Rapid shunting and distributing mechanism

A material distribution mechanism and fast technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems such as the inability of the filter residue to concentrate and the liquid to flow, and achieve the effect of ensuring cleanliness and avoiding mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

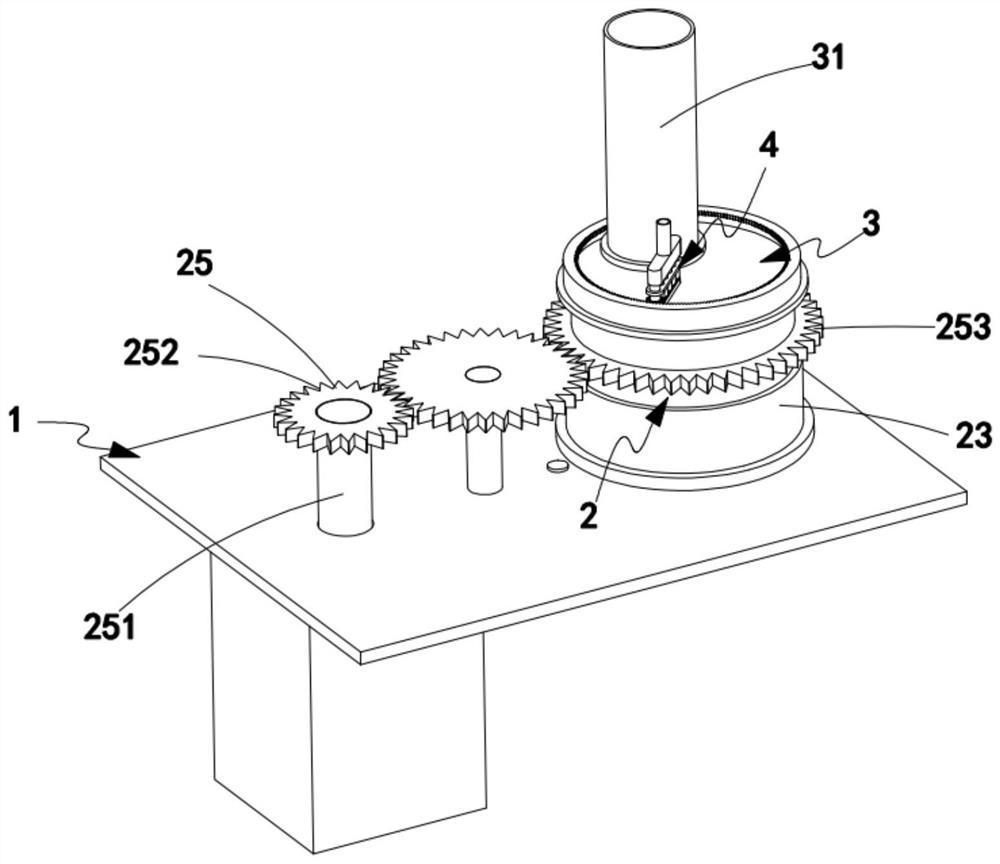

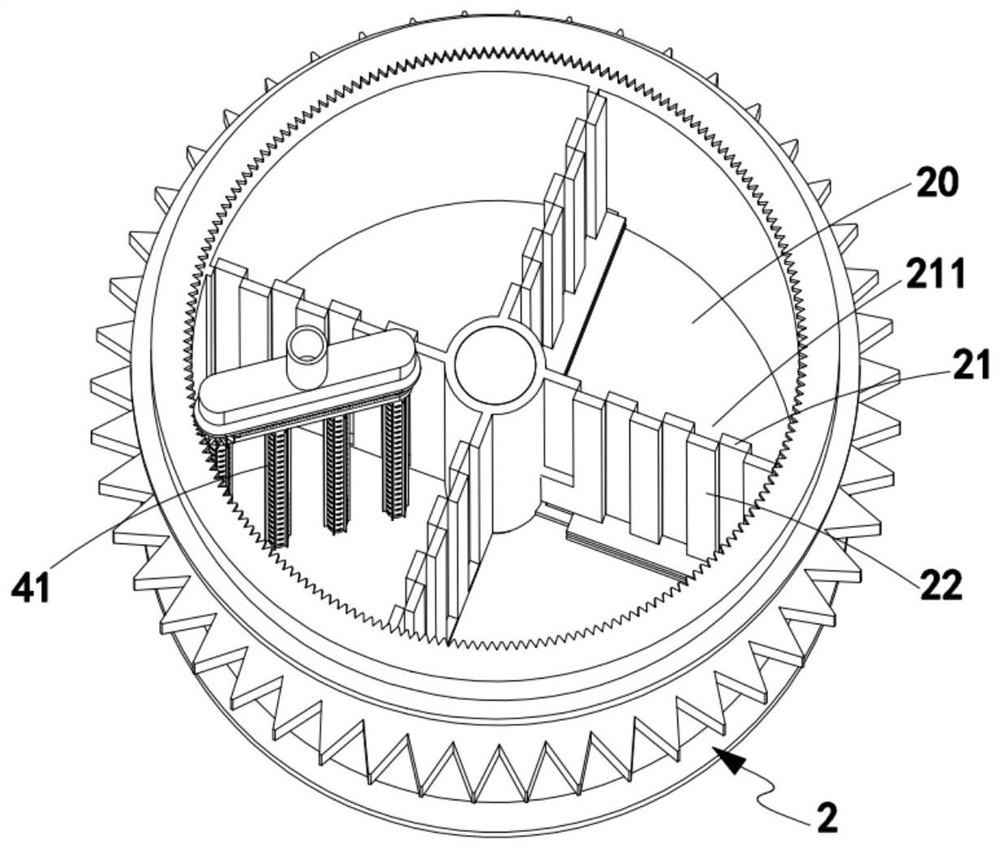

[0060] Such as Figure 1 to Figure 10 Shown, a kind of rapid diversion distribution material mechanism, comprises:

[0061] Mounting plate 1, the mounting plate 1 is arranged on the top of the stirring tank, the mounting plate 1 is provided with a feed port 11 communicating with the inside of the stirring tank;

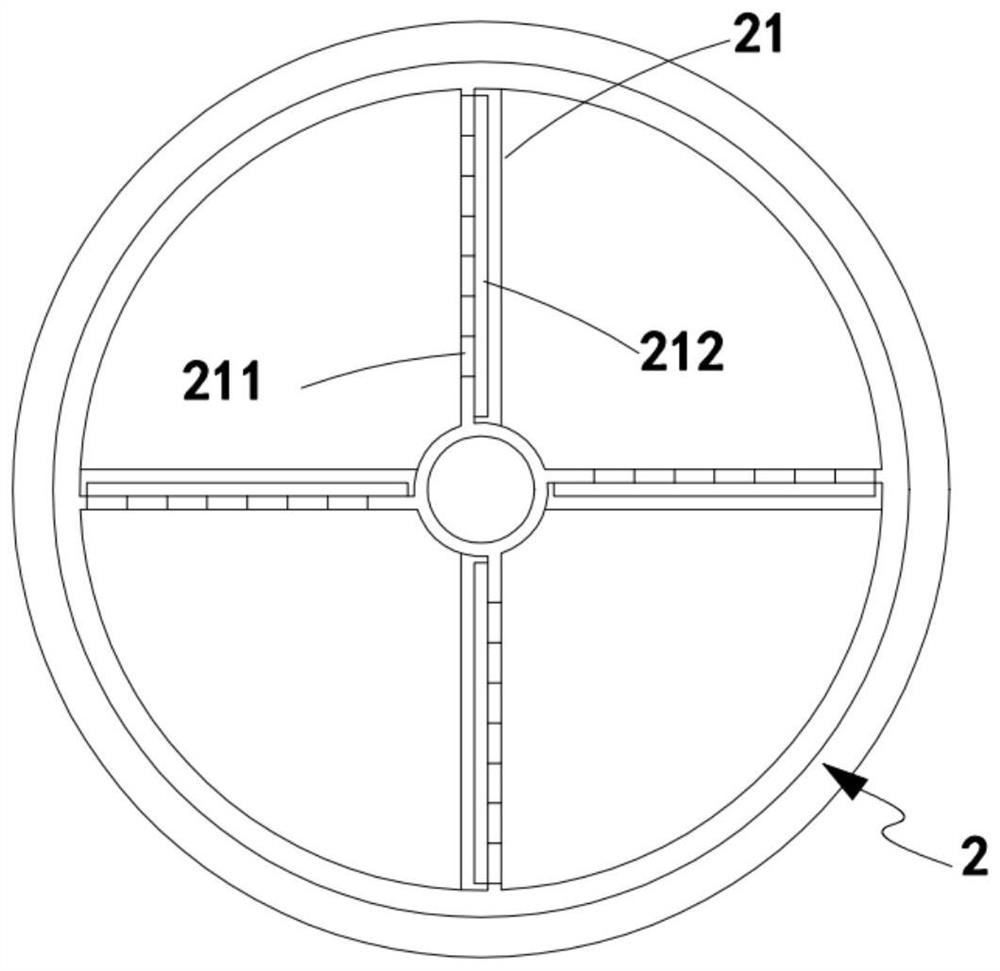

[0062] Distributing cylinder 2, said distributing cylinder 2 is rotatably installed at said feeding port 11, and said distributing cylinder 2 is provided with a number of distributing areas 20 through a partition 21, and said distributing areas 20 are rotated and switched one by one. Through the top of the feed port 11, the top cover of the distribution cylinder 2 is provided with a sealing cover plate 3, and the sealing cover plate 3 is provided with a feed pipe 31 connecting the filter press and the inside of the distribution cylinder 2, And the sealing cover plate 3 is connected with the filter press through the feed pipe 31, and the sealing cover plate 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com