Filtering assembly and capsule coffee making device

A filter assembly and brewing technology, which is applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problems of inability to brew coffee, different pore diameters, and difficult injection molding, etc., and achieve simple production process, simple manufacturing process, small aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

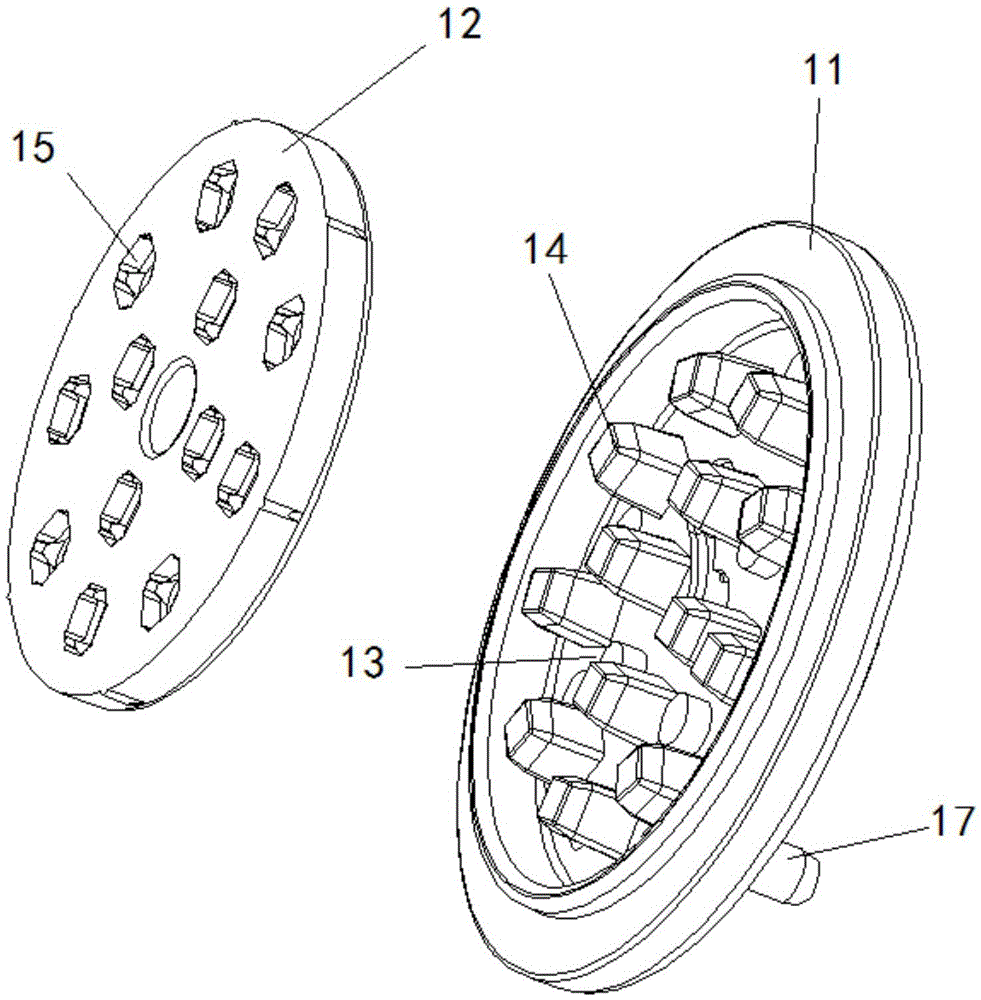

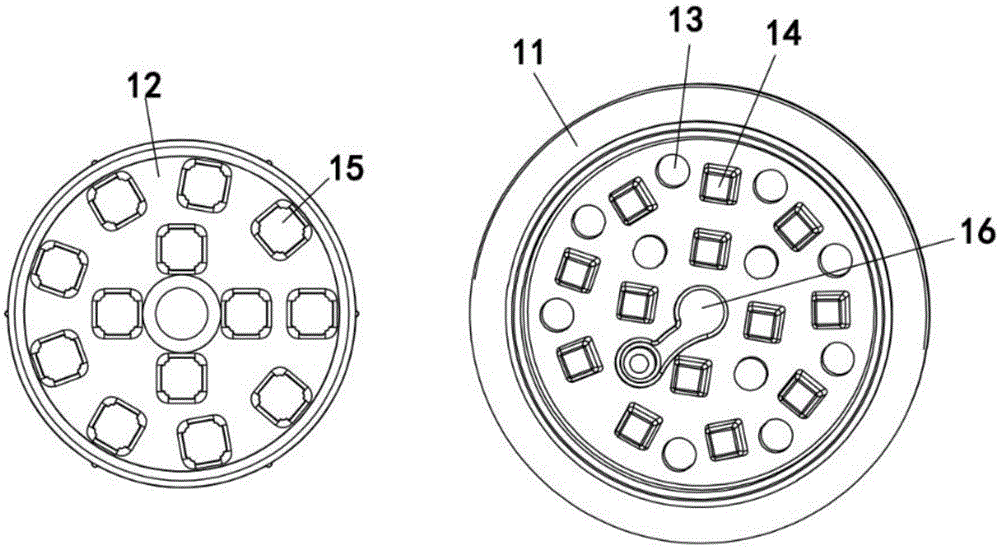

[0022] Such as figure 1 and figure 2 As shown, a filter assembly 10 of the present invention includes a filter screen 11, a plurality of filter holes 13 are provided on the filter screen 11, a plurality of bosses 14 are also provided on the filter screen 11, and a filter screen 11 is also provided. The mesh cover 12 that cooperates with the filter screen 11 has a plurality of assembly holes 15 that match the shape and position of the bosses 14, and the plurality of bosses 14 correspond to each other one by one. Inserting into the assembly hole 15 makes the mesh cover 12 fit with the filter screen 11 , and there is a gap between the assembly hole 15 and the boss 14 after assembly, and the boss 14 is higher than the plane of the mesh cover 12 . After the filter assembly 10 of the present invention is used in a capsule coffee brewer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com