Self-supporting doped metal hydroxide nanosheet electrode material, and preparation method and application thereof

A hydroxide and electrode material technology, applied in the field of electrocatalytic materials, can solve the problems of difficult large-scale production of the preparation method process, harsh preparation method conditions, and small active material layer area, etc., and achieves high efficiency cycle stability, metal doping Miscellaneous types can be adjusted to avoid the effect of extensive use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

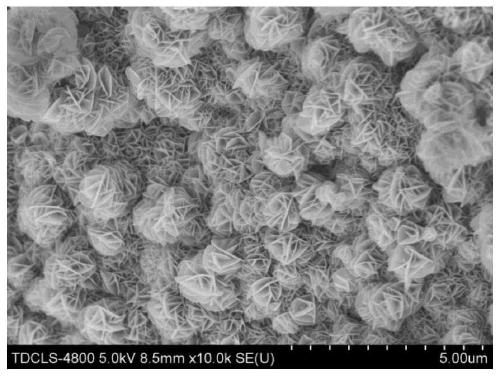

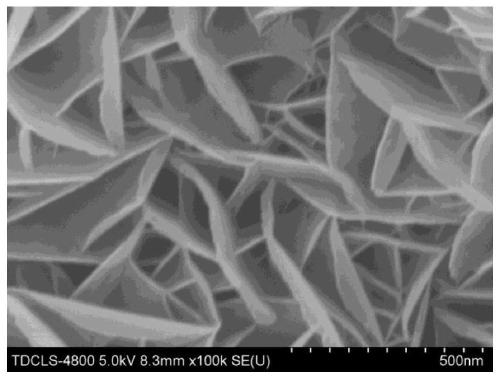

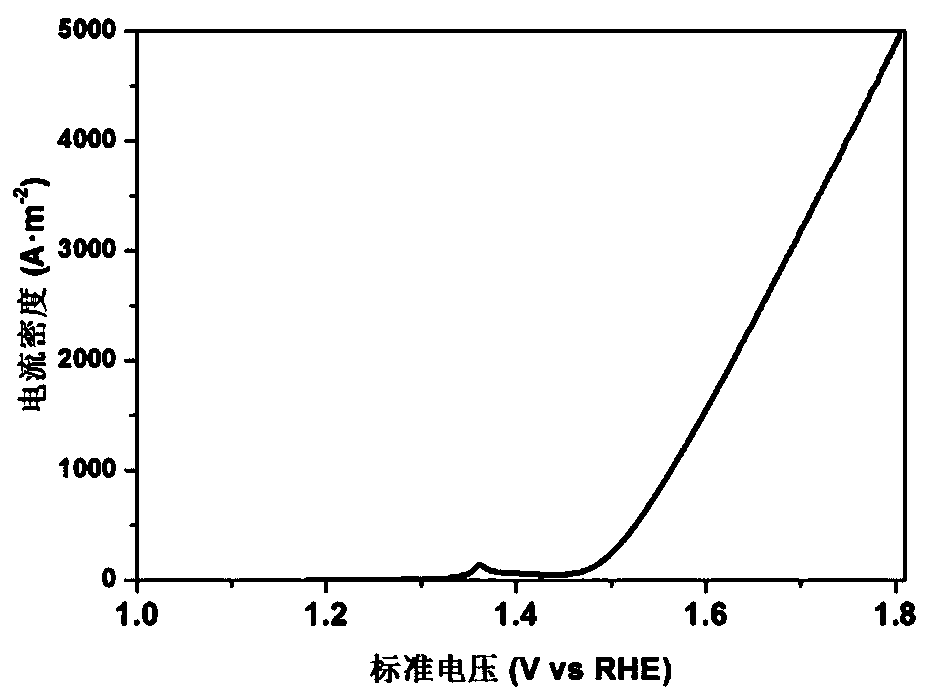

[0028] Example 1: Preparation of self-supporting ultra-thin Zn-doped nickel-iron hydroxide nanosheet electrode material

[0029] First, surface activation treatment is carried out on the metal conductive substrate: the iron foam with a thickness of 1.2mm is cut into a regular piece of 5cm x 5cm. Put the cut foam iron into 100mL of 1.0mol / L sulfuric acid, stir and activate for 20min; then put the pickled foam iron into 100mL of deionized water, stir three times, each time for 10min; After washing with water, the foam iron was washed with ethanol three times; then, the activated and cleaned foam iron was dried in a vacuum oven at 60° C. for 6 hours.

[0030]Growth of self-supporting ultrathin Zn-doped nickel-iron hydroxide nanosheets: 1.037g nickel chloride and 0.109g zinc chloride were dissolved in 40mL deionized water to obtain a 0.22mol / L mixed metal ion solution. After putting the above-mentioned activated foam iron into the mixed metal ions, submerge it completely, expose ...

Embodiment 2

[0033] Example 2: Preparation of self-supporting ultra-thin Co-doped nickel-iron hydroxide nanosheet electrode material

[0034] First, surface activation treatment is carried out on the metal conductive substrate: a stainless steel sheet with a thickness of 0.4 mm is cut into a regular sheet of 5 cm x 5 cm. Put the cut stainless steel sheet into 100mL of 2.0mol / L hydrochloric acid, and ultrasonically activate it for 10min; then put the pickled stainless steel sheet into 100mL of deionized water, stir three times, each time for 10min; Afterwards, the stainless steel sheet was rinsed with ethanol three times; and then the activated stainless steel sheet was dried in a vacuum oven at 60° C. for 6 hours.

[0035] Growth of self-supporting ultrathin Co-doped nickel-iron hydroxide nanosheets: 2.908 g of nickel nitrate hexahydrate and 0.291 g of cobalt nitrate hexahydrate were dissolved in 50 mL of deionized water to obtain a 0.22 mol / L mixed metal ion solution. Put the activated s...

Embodiment 3

[0037] Example 3: Preparation of self-supporting ultra-thin Al-doped nickel hydroxide nanosheet electrode material

[0038] First, surface activation treatment is carried out on the metal conductive substrate: the nickel foam with a thickness of 2.0mm is cut into a regular piece of 10cm x 5cm. Put the cut stainless steel sheet into 100mL of 2.0mol / L hydrochloric acid, and ultrasonically activate it for 10min; then put the foamed nickel sheet after pickling into 100mL of deionized water, and stir three times, each time for 10min; The activated nickel foam was dried in a vacuum oven at 60°C for 12 hours.

[0039] Growth of self-supporting ultrathin Al-doped nickel hydroxide nanosheets: 14.57g nickel nitrate hexahydrate and 0.750g aluminum nitrate nonahydrate were dissolved in 100mL deionized water to obtain a 0.52mol / L mixed metal ion solution. Put the activated foamed nickel sheet into the mixed metal ions, completely submerge it, expose it to the air and let it stand for 36 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com