Plate painting device for wood processing

A sheet and wood technology, which is applied in the field of sheet paint coating devices for wood processing, can solve problems such as unevenness, missing spray thickness of the nozzle of the paint body, etc., and achieve the effect of improving continuity and avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

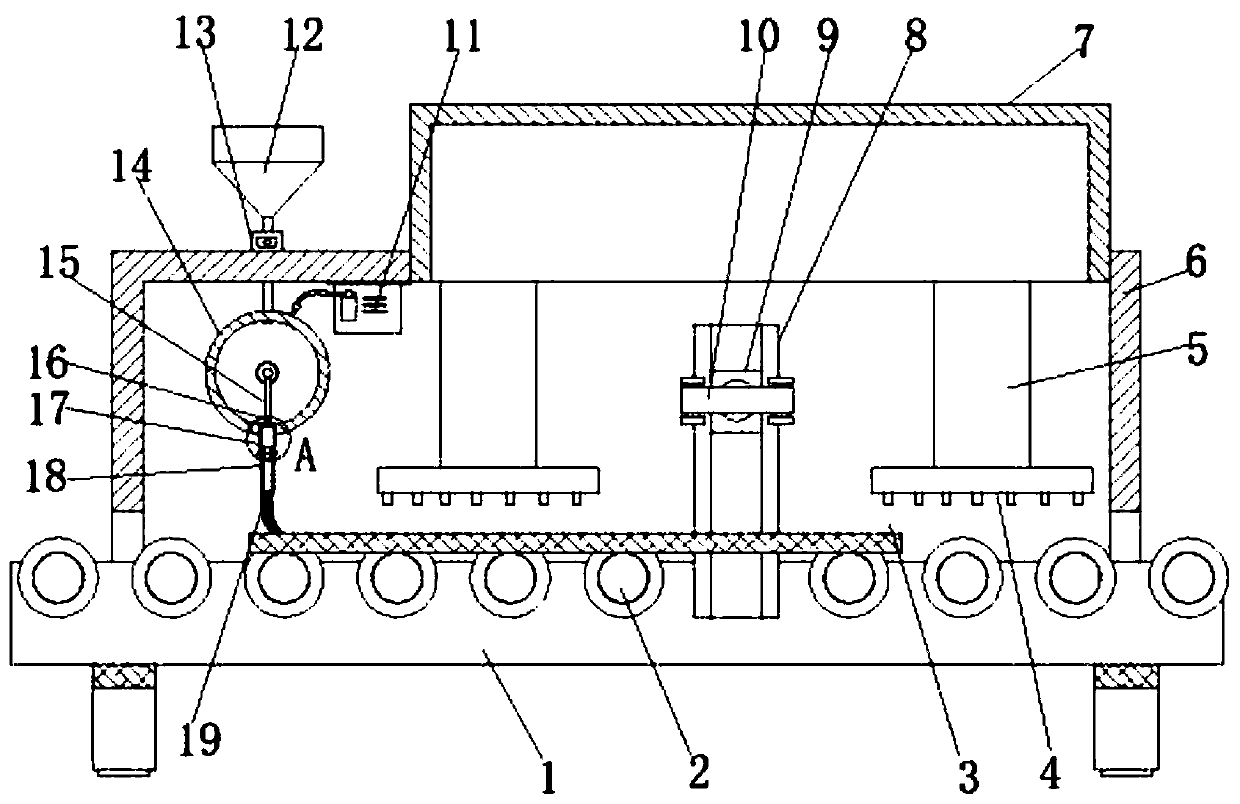

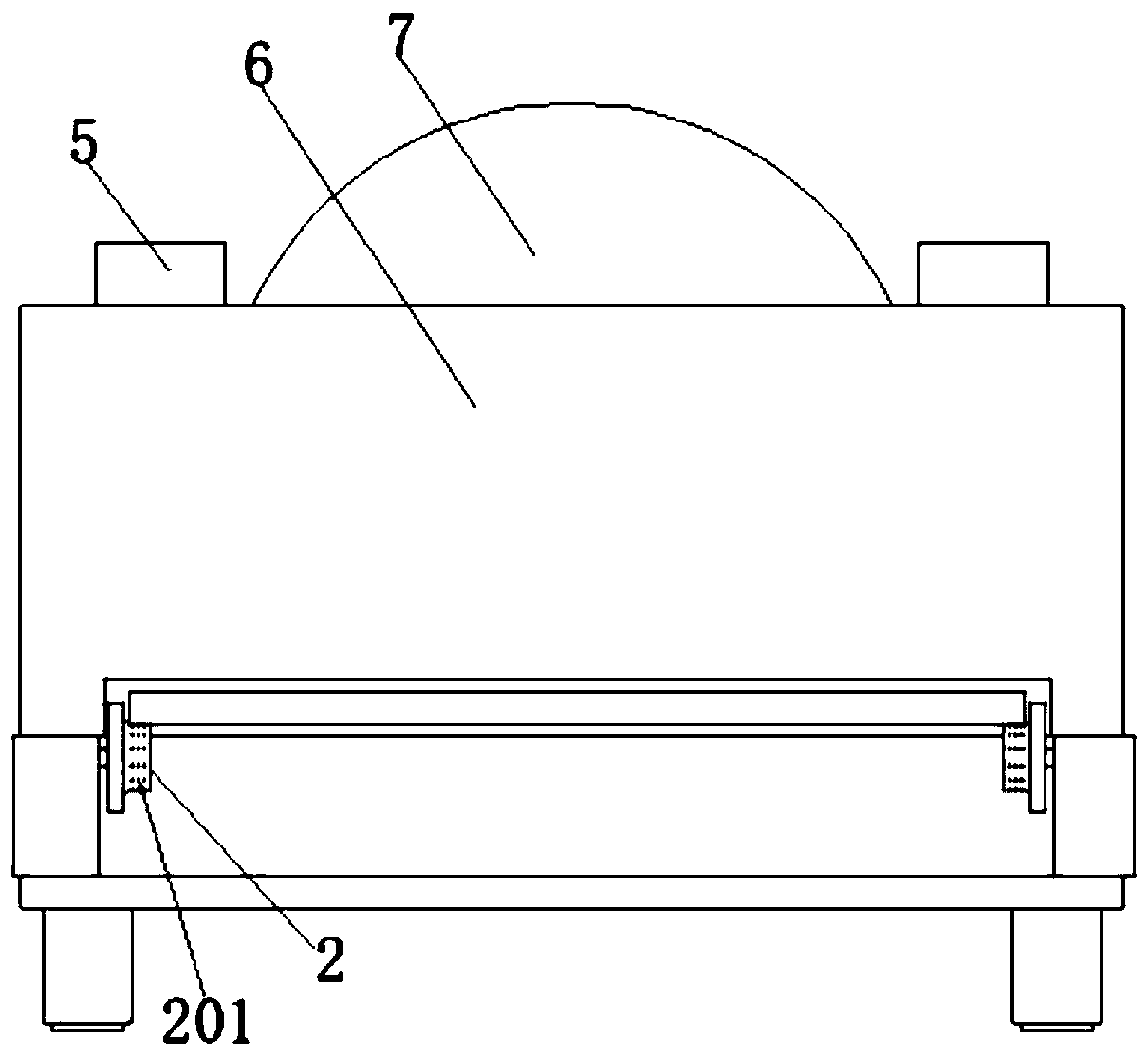

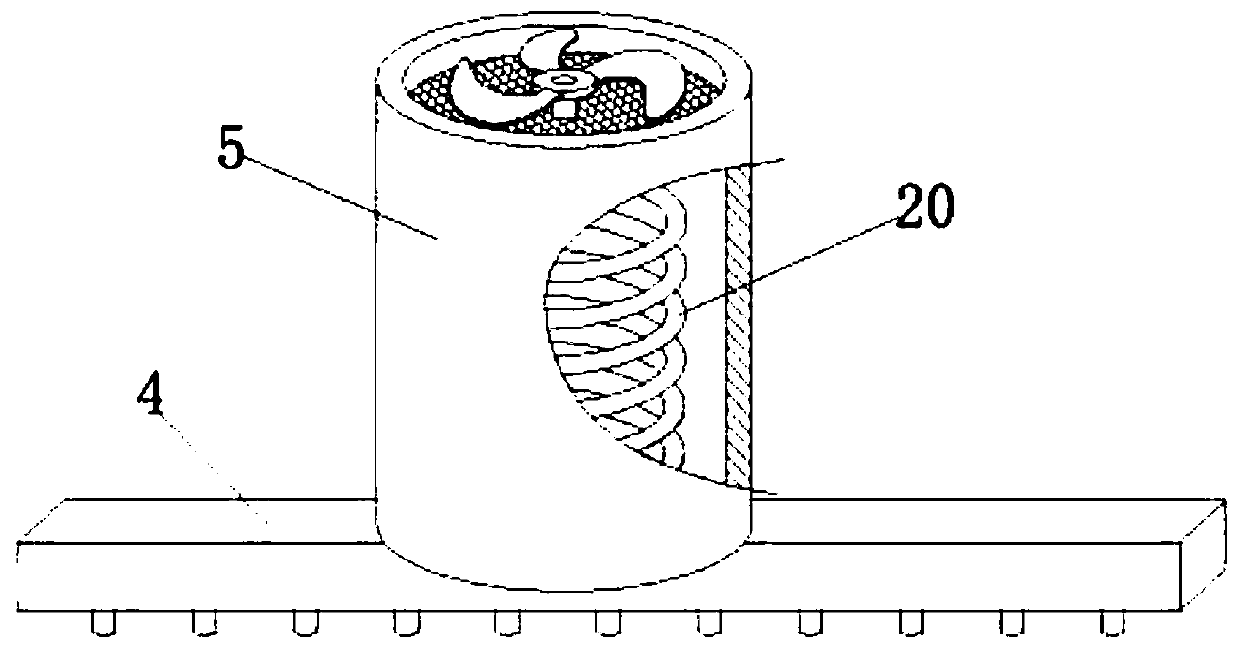

[0032] refer to Figure 1-6 , a kind of sheet metal painting device for wood processing, comprising a transmission frame 1 composed of two mutually parallel bearing plates, a box body 6 is fixed on the top of the transmission frame 1, and a box body 6 is fixed between the inner walls on both sides of the box body 6. A pressure-resistant spray tank 14 with a cylindrical structure with a cavity inside is fixed, and the circumferential outer wall of the pressure-resistant spray tank 14 is plugged with leak pipes 17 distributed equidistantly near the bottom end, and the bottom end of the leak pipe 17 is plugged with a connection Pipe two 25, and the bottom end of the connecting pipe 25 is connected with the same brush plate 18, and the brush plate 18 is a cuboid structure with a flat cavity inside, and the bottom of the brush plate 18 is provided with drain holes distributed equidistantly 22, and the bottom of the brush plate 18 is provided with bristles 19 at the gap between the ...

Embodiment 2

[0042] refer to figure 1 , 5 And 6, a kind of sheet material varnishing device device for wood processing, present embodiment compares embodiment 1, also comprises that the top of brush plate 18 has jack 21, and is inserted in jack 21 and is connected with connecting pipe-24 The outer wall of the connecting pipe 24 is sleeved with a connecting sleeve 23, and the outer wall of the connecting pipe two 25 is welded with an external thread ring suitable for the connecting sleeve 23 near the bottom end, and the bottom end of the connecting pipe two 25 is clamped with a sealing ring.

[0043] Wherein, the outer wall of the connecting sleeve 23 is provided with a toggle lever 28 .

[0044] When in use, the brush plate 18 can be disassembled only by turning the toggle lever 28, which facilitates later maintenance and cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com