Liquid layering stripping wrinkle-removing technology based on blunt needle

A liquid, wrinkle-removing technology, which is applied in the field of cosmetology, can solve the problems of few drug administration points and small skin activation area, achieve good injection effect, reduce skin penetration resistance, and improve injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

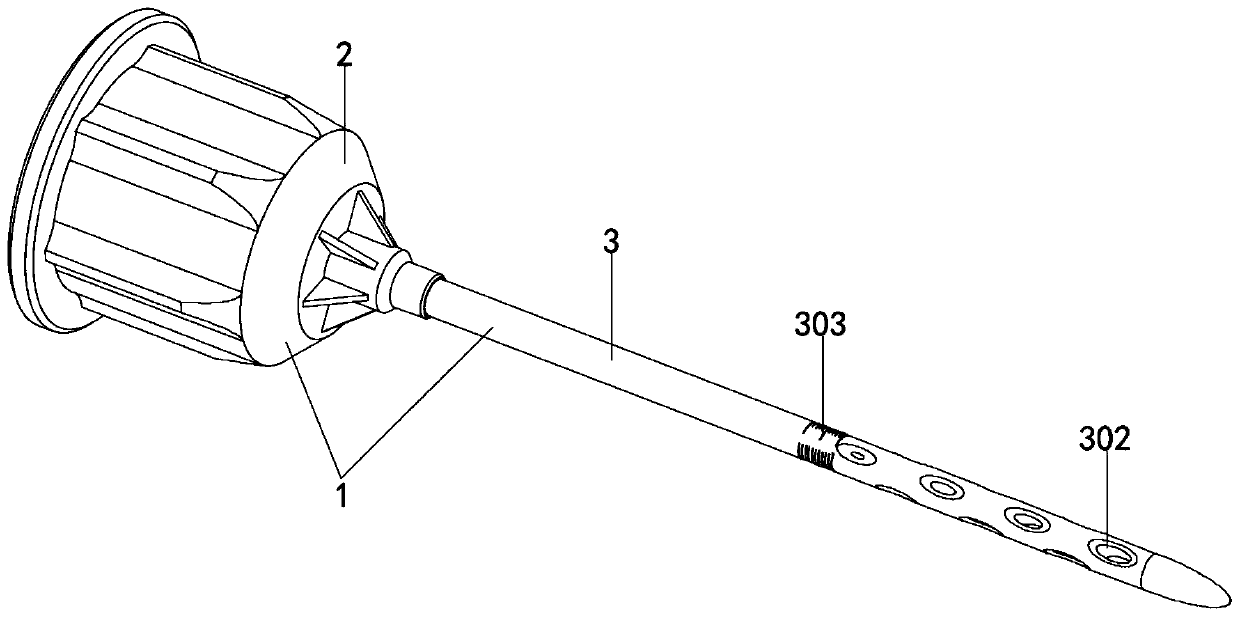

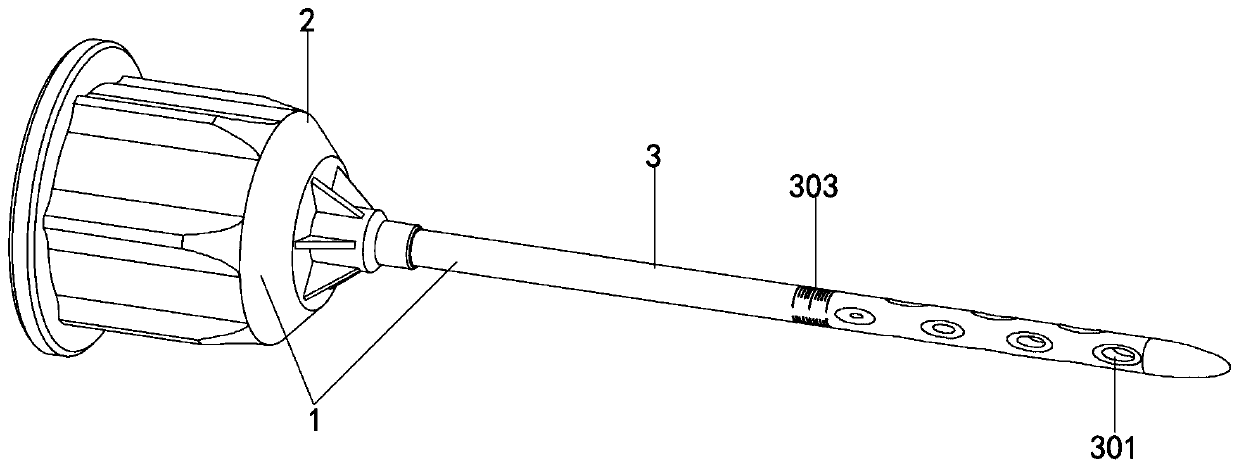

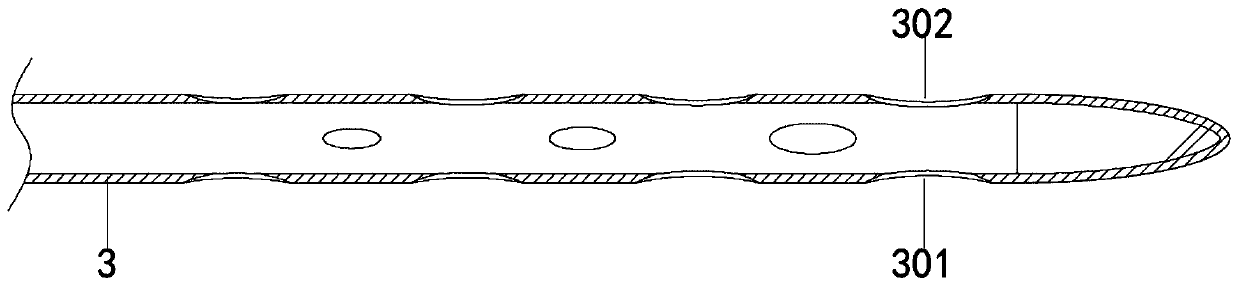

Embodiment approach

[0027] A blunt needle-based liquid delamination peeling wrinkle removal technology, including: a body 1, a needle seat 2, a needle body 3, a first liquid outlet 301, a second liquid outlet 302, and a scale 303; the body 1 consists of a needle seat 2 and the needle body 3, and the tail end of the needle body 3 and the needle base 2 are hot-melted and fixed; the side wall of the front side of the needle body 3 is provided with a first liquid outlet hole 301 and a second liquid outlet hole 302, and the first liquid outlet hole 302 The liquid outlet hole 301 and the second liquid outlet hole 302 are left-right symmetrical; the first liquid outlet hole 301 and the second liquid outlet hole 302 have at least three spiral arrays from front to back along the axis of the needle body 3, and there are multiple first outlet holes. The diameters of the liquid hole 301 and the second liquid outlet hole 302 decrease from front to back; a scale 303 is provided on the outer wall of the front si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com