Piston pump exhaust structure

A piston pump and piston technology, which is applied to pump components, variable displacement pump components, and components of pumping devices for elastic fluids, etc., can solve the problems of unsmooth liquid discharge, affecting the use effect, etc. , use the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

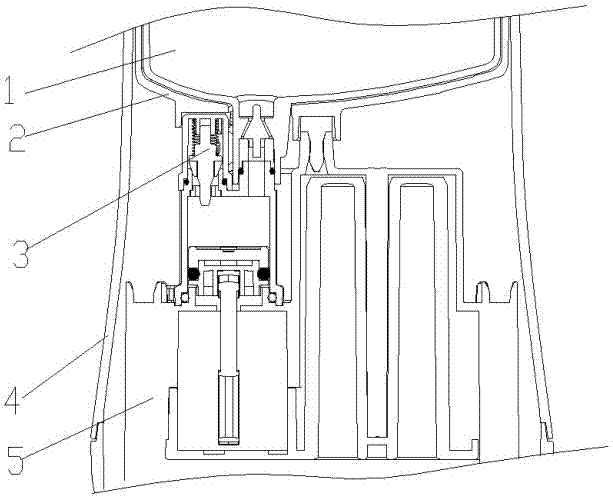

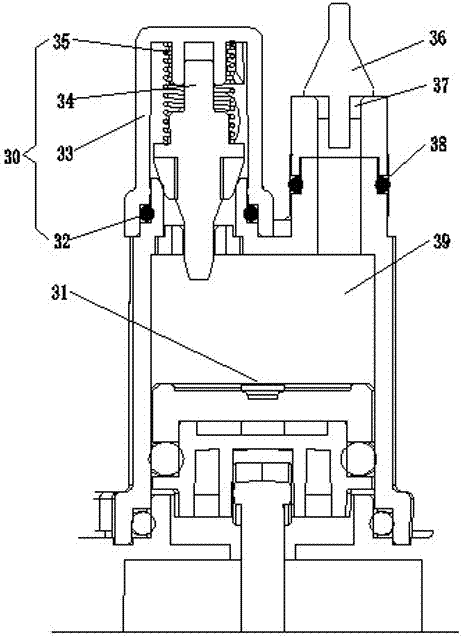

[0017] Referring to the accompanying drawings, a piston pump exhaust structure of the present invention, the piston pump includes a hydraulic cylinder 39, a piston 31 and a liquid inlet check valve 36, the liquid inlet check valve 36 is connected to the hydraulic cylinder 39, and is characterized in that: It includes a liquid outlet check valve 30 communicating with a hydraulic cylinder 39, the liquid outlet check valve 30 includes a liquid outlet valve seat 33, a sealing ring 32, a needle valve 34 and a spring 35 installed in the liquid outlet valve seat 33, The sealing ring 32 is installed between the liquid outlet valve seat 33 and the needle valve 34, a spring 35 is arranged above the needle valve 34, and there is a liquid outlet (not shown in the figure) above the liquid outlet valve seat 33.

[0018] see figure 1 , in an embodiment of the present invention, the piston pump 3 is installed on the soap dispenser, and the liquid inlet check valve 36 communicates with the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com