Rapid flow dividing and self-cleaning material dividing mechanism

A material separation mechanism and self-cleaning technology, applied in mixers, filtration separation, separation methods, etc., can solve problems such as reducing the purification effect, and achieve the effect of avoiding agglomeration and mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

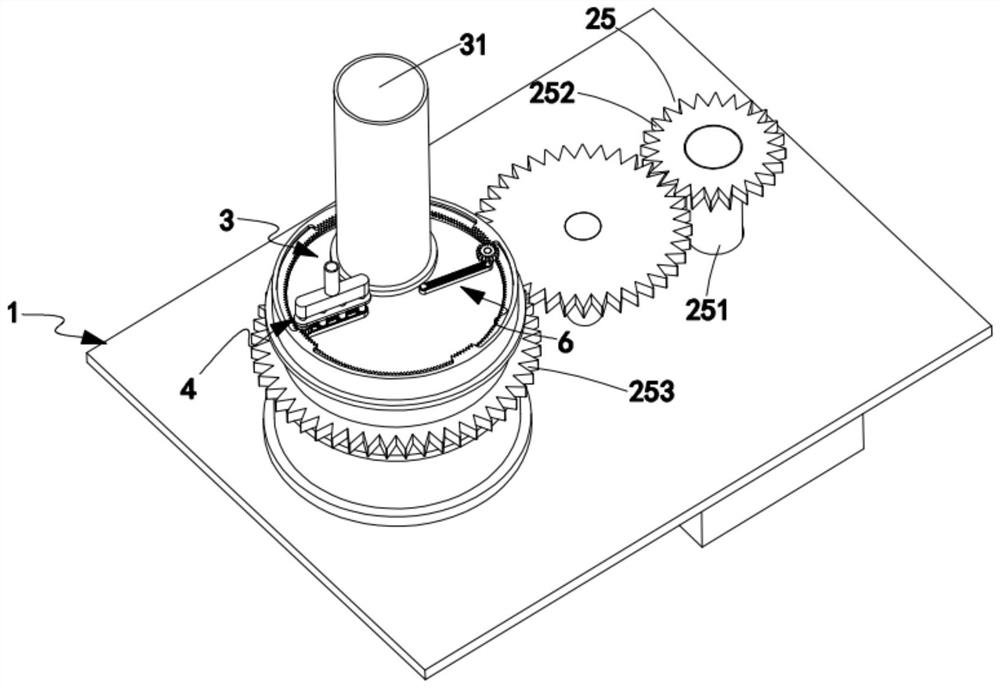

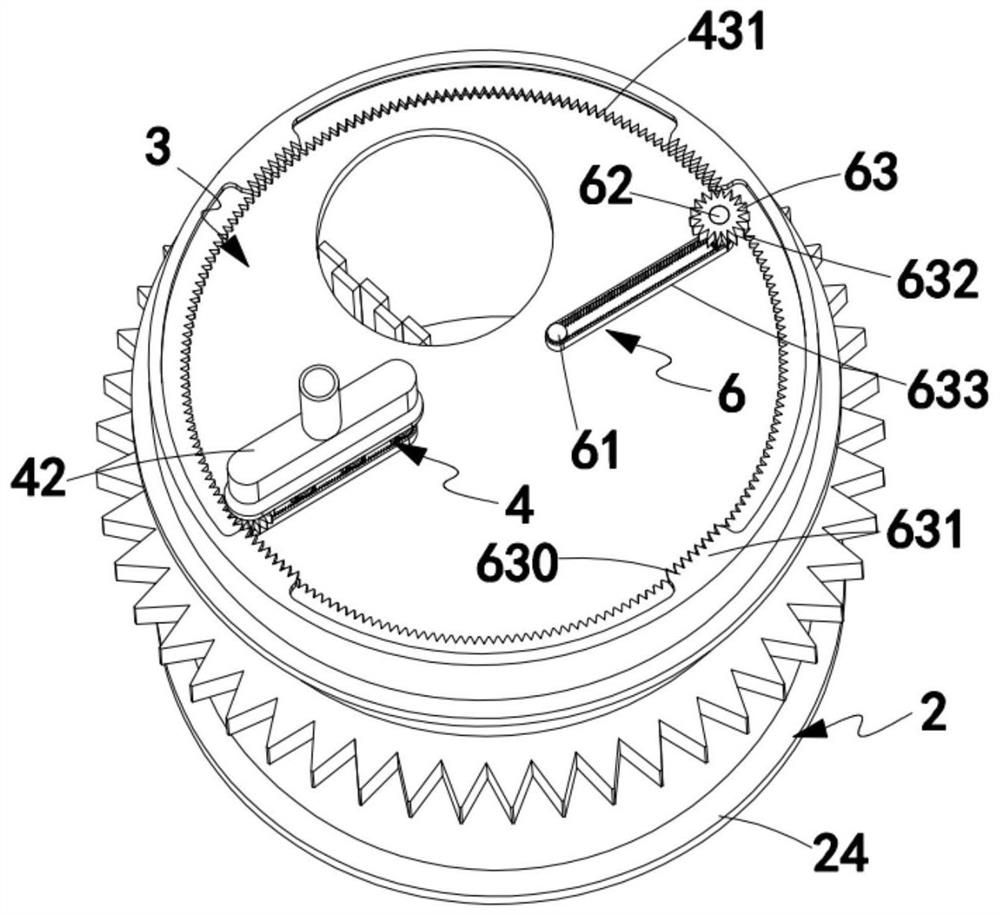

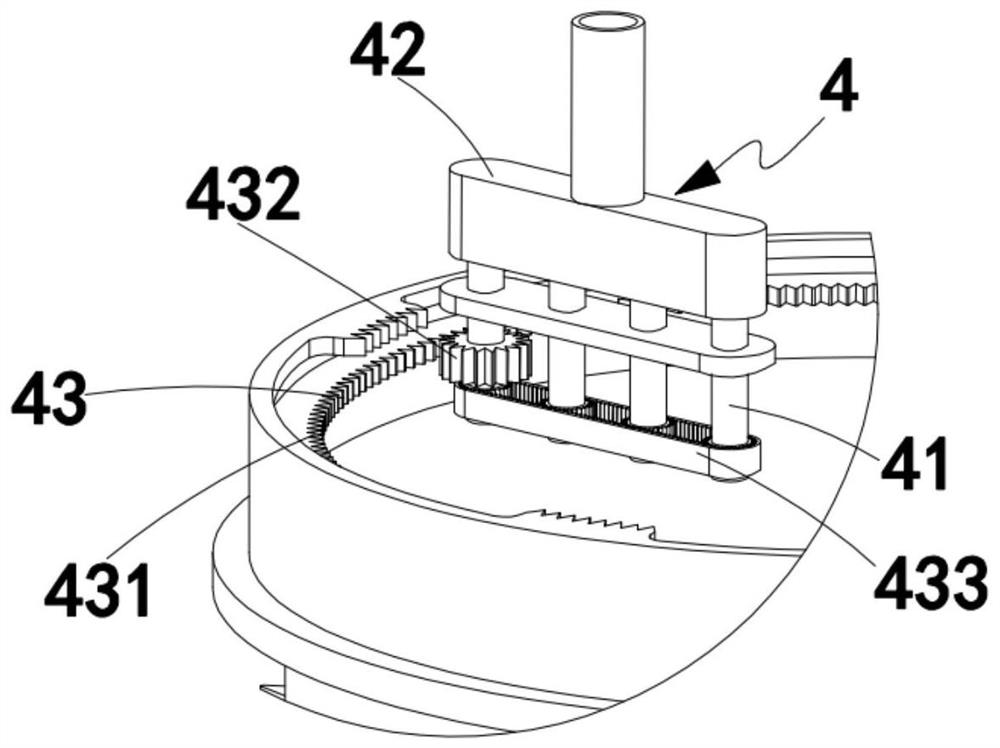

[0066] Such as Figure 1 to Figure 15 As shown, a rapid diversion self-cleaning distribution mechanism, including:

[0067] Mounting plate 1, the mounting plate 1 is arranged on the top of the stirring tank, the mounting plate 1 is provided with a feed port 11 communicating with the inside of the stirring tank;

[0068] Distributing cylinder 2, said distributing cylinder 2 is rotatably installed at said feeding port 11, and said distributing cylinder 2 is provided with a number of distributing areas 20 through a partition 21, and said distributing areas 20 are rotated and switched one by one. Through the top of the feed port 11, the top cover of the distribution cylinder 2 is provided with a sealing cover plate 3, and the sealing cover plate 3 is provided with a feed pipe 31 connecting the filter press and the inside of the distribution cylinder 2, And the sealing cover plate 3 is connected with the filter press through the feed pipe 31, and the sealing cover plate 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com