Telescopic side-tearing cover assembly

A cover assembly and rod technology, which is applied to the device for preventing the repeated filling of the container, the locking device, the closing, etc., can solve the problems of high assembly and manufacturing costs, poor sealing performance, and unsatisfactory sealing performance, and achieve convenient operation. , smooth liquid discharge, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

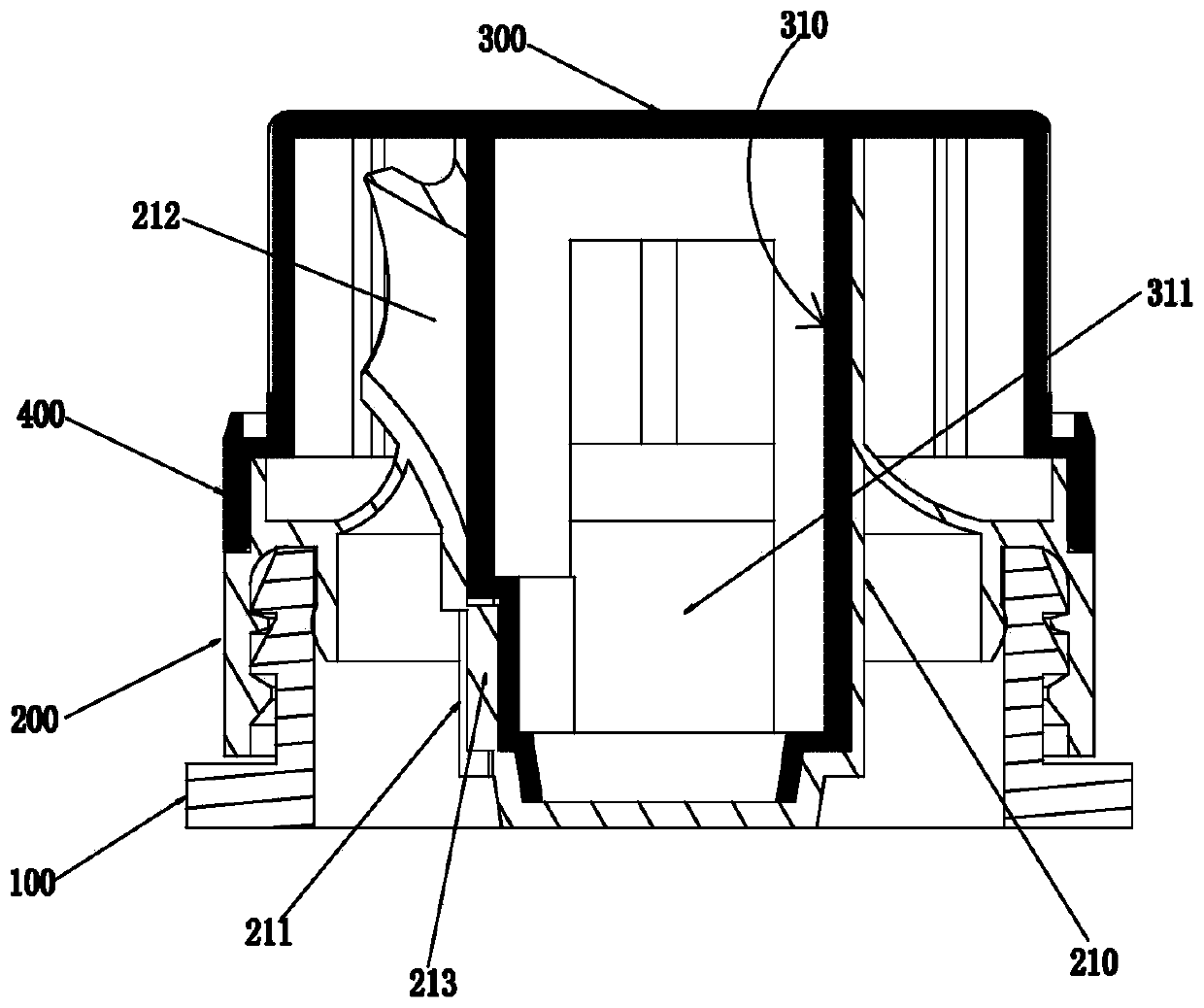

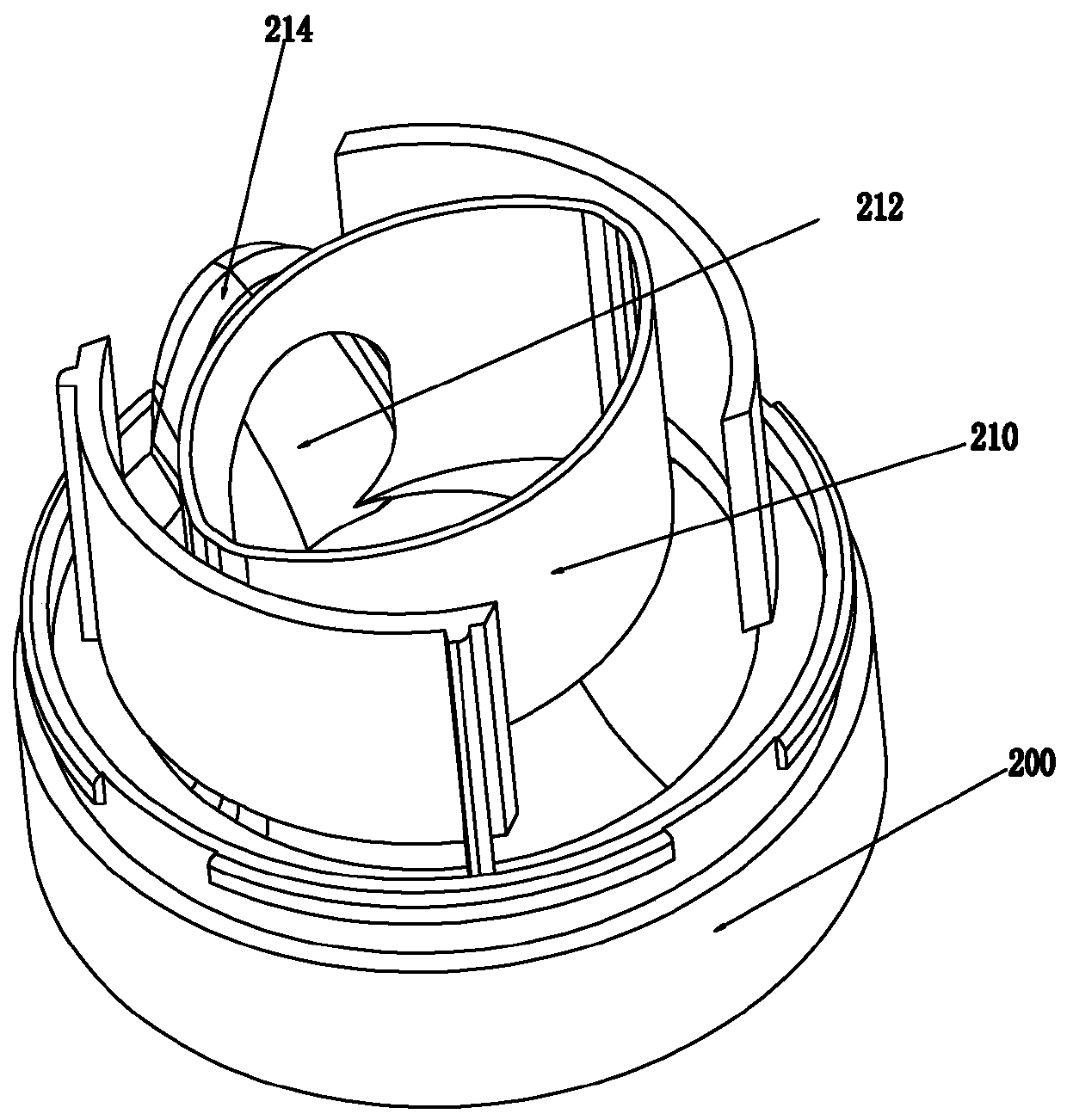

[0030] Such as Figure 1-6 As shown, a retractable side-tearable lid assembly of the present invention includes a base 200 for connecting with the mouth of the container body 100, the inner wall of the base 200 extends toward the center to form a liquid outlet column 210, and the liquid outlet column 210 It is hollow and has an open end and a sealed end. The open end of the liquid outlet column 210 is set opposite to the sealed end of the liquid outlet column 210. The sealed end of the liquid outlet column 210 extends toward the inner cavity of the container body 100. The liquid outlet column 210 is sealed A liquid outlet 211 is provided on the side wall of the end, a liquid outlet sleeve 212 is provided on the side wall of the opening end of the liquid outlet column 210, and an upper cover 300 that covers the opening end of the liquid outlet column 210 is connected to the base 200 , the inner bottom of the upper cover 300 is extended to form a rod 310 that extends into the in...

Embodiment 2

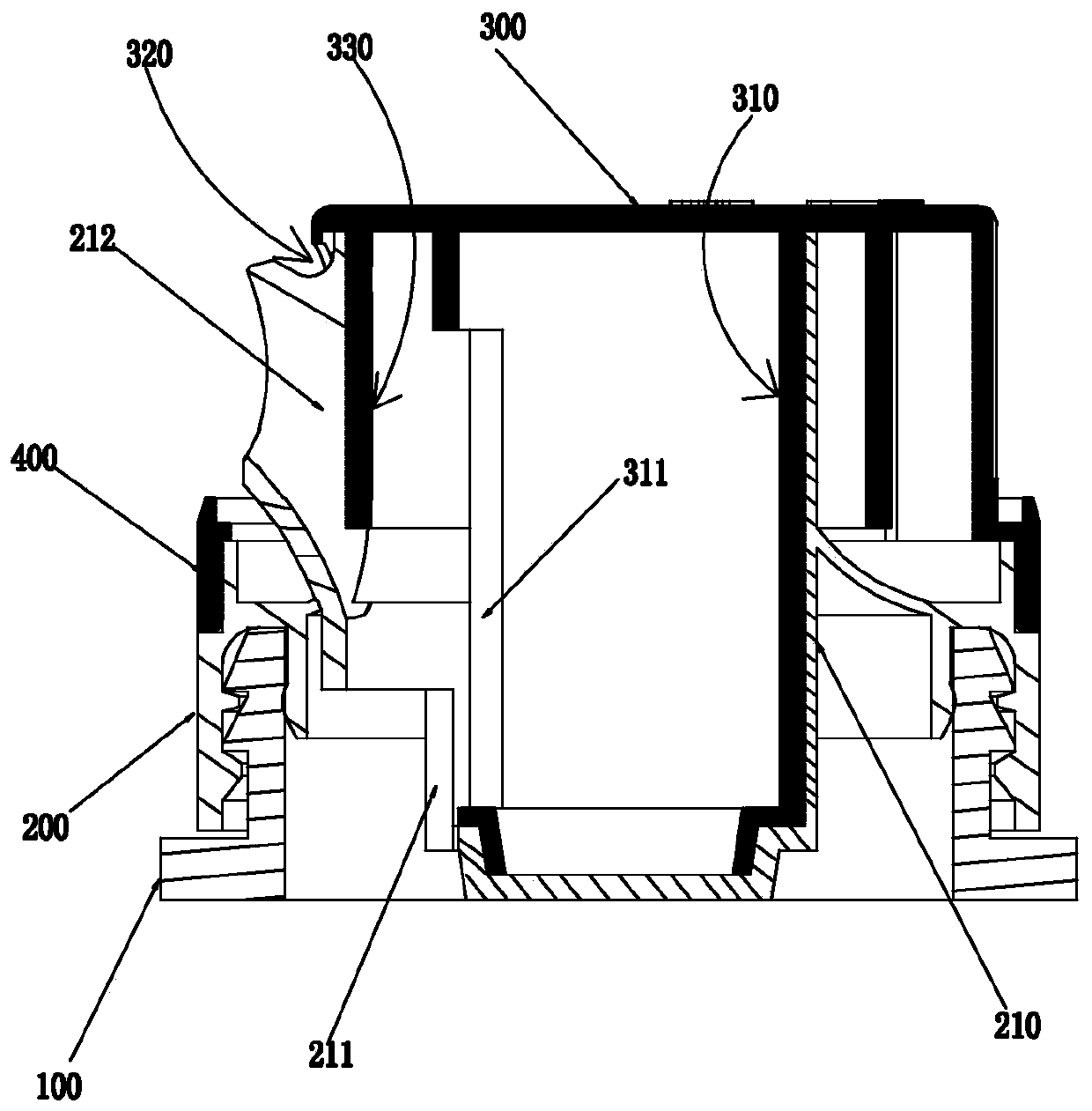

[0036] Embodiment 2: as Figure 7 As shown, in order to provide multiple ways of use and meet the different needs of users, the number of the liquid outlet sleeve 212 is two, and the two liquid outlet sleeves 212 are oppositely arranged on the side wall of the opening end of the liquid outlet column 210 , the upper cover 300 is correspondingly provided with two liquid outlet windows 320 for use with the two liquid outlet sleeves 212, and the rod member 310 is correspondingly provided with two rod member liquid outlets for use with the two liquid outlet sleeves 212. Mouth 311. When in use, one liquid outlet sleeve is used to pour out the substance, and an air inlet channel is formed relative to the other liquid outlet sleeve, so that a channel is formed between the liquid outlet sleeve and the inner cavity of the container body so that the liquid filled in the inner cavity of the container body The substance can be quickly poured out.

[0037] Such as figure 1 , 2 , 5 and 6...

Embodiment 3

[0044] Such as Figure 8 As shown, the difference between Embodiment 3 and Embodiment 1 is that Embodiment 3 changes the liquid outlet sleeve 212 of Embodiment 1 into a liquid nozzle.

[0045] The rest of the structure of embodiment 3 is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com