A normal surface funnel reservoir sediment discharge device

A funnel and reservoir technology, applied in water conservancy projects, sea area engineering, construction, etc., can solve the problems of difficult control of the shape and scale of the scour funnel, difficult to achieve sand discharge effect, river bed scour, etc., to solve sediment deposition and strengthen siphon effect, the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

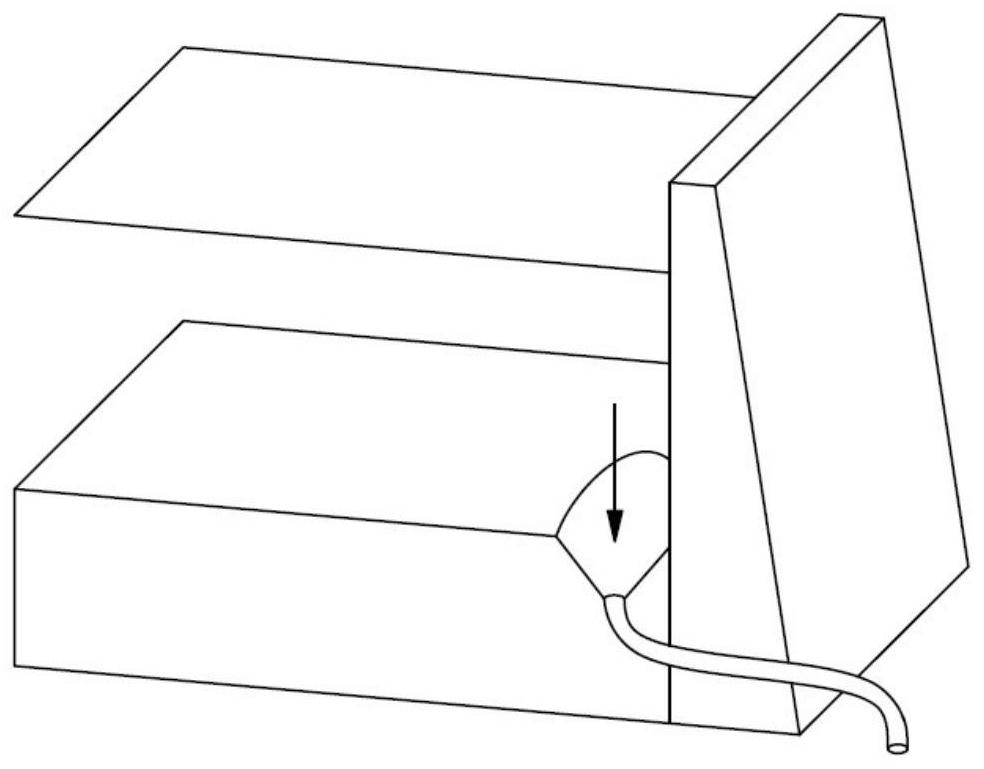

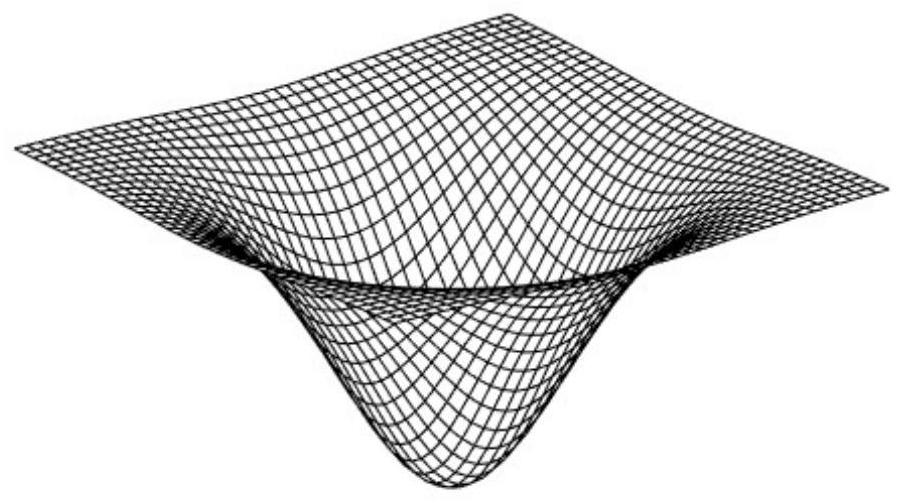

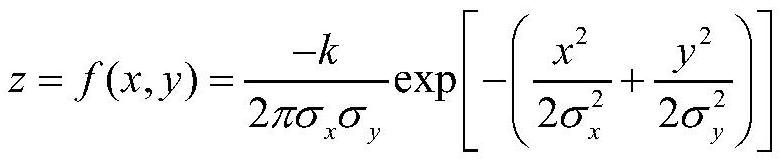

[0015] Such as figure 1 It is a schematic cross-sectional view of a normal curved surface funnel reservoir sand discharge device of the present invention. The reservoir sand discharge device includes a sand inlet funnel and a sand delivery pipeline; the sand inlet funnel is located in the sediment deposit area in the reservoir, and the sand delivery pipeline is laid on the river bed of the reservoir Above, the bottom of the sand inlet funnel is connected to one end of the sand delivery pipeline, and the other end of the sand delivery pipeline passes through the bottom of the dam. The shape of the sand conveying pipeline is an inverse hyperbolic tangent curve, and the sand conveying pipeline takes the positive direction of the y-axis upward along the water depth, and the positive direction of the x-axis along the water flow direction, and the shape of the sand conveying pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com