Rolling oil volatility testing method for stainless steel cold rolling

A test method and volatile technology, applied in the field of calendering oil, can solve the problems of poor dripping effect, influence test results, inaccurate test data, etc., and achieve the effect of accurate dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

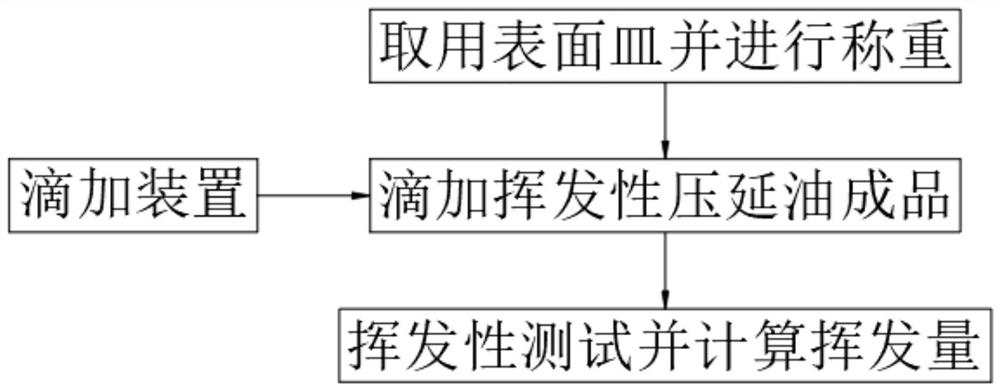

[0036] A method for testing the volatility of rolling oil for stainless steel cold rolling, characterized in that it comprises the following steps:

[0037] S1. First, take a clean watch glass and weigh it, and its weight is 47.84g;

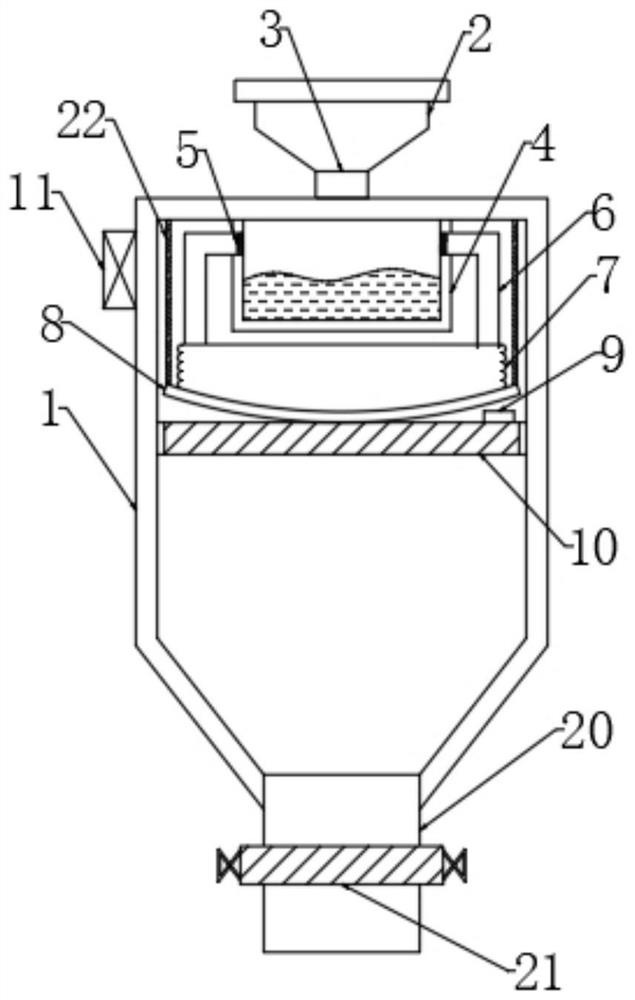

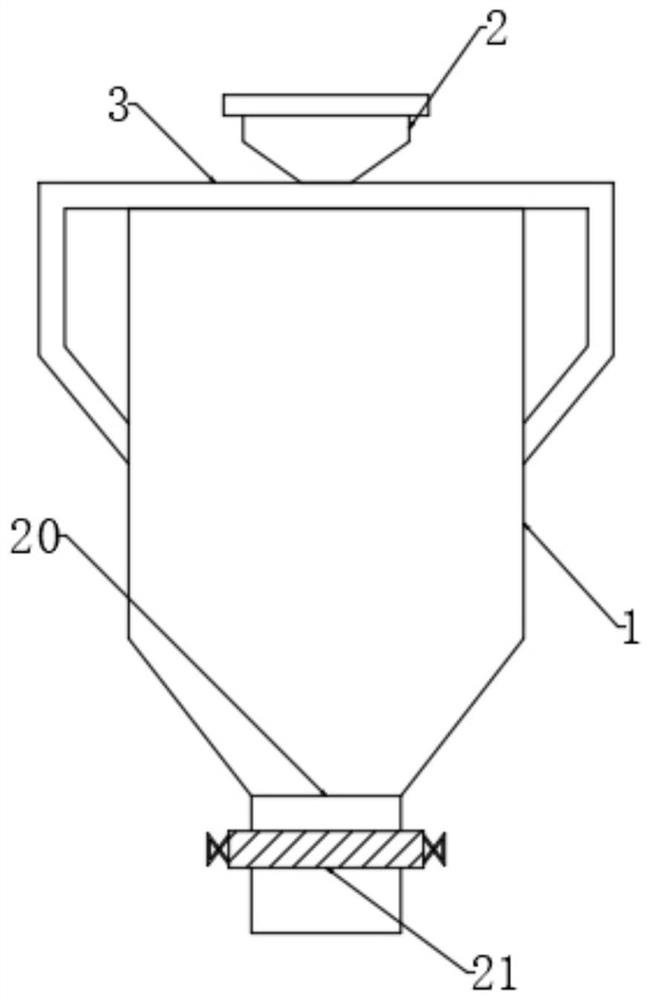

[0038] S2. Add the finished product of volatile calendering oil dropwise on the surface dish through a dripping device. The dripping amount of the finished product of volatile calendering oil is 10.19g, wherein the finished product of volatile calendering oil is vulcanized by 40% of paraffin-based mineral oil and extreme pressure lubricant 8% of fatty acid ester, 3% of refined sodium petroleum sulfonate, 8% of oleic acid, 1% of oil-based antirust agent and 40% of low-flash point solvent oil and other industrial-grade ingredients;

[0039] S3. Under the constant temperature condition of 25°C, measure the weight of the watch glass and the volatile rolling oil product in different time periods, and calculate the volatilization amount.

[0040] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com