Scrap discharging elbow with scrap guiding, filtering and self-cleaning functions

A self-cleaning and elbow technology, which is applied in the manufacture of tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of dirty liquid, easy blockage of the mesh, and influence on the discharge of cutting fluid, etc., so as to improve the filtration accuracy , Improve the operating environment and prolong the effect of cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

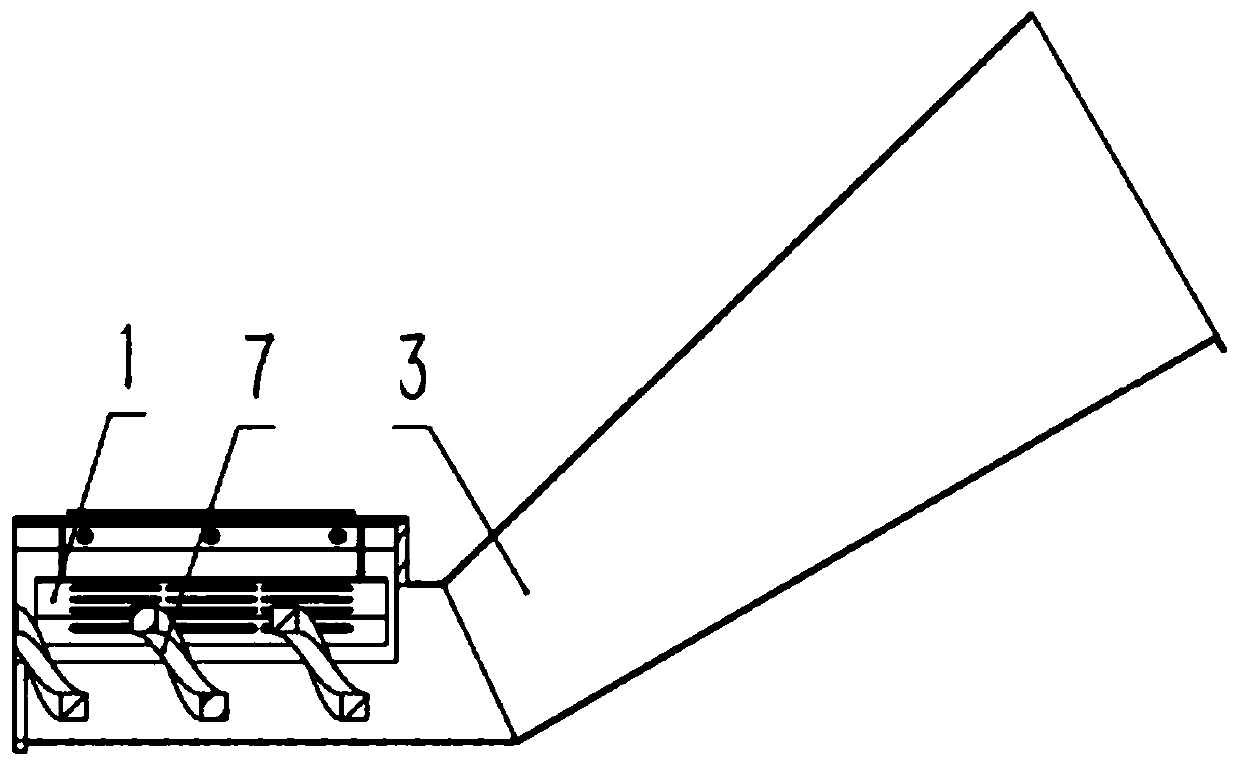

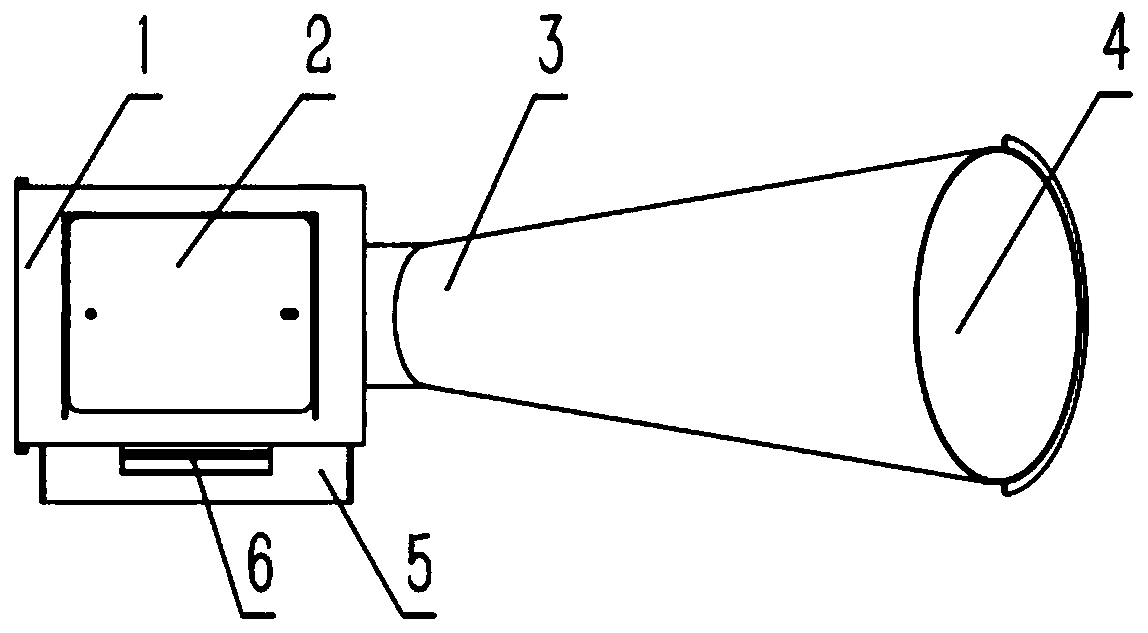

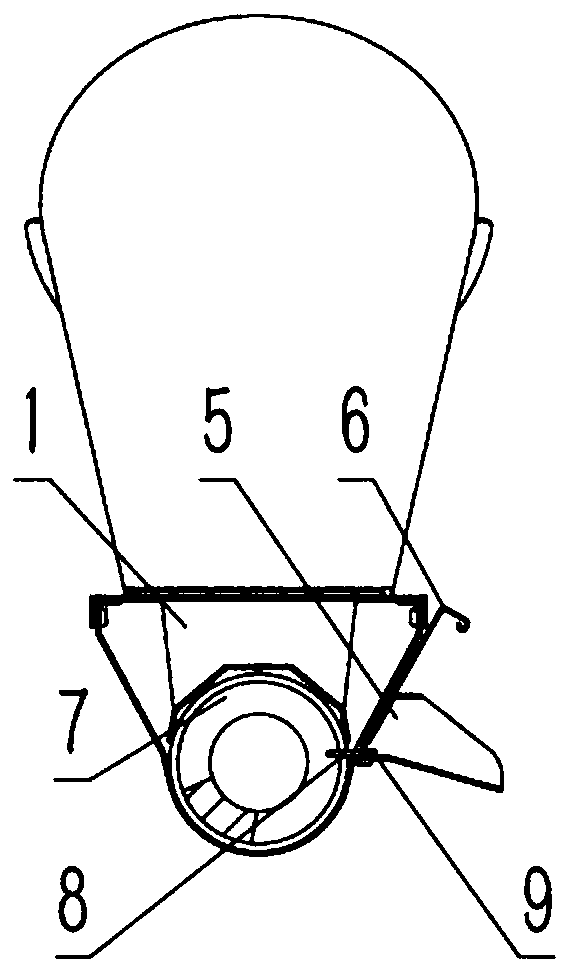

[0019] see Figure 1-4 , The chip removal elbow of the present invention includes a chip removal structure, a filtering structure and an observation structure.

[0020] The chip removal structure involves the filter guide cover 1, the elbow body 3, the chip outlet 4, the screw 7, the rubber scraper 8 and the rubber pressure plate 9, and the filter guide cover 1 is divided into the connecting part at the top and the filter guide part at the bottom The connection part on the top of the filter guide cover plate 1 is covered on the elbow body 3, the connection part and the elbow body are connected together by screws, and the top plate of the connection part is left with a rectangular hole, and there are bosses on three sides of the hole for Place the acrylic see-through plate 2; the filter guide part at the bottom is a cover surrounded by several sides of a regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com