Rocker type automatic truck loading mechanical arm

A technology of rocker arm type and manipulator, which is applied in the direction of manipulator, program control manipulator, loading/unloading, etc. It can solve the problems of difficult material package stacking, blind loading area, low efficiency of automatic loading, etc., and achieve position adjustment response Faster, less moving frequency, and more accurate palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

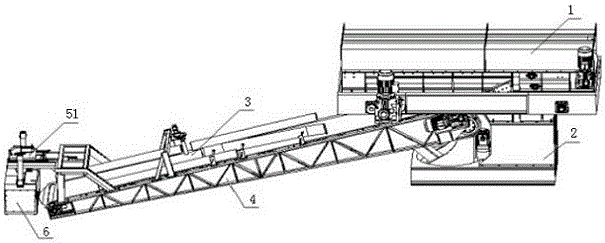

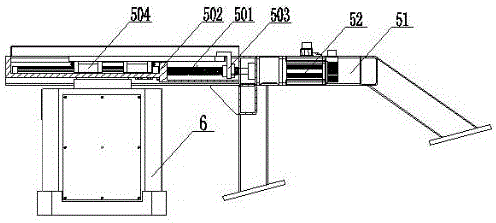

[0081] A rocker arm type automatic loading manipulator of this embodiment, such as figure 1 As shown, it includes a mechanical arm 4 and a blanking box 6 installed at the discharging end of the mechanical arm 4, characterized in that: the mechanical arm 4 is fixedly installed with a small frame 51 of rigid structure connected with the blanking box 6, and The material box 6 is connected with the small frame 51 through a universal adjusting device provided on the small frame 51; a transmission mechanism is installed in the mechanical arm 4, and the feeding end of the transmission mechanism is arranged corresponding to the discharge box 6.

[0082] The small frame 51 can not only play a guiding role during the compensation movement of the blanking box 6, but also serve as an auxiliary load-bearing function for the blanking box 6 and the material package loaded in the blanking box 6.

[0083] In this embodiment, multiple material packages enter the conveying mechanism one by one from th...

Embodiment 2

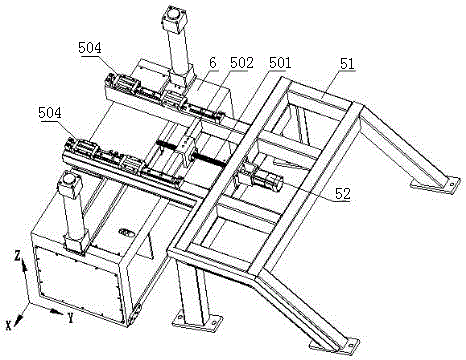

[0094] This embodiment further discloses the structure of the universal adjusting device. A rocker arm type automatic loading manipulator includes a manipulator 4 and a blanking box 6 installed at the discharging end of the mechanical arm 4. A small frame of rigid structure connected to the blanking box 6 is fixedly installed on the mechanical arm 4 51. The unloading box 6 is connected to the small rack 51 through a universal adjusting device provided on the small rack 51; a transmission mechanism is installed in the mechanical arm 4, and the unloading end of the transmission mechanism is arranged corresponding to the unloading box 6 .

[0095] The universal adjustment device includes a compensation adjustment device, a deflection correction device, and a horizontal leveling device. In the present invention, the universal adjusting device mainly composed of a compensation adjusting device, a skew correction device, and a horizontal leveling device realizes that the unloading box...

Embodiment 3

[0131] This embodiment is further optimized on the basis of embodiment 1 or 2, such as figure 1 As shown, a rocker arm type automatic loading manipulator includes a mechanical arm 4, a blanking box 6 installed at the unloading end of the mechanical arm 4, and a device that detects the position and state of the blanking bin 6 and drives the blanking bin 6 to adjust the position and state Control System. The mechanical arm 4 is fixedly installed with a small frame 51 of rigid structure connected to the blanking box 6, and the blanking box 6 is connected to the small frame 51 through a universal adjustment device provided on the small frame 51; A transmission mechanism is installed in the mechanical arm 4, and the discharging end of the conveying mechanism is arranged corresponding to the discharging box 6.

[0132] The control system includes a sensor assembly installed on the blanking box 6 and a control module connected to the sensor assembly; the signal output end of the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com