Intelligent valve port packaging machine and control system thereof

A technology of intelligent valve port and packaging machine, applied in packaging machine, packaging, transportation and packaging, etc., can solve the problems of material leakage, hidden danger, deformation of finished packaging bags, etc., to achieve the effect of good flexibility and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

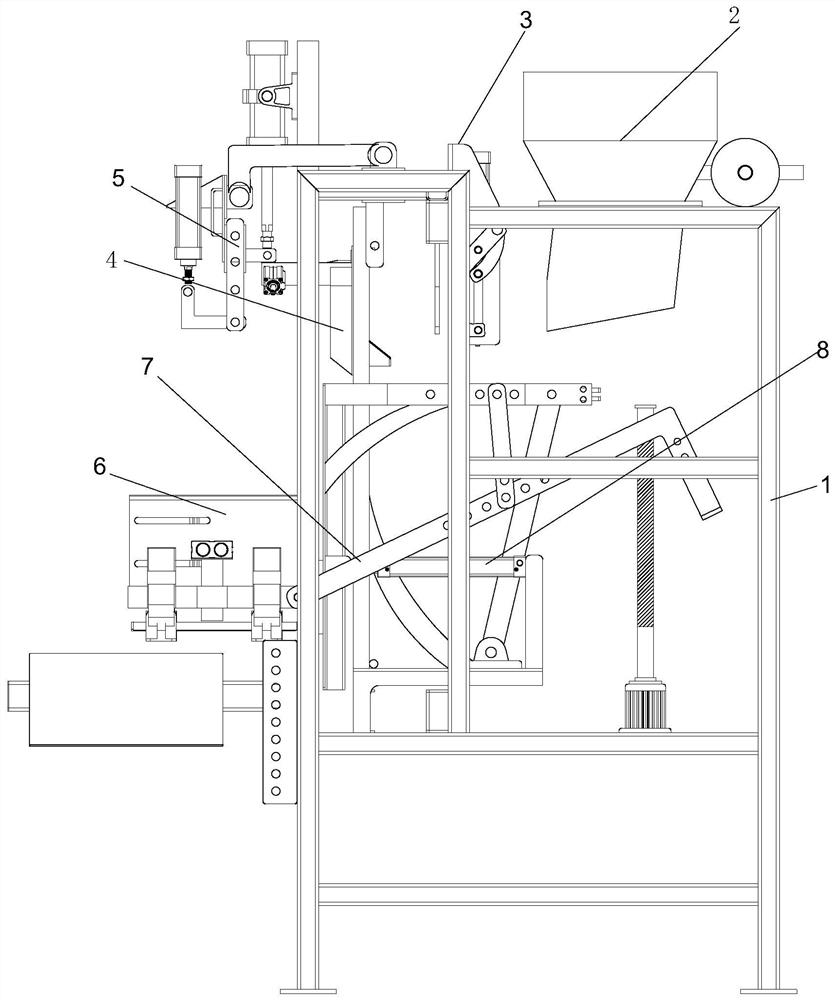

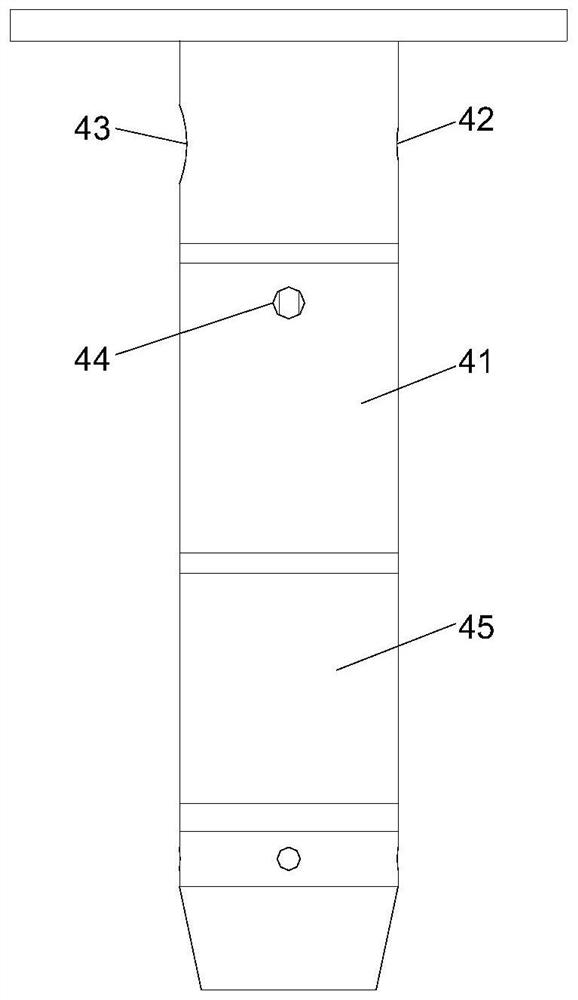

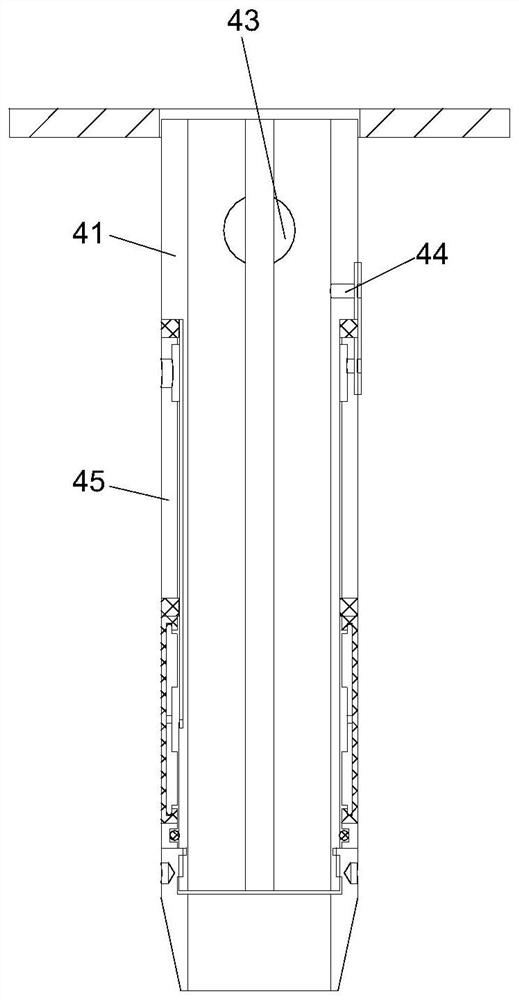

[0051] Refer Figure 1-9 For a smart valve port package disclosed in this example, a transmitting bin 2 is provided on the rack 1, the transmit bond 2 connecting the tube 4, the tube 4 including a tubular body 41 and a sleeve The airfladding sleeve 45 is provided on the tubular body 41, and the tube body 41 is connected between the transmitting bin 2, the airfrof sleeve 45 includes an airflant air opening 44; in the tubular body 41 Also open, the return port 43 and the cleaning port 42 are also provided with a pneumatic air amplifier; a discharge device 3 is provided between the discharge tube 4 and the transmission bin 2, in which the rack is 1 is also provided with an ultrasonic device 5 and a helper assembly 6; the ultrasonic device 5 is located above the helper cover assembly 6, and both of which are provided from the discharge tube 4 from the side of the discharge device 3. A belt conveyor is provided below, and the ultrasonic device 5 is used to close the bag of the material ...

Embodiment 2

[0059] Based on the first embodiment, it is different from that of Example 1. Figure 10-12 The intelligent valve port package disclosed in the present embodiment further includes a flat assembly 9, and the flattening assembly 9 is provided on one side of the pinch 61 that is not connected to the helper cylinder 62; the leveling assembly 9 includes vertical The rod 91, the second motor 10 drives the vertical rod 91 and the two levels provided on the vertical rod 91, the vertical rod 91 rotates on the protruding plate, the projection plate fixed in two splints 61 opposite the opposite side; two lengths of the threaded zone 911 opposite the rod 91, each of the threaded zone 911, in each of the threaded zones 911, and two of the threaded zones 911. The flat mechanism is opposite to the moving path on the two threaded zones 911; the second motor 10 is provided on the splint 61, and the output terminal of the second motor 10 and the end portion of the vertical rod 91 are provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com