Multi-purpose functional material package bracket

A functional and multi-purpose technology, applied in packaging, external frame, transportation and packaging, etc., can solve the problems of high equipment repair and maintenance costs, small dosage, high investment costs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

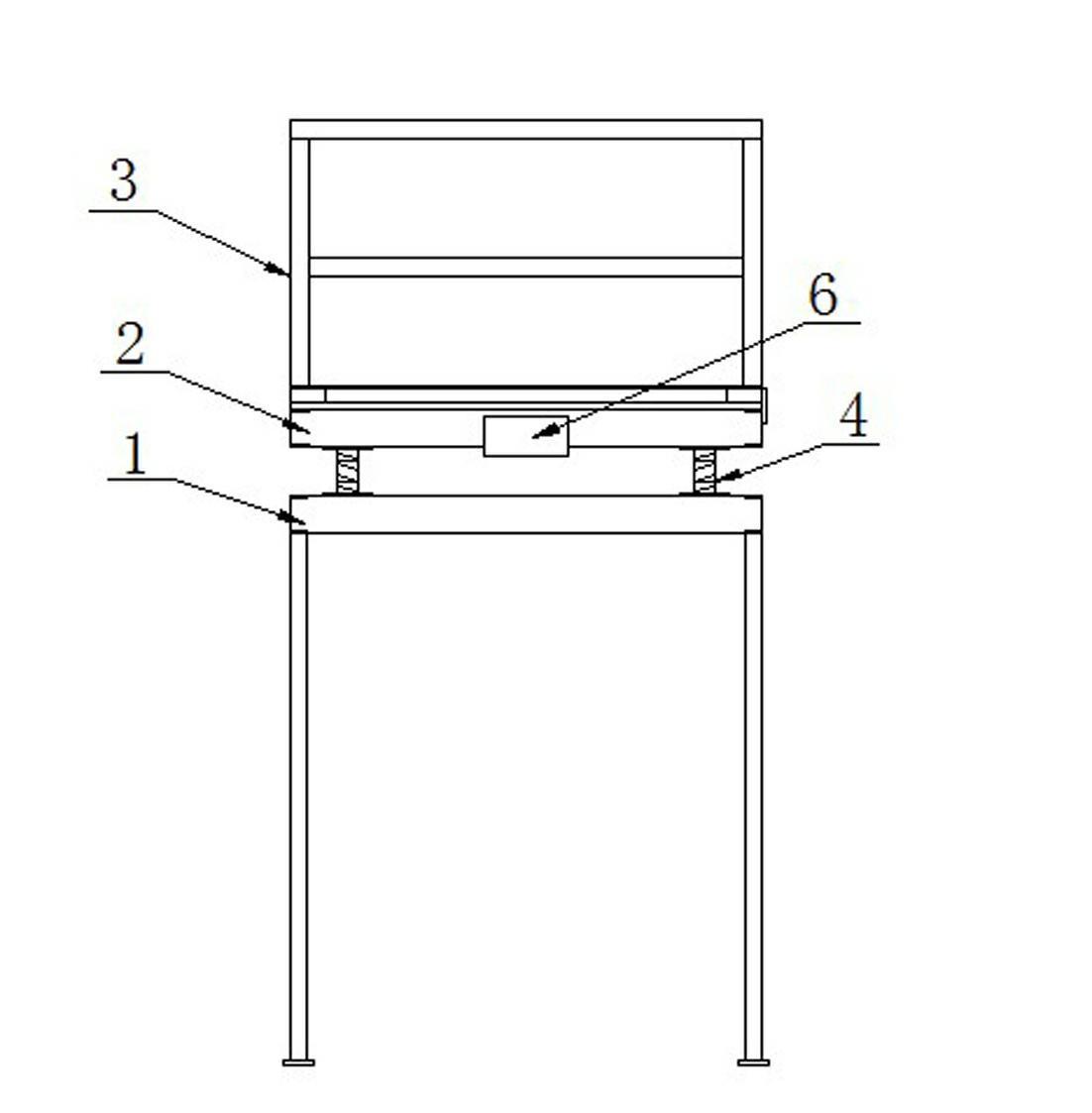

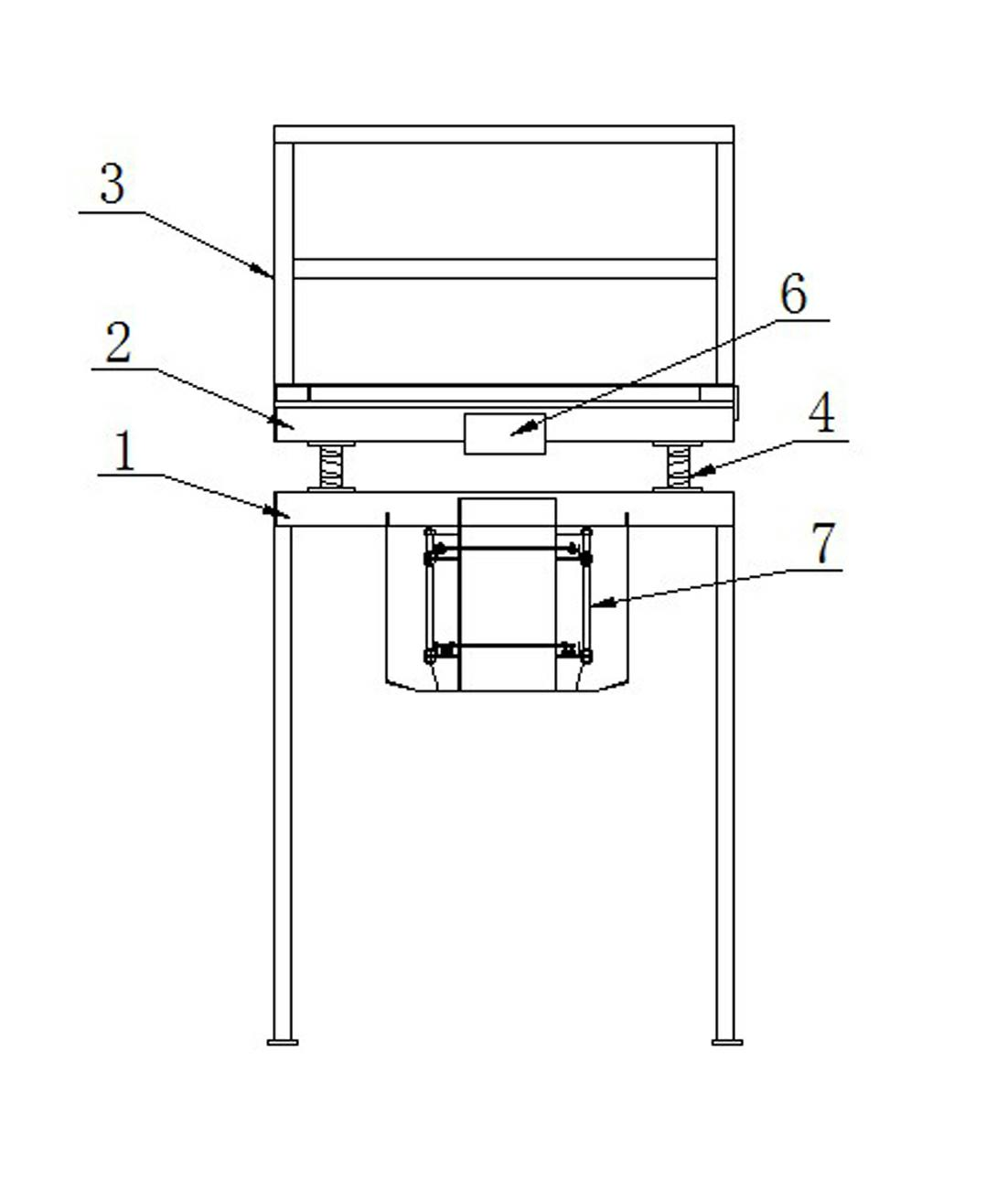

[0025] Embodiment 1: A multi-purpose functional material bag support, including a supporting chassis 1, a bracket 2 and a material bag frame 3, the bracket is located above the supporting chassis, and is provided with an elastic buffer device 4, the The bracket is connected to the supporting chassis through the elastic buffer device, and the bag containing powdered activated carbon is positioned in the bag frame, and the bag frame is provided with a handling structure for moving the bag frame , the bag frame can be placed on the bracket and moved away. Place the material bag containing powdered activated carbon in the material bag frame, and use a forklift, crane or other handling equipment to place the material bag frame on the bracket through the handling structure set on the material bag frame, so as to achieve the support of the material bag. The purpose of lifting the material bag is to facilitate the discharge of the material bag for subsequent equipment such as the feed...

Embodiment 2

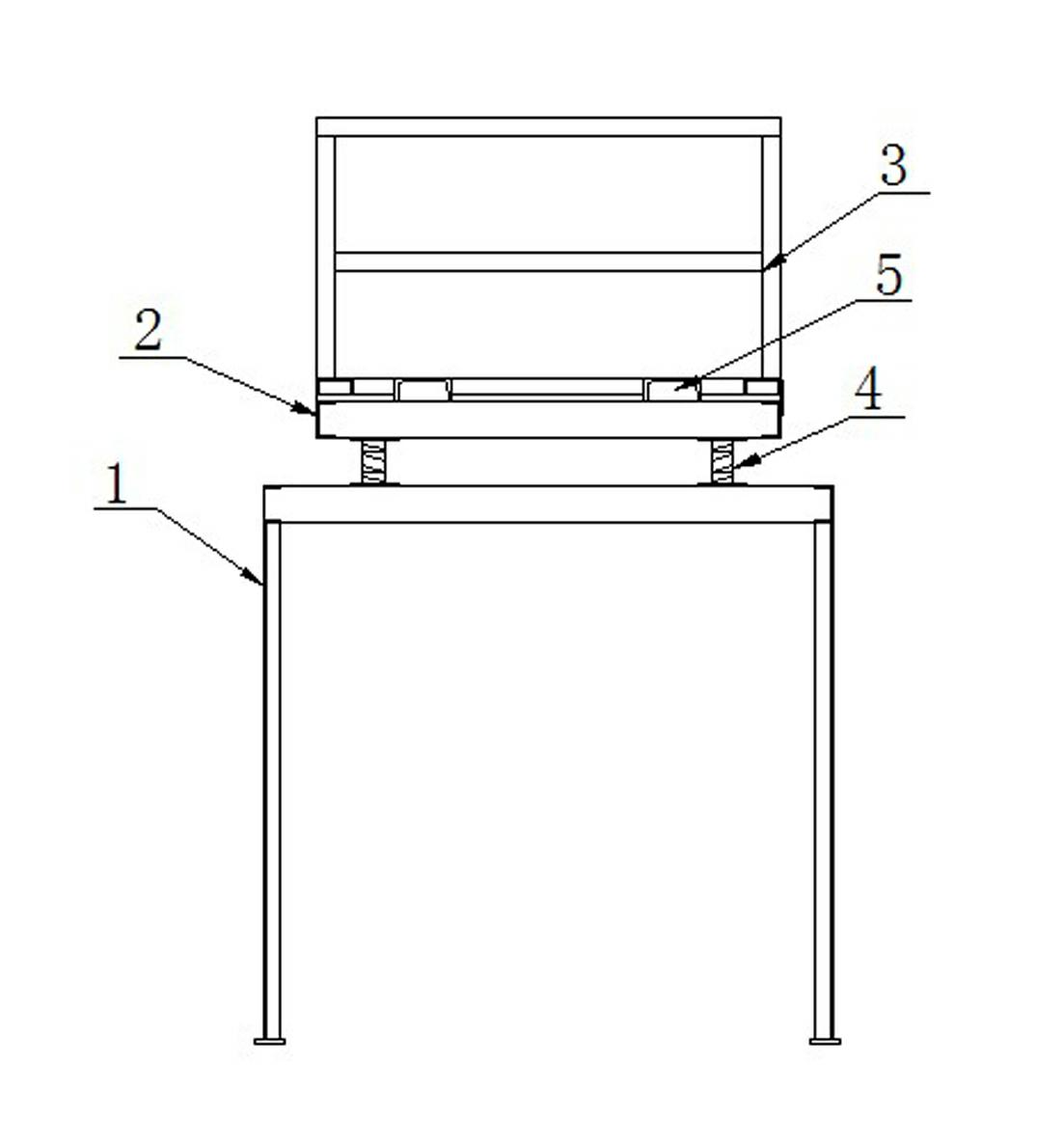

[0032] Embodiment 2: A multi-purpose functional material bag support, including a support base 1, a bracket 2 and a material package frame 3, the bracket is located above the support base, and is provided with an elastic buffer device 4, the The bracket is connected to the supporting chassis through the elastic buffer device, and the bag containing powdered activated carbon is positioned in the bag frame, and the bag frame is provided with a handling structure for moving the bag frame , the bag frame can be placed on the bracket and moved away. Place the material bag containing powdered activated carbon in the material bag frame, and use a forklift, crane or other handling equipment to place the material bag frame on the bracket through the handling structure set on the material bag frame, so as to achieve the support of the material bag. The purpose of lifting the material bag is to facilitate the discharge of the material bag for subsequent equipment such as the feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com