Lateral flow inclined tube sedimentation separator and sedimentation tank

A technology of inclined tube precipitation and separation device, applied in the direction of precipitation separation, precipitation treatment, separation method, etc., can solve problems such as poor precipitation and separation, and achieve the effect of short settling distance, low settling height, and stable precipitation and separation operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

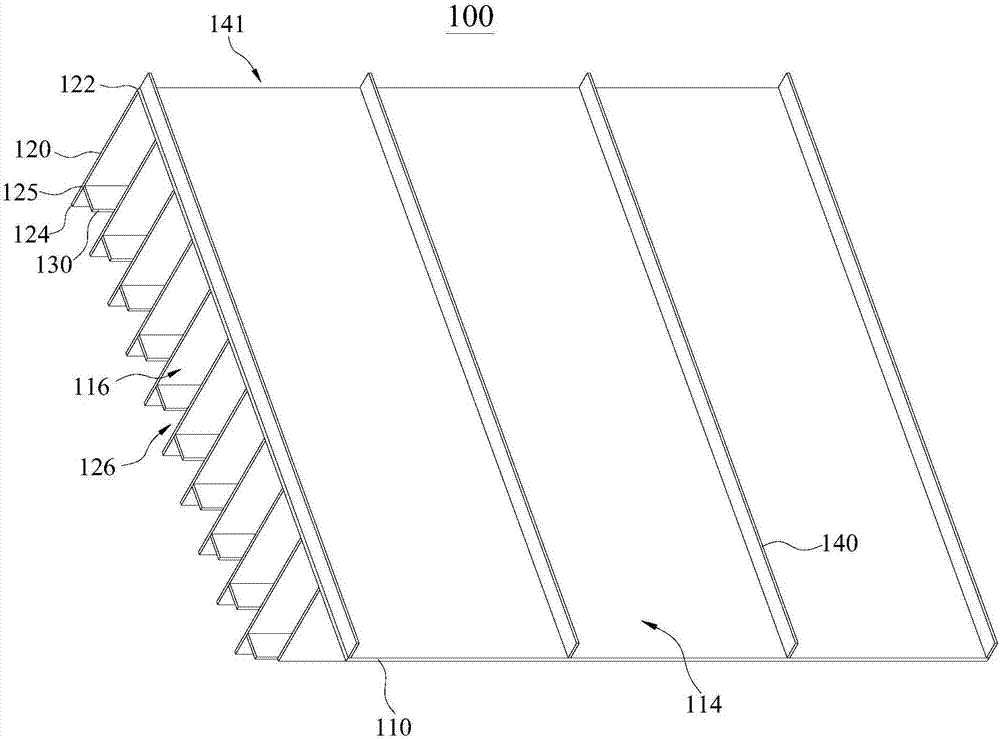

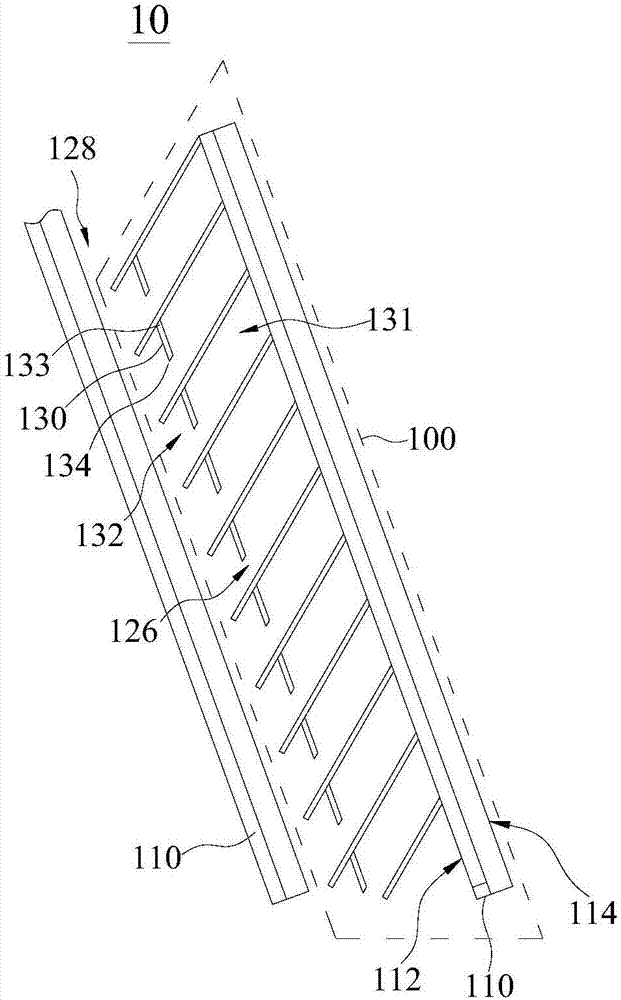

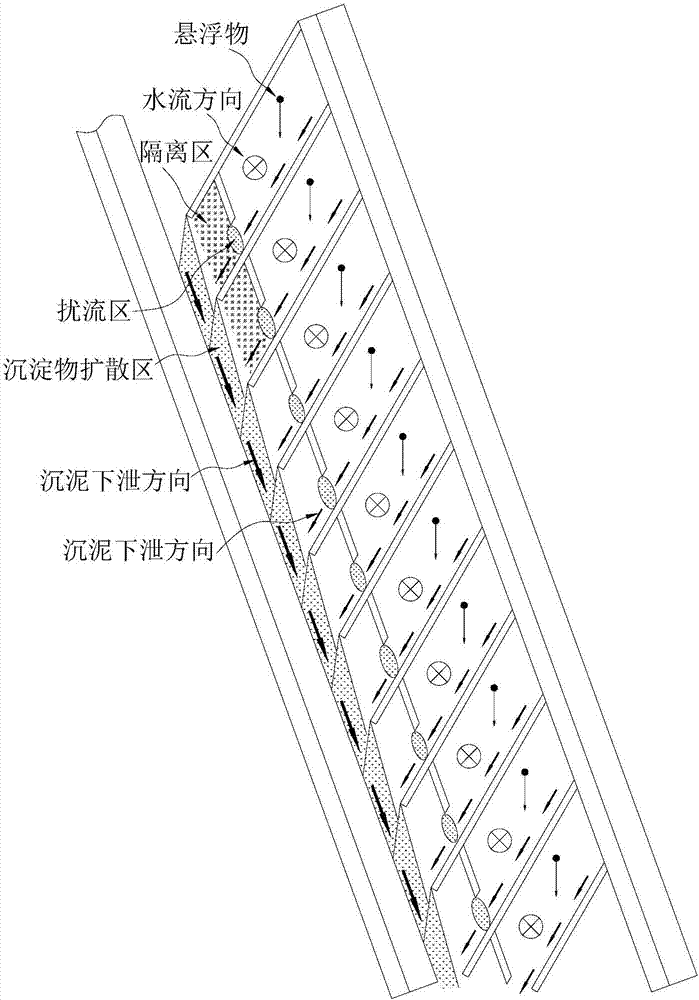

[0047] Please refer to figure 1 with figure 2 , a lateral flow inclined tube sedimentation separation device 10 provided in this embodiment includes at least one sedimentation separation unit 100, wherein the sedimentation separation unit 100 includes a sloping plate 110, a plurality of fins 120 arranged at intervals, and a plurality of webs 130 . The number of sedimentation separation units 100 included in the lateral flow inclined tube sedimentation separation device 10 can be set according to actual needs, and is not limited here. In this embodiment, one inclined plate 110 is correspondingly provided with a plurality of wing plates 120 , and each wing plate 120 is correspondingly provided with a web plate 130 . A first gap 116 is formed between two adjacent wing plates 120 . The web 130 is disposed in the first gap 116 and divides the first gap 116 into two parts, which are a sedimentation separation working area 131 and an isolation area 132 . Wherein the sedimentatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com