Planar support of three-dimensional mask and three-dimensional mask provided with planar support

A technology of a bracket body and a mask, applied in the field of masks, can solve the problems of long injection and cooling time of rubber material, increased production difficulty of the support frame, large space occupied by packaging and storage, etc., so as to facilitate automatic mass production and low manufacturing cost. , the effect of fast injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

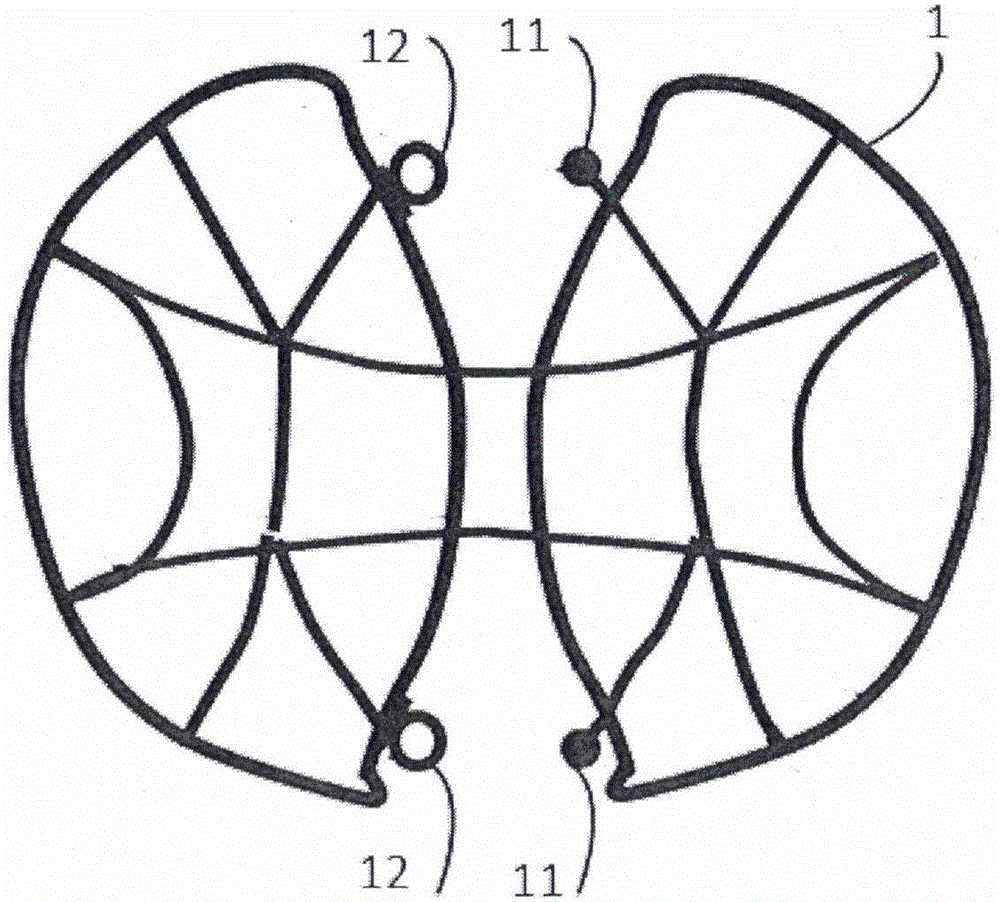

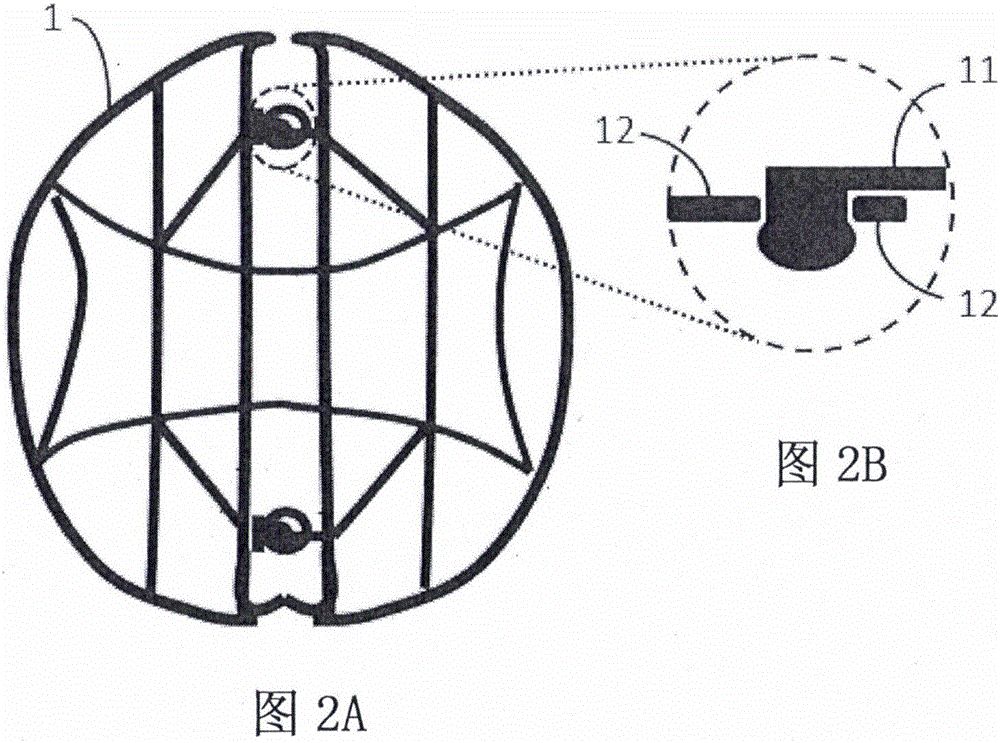

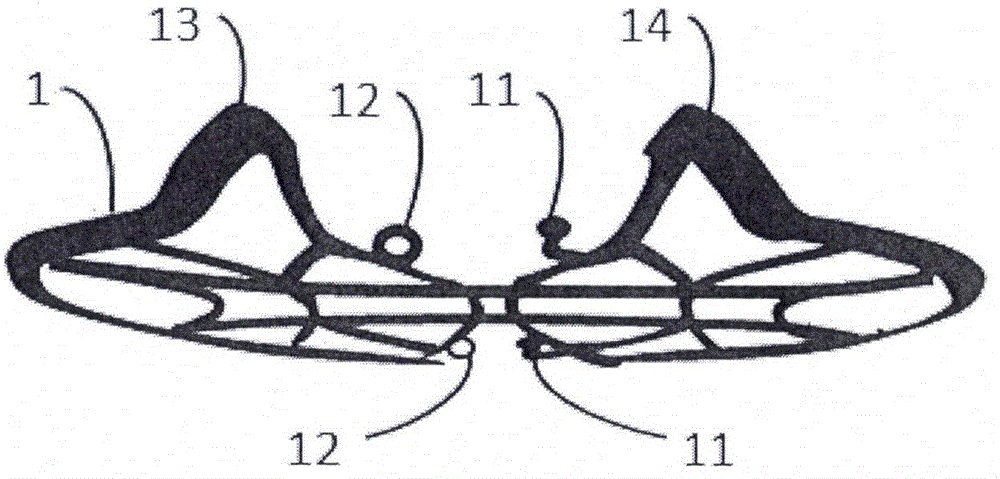

[0030] see figure 1 and Figure 2A As shown, it is a schematic diagram of the unfolded state and a schematic diagram of the structure of the connected state of a preferred embodiment of the plane three-dimensional mask bracket of the present invention. As shown in the figure, a planar three-dimensional mask support 1 of the present invention is used to be installed in the mask body 2 with a three-dimensional support space. Preferably, it is an elastic flat frame structure with mutual Two stents placed symmetrically; the adjacent sides of the two stents are the inner periphery of the stent, and the non-adjacent sides are the outer periphery of the stent; the sides of the two stents The middle position of the inner peripheral edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com