Solid oxide fuel cell composite cathode Ln2CuO4-Ce0.9Gd0.1O1.95 and preparation method thereof

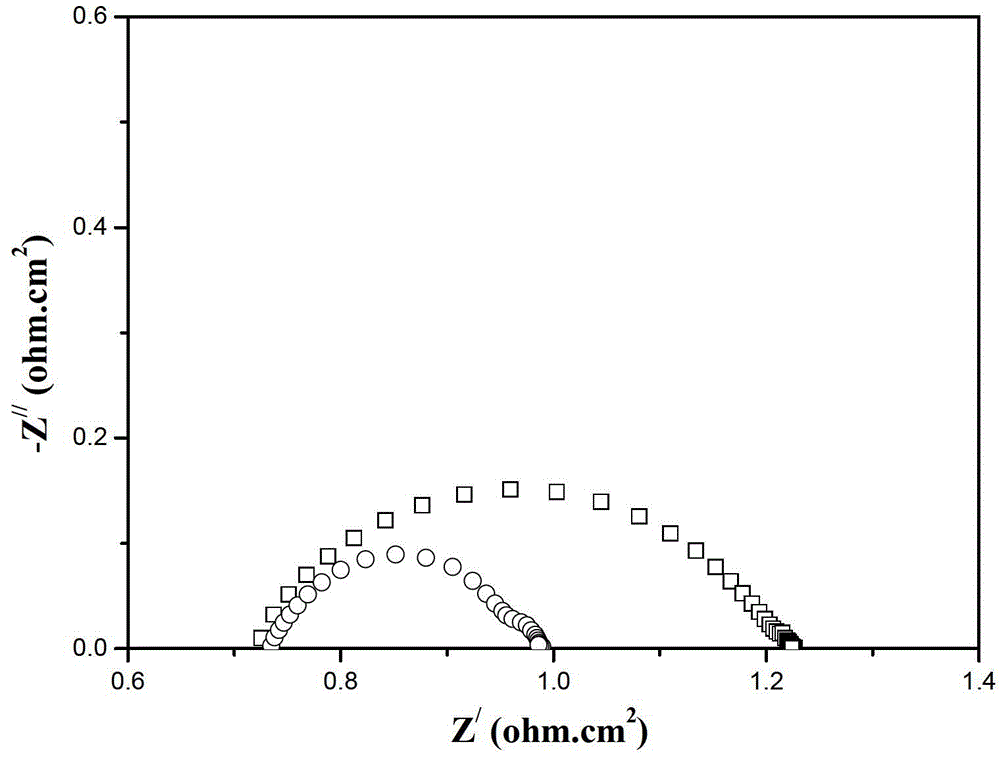

A technology of ln2cuo4-ce0.9gd0.1o1.95, ce0.9gd0.1o1.95, which is applied in the field of battery composite cathode materials and its preparation, can solve the problems of poor catalytic activity and electrochemical performance, and achieves improved catalytic activity and Electrochemical performance, effect of increasing mixed conductivity, increasing active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

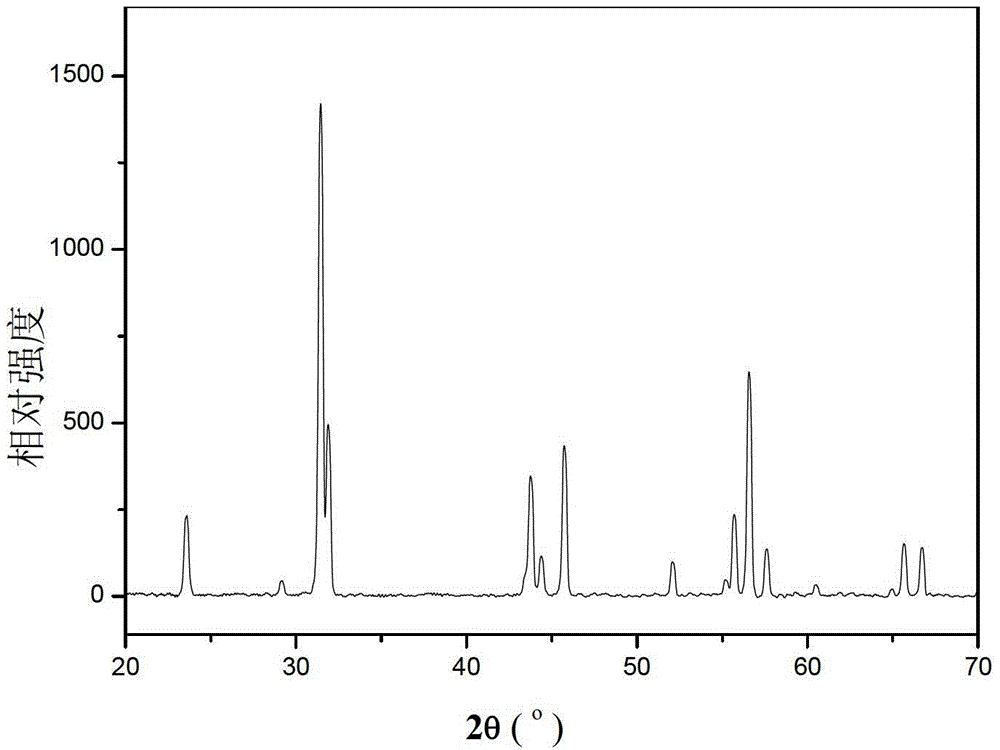

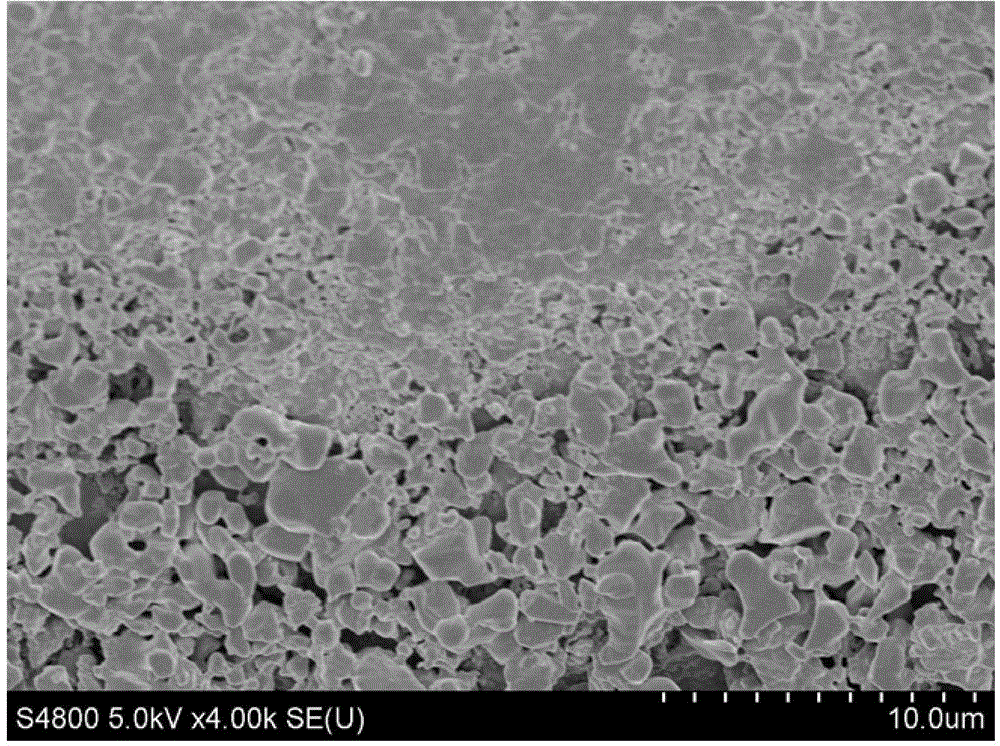

[0017] Specific implementation mode 1: The composite cathode Ln of the solid oxide fuel cell in this implementation mode 2 CuO 4 -Ce 0.9 Gd 0.1 o 1.95 By weight percentage from 50% to 90% of Ln 2 CuO 4 and 10% to 50% solid electrolyte Ce 0.9 Gd 0.1 o 1.95 Made, where Ln is Pr, Nd, Sm or Eu element.

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the Ln 2 CuO 4 The preparation method is carried out according to the following steps: press Ln 2 CuO 4 The stoichiometric ratio, the purity greater than 99.99% of Ln x o y Mix with CuO, where x=2 or 6, y=3 or 11; then grind in a ball mill for 12h to 24h, and then sinter at a temperature of 1000°C to 1100°C for 18h to 24h to obtain Ln 2 CuO 4 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: this implementation mode is the same as the specific implementation mode: the Ce described 0.9 Gd 0.1 o 1.95 The preparation method is carried out according to the following steps:

[0020] A. At a temperature of 50°C to 80°C, add 4.4g of Ce(NO 3 ) 3 and Gd(NO 3 ) 3 Dissolve in 250mL of deionized water, then heat and stir for 5h at a temperature of 80°C and a stirring rate of 100 rpm, and then add 12.0g of glycine to obtain a mixed solution;

[0021] B. Stir the mixed solution until uniform and transparent, then heat and evaporate to a viscous jelly at a temperature of 120°C, and then continue heating at a temperature of 200°C until the jelly spontaneously ignites to obtain a light yellow powder;

[0022] C. Sinter the light yellow powder obtained in step B at a temperature of 900°C in an air atmosphere for 12 hours to obtain Ce 0.9 Gd 0.1 o 1.95 . Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com