An industrial noodle packaging box equipment

A packaging box and industrial technology, applied in the field of boxing equipment, can solve the problems of bread falling on the ground, low work efficiency, cumbersome operation, etc., and achieve the effect of high work efficiency, improved efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

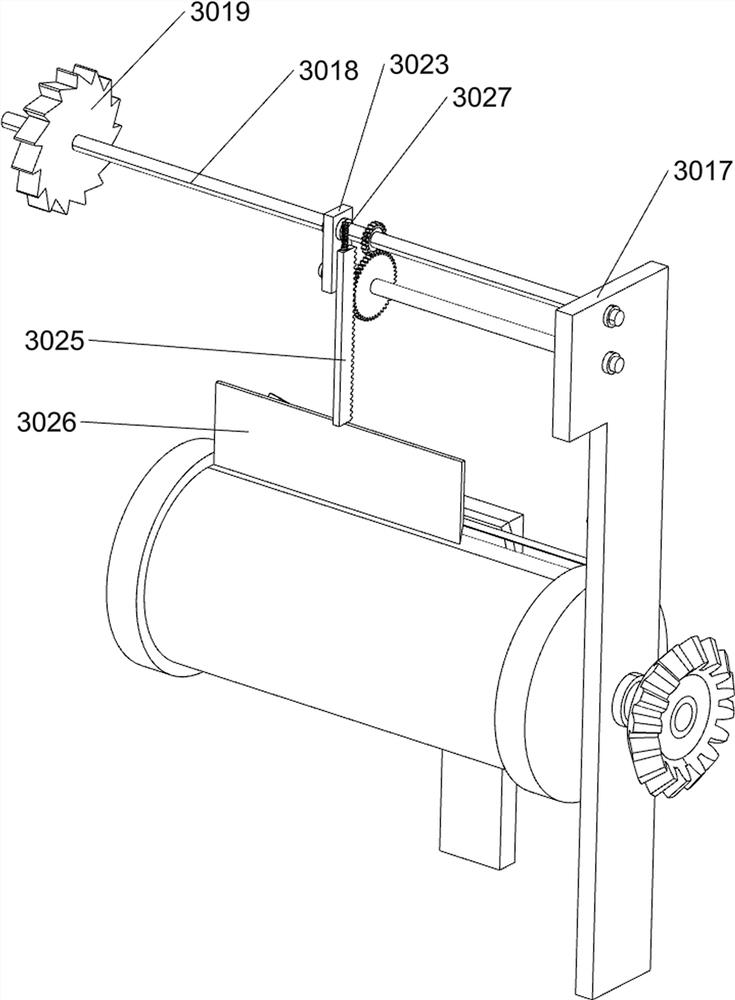

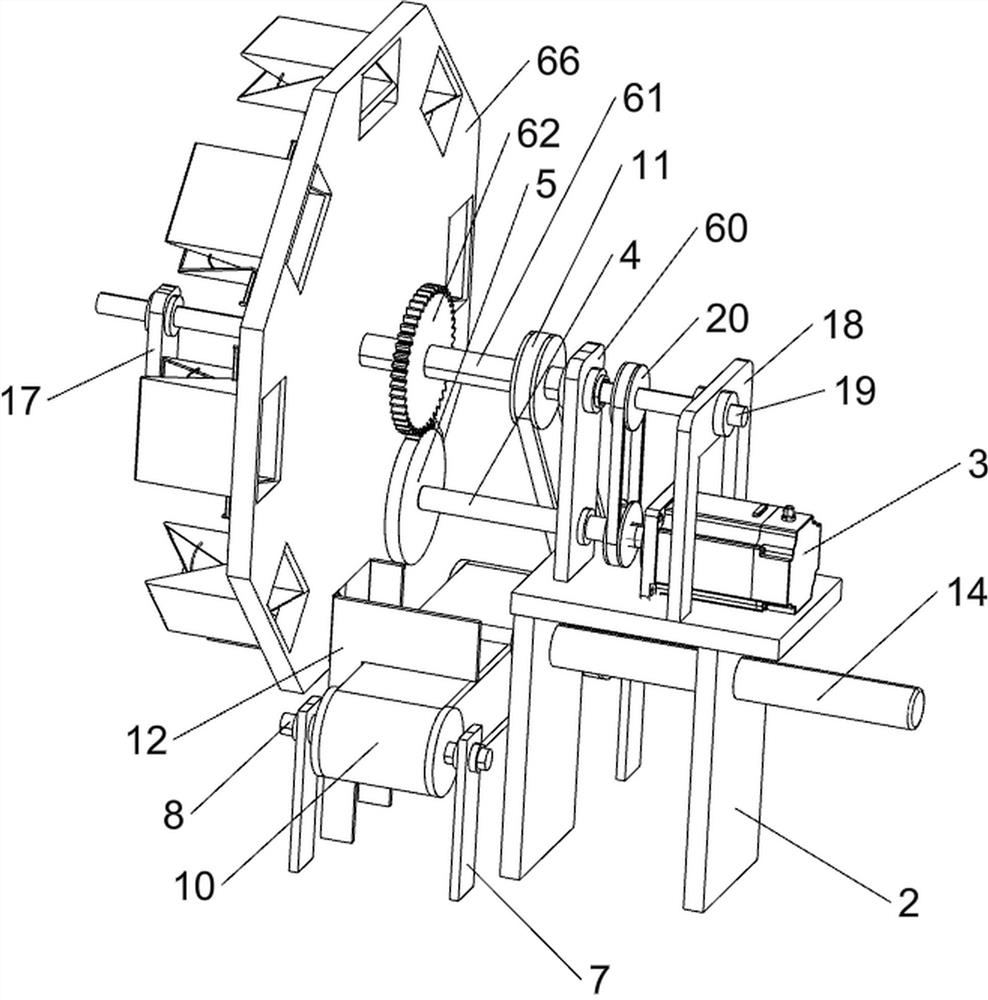

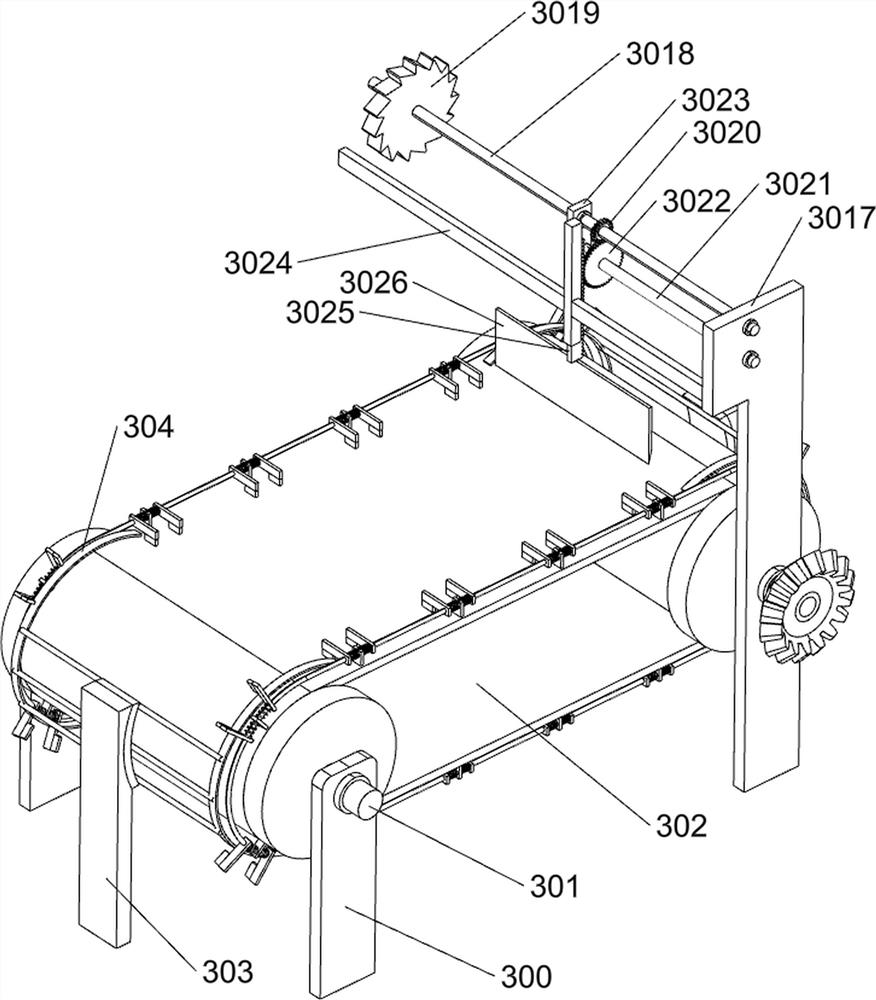

[0023] A kind of industrial noodles packaging box equipment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, it includes a base plate 1, a first bracket 2, a servo motor 3, a first rotating shaft 4, a missing gear 5, a rotating mechanism 6, a third bearing seat 7, a third rotating shaft 8, a fourth rotating shaft 9, and a first conveyor belt 10. , the first pulley assembly 11, the first protective plate 12, the second protective plate 13, the first cylinder 14, the push plate 15, the second bracket 16, the fourth bearing seat 17, the fifth bearing seat 18, the fifth shaft 19, The second pulley assembly 20, the support member 21, the third bracket 22, the storage box 23, the opening and closing door 24, the sixth rotating shaft 25, the seventh rotating shaft 26, the first bevel gear 27, the third pulley assembly 28, the second bevel gear 29. The feeding mechanism 30, the seventh bearing seat 31, the eleventh ...

Embodiment 2

[0030] On the basis of Example 1, as Figure 4As shown, a third protective plate 35 is also included, and a third protective plate 35 is connected between the tops of the seventh bearing seats 31 on the front and rear sides.

[0031] The third protective plate 35 can make the bag containing the bread better to be transported out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com