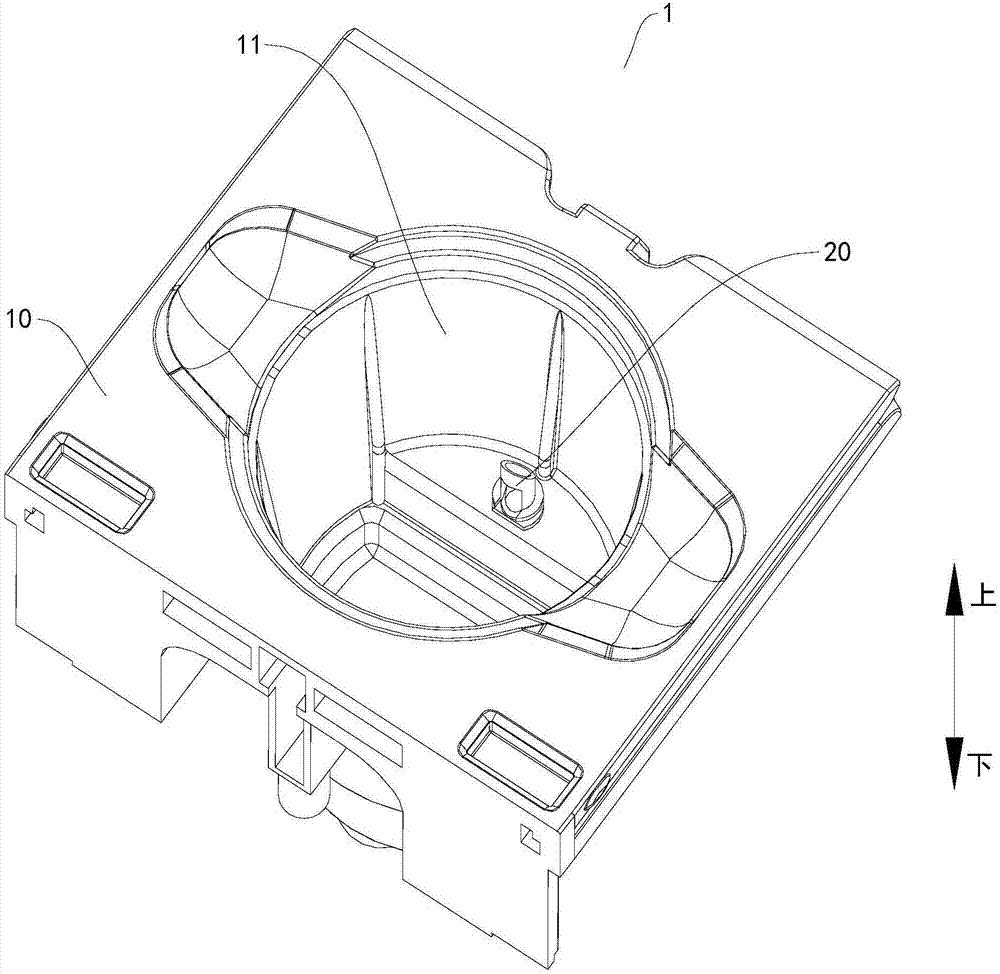

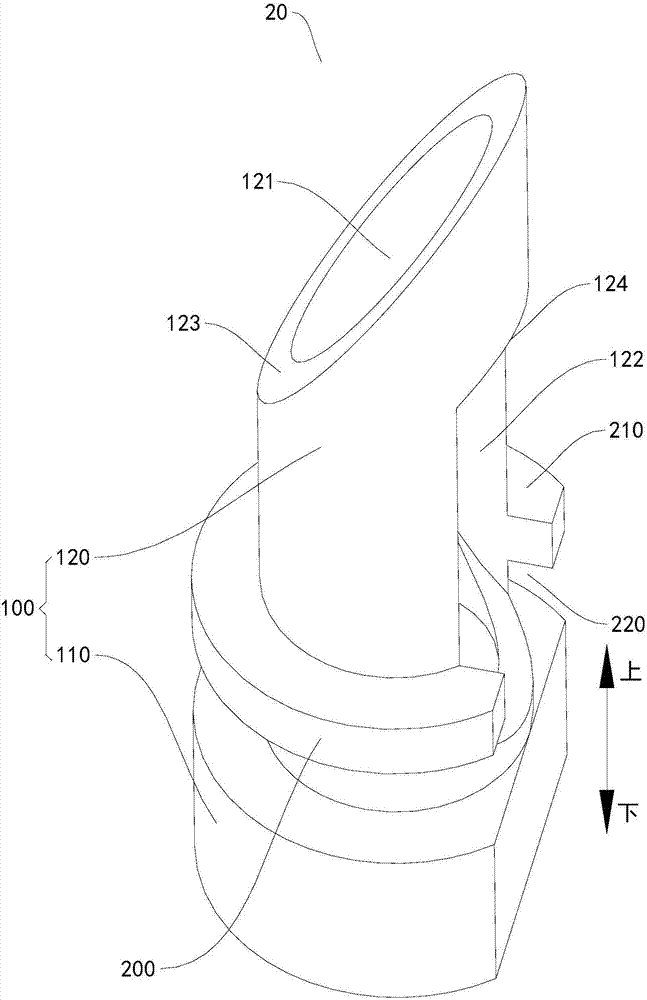

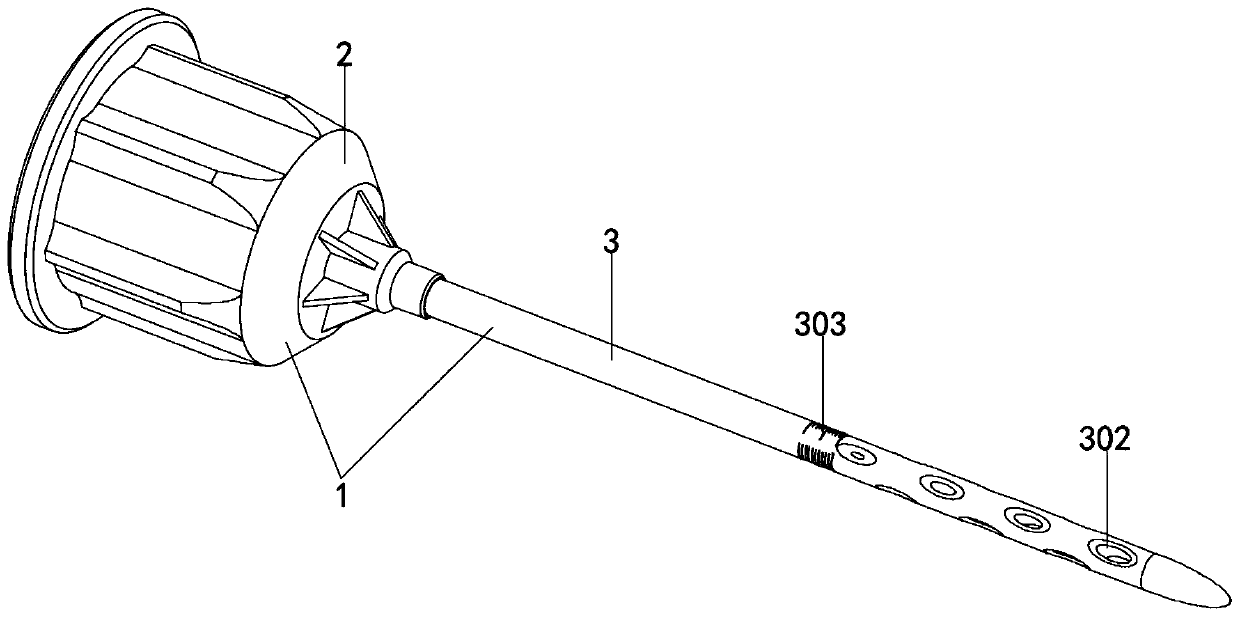

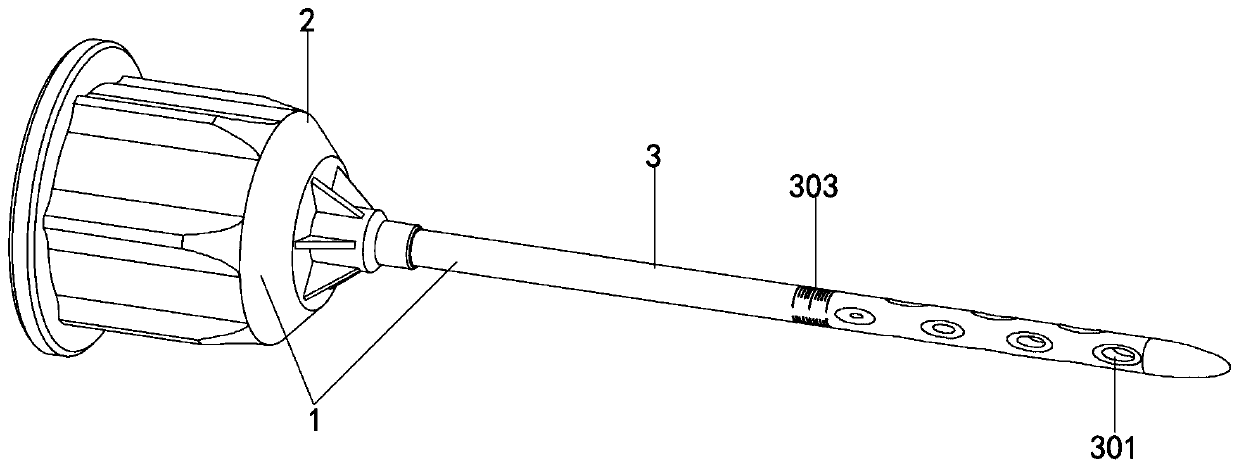

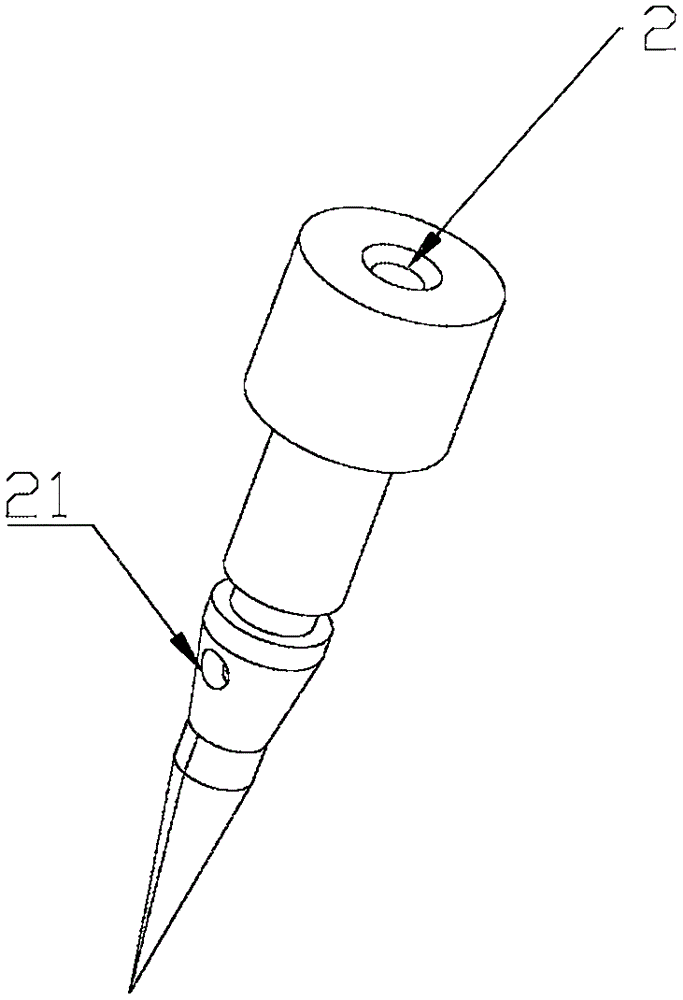

Ejector pin for coffee machine and coffee machine having same

PendingCN107997598AAvoid easy cloggingPrevent burstBeverage vesselsEngineeringBiomedical engineering

The invention discloses an ejector pin for a coffee machine and the coffee machine having the same. The ejector pin for the coffee machine comprises an ejector pin body and a step. A flow passage is arranged in the ejector pin body and provided with an inlet and an outlet. The step is arranged on the ejector pin body and provided with a capsule support surface. At least a part of the outlet is located below the capsule support surface. The ejector pin for the coffee machine has the advantages that the ejector pin is not easily clogged and can avoid bursting of coffee capsules and overflowing of a coffee liquid out of the top.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG

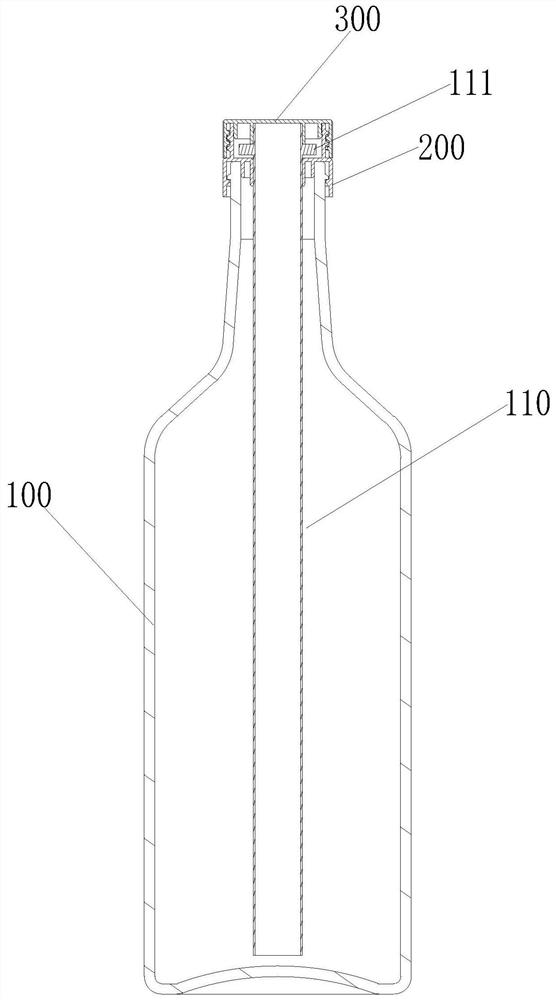

Container convenient for pouring

PendingCN114275312AEasy to pourQuantitative pourCapsDispensing apparatusStructural engineeringIndustrial engineering

An opening of a container body is connected with a base, the container body or the base is connected with a pipeline which can movably stretch out and draw back relative to the container body and is used for liquid outlet and air inlet, and the upper portion and the lower portion of the pipeline are open. The lower portion of the pipeline extends into an inner cavity of the container body, a lower opening of the pipeline is communicated with the inner cavity of the container body, the upper portion of the pipeline penetrates through the base, an upper opening of the pipeline is communicated with the outside, and the base or the upper portion of the pipeline is detachably connected with an upper cover covering the upper opening of the pipeline. During use, a user acts to open the upper cover, the pipeline upper opening can be opened, then the container body is inclined, liquid in the inner cavity of the container body passes through the pipeline lower opening and the pipeline inner cavity and is finally poured out from the pipeline upper opening, and meanwhile external air passes through the pipeline upper opening and the pipeline inner cavity and enters the inner cavity of the container body from the pipeline lower opening. Therefore, the device has the characteristics of simple structure, smooth liquid discharge and convenience in use, and also has a quantitative pouring function.

Owner:李红彪

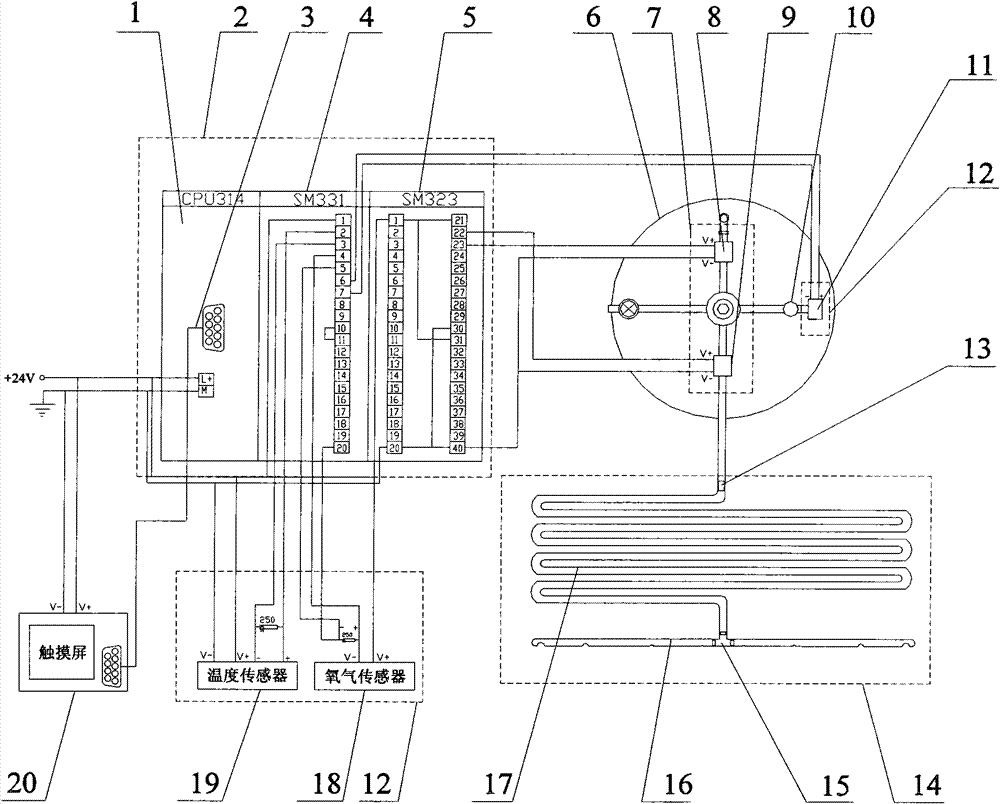

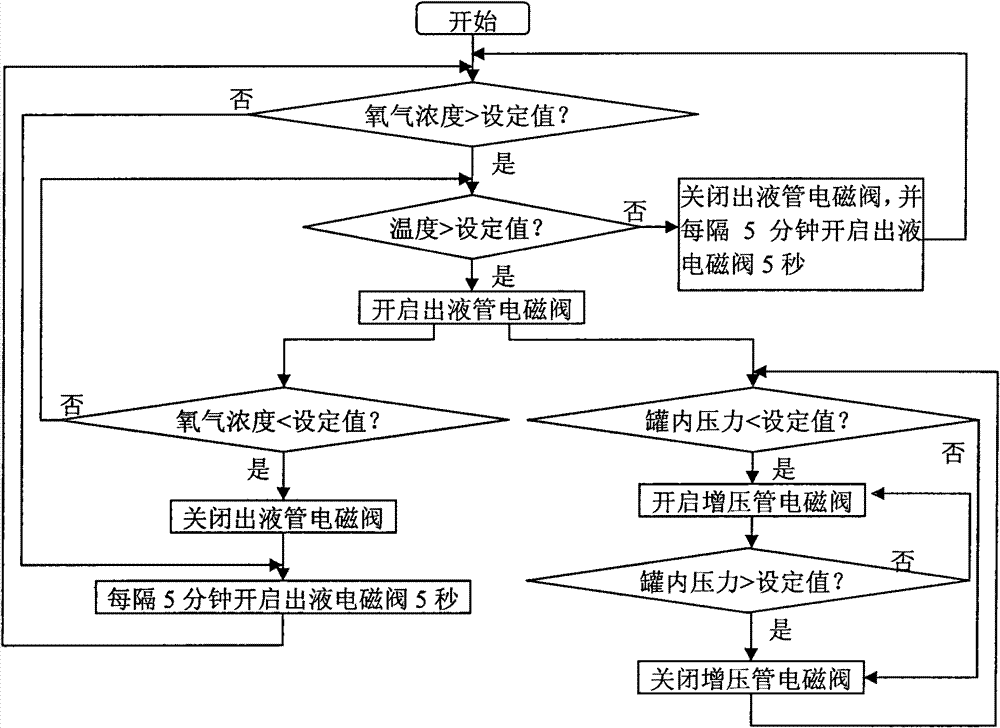

Air conditioning system for fresh-keeping transportation of fruits and vegetables and implementation method thereof

ActiveCN101941561BThe effect of modified atmosphere is fastFreshness and fast transportationLarge containersPackaging under vacuum/special atmosphereEngineeringAir conditioning

The invention discloses an air conditioning system for fresh-keeping transportation of fruits and vegetables, which comprises a liquid nitrogen tank, a liquid nitrogen flow control mechanism, a vaporization device, a signal acquisition module, a human-machine interactive interface and an ECU. The invention also discloses an implementation method for the air conditioning system for the fresh-keeping transportation of the fruits and vegetables, which comprises the following steps of: acquiring signals of a temperature sensor, an oxygen sensor and a pressure sensor; if the monitored oxygen concentration is higher than a set value and the temperature is higher than a set value, starting a liquid outlet pipe electromagnetic valve of the liquid nitrogen flow control mechanism; if the oxygen concentration is higher than the set value or the temperature is lower than or equal to the set value, closing the liquid outlet pipe electromagnetic valve of the liquid nitrogen flow control mechanism; and if the monitored oxygen concentration is lower than or equal to the set value and the monitored temperature is higher than the set value, closing the liquid outlet pipe electromagnetic valve of the liquid nitrogen flow control mechanism. The system and the method have the advantages of high oxygen reducing speed, benefit for balance of temperature field, high intellectualization degree, good fresh-keeping effect, system safety and reliability, high accuracy, good stability and the like.

Owner:SOUTH CHINA AGRI UNIV

Telescopic side-tearing cover assembly

PendingCN110482009AImprove sealingFluid dischargeSealingClosures to prevent refillingEngineeringMechanical engineering

The invention discloses a telescopic side-tearing cover assembly. The cover assembly comprises a base and an upper cover; and a user acts on the upper cover to enable a rod piece to move relative to aliquid outlet column, so that a liquid outlet of the rod piece communicates with a liquid outlet sleeve, and the liquid outlet sleeve is aligned to a liquid outlet window to enable an inner cavity ofa container body to communicate with the outside, and at the moment, the user can pour substances injected in the inner cavity of the container body out of the liquid outlet sleeve. Therefore, the telescopic side-tearing cover assembly is characterized by being good in sealing performance, smooth in liquid outlet and convenient to operate; and the substances in the inner cavity of the container body can be poured out without separating the upper cover from the base, so that the cover assembly is clean and sanitary.

Owner:ZHONGSHAN HUABAOLE DAILY NECESSITIES IND CO LTD

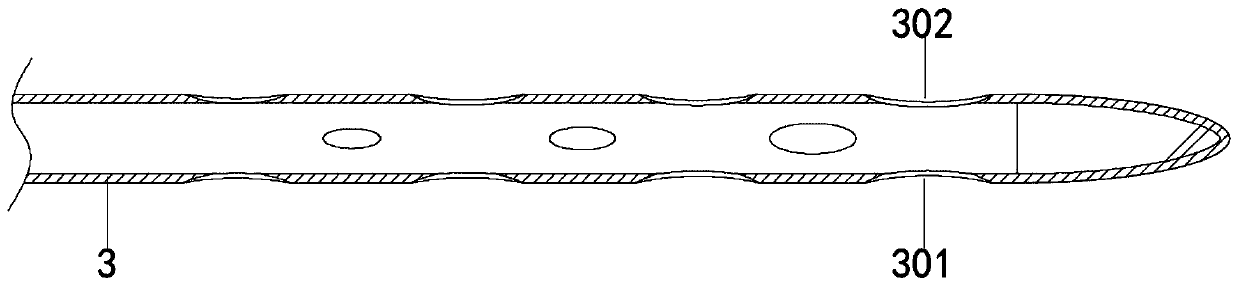

Liquid layering stripping wrinkle-removing technology based on blunt needle

InactiveCN110755739AIncrease active areaFluid dischargeSurgeryMedical devicesLiquid layerBlunt needle

The invention provides a liquid layering stripping wrinkle-removing technology based on a blunt needle. The liquid layering stripping wrinkle-removing technology comprises a body, a needle base and aneedle body. The body is composed of the needle base and the needle body, and the tail end of the needle body and the needle base are fixed in a hot melting mode. A first liquid outlet hole and a second liquid outlet hole are formed at the side wall of the front side of the needle body, and the first liquid outlet hole and the second liquid outlet hole are in bilateral symmetry. The invention relates to an improvement of the liquid layering stripping wrinkle-removing technology based on the blunt needle. The needle body is provided with a plurality of dosing points, multi-point administrationis achieved, the skin activation area is increased, the blunt needle has the advantages of being smooth in liquid outlet, good in injection effect, small in puncture resistance and small in wound, andthe problems and defects that according to an existing blunt needle for liquid layering stripping wrinkle removal, only one liquid outlet hole is laterally formed in the end of the needle body, the number of administration points is small during one-time puncture, and the skin activation area is small are solved.

Owner:王枫

Liquid outlet massager

The invention discloses a liquid outlet massager which comprises a liquid storage assembly and a toothed plate. The toothed plate is connected with the liquid storage assembly to form at least one liquid storage cavity, a plurality of liquid outlet teeth are arranged on the toothed plate and are soft teeth, at least one liquid outlet hole is formed in the tips of each liquid outlet tooth and communicated with the liquid storage cavity, and after the liquid outlet teeth are pressed, liquid can be discharged from the liquid outlet holes. By slightly pressing the liquid outlet massager, the heads(namely the tips) of the liquid outlet teeth make contact with the skin, the liquid outlet teeth deform through external force in the massage process to enable the internal pressure intensity to be smaller than the atmospheric pressure to discharge liquid, the massage effect can be achieved while care liquid is guided out, and when the soft tooth structures are used for massaging by contact, thephenomena of pain, hair pinching or skin scratching are avoided. Compared with an existing high-hardness hardware liquid outlet massager or a liquid outlet massager needing pump pressure, the liquid outlet massager has the advantages of being smooth in liquid outlet, high in comfort level, simple in structure, low in machining process requirement and the like, and the production cost is effectively reduced.

Owner:深圳市景美瑞科技股份有限公司

Gas-liquid assembly of beauty spray gun

Disclosed is a gas-liquid assembly of a beauty spray gun. The gas-liquid assembly of the beauty spray gun comprises a shell, a spray needle and a spray nozzle, wherein a spray head seat with a through hole in the middle is arranged in the shell; one end of the spray head seat is connected with a gas pump, and the other end of the spray head seat is connected with the spray nozzle; an inner cavity of the spray head seat is provided with a pipeline which is coaxial with the through hole; one end of the pipeline is closed, and the other end of the pipeline is open. A liquid inlet pipeline is arranged at the lower end of the spray head seat, the rear end of the spray head seat is connected with the gas pump, and the inner cavity of the spray head seat is provided with the pipeline with one end closed so that a liquid inlet channel and a gas inlet channel which are relatively independent can be formed; the two ends of the liquid inlet channel are directly connected with a solution device and the spray nozzle, so that the phenomenon that the solution flows back into a gun body is absent, maintaining and cleaning of the spray gun are facilitated, and the service life of the spray gun is prolonged. Meanwhile, a gas-liquid adjusting device of the spray gun is moved outwards to the spray nozzle, so that the length of the spray needle is effectively reduced, and the effect of reducing production cost is achieved. The gas-liquid assembly of the beauty spray gun is reasonable in design and suitable for being massively popularized.

Owner:NINGBO CHUANGJIA IND DESIGN

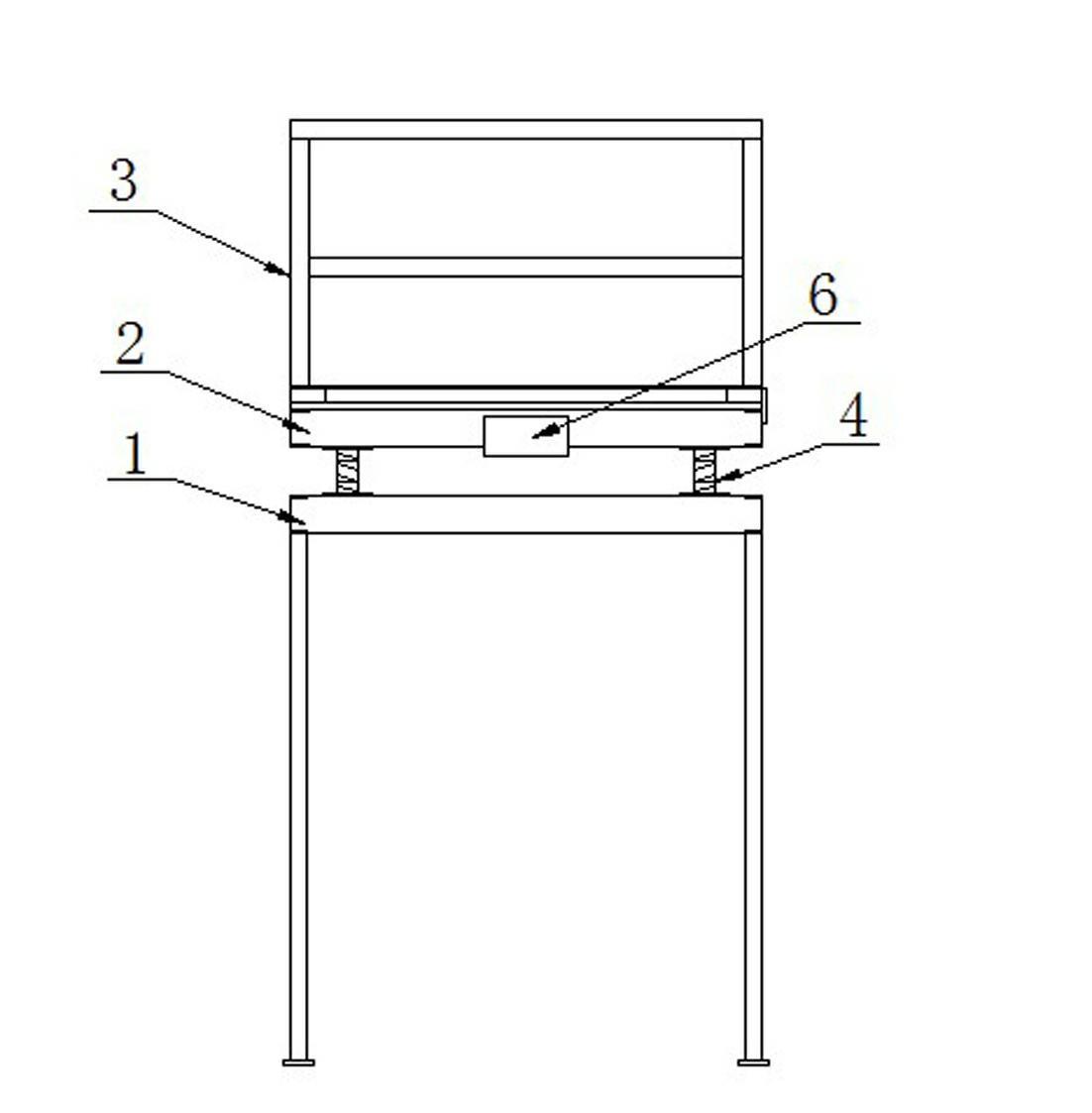

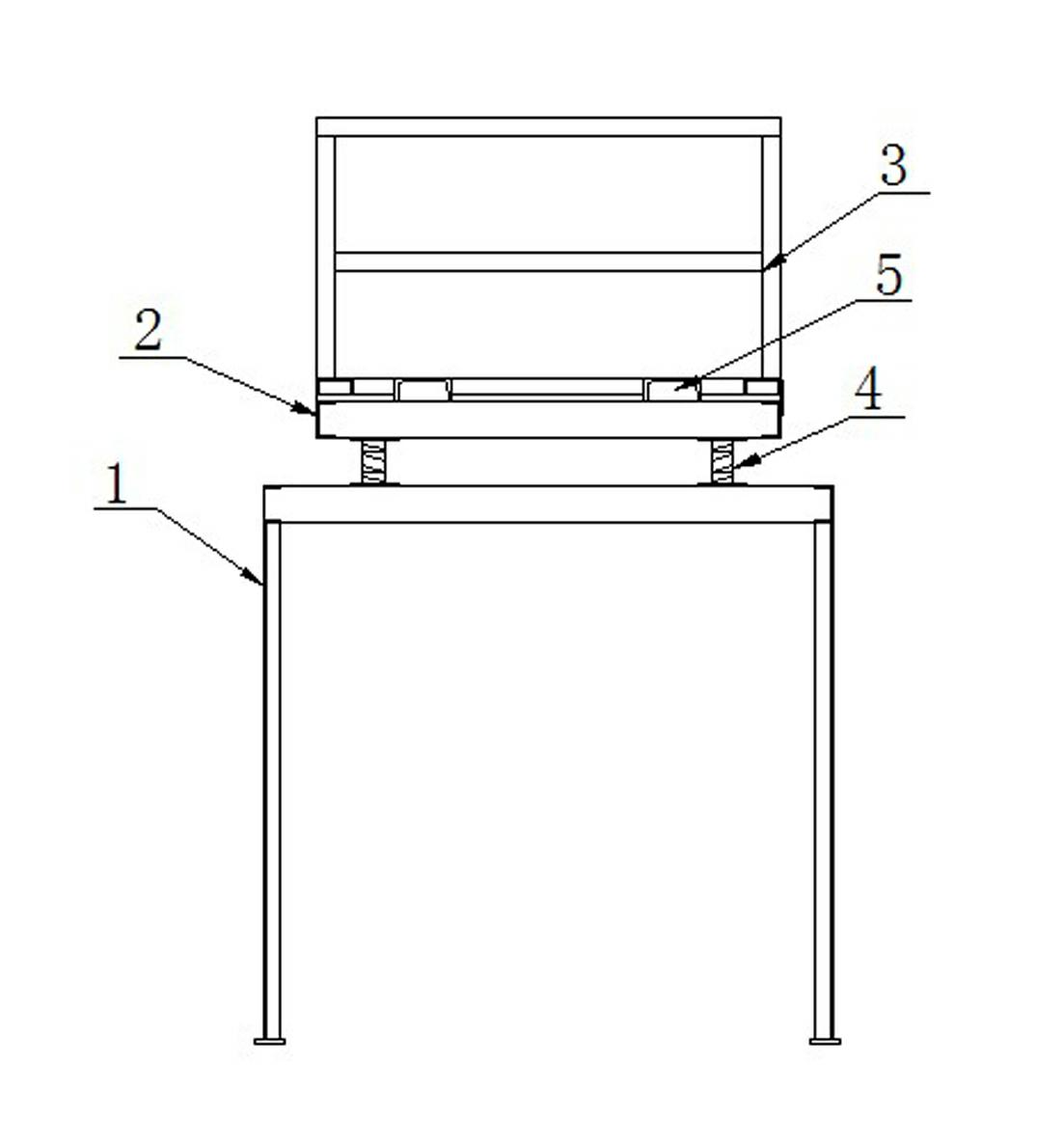

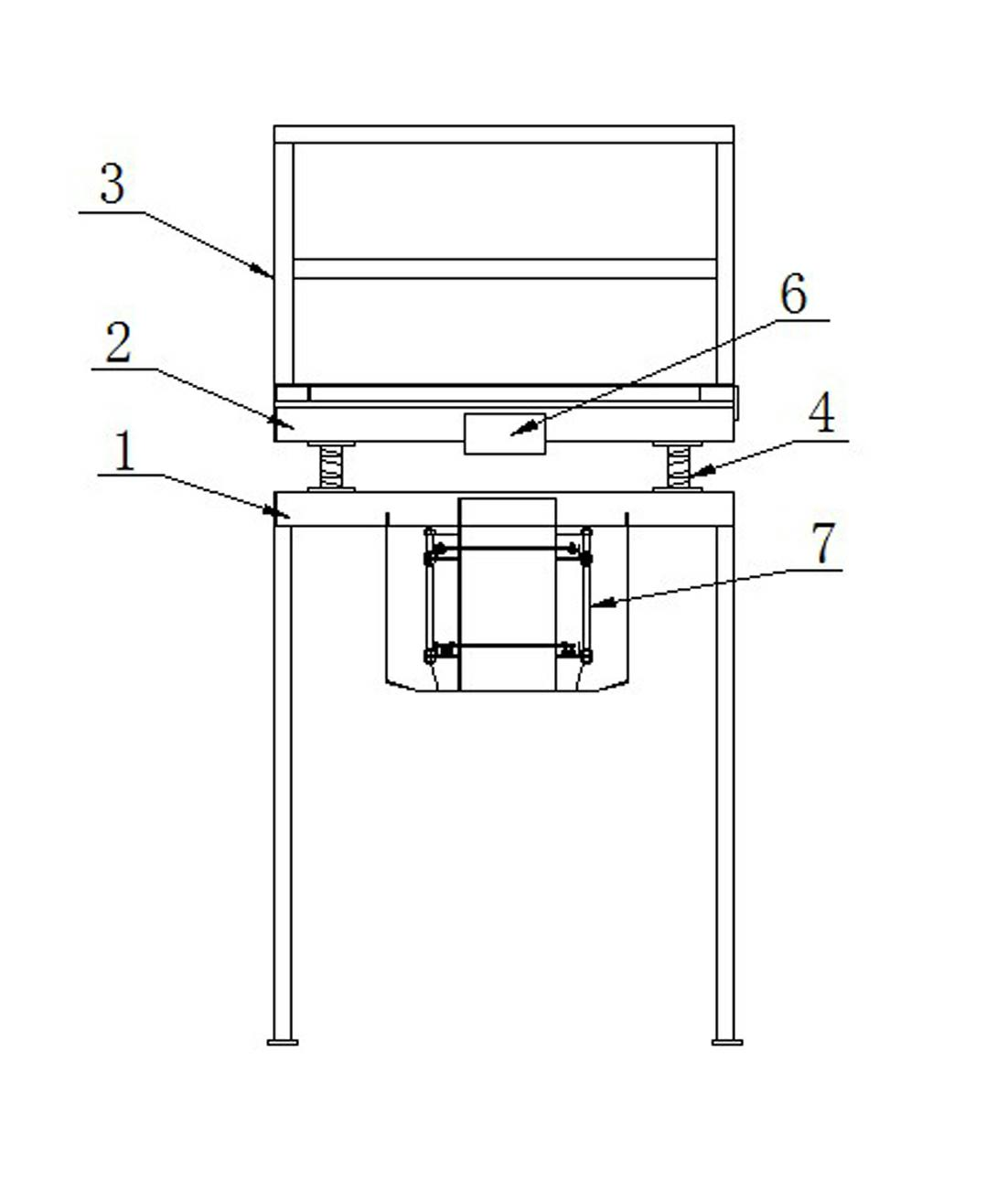

Multi-purpose functional material package bracket

InactiveCN102689737AImprove leakageKeep standingExternal framesWater/sewage treatment by sorptionActivated carbonEngineering

The invention discloses a multi-purpose functional material package bracket, which mainly comprises a supporting base frame, a supporting frame and a material package framework, wherein the supporting frame is connected with the supporting base frame through an elastic buffering device; a carrying structure is arranged on the material package framework; a material package with powdered active carbon is arranged in the material package framework; the material package framework is arranged on the supporting frame through carrying equipment, so that aims of supporting the material package and lifting the material package are fulfilled, and the material package can discharge materials conveniently; a vibrator is arranged on the supporting frame, so that the active carbon powder can be discharged from the material package smoothly; due to the material package framework, the material package can be put into the material package framework from the upper side and the side edge; four corners of the material package can be fixed on the material package framework, so that the material package is in a standing state; the supporting base frame can be used for fixing a material feeding device; and when the supporting base frame is liftable, the supporting frame, the material package framework arranged above the supporting frame and the material package in the material package framework have high levels and low levels, so that the material package can be connected with the material feeding device and can discharge the materials conveniently.

Owner:江苏瀚深水业科技发展有限公司

Scrap discharging elbow with scrap guiding, filtering and self-cleaning functions

InactiveCN110293436APrevent accumulation and stagnationReduce wasteMaintainance and safety accessoriesFiltrationMachine tool

The invention relates to a scrap discharging elbow with scrap guiding, filtering and self-cleaning functions. The scrap discharging elbow with the scrap guiding, filtering and self-cleaning functionscomprises an elbow main body and a scrap outlet; one end of the elbow main body is connected with a scrap discharging elbow in a machine tool; the other end of the elbow main body is a scrap outlet which is opened upwards; a push screw rod is arranged in the scrap discharging groove in the machine tool; a filtering guide cover plate is arranged on the connecting part of the elbow main body and thescrap discharging groove in the machine tool; the filtering guide cover plate and the elbow main body form a rotating space of the push screw rod; the filtering guide cover plate comprises a connecting part at the top and a filtering guide part at the bottom; the connecting part and the elbow main body are connected together; the filtering guide part is a cover which is formed by splicing a cambered surface and a polygon to surround the push screw rod; a first strip-shaped hole is formed in the cover, can realize primary filtration on cutting liquid and also can generate guide effect on the scraps; an overflow type liquid outlet is formed in the side surface of the elbow main body; and a filtering baffle is arranged at the overflow type liquid outlet. The scrap discharging elbow providedby the invention is reasonable in structure, can discharge the scraps smoothly and output liquid cleanly, and greatly improves the on-site operation environment.

Owner:西安精雕软件科技有限公司

Valve body capable of discharging small particles and liquid outlet device provided with valve body

InactiveCN109027312AAvoid cloggingSmooth dischargeOperating means/releasing devices for valvesMultiple way valvesSolenoid valveEngineering

The invention discloses a valve body capable of discharging small particles and a liquid outlet device provided with the valve body. The valve body comprises an upper cover, an upper valve element, alower valve element, a shell and a motor. A first opening and a second opening are formed in the upper cover, a first hole communicating with the first opening and a second hole communicating with thesecond opening are formed in the upper valve element, and a water guide groove which can conduct or close the first hole and the second hole is formed in the lower valve element. The upper valve element and the lower valve element are attached together and assembled in the shell, the upper cover covers the shell, and the lower valve element is rotatably connected with the motor. The motor drivesthe lower valve element to rotate, and the water guide groove conduct or close the first hole and the second hole. The hole diameter of the first and second holes is greater than or equal to 2mm. Withthe structure, the hole diameter of the first and second holes of the valve body is greater than or equal to 2mm, the hole diameter of the first hole and the second hole is greater than that of a valve hole on an existing solenoid valve, the thick liquid containing the small particles, small powder or residues can be discharged smoothly, and the valve body is effectively prevented from being blocked.

Owner:白斌将

Multifunctional container

A left liquid outlet nozzle capable of communicating or isolating a left liquid outlet window from an inner cavity of a container body is rotatably connected to the inner side wall of an upper cover, and a left balancing weight capable of rotating the left liquid outlet nozzle to block the left liquid outlet window when the container body is vertically placed is arranged at the inner end of the left liquid outlet nozzle; the inner side wall of the upper cover is further rotationally connected with a right liquid outlet nozzle capable of communicating or isolating the right liquid outlet window and the inner cavity of the container body, and the inner end of the right liquid outlet nozzle is provided with a right balancing weight capable of enabling the right liquid outlet nozzle to rotate to block the right liquid outlet window when the container body is vertically placed. When the container body inclines towards one side of the left liquid outlet window to pour substances, the left liquid outlet window is communicated with the inner cavity of the container body through the left liquid outlet nozzle to form a liquid outlet passage, and the right liquid outlet window is communicated with the inner cavity of the container body through the right liquid outlet nozzle to form an air inlet passage; therefore, the invention has the advantages of repeated sealing, safety, sanitation, convenience in pouring and smooth liquid discharge.

Owner:李红彪

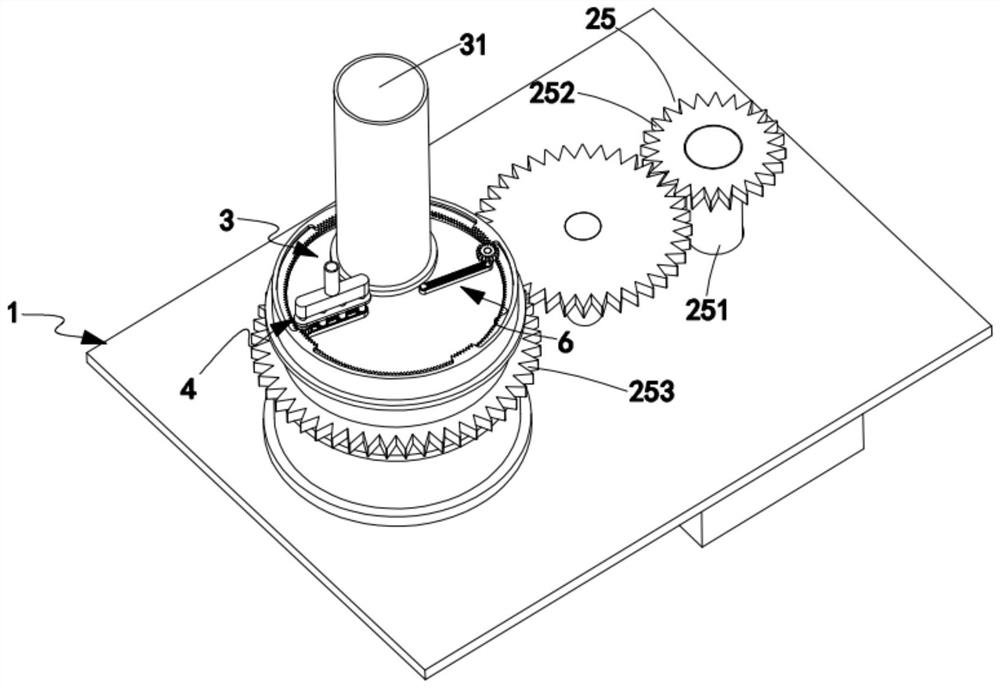

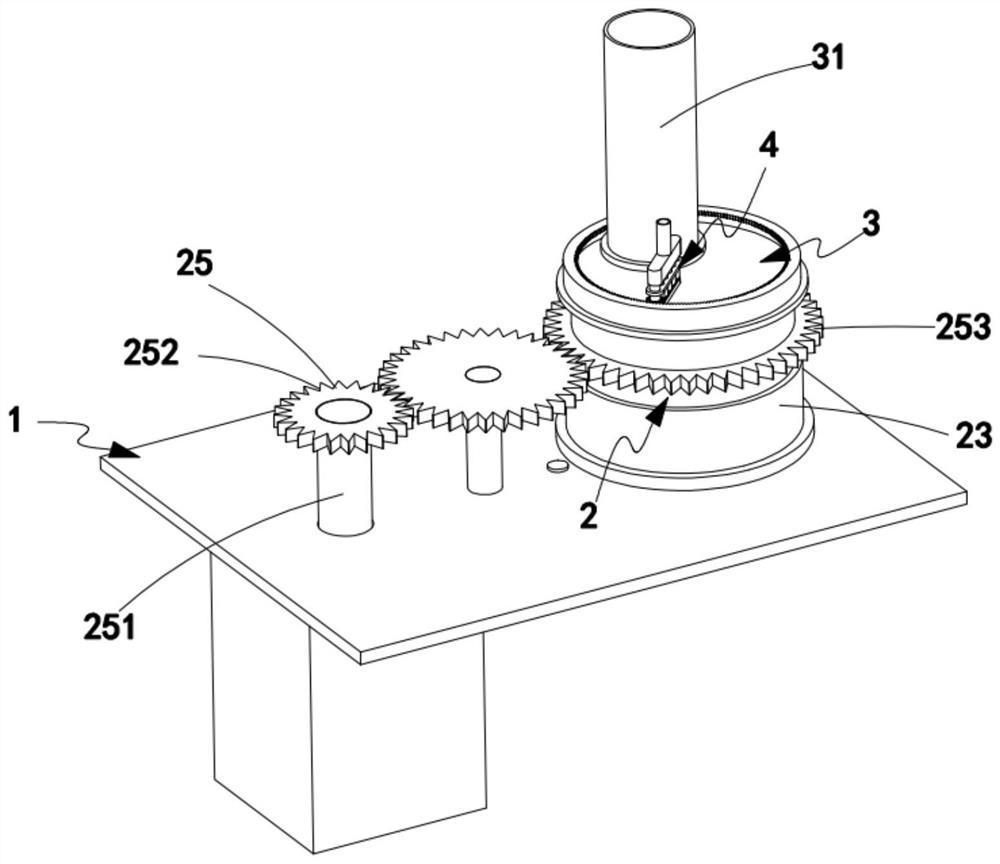

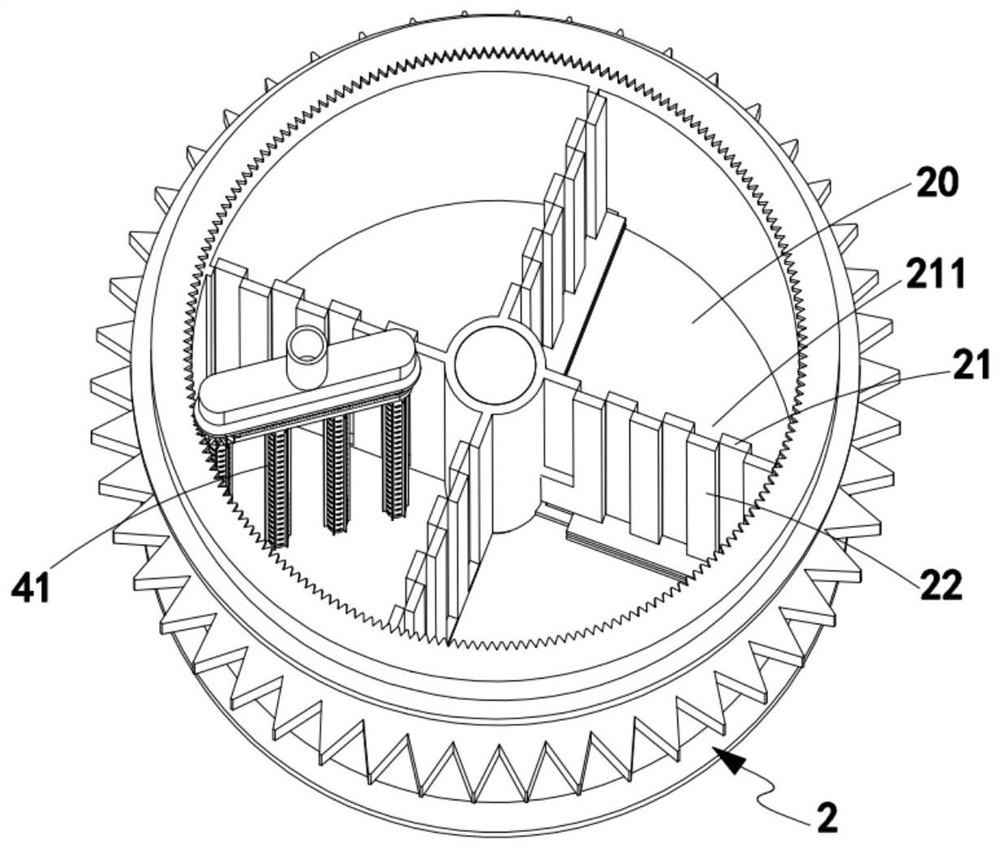

Rapid shunting and distributing mechanism

InactiveCN112587973AAvoid condensationTroubleshoot technical problemsFiltration separationFilter pressControl theory

The invention provides a circulating type rapid multi-stage filter pressing and distributing mechanism which comprises a mounting plate, a distributing assembly and a dividing assembly; the distributing assembly is arranged at a feeding port, the distributing assembly is mounted above the mounting plate, and the distributing assembly comprises a distributing cylinder unit, a liquid adding unit anda driving unit; a plurality of distributing areas are arranged in the distributing cylinder unit; the distributing areas are rotationally switched and pass through the feeding port one by one; the feeding unit is mounted on the distributing cylinder unit; the liquid adding unit is used for adding liquid to filter residues in the distributing areas from inside to outside; the driving unit is arranged on one side of the distributing cylinder unit, and the driving unit synchronously drives the distributing cylinder unit and the liquid adding unit to operate; the filter residues subjected to filter pressing are conveyed in batches by utilizing the distribution cylinder unit in the distributing assembly, and moisture is input into the filter residues in the conveying process, so that the filter residues are wetted from inside to outside, the surface layers of the filter residues are prevented from being condensed into balls, and the technical problem that the filter residues cannot be efficiently purified due to condensation into balls is solved.

Owner:张克军

A normal surface funnel reservoir sediment discharge device

The invention discloses a sand discharge device for a reservoir based on a normal curved funnel, which belongs to the technical field of water conservancy engineering. The device includes a sand inlet funnel and a sand delivery pipeline; The pipeline is laid on the river bed of the reservoir, the bottom of the sand inlet funnel is connected to one end of the sand delivery pipeline, and the other end of the sand delivery pipeline passes through the bottom of the dam; the shape of the sand inlet funnel is a bivariate normal curved surface , the shape of the sand transport pipeline is an inverse hyperbolic tangent curve, and a valve is arranged on the sand transport pipeline. When the device is in operation, the valve on the sand delivery pipeline is opened, and under the action of water pressure in the reservoir, the water flow carries the sediment through the sand discharge pipeline and is discharged into the downstream of the reservoir. The normal surface shape of the sand inlet funnel and the hyperbolic tangent shape of the sand delivery pipeline can effectively solve the problem of easy silting in the sand inlet and pipeline, and significantly improve the sand discharge efficiency.

Owner:ZHEJIANG UNIV

Taking device convenient for taking liquid from container

The taking device comprises a base used for being connected with an opening of the container and a liquid pumping device capable of being movably arranged relative to the base, and the liquid pumping device comprises a liquid pumping cylinder with the lower end sealed and the upper end open and a movable plug movably and telescopically connected to the liquid pumping cylinder. The lower end of the liquid pumping cylinder is communicated with a liquid inlet / outlet pipe which is directly or indirectly communicated with the inner cavity of the container, and an auxiliary pumping structure which can act the movable plug to move relative to the liquid pumping cylinder to pump liquid filled in the inner cavity of the container into the liquid pumping cylinder when the liquid pumping device moves relative to the base is arranged between the base and the liquid pumping device. Therefore, the device has the advantages of being simple in structure, smooth in liquid discharging and convenient and fast to use, and meanwhile the quantitative cavity is formed in the inner cavity of the liquid pumping barrel, so that quantitative taking is facilitated.

Owner:李红彪

Container convenient for quantitative taking

PendingCN114275313AEasy to use quantitativelySimple structureDischarging meansEngineeringMechanical engineering

Owner:ZHONGSHAN HUABAOLE DAILY NECESSITIES IND CO LTD

Piston pump exhaust structure

PendingCN107061254AFluid dischargeEasy to usePositive displacement pump componentsLiquid fuel engine componentsHydraulic cylinderEngineering

Provided is a piston pump exhaust structure. A piston pump comprises a hydraulic cylinder, a piston and a liquid inlet one-way valve connected with the hydraulic cylinder. The piston pump further comprises a liquid outlet one-way valve communicating with the hydraulic cylinder; the liquid outlet one-way valve comprises a liquid outlet valve seat, a sealing ring, a needle valve and a spring; the sealing ring, the needle valve and the spring are installed in the liquid outlet valve seat; the sealing ring is installed between the liquid outlet valve seat and the needle valve; the spring is installed on the needle valve; and a liquid outlet is formed in the upper portion of the liquid outlet valve seat. The piston pump exhaust structure has the advantages that discharged liquid does not carry gas, liquid is discharged smoothly, and the use effect is good.

Owner:江西万年芯微电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com