Novel chemical material screening machine for chemical engineering

A screening machine and chemical technology, which is applied in the field of screening machines, can solve the problems of large screening machine, material waste, and increased friction on the surface of the magnetic plate, so as to ensure the magnetic separation effect, improve the screening effect, and reduce material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

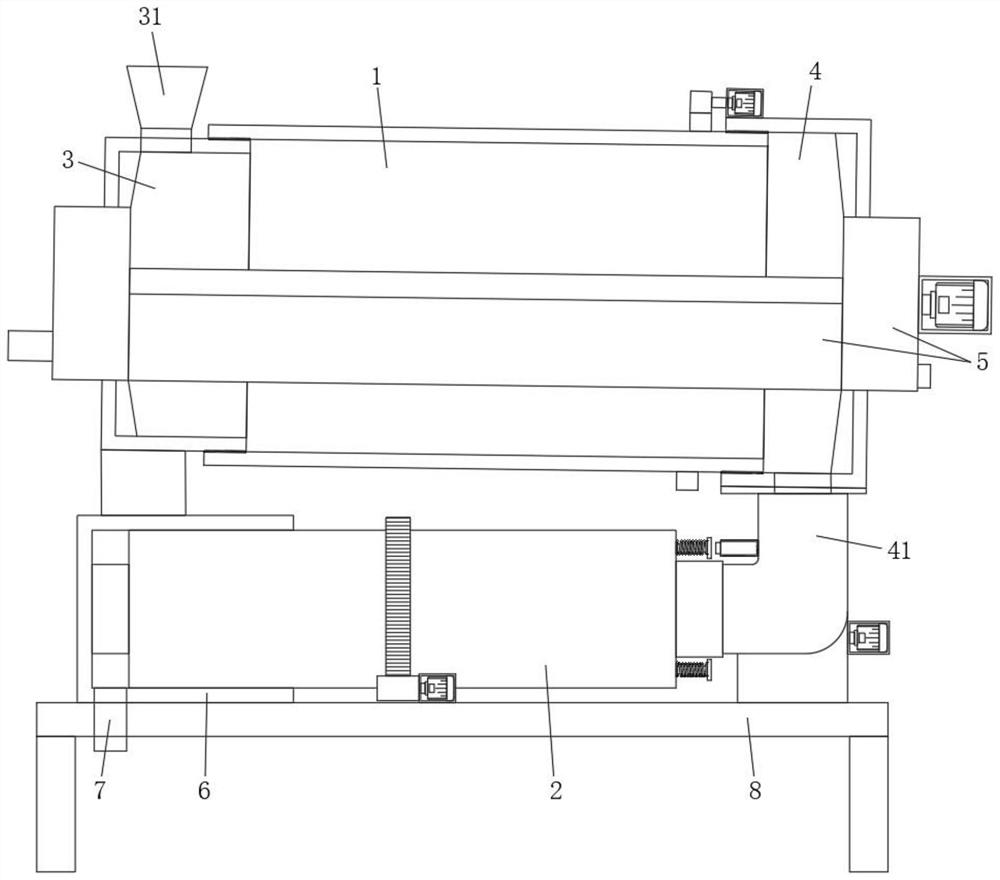

[0038] see Figure 1-Figure 5 As shown, the present invention provides the following technical solutions: a novel chemical material screening machine for chemical industry, comprising a magnetic separation cylinder 1 and a screening cylinder 2 connected sequentially from top to bottom, and the magnetic separation cylinder 1 and the screening cylinder 2 can rotate independently The magnetic separation cylinder 1 is arranged obliquely, and the two ends of the magnetic separation cylinder 1 are respectively rotated and fitted with an upper end cover 3 and a lower end cover 4, the top of the upper end cover 3 is provided with a feed hopper 31, and the bottom of the lower end cover 4 is provided with a material guide elbow 41 , and the magnetic separation cylinder 1 is connected to the screening cylinder 2 through the material guide elbow 41;

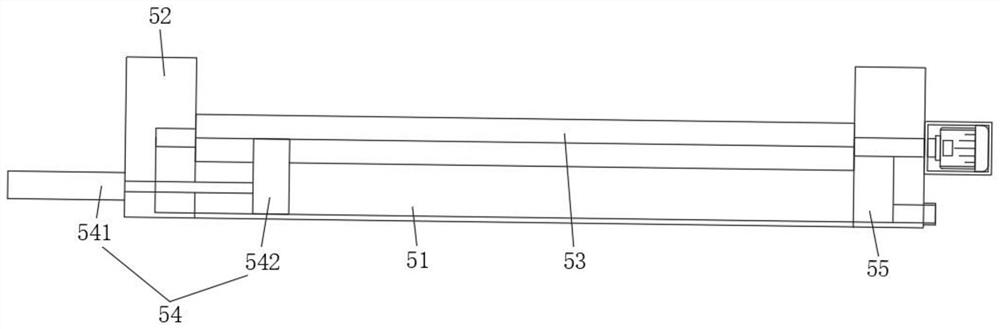

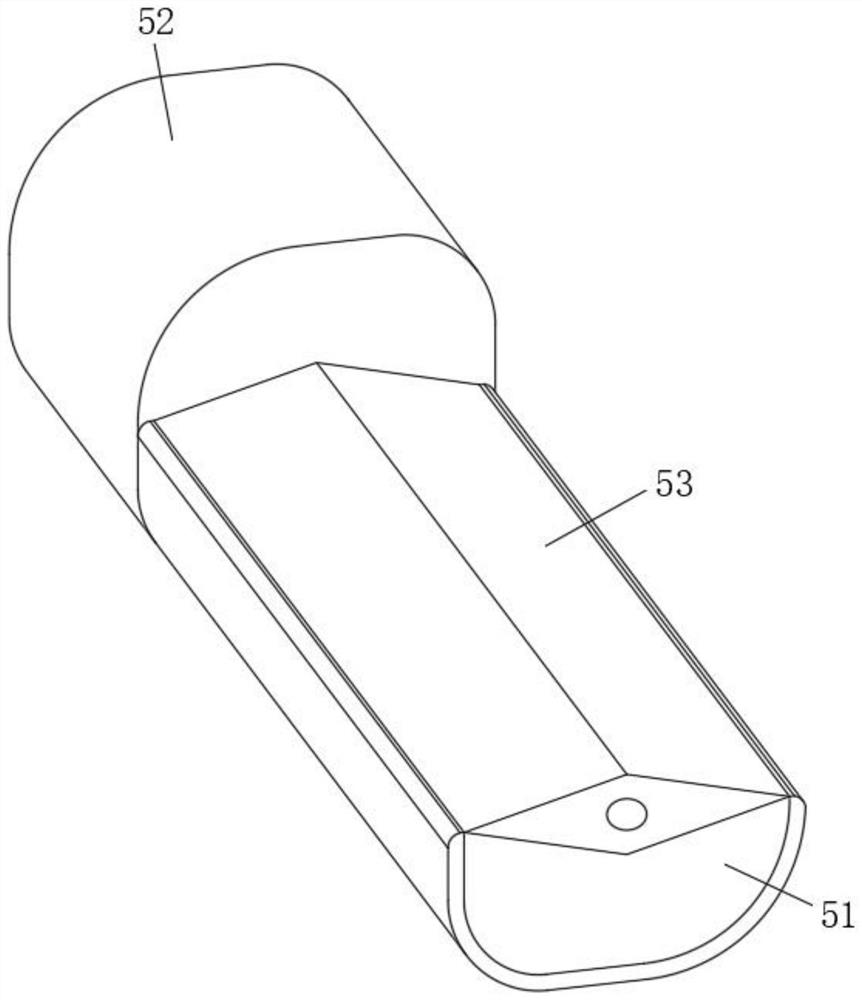

[0039]The upper end cover 3 and the lower end cover 4 are all fixedly arranged, and a magnetic separation device 5 is fixed between the upp...

Embodiment 2

[0052] see Figure 1-Figure 10 As shown, the present invention provides the following technical solutions: a novel chemical material screening machine for chemical industry, comprising a magnetic separation cylinder 1 and a screening cylinder 2 connected sequentially from top to bottom, and the magnetic separation cylinder 1 and the screening cylinder 2 can rotate independently .

[0053] Above-mentioned, regarding magnetic separation cylinder 1, can adopt the same structure in embodiment 1; And about screening cylinder 2, comprise following structure:

[0054] to combine figure 1 As shown, the end of the screening cylinder 2 away from the material guide elbow 41 is rotated with a fixed sleeve 6, and a discharge space is reserved between the fixed sleeve 6 and the screening cylinder 2, and a discharge pipe 7 is installed at the bottom of the discharge space.

[0055] In this embodiment, as a possible implementation, the screening cylinder 2 includes an outer cylinder 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com