Illuminating lamp metal shell punch forming device

A metal shell and stamping forming technology, which is applied in the field of stamping and forming devices for metal shells of lighting fixtures, can solve problems such as limitation, affecting the stamping accuracy of aluminum sheets, and the inability to guide aluminum sheets, so as to facilitate disassembly and replacement and improve guidance accuracy , Enhance the effect of stamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

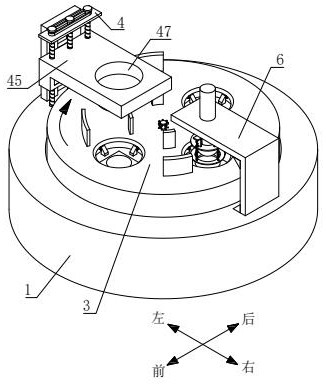

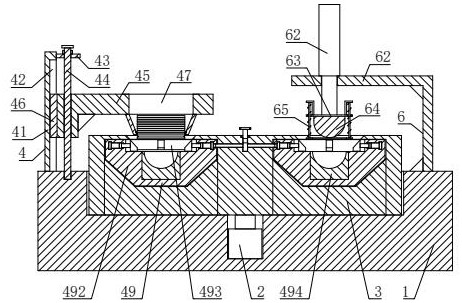

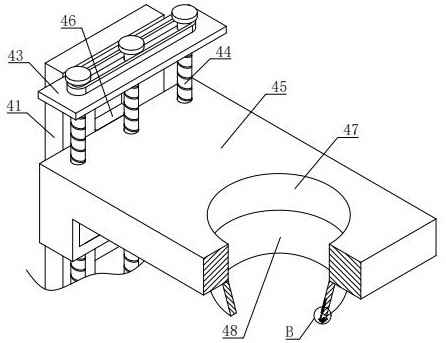

[0036] see figure 1 and figure 2 , a metal shell stamping and forming device for lighting lamps, including a workbench 1, an intermittent motor 2, a support base 3, a discharging part 4 and a stamping part 6, the upper end of the workbench 1 is provided with a circular chute, the circular chute An installation groove is opened at the bottom and at the center, the intermittent motor 2 is arranged in the installation groove, and a support seat 3 is rotated in the circular chute. Parts, the bottom of the support seat 3 is connected with the output shaft of the intermittent motor 2, and the upper end of the support seat 3 is evenly provided with a plurality of processing grooves along its circumferential direction, and the left and right sides of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com