Patents

Literature

56results about How to "Facilitate automated mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Winding power inductor and production method thereof

ActiveCN103295732AObvious high currentReduce DC resistanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresEpoxyButt welding

Disclosed are a winding power inductor and a production method thereof. An I-shaped core is made of ferrous alloy soft magnet powder. A coil winding is a butt-wound flat enameled wire winding made by butt-welding flat wires. A glue layer is a magnetic glue layer made of ferrous alloy soft magnet and epoxy resin system. The production method includes: making the I-shaped core of the ferrous alloy soft magnet powder, making an L-shaped sputtered metallized layer on the vane swing side of the I-shaped core by means of sputtering, winding the flat enameled wires on a middle post of the I-shaped core by means of butt welding to make the butt-wound flat enameled wire winding, connecting wire ends of the butt-wound flat enameled wire winding to the L-shaped-section metallized layer by spot welding to form electrodes, and using a glue dispenser to coat the surface of the butt-wound flat enameled wire winding after the wire ends are fused so as to make the magnetic glue layer. The winding power inductor has the advantages of evident high current and low-current impedance, is simple in process, and is convenient for automatic batch production.

Owner:贵阳顺络迅达电子有限公司

Granular organic composite straw fertilizer

ActiveCN104446775AImprove utilization efficiencyExpand areaFertilising methodsOrganic fertilisersDry weightTrace element

The invention discloses a granular organic composite straw fertilizer. The granular organic composite straw fertilizer comprises the following components in percentage by dry weight: 50-70% of crop straws, 10-15% of straw-prepared bio-char, 10-20% of humic acid fertilizer, 1-3% of bone meal and 3-5% of trace element compounds, and is prepared through the following steps of mixing according to certain weight percentage after smashing all the components in dry weight, sufficiently and uniformly mixing, and then, carrying out granulation treatment. By applying the granular organic composite straw fertilizer, the soil structure can be improved, and the utilization efficiency of the fertilizer can be increased.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

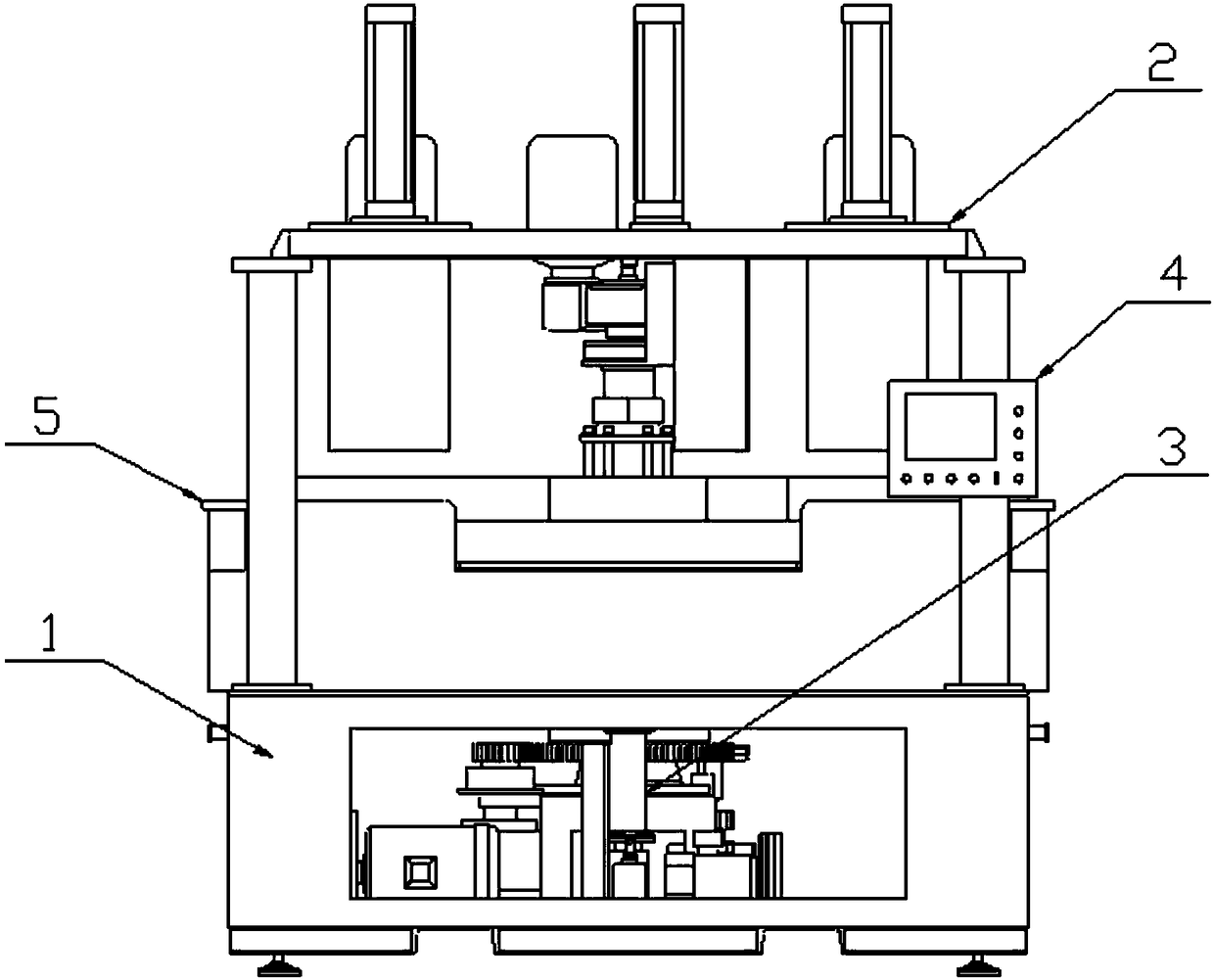

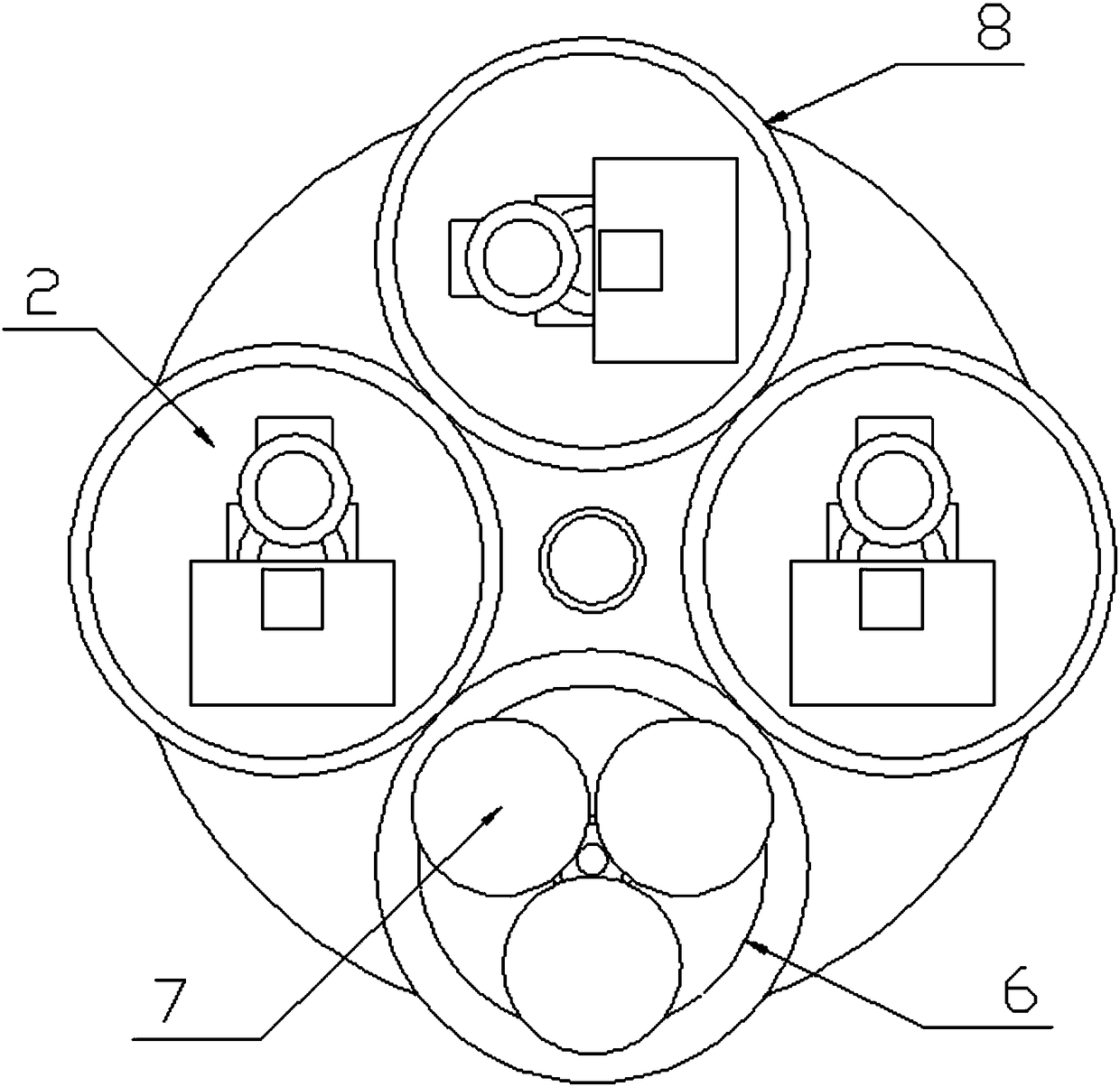

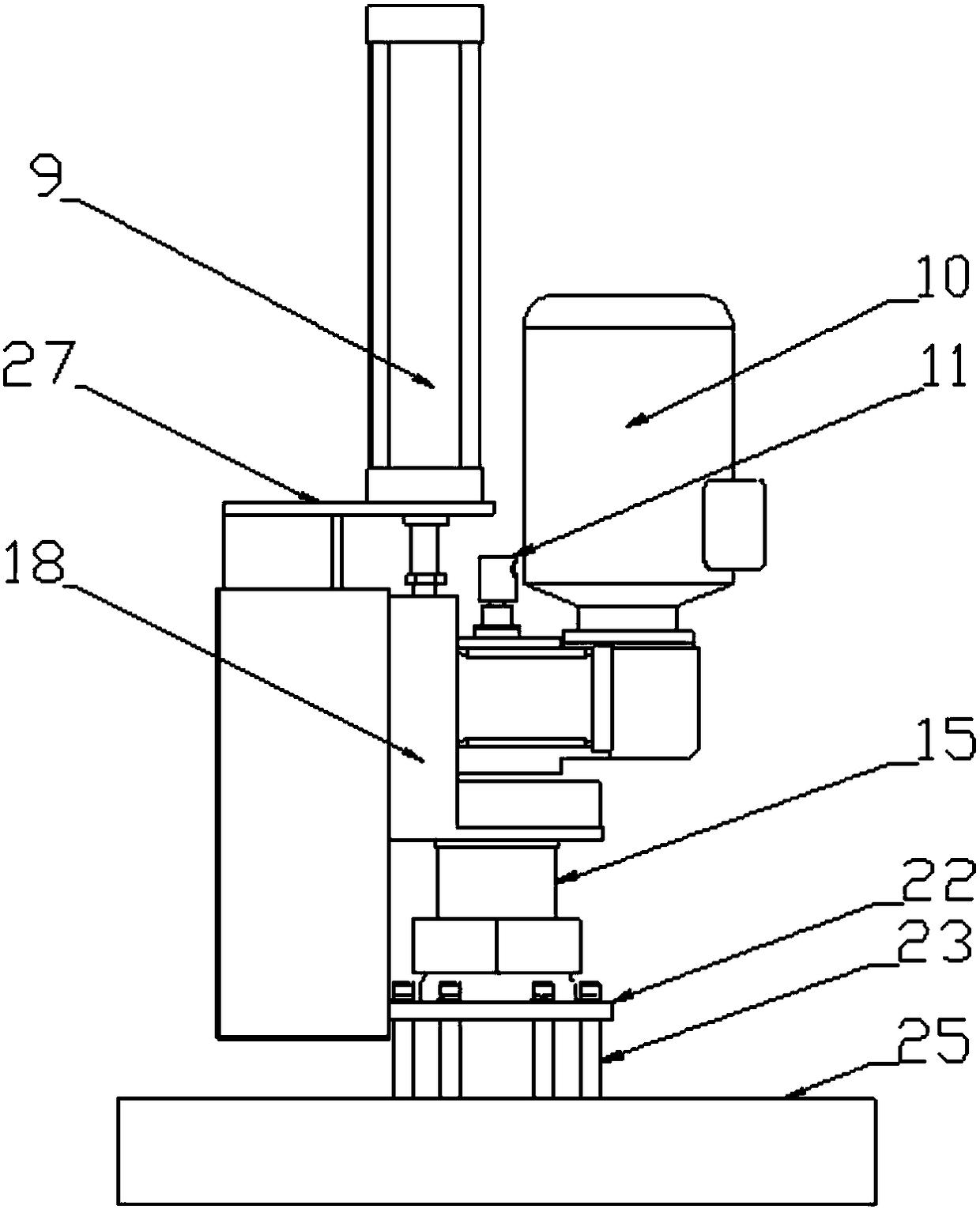

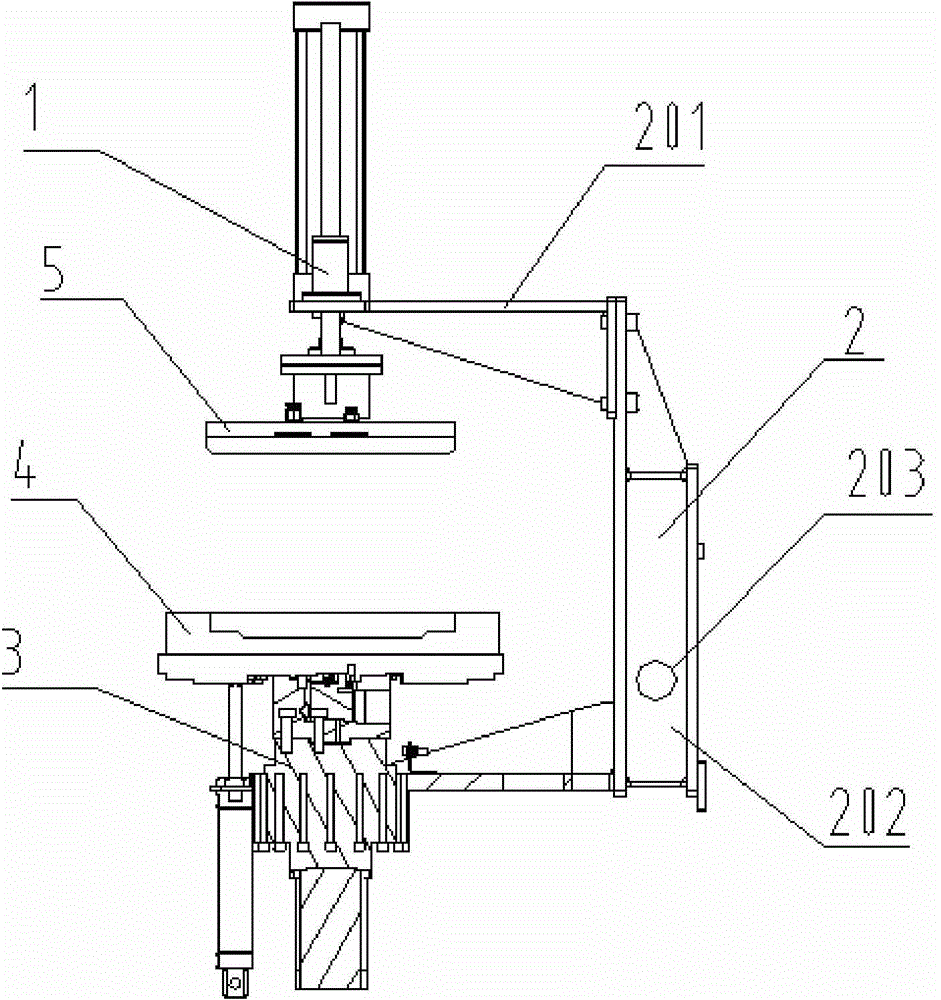

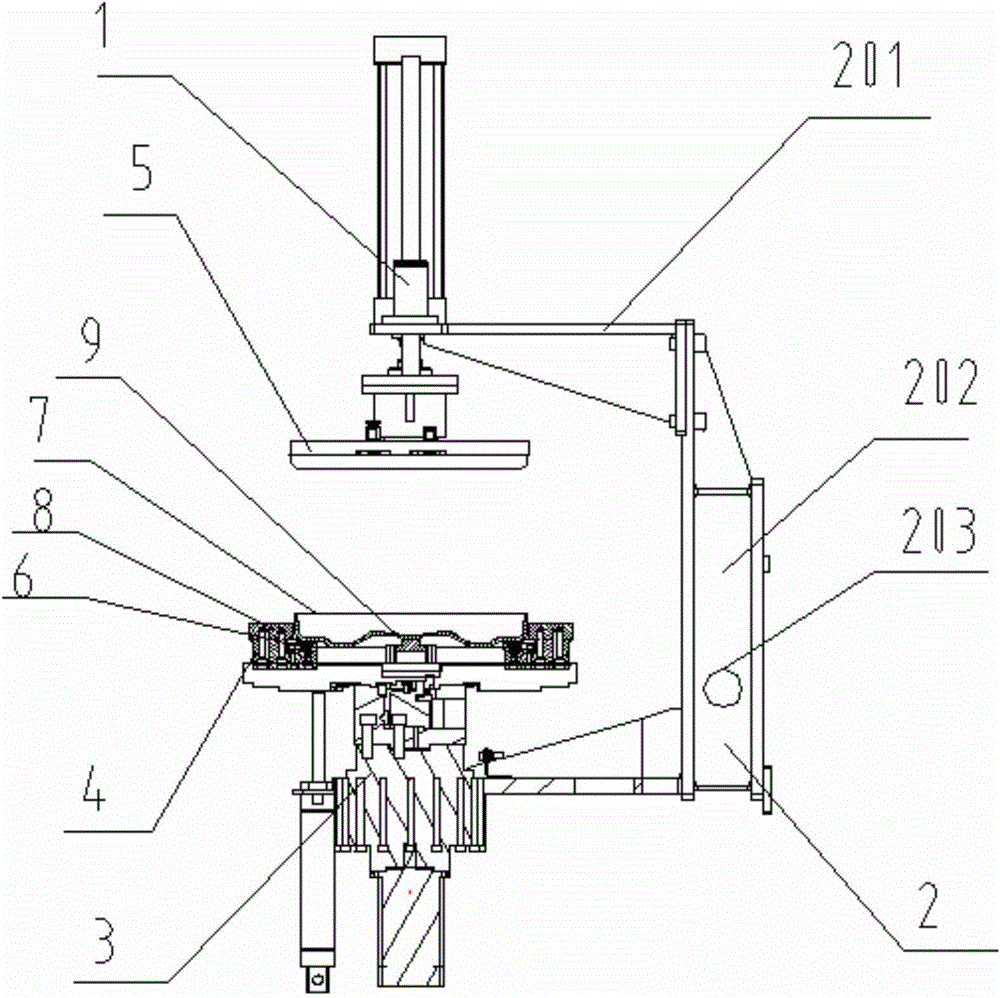

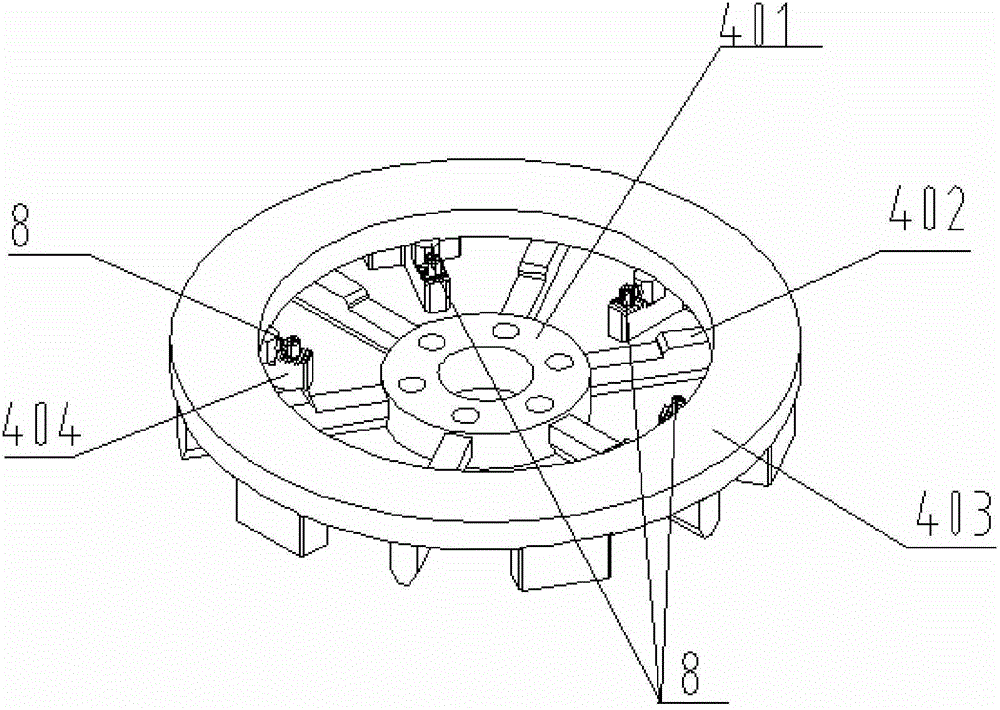

Continuous multi-station curved surface polishing machine

PendingCN108214265ARealize multi-station polishingRealize continuous operationPolishing machinesGrinding feedersReducerEngineering

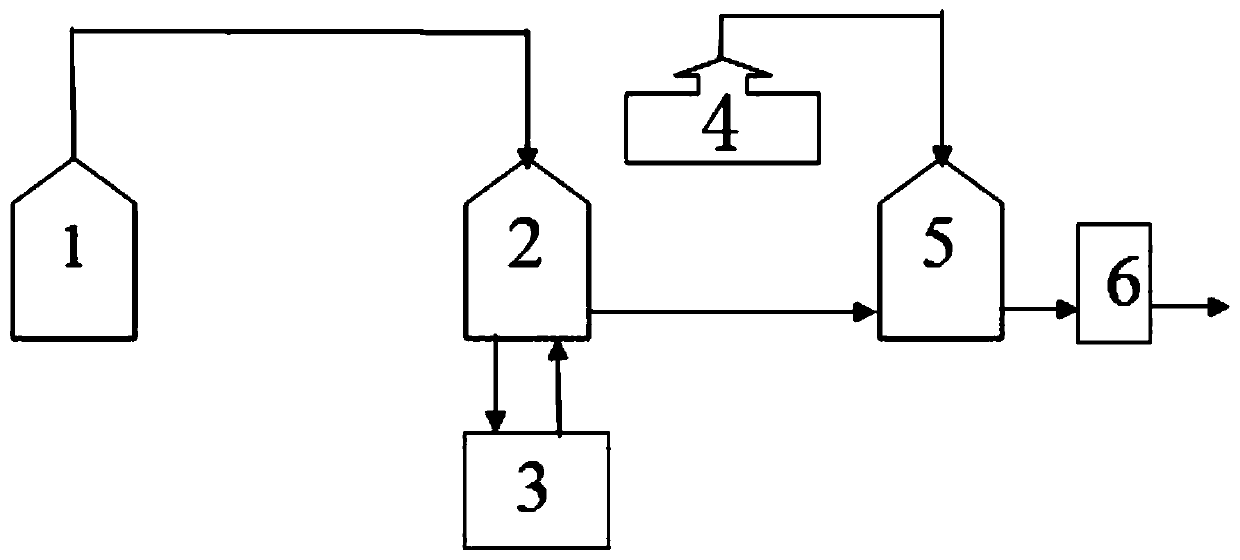

The invention provides a continuous multi-station curved surface polishing machine. The continuous multi-station curved surface polishing machine comprises a machine frame, an upper disc unit, a transmission main body, an electric control operation box and a vacuum adsorption device; the upper disc unit comprises an upper disc rotating device and an upper disc lifting device, and the upper disc rotating device comprises an upper disc speed reducing motor, a rotary joint, a main shaft, a round nut, a bearing cover, a bearing block, a bearing, a shaft sleeve, a lifting movable plate, a water retaining cover, an end cover, a universal device, a connecting seat, a supporting screw rod, an upper polishing disc, an upper disc retainer ring and a brush clamping piece; and the transmission main body comprises a station unit, a large liquid baffle cover, a station disc, a tray shaft, a bearing, a tray bearing seat and a large gear, a gear seat, a transmission gear, a revolution speed reducer gear, a station transmission gear, a station speed reducer gear, a four-channel rotary joint, a gear claw type clutch device, a station speed reducing motor set and a revolution speed reducing motor set. According to the continuous multi-station curved surface polishing machine, multi-station polishing can be achieved, continuous operation can be achieved, and the grinding and polishing efficiency is greatly improved; and meanwhile, the automatic batch production is facilitated.

Owner:HUNAN YUJING MACHINE

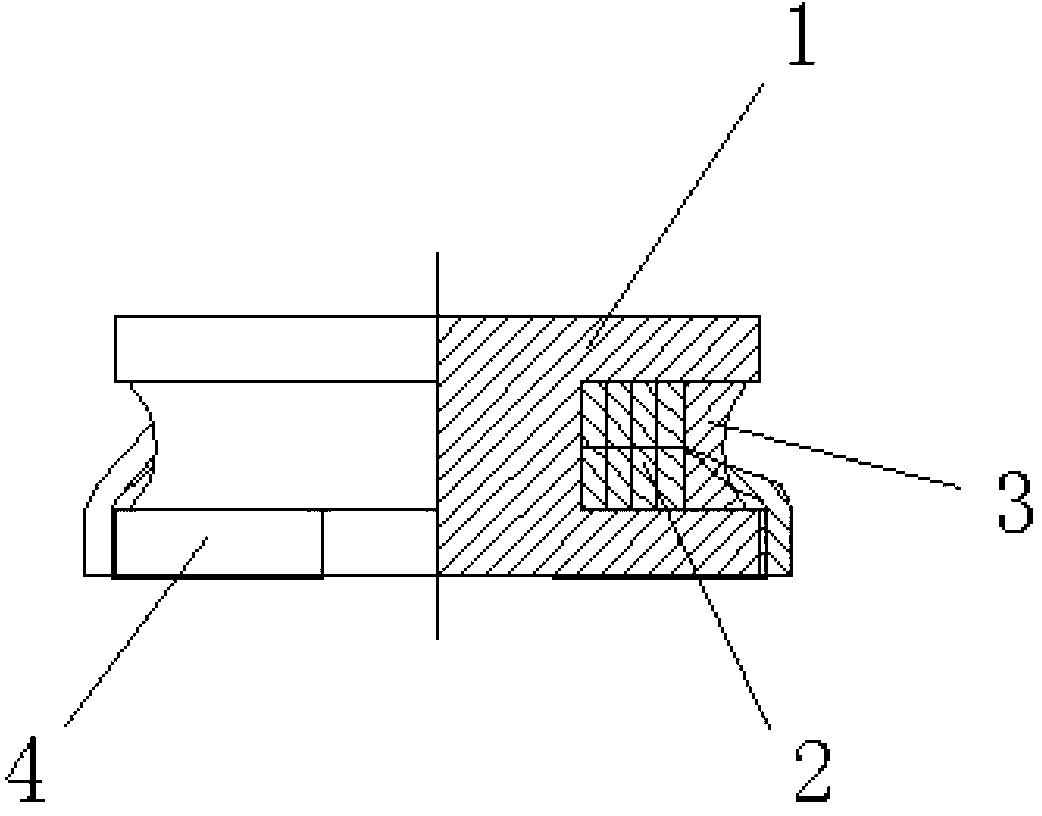

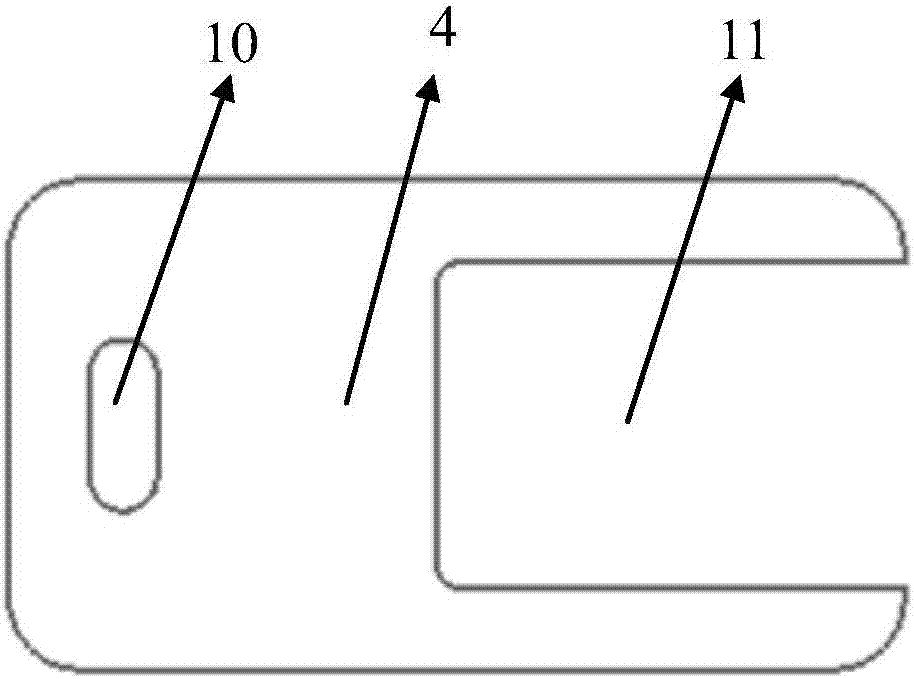

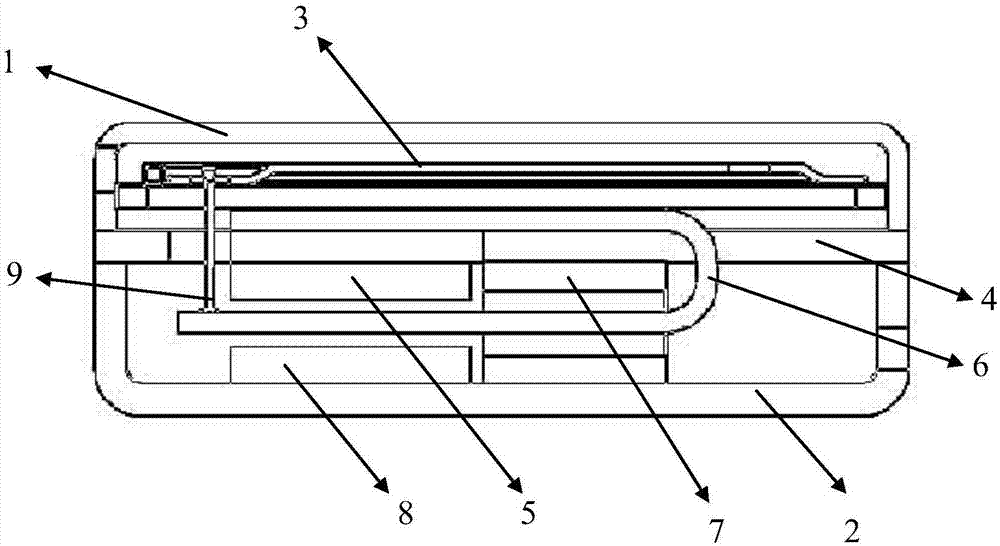

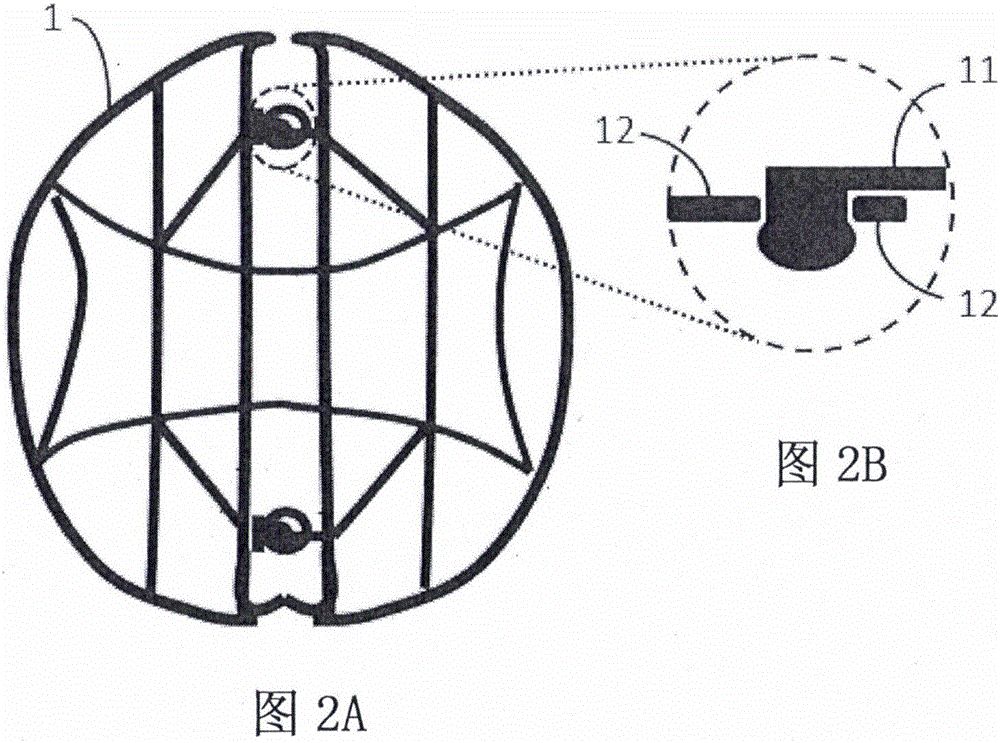

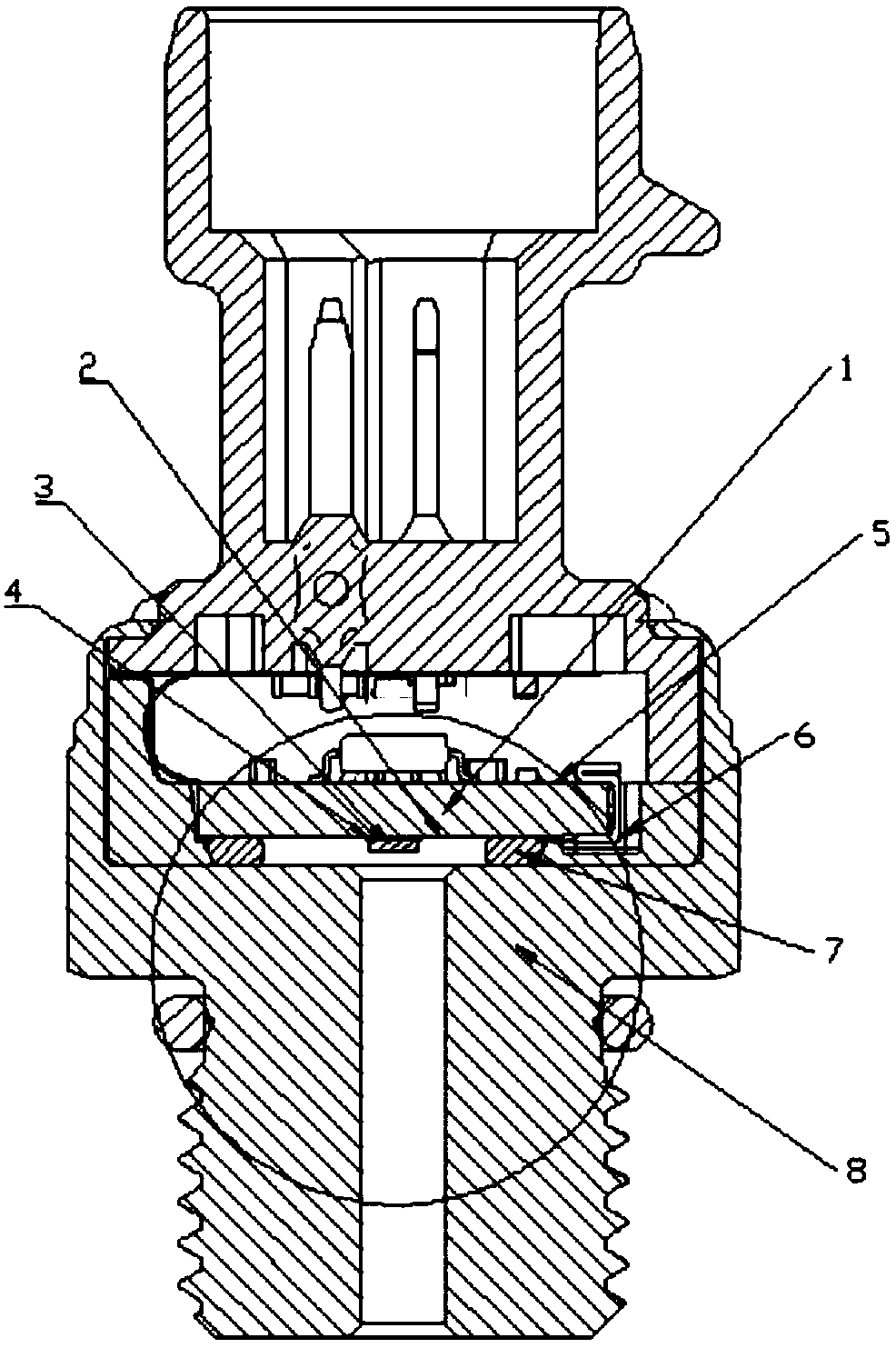

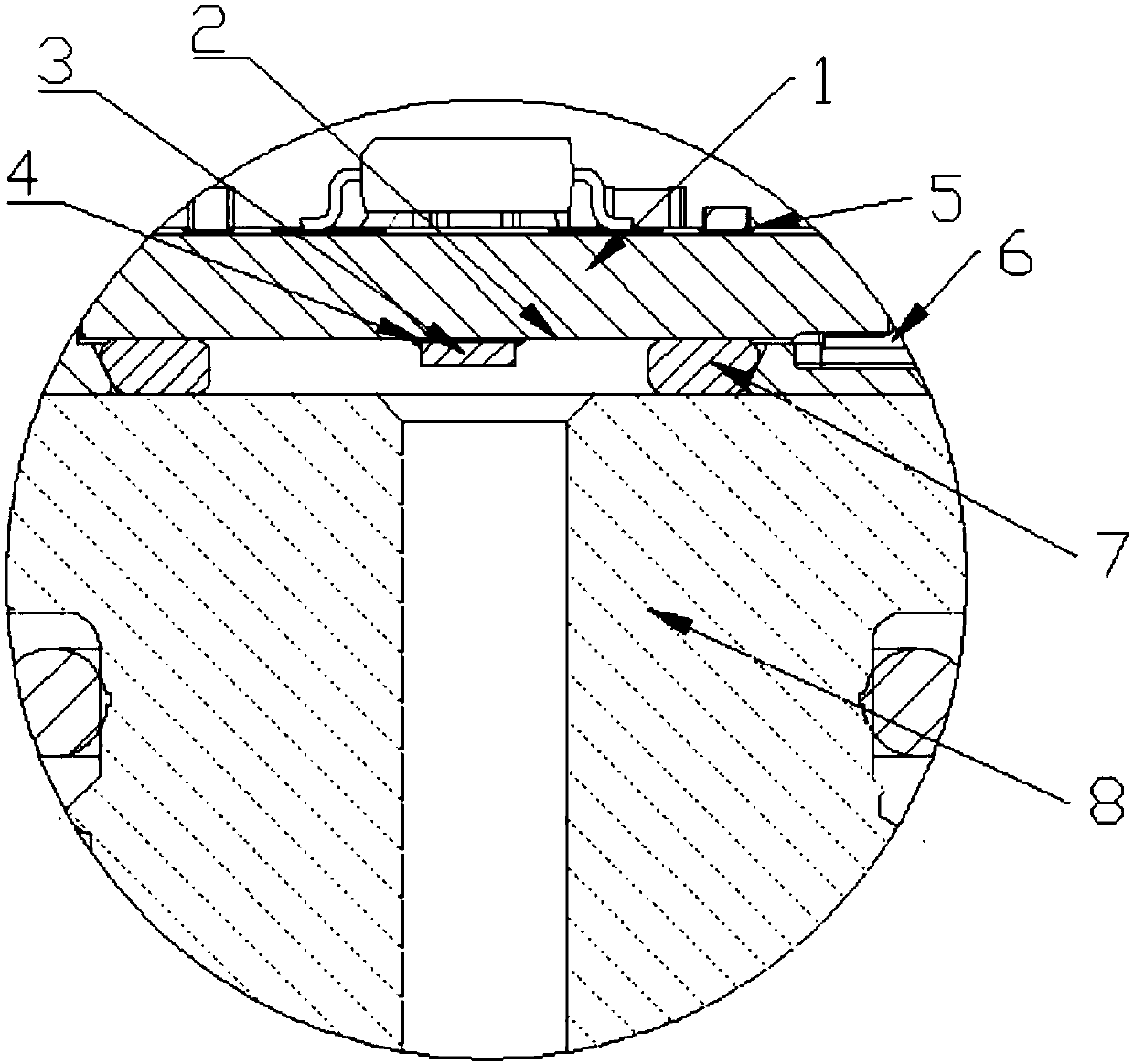

Moving iron receiver with novel magnetic conduction structure

PendingCN107135449ASimple designImprove performanceElectrical transducersLoudspeakersEngineeringL-shell

The invention discloses a moving iron receiver with a novel magnetic conduction structure. The moving iron receiver comprises a shell, and a vibrating diaphragm, a reed, a magnetic conduction plate, an upper magnet, a coil, a driving rod and a lower magnet arranged in the shell, wherein the shell consists of an upper shell and a lower shell, the vibrating diaphragm is arranged in the upper shell and divides the inner space of the shell into a front cavity and a rear cavity, the magnetic conduction plate is in a sheet shape and is arranged in the rear cavity, and the edge of the magnetic conduction plate is fixed with the upper shell and the lower shell. According to the moving iron receiver disclosed by the invention, an existing square magnet yoke structure is replaced by the sheet-like magnetic conduction plate, and thus the product design can be simplified, the product performance can also be improved, and the automatic mass production can be facilitated.

Owner:SUZHOU E AUDIO ELECTRONICS

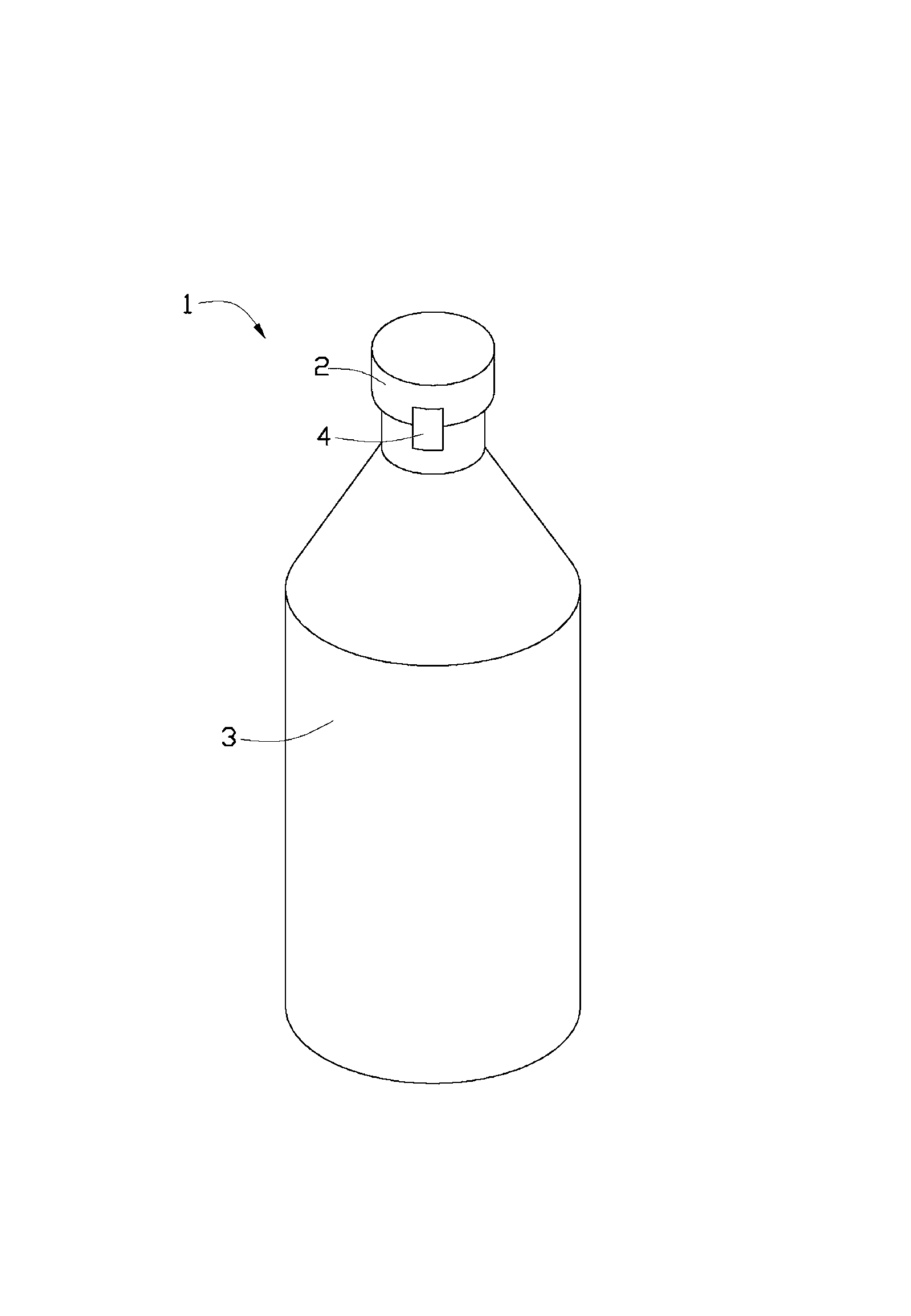

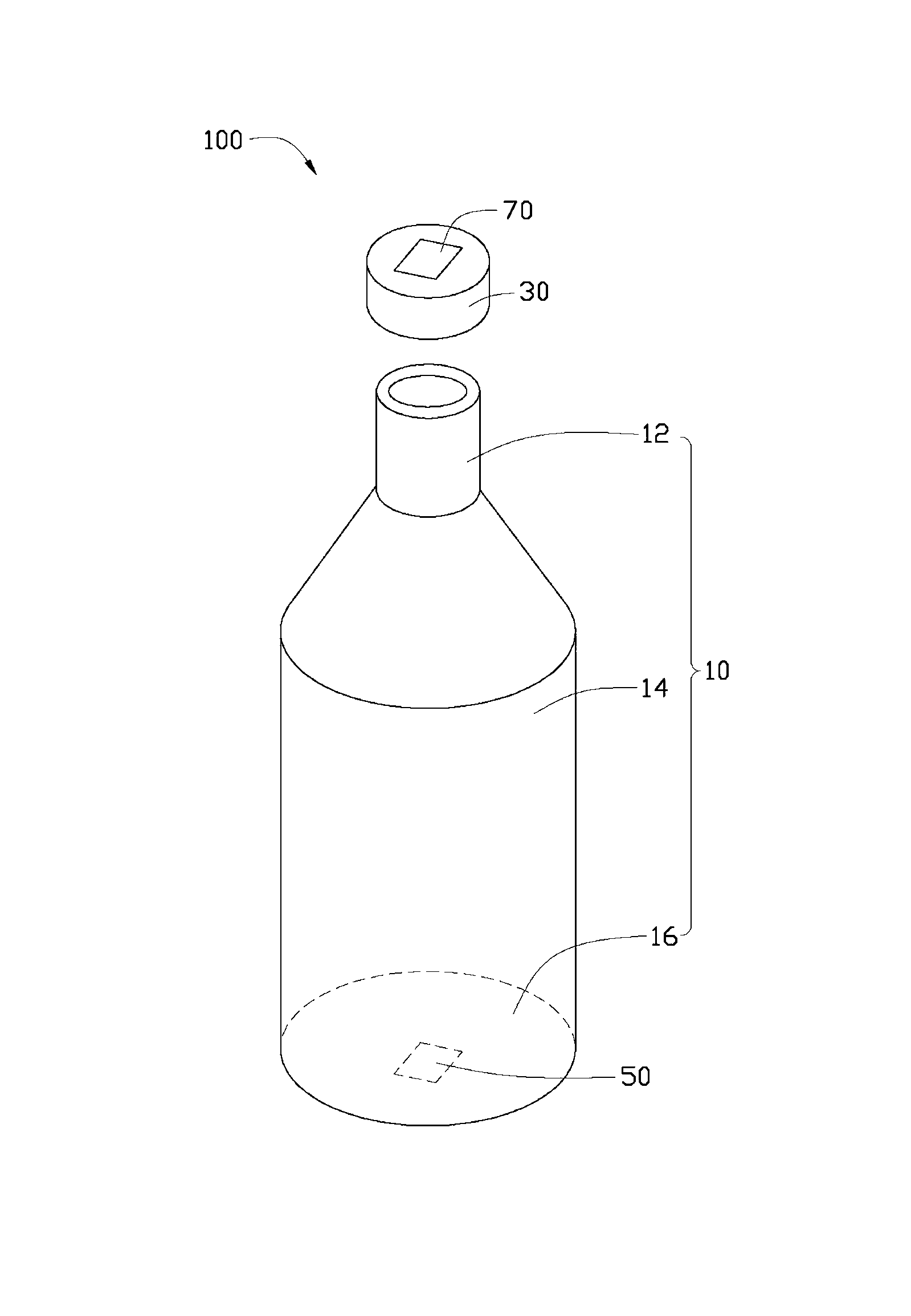

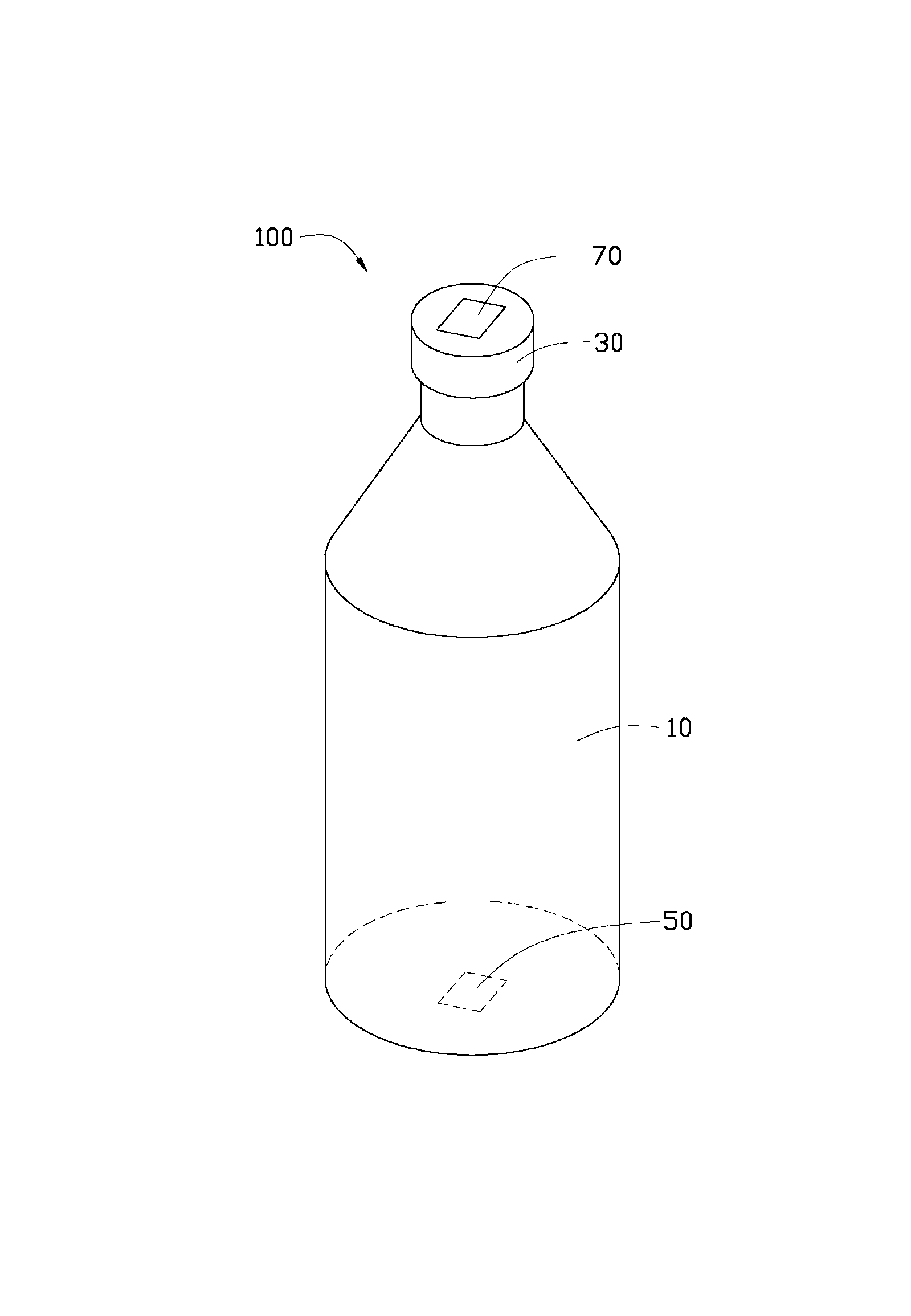

Anti-counterfeiting method and product using same

InactiveCN103186863ASo as not to damageFacilitate automated mass productionContainer decorationsLevel indicationsWorld Wide WebSeries production

The invention provides an anti-counterfeiting method and an anti-counterfeiting product using the anti-counterfeiting method. The anti-counterfeiting method comprises the following steps: providing a first electronic tag, arranging the first electronic tag on a first component, storing an identity identification code in the first electronic tag, proving a second electronic tag, arranging the second electronic tag on a second component, detachably arranging the second component on the first component, storing an identity identification code in the second electronic tag, and judging whether the identity identification code corresponds to or is matched with the identity identification code of the second electronic tag or not to judge the authenticity of a product. The automatic mass production of the anti-counterfeiting product is easy to achieve.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

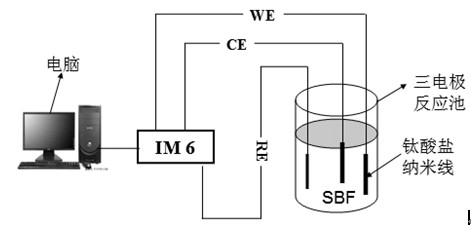

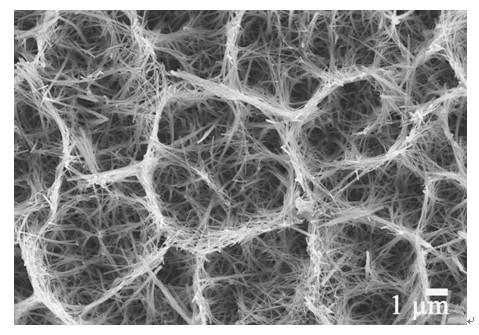

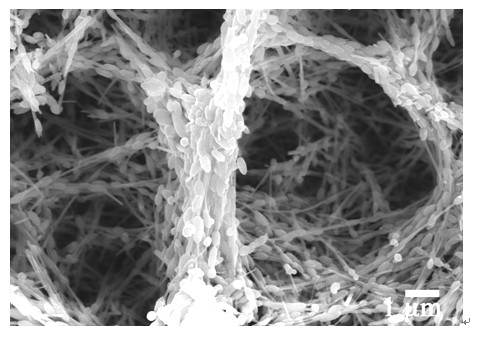

Porous hydroxy calcium phosphate nanometer particle-modified titanium-based titanate nanowire biologic support material and preparation method thereof

ActiveCN102100927AGood biocompatibilityGood mechanical propertiesSuperimposed coating processProsthesisBiocompatibility TestingGrowth cell

The invention discloses a porous hydroxy calcium phosphate nanometer particle-modified titanium-based titanate nanowire biologic support material and a preparation method thereof, and belongs to the field of nanometer biologic materials. In the biologic support material, a titanium-based titanate nanowire with a grid micropore structure is formed by growing a titanate nanowire on a titanium metal substrate; and a porous hydroxy calcium phosphate nanometer particle coating is grown on the surface of the titanium-based titanate nanowire. In the biologic support material, porous hydroxy calcium phosphate nanometer particles are modified on the titanium-based titanate nanowire, so that the biocompatibility and biologic inductivity of the titanium-based titanate nanowire can be improved effectively. Simultaneously, a large quantity of gaps are reserved on the surface and inner part of porous hydroxy calcium phosphate, so the porous hydroxy calcium phosphate is favorable for the loading and control release of medicaments or cell growth factors and can promote newborn bones to grow further to realize double effects of medicinal treatment and bone transplantation or damage repair.

Owner:万家润(常州)环保新材料有限公司

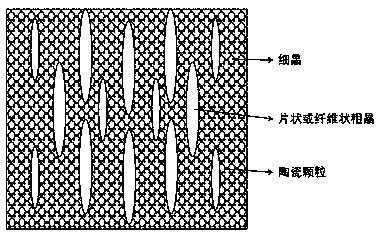

Preparation method of hierarchically-structured composite material with nano-ceramic particle reinforced metal matrix

The invention relates to a preparation method of a hierarchically-structured composite material with nano-ceramic particle reinforced metal matrix and belongs to the technical field of metal matrix composite materials. The method comprises the following steps: carrying out high-energy ball mill mixing of nanoscale ceramic particles with metal powder; then melting to obtain molten metal, keeping the temperature at 30-80 DEG C below a liquid phase line and forming part of spherical grains in the molten metal; adding ceramic-metal mixed powder into the molten metal, stirring and enabling nano-ceramic powder to be uniformly dispersed in the molten metal among the spherical grains; preparing cast ingots; processing the cast ingots by rolling, extruding and drawing, enabling the spherical grainsin the cast ingots to be changed into lamellar or fibrous grains so as to obtain the hierarchically-structured composite material composed of the nano-ceramic particle reinforced metal matrix and thelamellar or fibrous grains. The method is capable of preparing a metal matrix composite material with excellent strength, plasticity and comprehensive performance.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

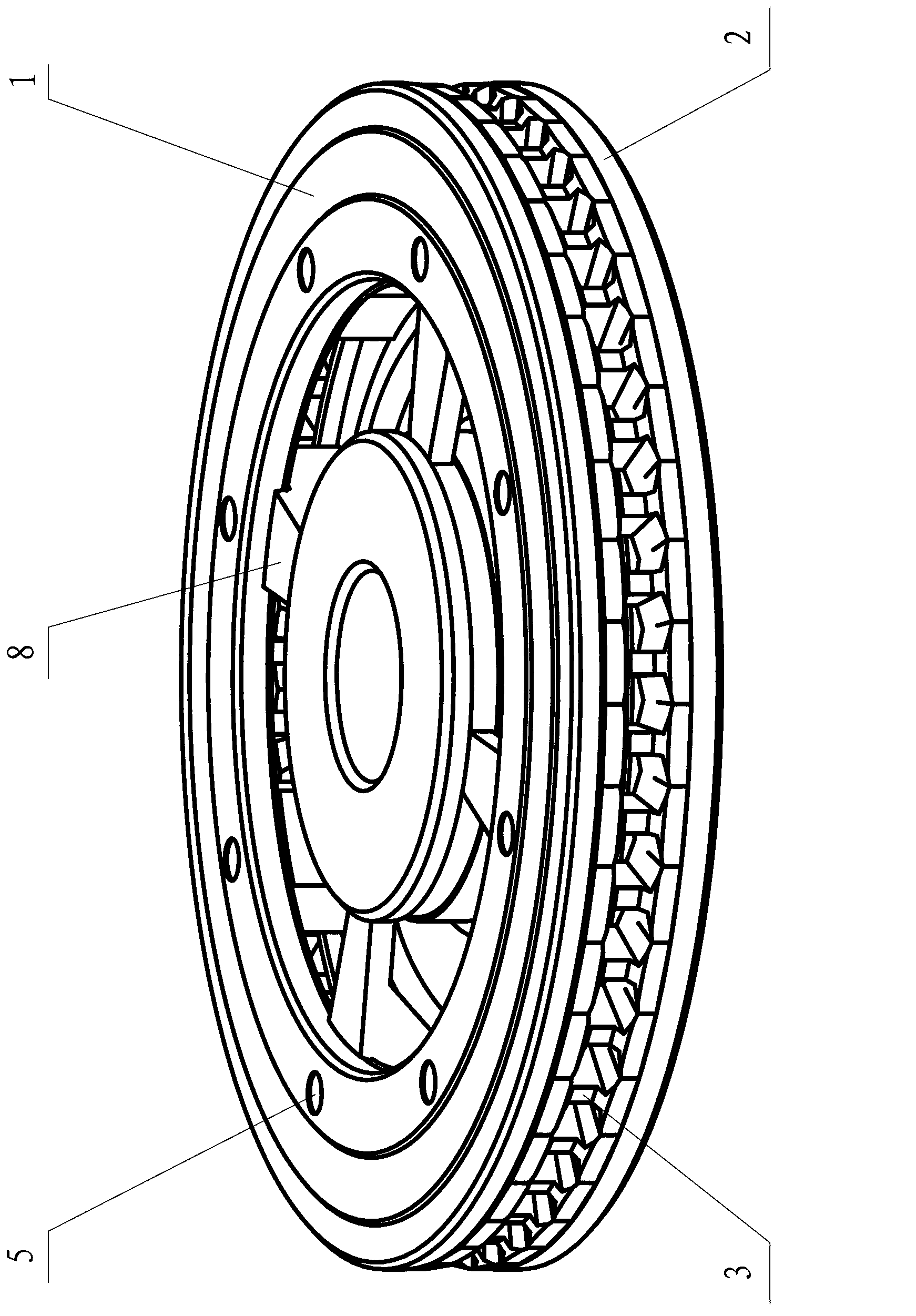

Split type diamond specially-shaped grinding wheel and manufacturing technology thereof

InactiveCN103223647AEasy to implementReduce processing difficultyBonded abrasive wheelsGrinding devicesManufacturing technologyDegrees of freedom

The invention discloses a split type diamond specially-shaped grinding wheel. The split type diamond specially-shaped grinding wheel comprises a grinding ring clamped between a pressing plate and a base plate, wherein the grinding ring is formed by splicing a plurality of single teeth; an anti-flying mechanism for limiting the radial, axial and circumferential degrees of freedom is arranged among each single tooth, the pressing plate and the base plate; the anti-flying mechanism comprises a flange as well as a blocking structure and a metal body which are matched with a groove; the flange and the groove are arranged among / between each signal tooth and the pressing plate and / or the base plate; and the metal body is arranged between a spliced grinding ring and a pressing plate clamping surface, or a base plate clamping surface, or a pressing plate and the base plate clamping surface. The manufacturing technology of the specially-shaped grinding wheel comprises the following steps of: firstly manufacturing the single teeth of an equal-shaped abrasion structure; then splicing the single teeth into the grinding ring; and finally clamping the spliced grinding ring between the pressing plate and the base plate, and setting the anti-flying mechanism for limiting the radial, axial and circumferential degrees of freedom of the single teeth. The equal-shaped abrasion structure difficultly processed on the integral grinding wheel is decomposed into the single teeth and then the single teeth are spliced, so that the split type diamond specially-shaped grinding wheel is convenient to realize.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

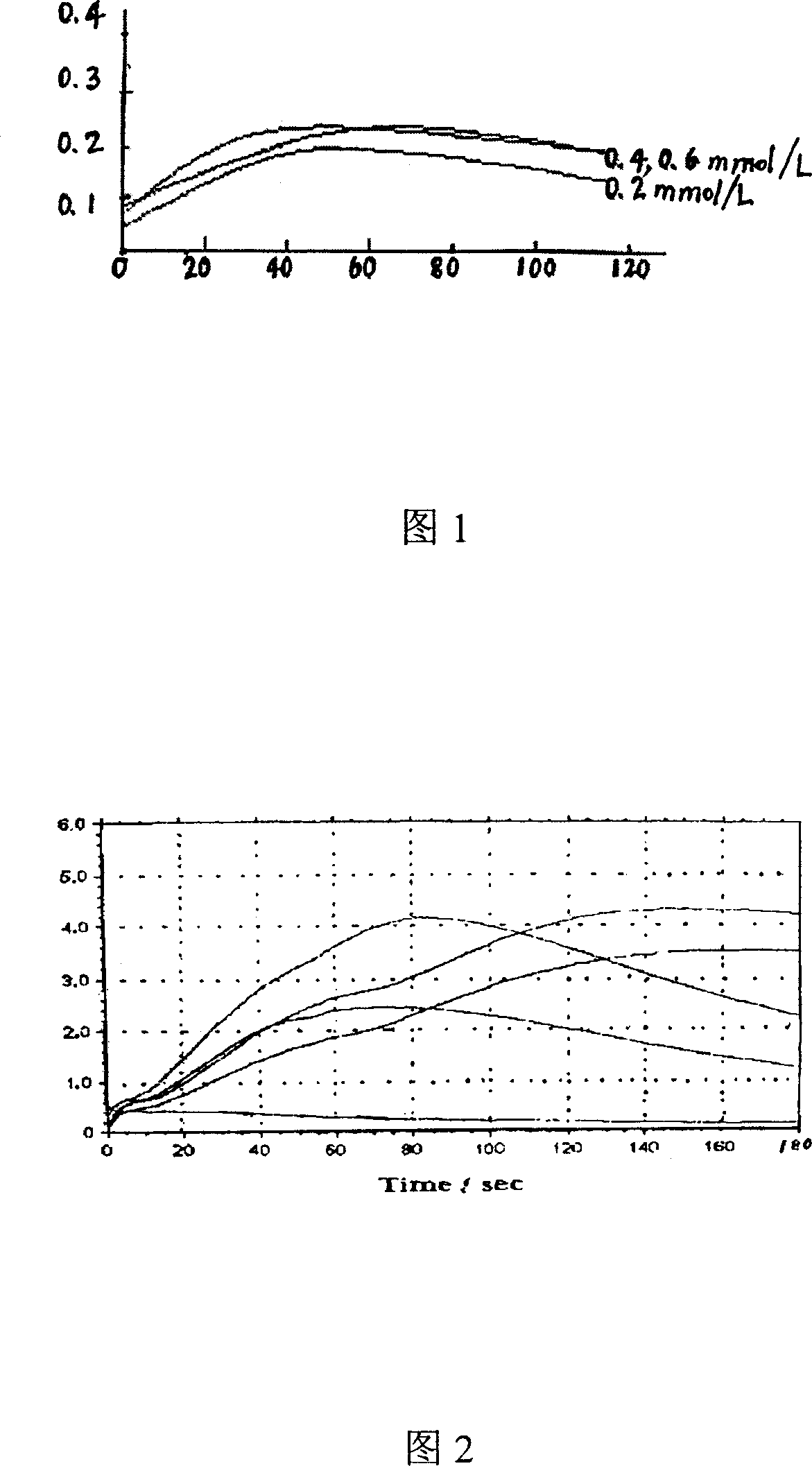

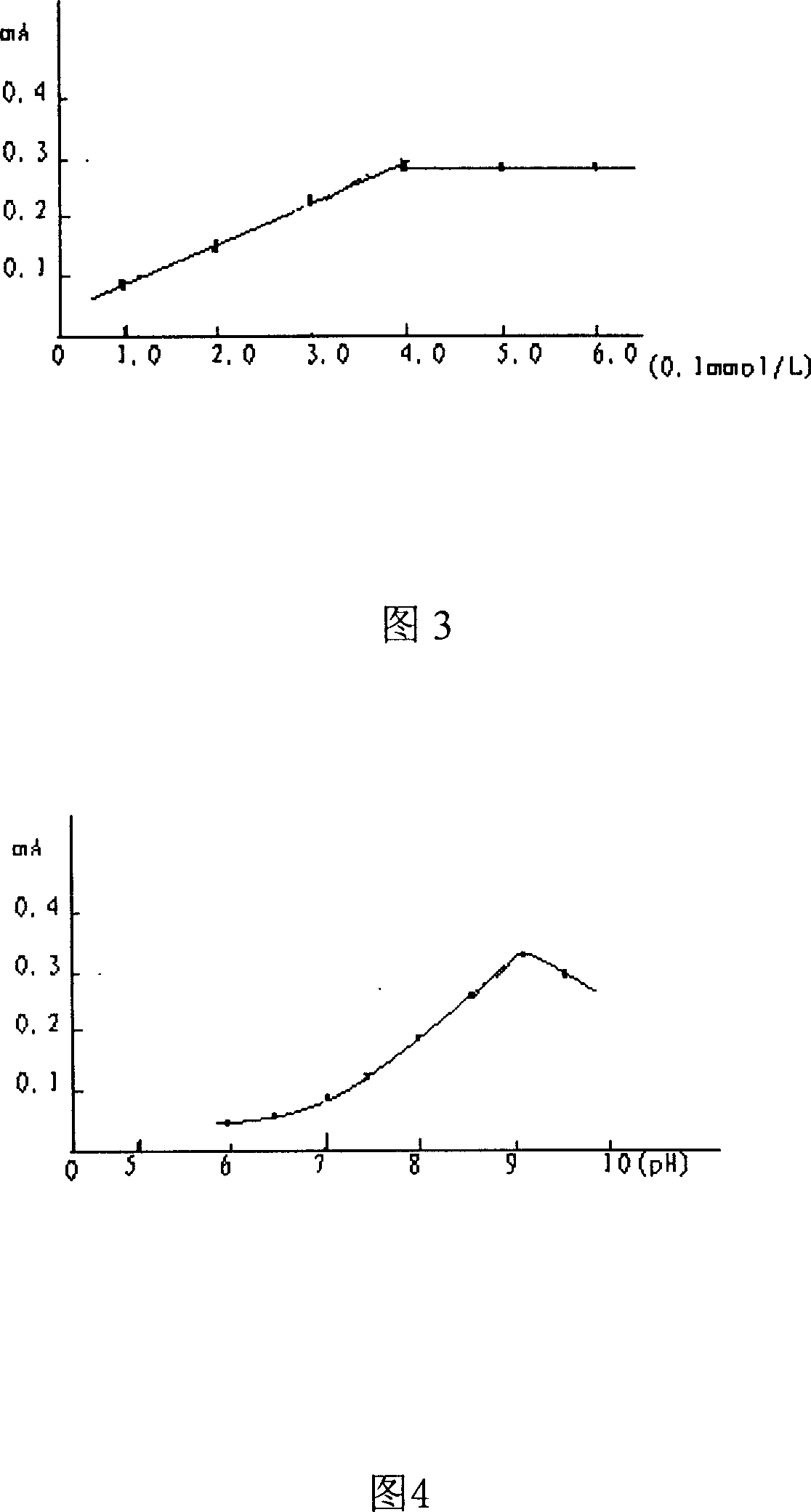

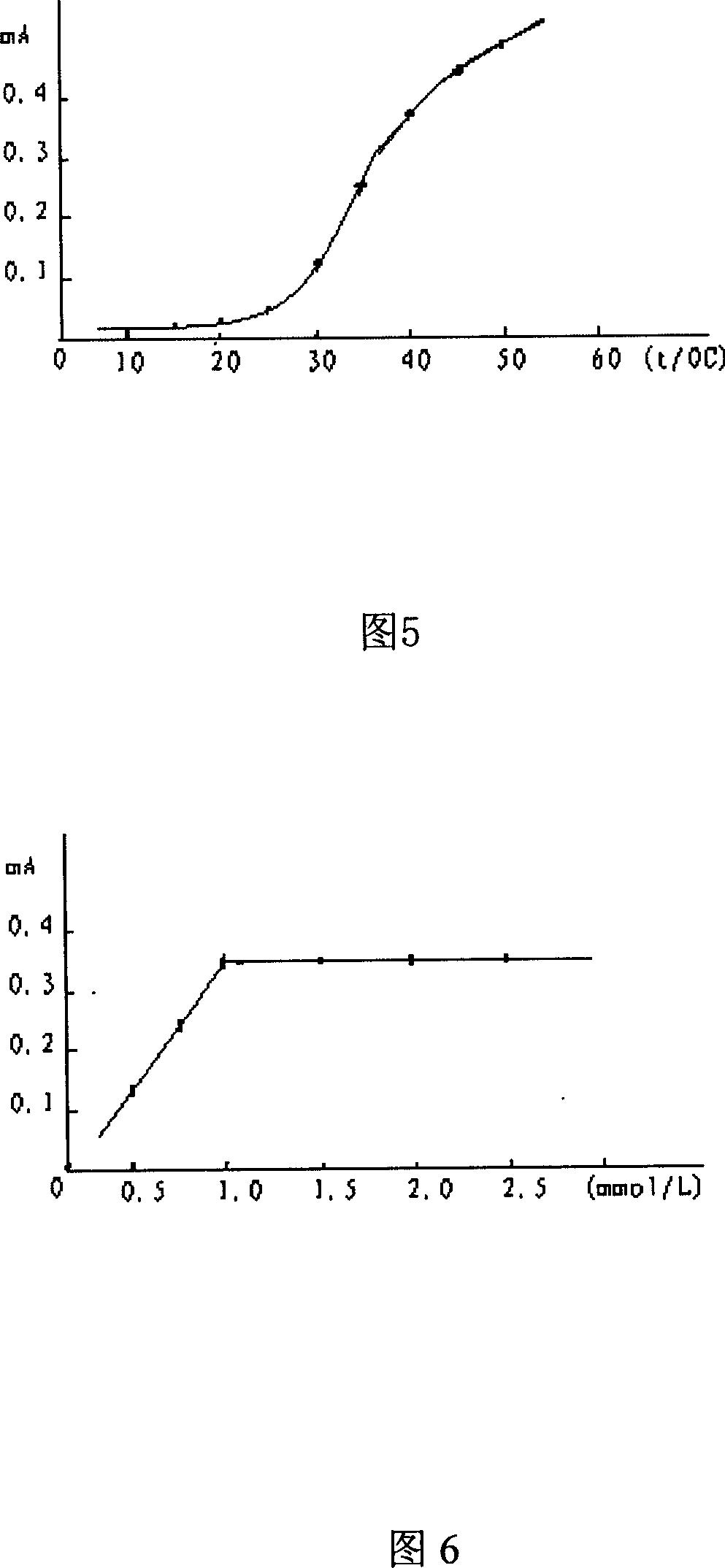

Disposable biological sensor for detecting blood alcohol concentration

InactiveCN1987474AHigh selectivityImprove accuracyMaterial analysis by electric/magnetic meansBiological testingAdhesiveElectron transfer

Through one-off screen-printing, working electrode is prepared by printing commercial carbon ink on plastic film. Printing Ag / AgCl ink produces a counter electrode and a reference electrode. Then, analysis fluid of alcohol dehydrogenase is dropped to a reaction cavity between the working electrode and the reference electrode. After natural seasoning electrode piece, using double face adhesive tape sticks the transparent glue onto the electrode piece so as to form a small electrolytic cell between the transparent glue and the plastic film. When enzyme electrode immerges to blood sample to be tested, reaction is taken place between the enzyme electrode and the sample. Under action of electric field, electron transfer occurs to for current. Based on coincidence relation between electric chemical signal and concentration of substrate to be measured, alcohol concentration in blood can be measured. Features are: high sensitivity, accuracy, low cost, one-off use, and batch production.

Owner:CHONGQING MEDICAL UNIVERSITY

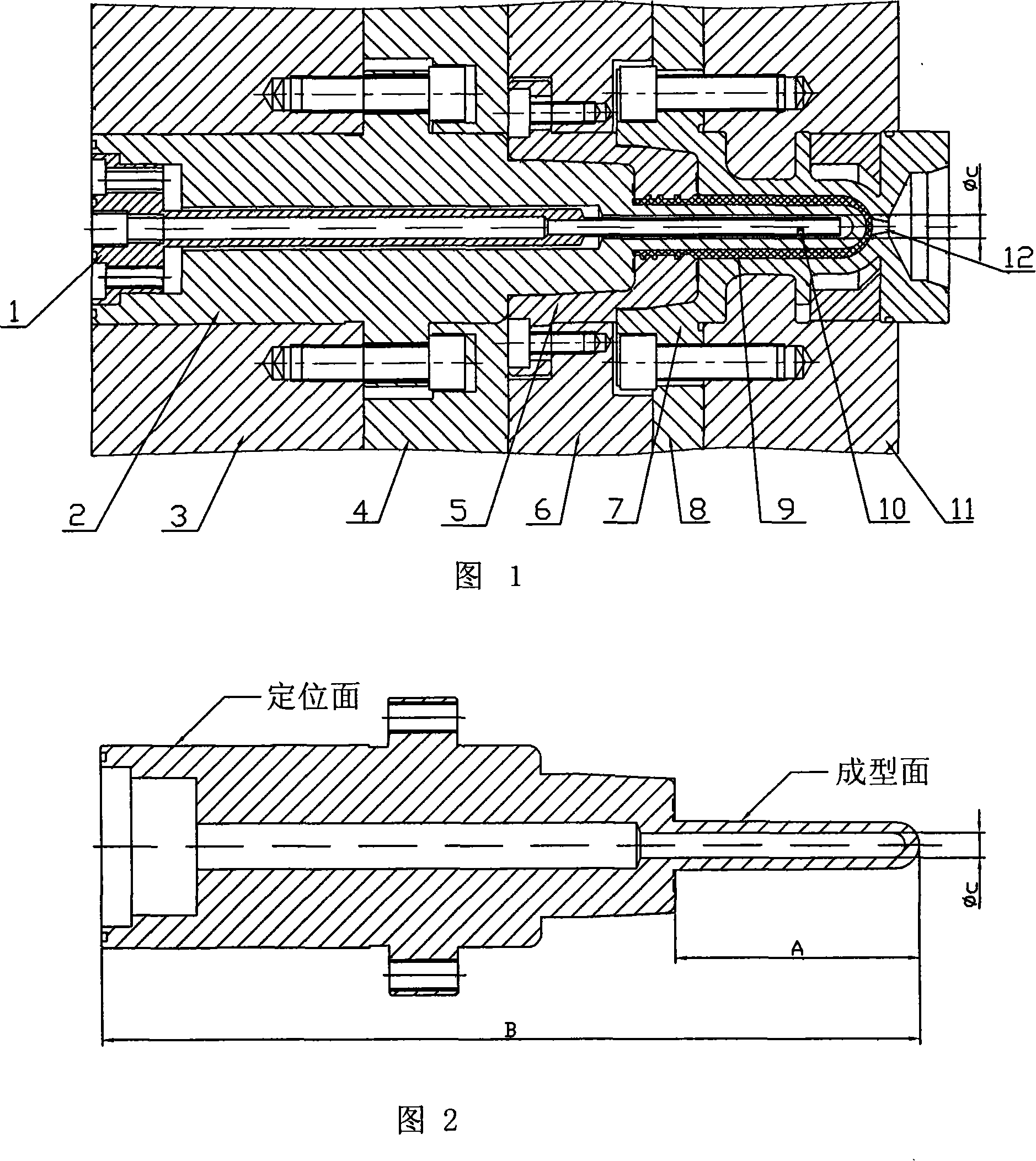

Method for ensuring the axiality of the injection molding cooling deep borehole and the external-molding surface

The invention discloses a manufacture method ensuring the coaxiality between die core cooling deep hole and the external forming surface. The method includes the steps that (1) coarsely cutting the externality: the injection die-core die externality is coarsely cut, and the surface coarseness of the external cylindrical surface of the die core is controlled less than 3.2 microns; (2) drilling the hole of water passage and adjusting the eccentrics: the processing and cooling hole is drilled to ensure that the difference value of the wall thickness of the die-core forming water passage wall thickness is less than or equal to 0.3 mm; (3) heating disposal: the heating disposal is carried out on the conditions of equal-temperature quenching and tempering ranging from 1000 DEG C to 1050 DEG C and the artificial aging disposal ranging from 350 DEG C to 400 DEG C; (4) processing the external cylindrical surface after heating disposal, ensuring that the difference value of the wall thickness of the die-core forming water passage is less than or equal to 0.15 mm; (5) finely processing the externality. In the process to the injection core parts in the injection die of the invention, each working procedure measures and controls the wall thickness, and enables the cooling deep hole to keep consistent with the wall thickness of the external forming surface. The processing method is simple, the cost is low, the adjustment is easy, and the invention is beneficial for the automatic batch production.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY +1

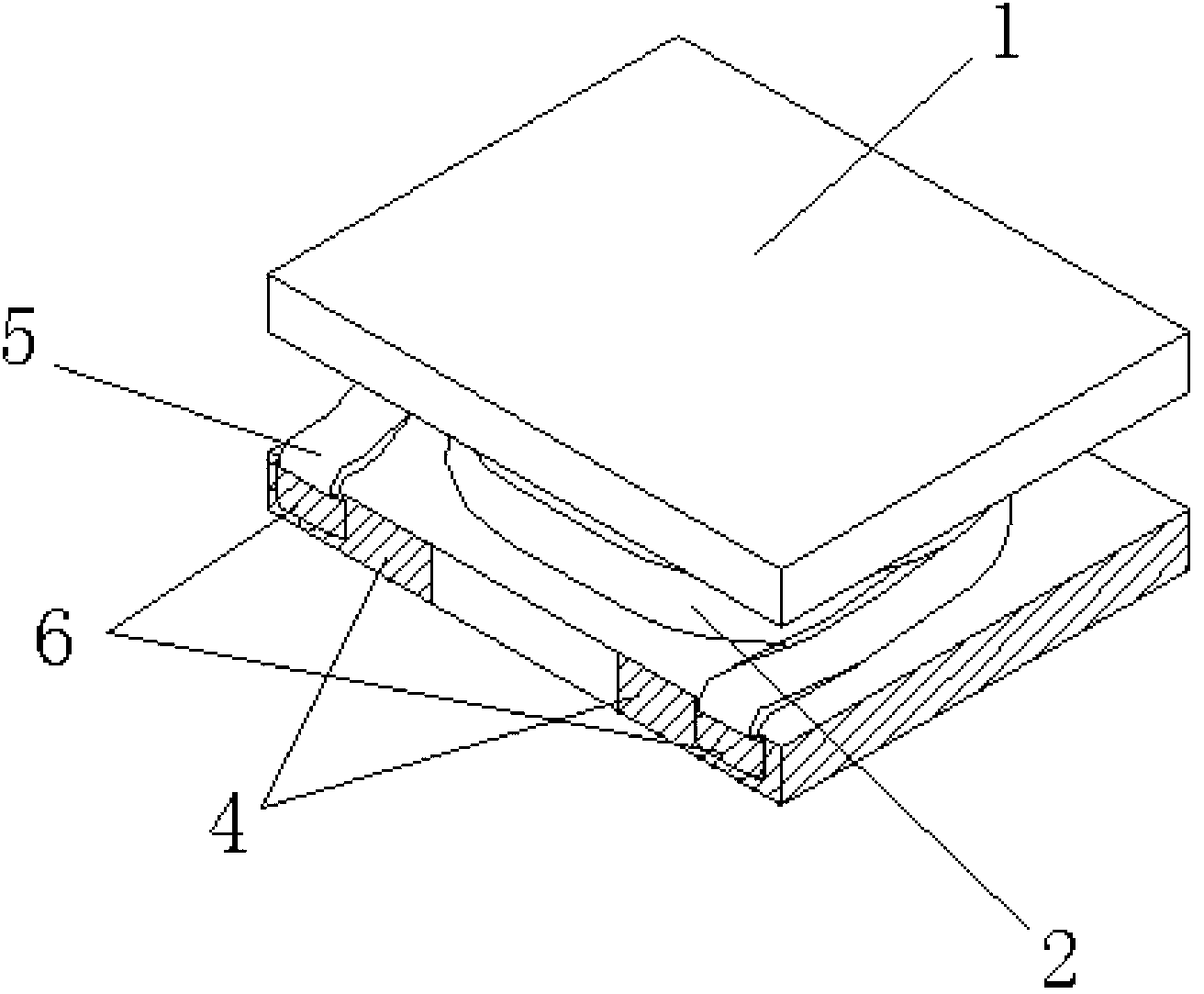

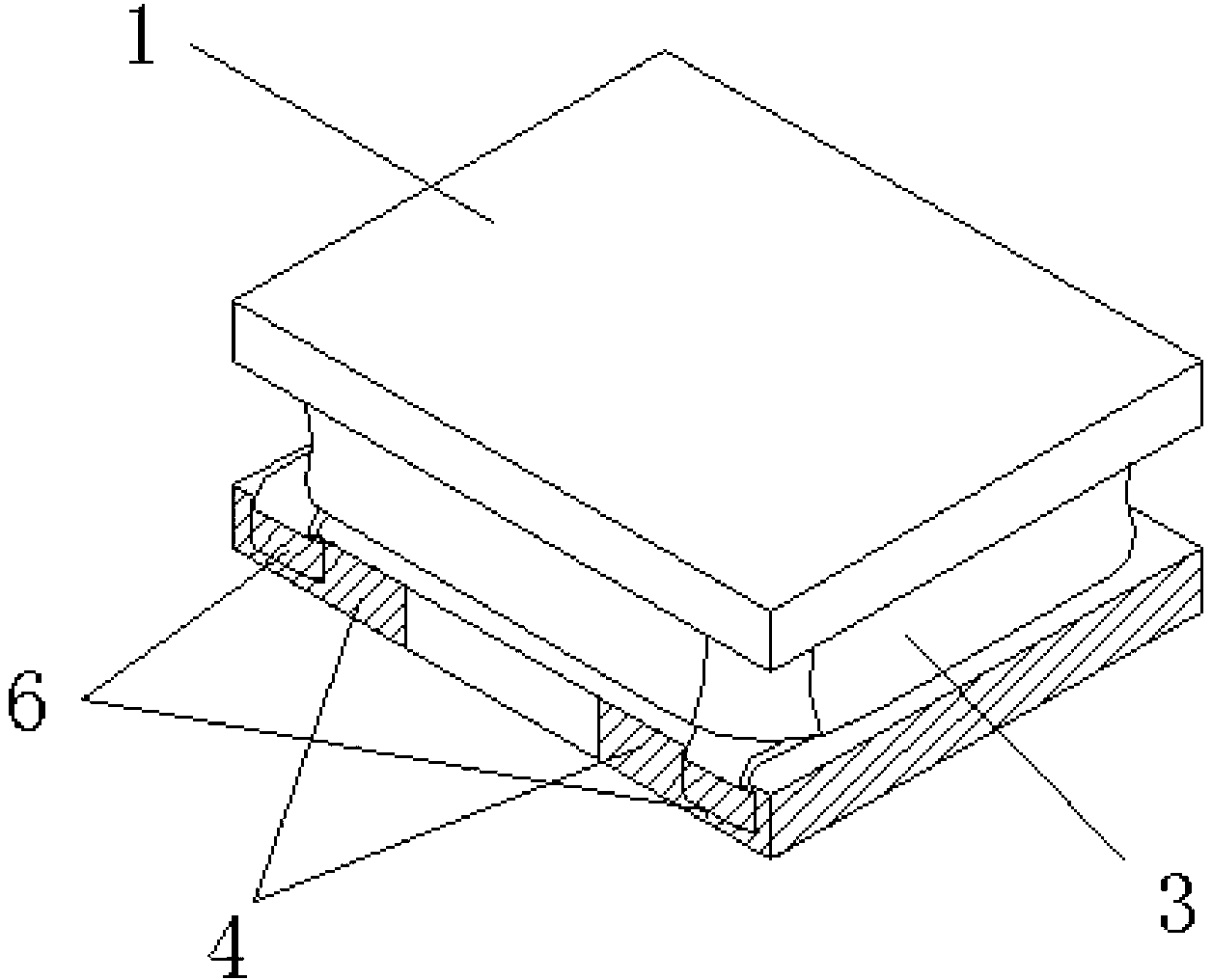

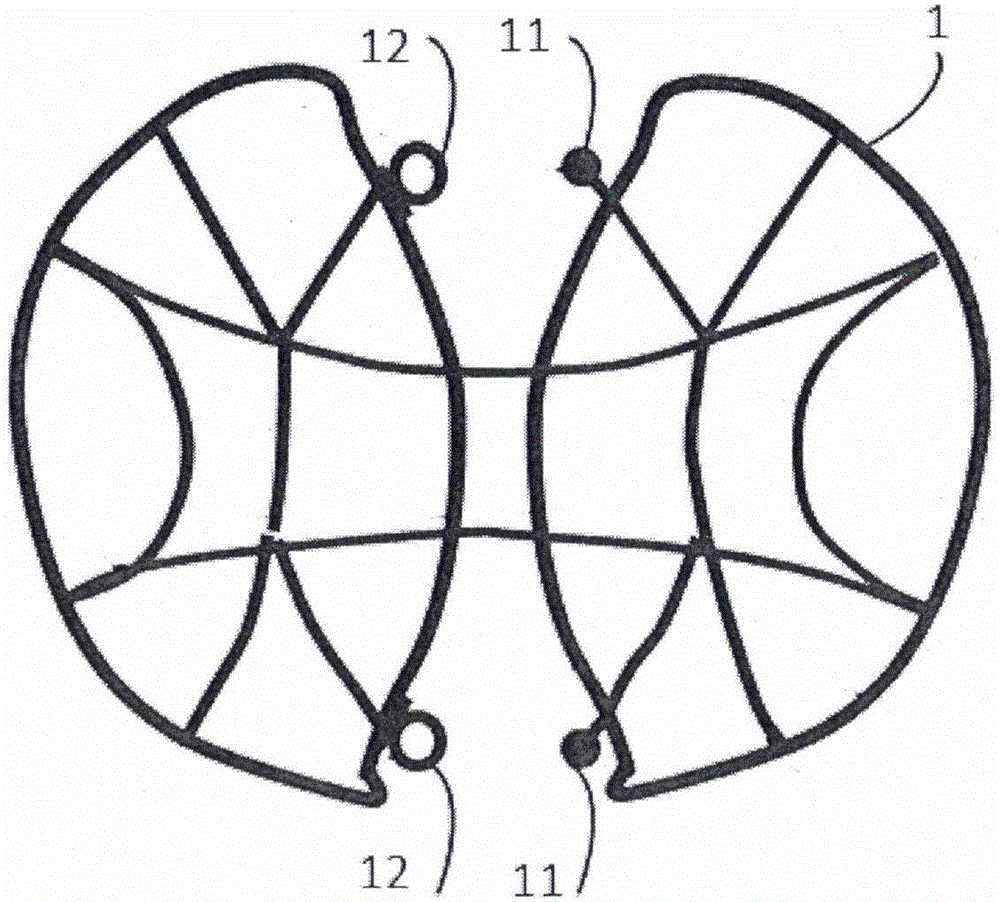

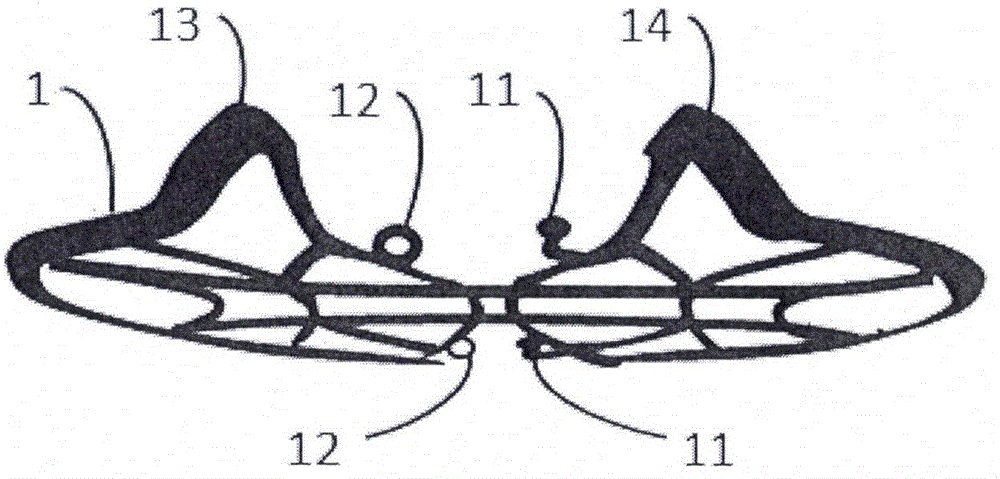

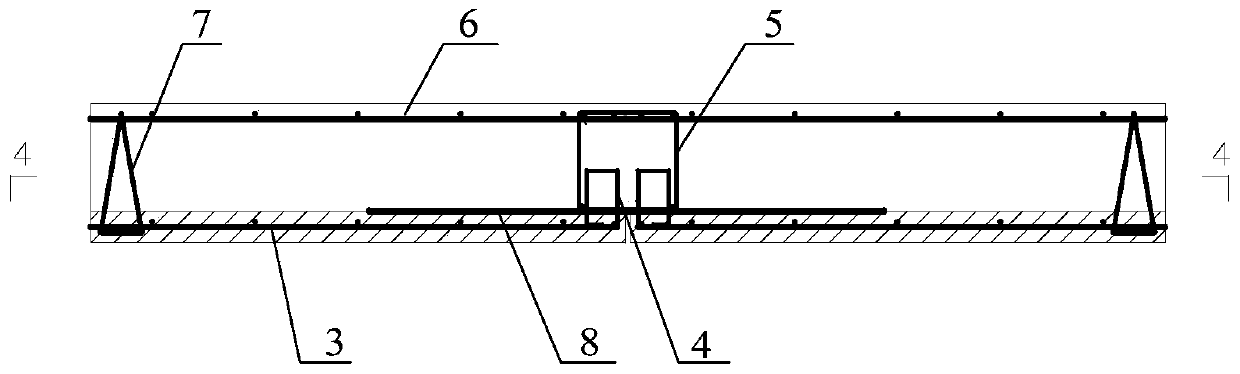

Planar support of three-dimensional mask and three-dimensional mask provided with planar support

A planar support of a three-dimensional mask is used for being mounted in a mask body provided with three-dimensional support space, adopts an elastic planar frame structure and comprises two support bodies which are symmetrically arranged, wherein adjacent side edges of the two support bodies are inner circumferential edges, and non-adjacent side edges are outer circumferential edges; a connecting body for connecting the two support bodies is arranged between the inner circumferential edges of the two support bodies, and mutually matched connectors for connecting the two support bodies are arranged on the inner circumferential edges or on inner sides of the inner circumferential edges on two sides of the connecting body; the two support bodies can bend and deform simultaneously around the connecting body towards one side surface of the planar support of the three-dimensional mask, and combine through corresponding connection by the connectors to form a three-dimensional support structure with the connecting body as the top, and outer circumferential edges of the two support bodies bend and combine to form a face attaching surface. The invention further provides the three-dimensional mask provided with the planar support. The three-dimensional mask is simple and convenient to package and store, automatic batch production is facilitated, and the three-dimensional mask producing efficiency is increased.

Owner:北京可可考拉科技有限公司

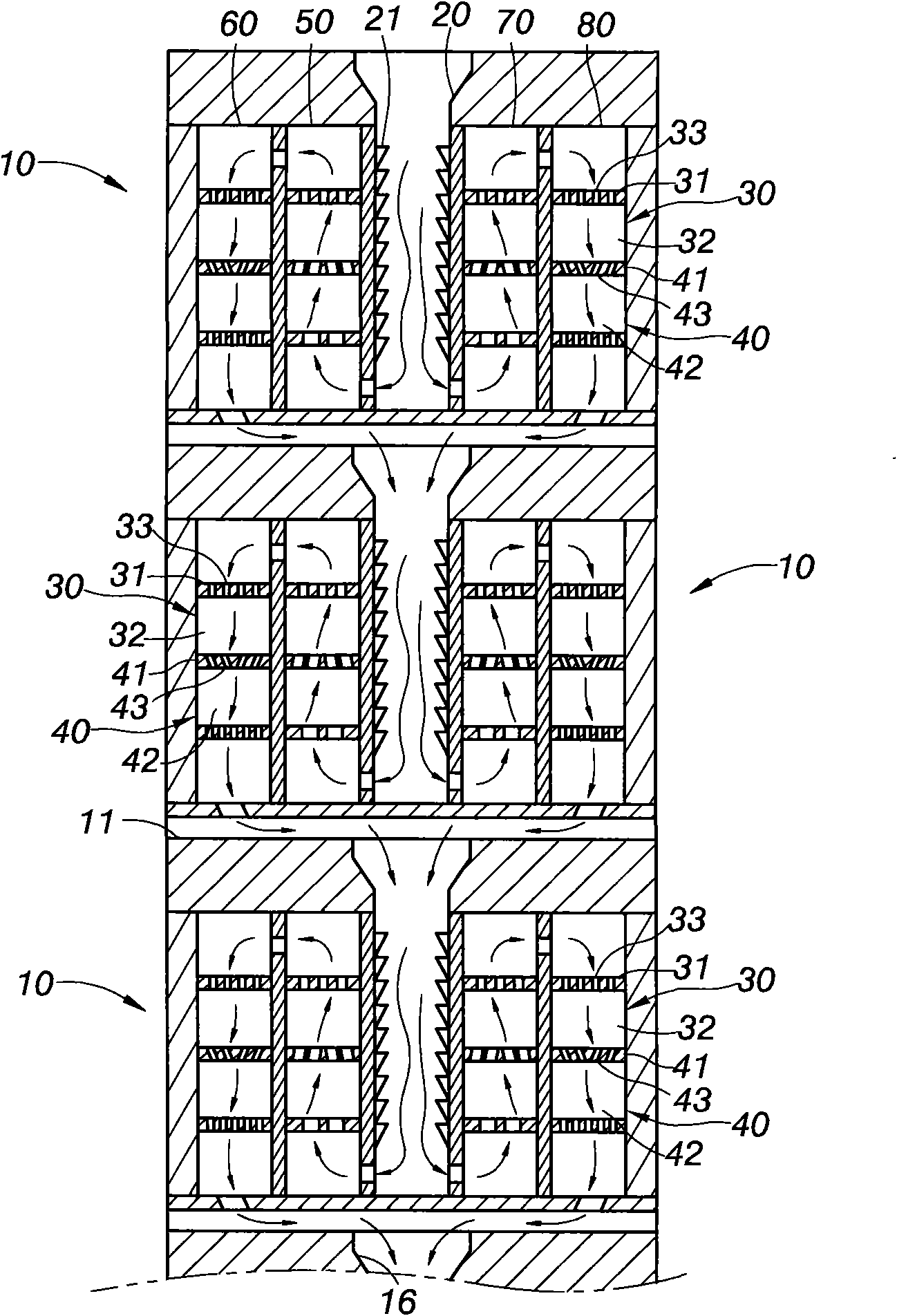

Spiral-flow sectional tube type liquid stirring device

InactiveCN101992038APrecise control of particle sizeImprove qualityLiquid fuel feeder/distributionFlow mixersParticulatesActive agent

The invention discloses a spiral-flow sectional tube type liquid stirring device. A rectifying tube is arranged in an accommodating groove; and a plurality of turbulent flow layers and a rectifying and mixing layer are arranged on the sides of the rectifying tube. After flowing through the turbulent flow layers and the rectifying and mixing layer, fluid can be stirred to form a particulate structure. When the stirring device is used for materials with relatively high viscosity, such as heavy oil, rubber and the like, particles can be relatively uniformly distributed under the condition of not adding an expensive interface active agent (an emulsifier), so that the material cost is saved and the problems of environmental pollution and acid corroded pipelines probably cause by the interface active agent are solved. Particularly, the proportion of the aperture size to the total area on the turbulent flow layers and the rectifying and mixing layer can be calculated to precisely control refining grain diameter. The device has the advantage of improving quality and contributing to automatic mass production.

Owner:陈黄传

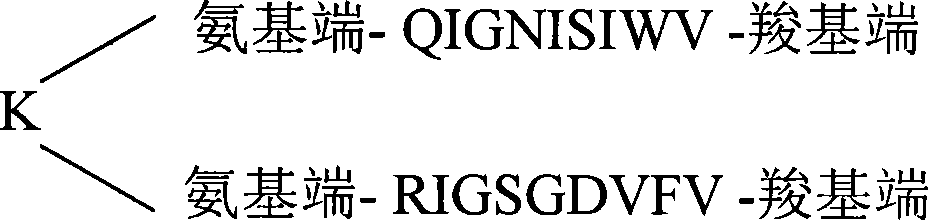

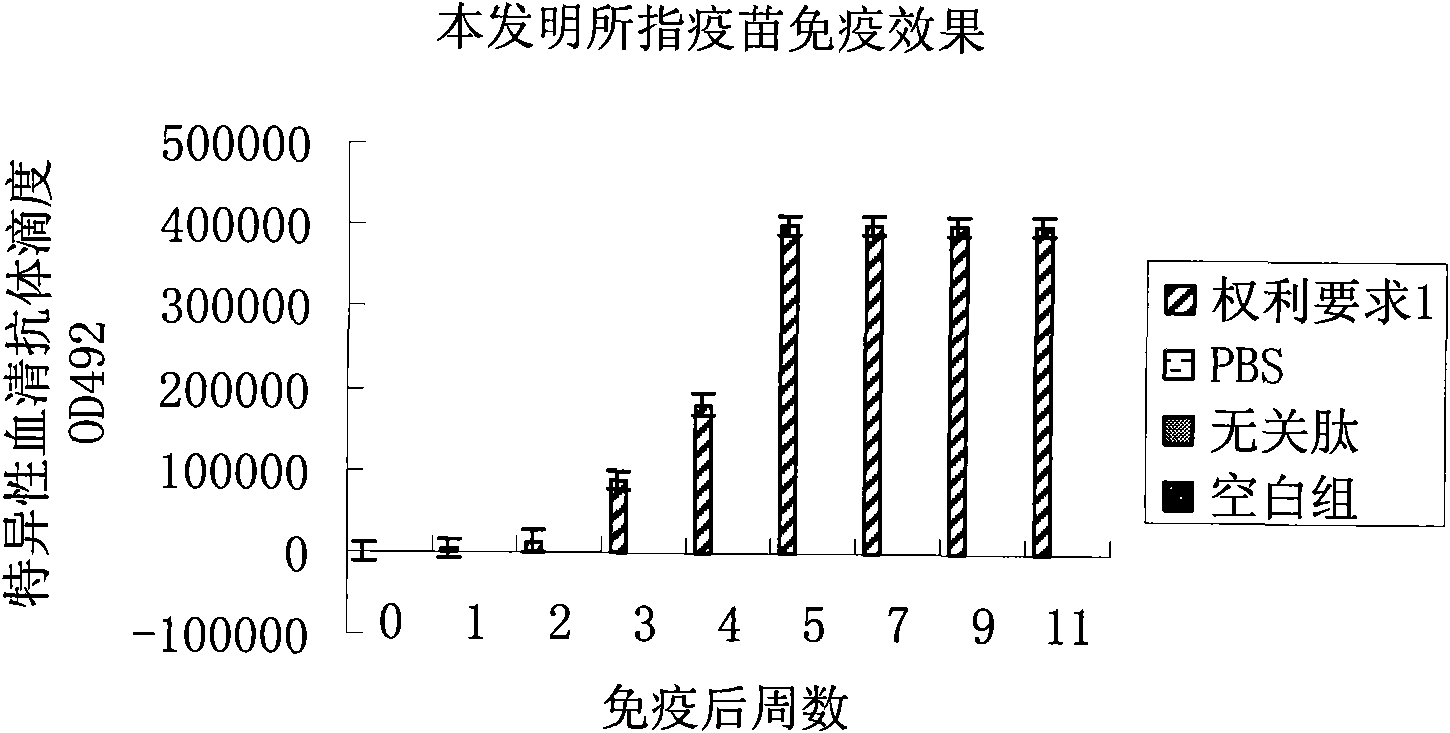

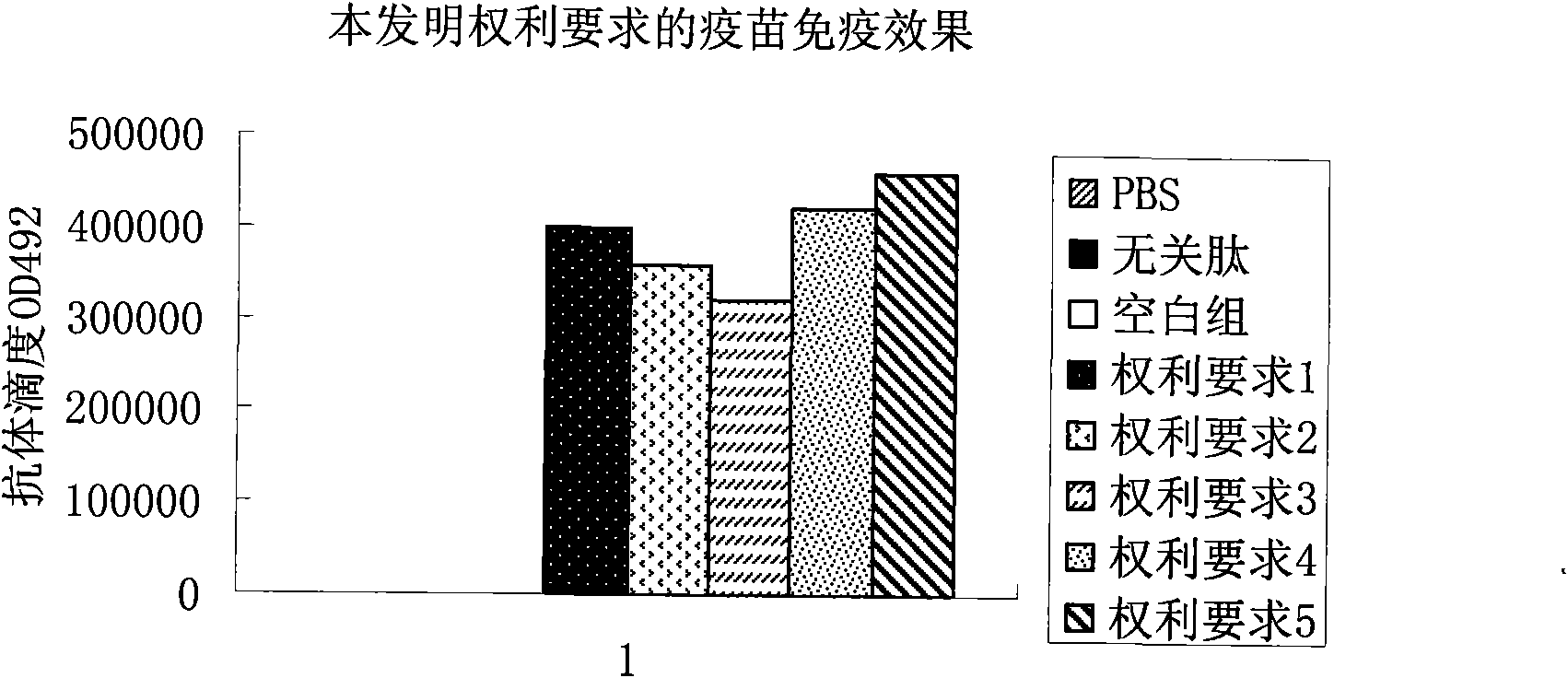

Polypeptide vaccine for treating diseased induced by high pathogenic avian influenza virus H5N1

InactiveCN101380466AEasy to store and transportFacilitate automated mass productionAntiviralsAntibody medical ingredientsDiseaseSide effect

The invention relates to a polypeptide vaccine for treating diseases caused by highly pathogenic avian influenza virus H5N1, which is characterize in that: the amino acid sequence is as follows: amino terminal-QIGNISIWV-carboxyl terminal; and lysine is adopted as a linker to connect a plurality of amino acid sequences to form a multi-copy series structure. The invention has the advantages of convenient transportation and preservation and automated mass production, and can activate specific cytotoxic T lymphocyte (CTL) which can effectively kill and lyses target cells with the N1 protein of the highly pathogenic avian influenza virus H5N1 without toxicity and side effects.

Owner:CHONGQING UNIV

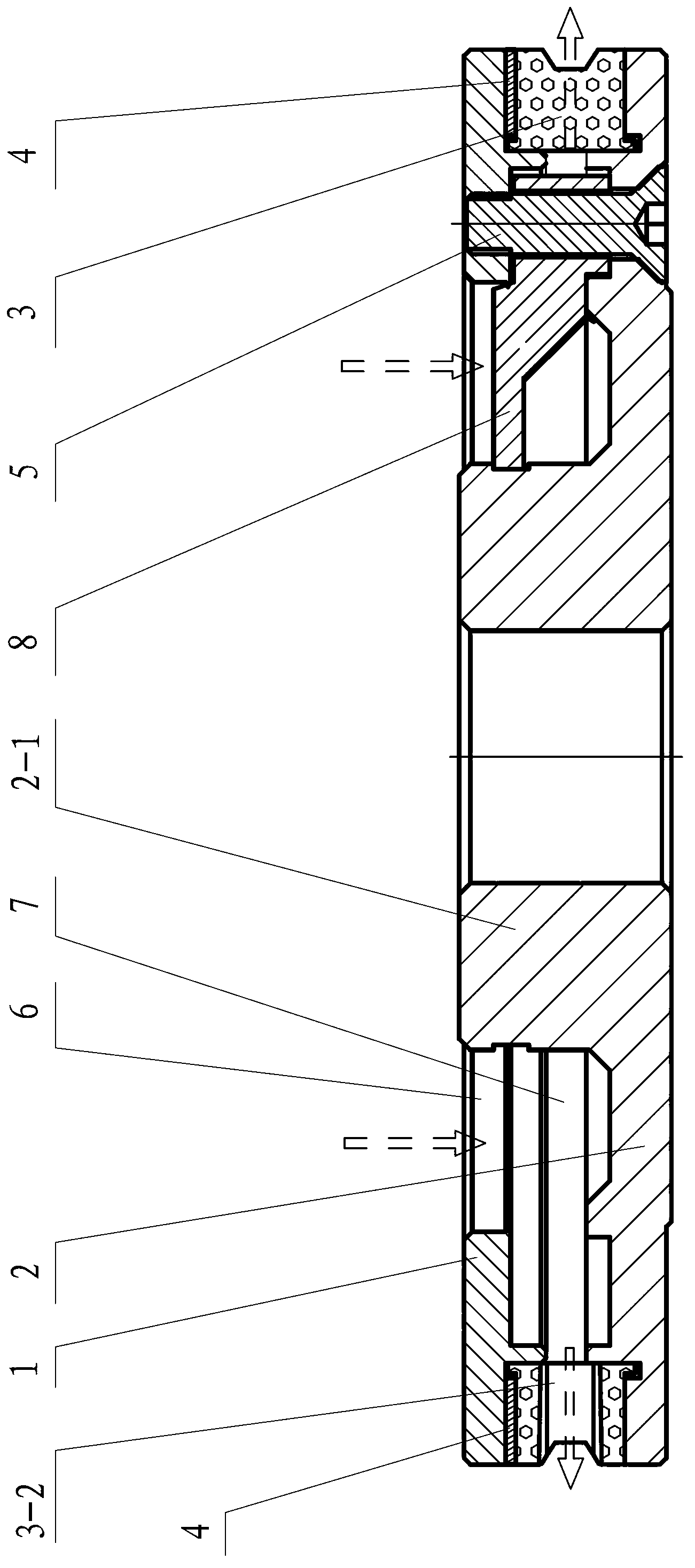

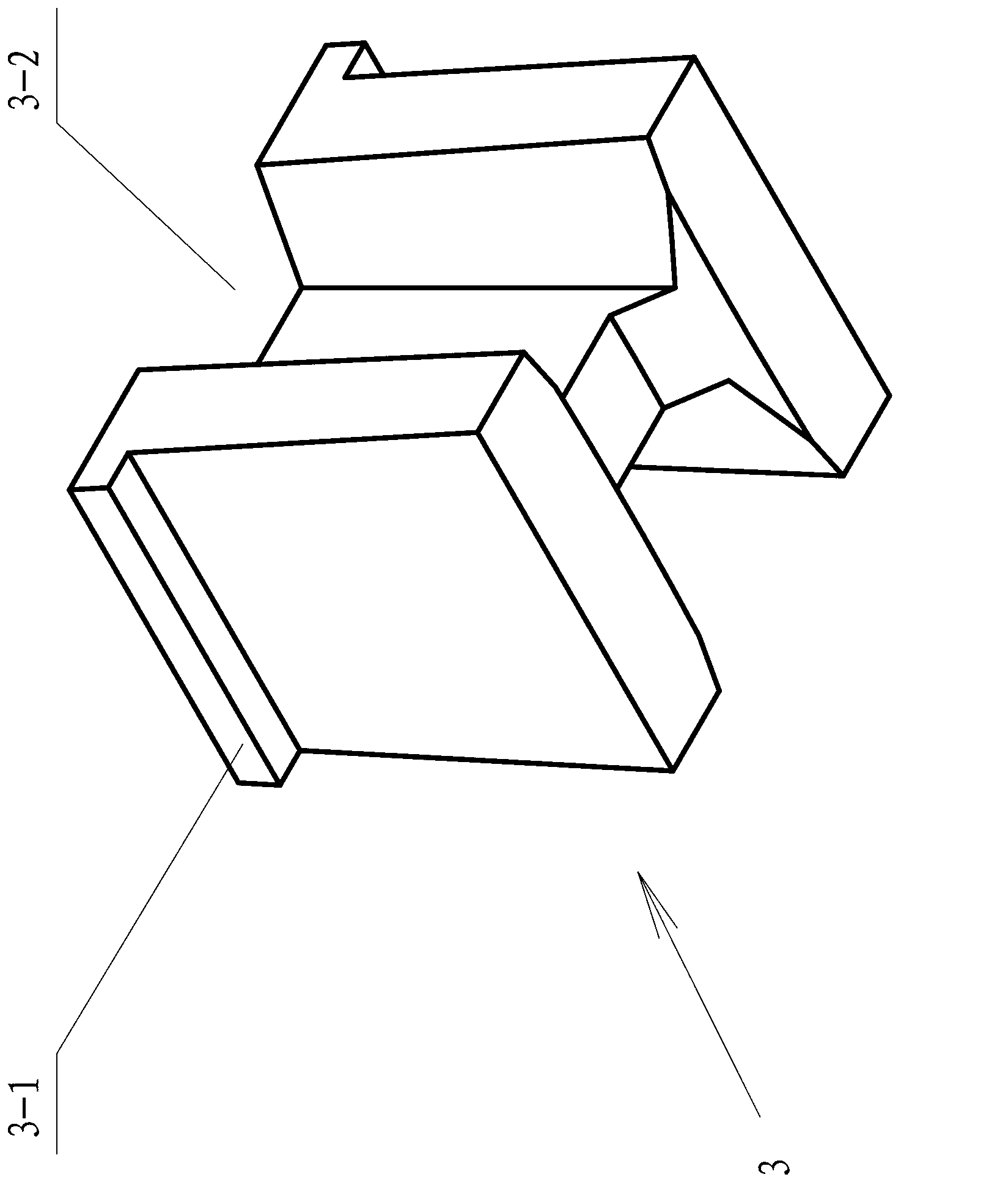

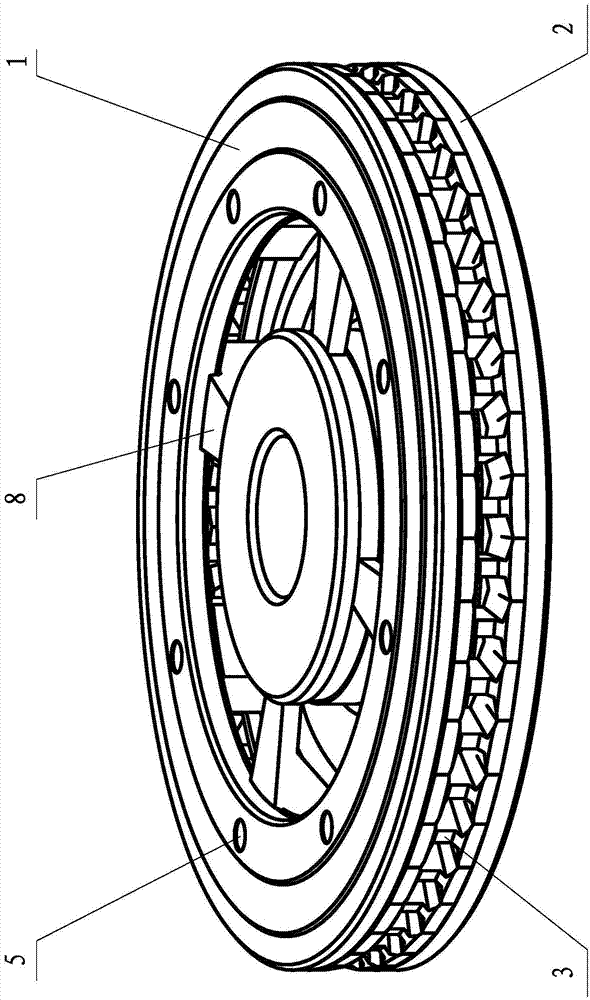

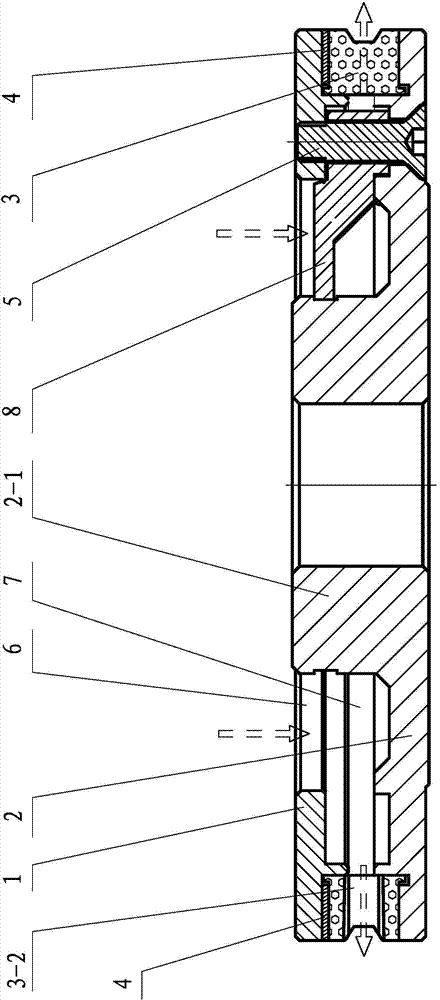

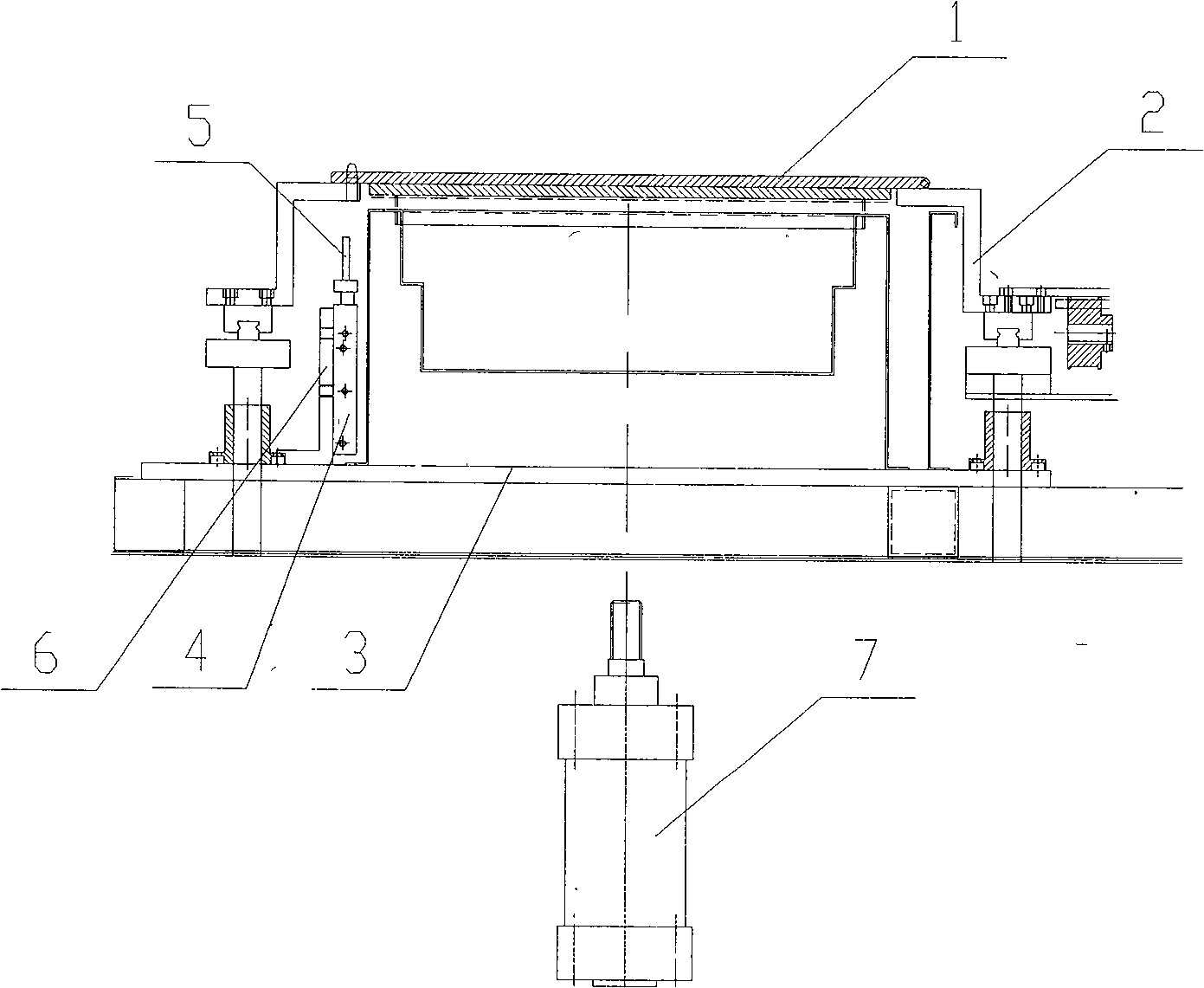

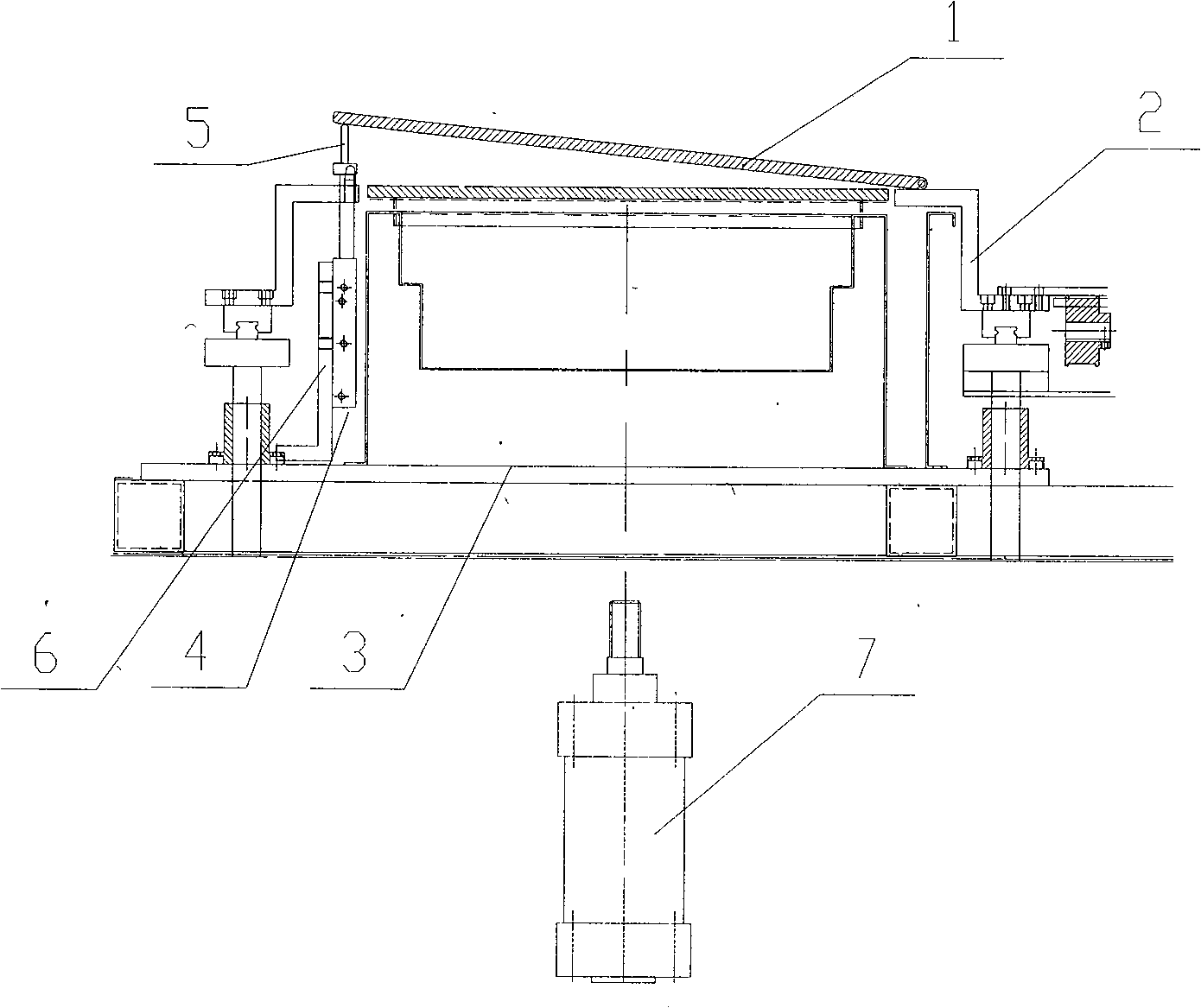

Welding jig for covering roller assembly connection block of hydraulic torque converter and process thereof

InactiveCN104308438AGood positioning effectStable and controllable position accuracyWelding/cutting auxillary devicesAuxillary welding devicesBatch productionEngineering

The invention aims to provide a process for welding a covering roller assembly of a hydraulic torque converter. The process is characterized in that the process can implement an upward welding and / or turning machining face and is favorable for machining and batch production, a connection block, a centering block and the covering roller assembly can be finished after being welded, and the problem of size precision is solved. The process comprises the following steps: a, stamping the covering roller assembly of the hydraulic torque converter; b, machining a positioning block which leaves some margin, c, welding the positioning block in the center of the outer surface of the covering roller assembly, d, welding the connection block on the outer surface of the covering roller assembly, e, clamping an inner side of the covering roller assembly and turning the connection block and the positioning block, and f, clamping the positioning block and turning and clamping an inner side of the covering roller assembly.

Owner:重庆红宇精密工业集团有限公司

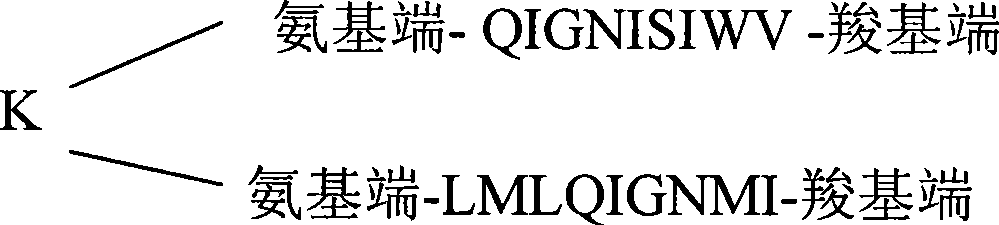

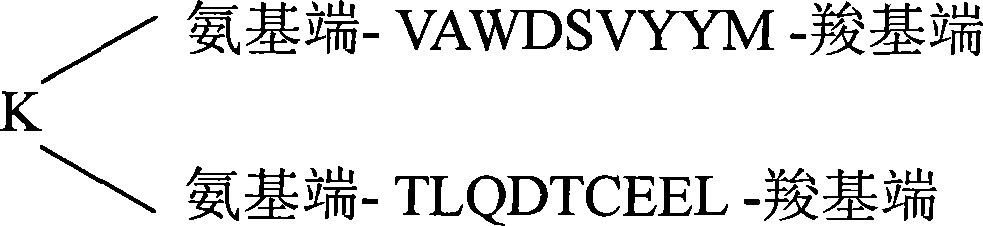

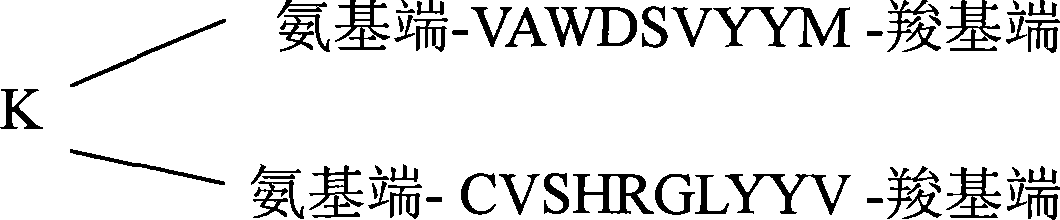

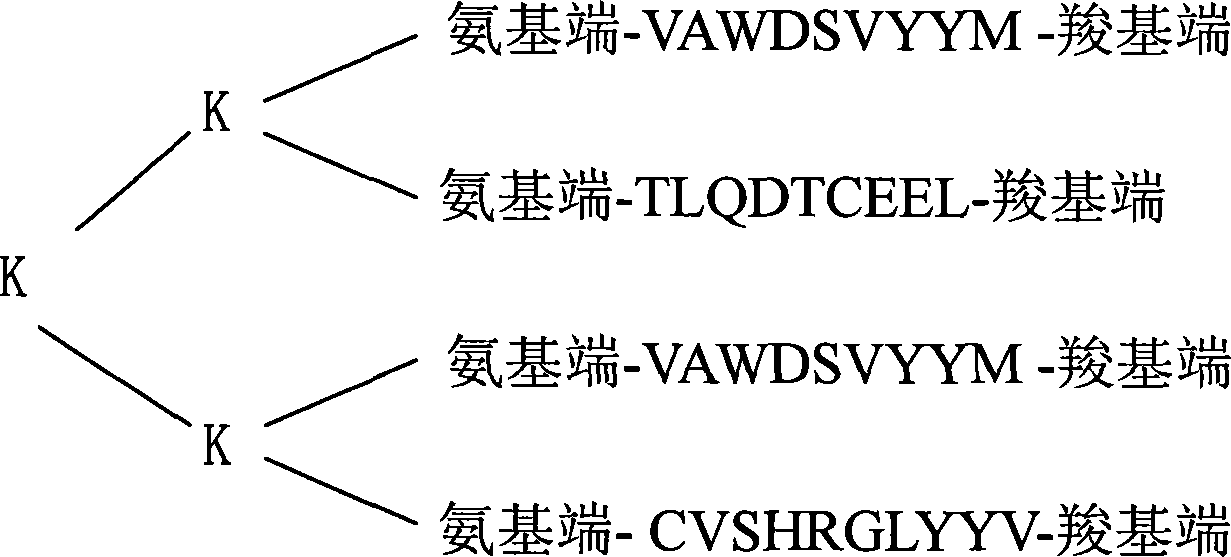

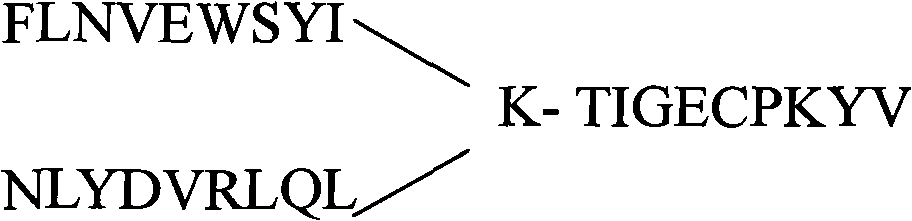

Polypeptide medicament for treating tumor caused by human papillomavirus type 18 or vaccine

InactiveCN101214369AEasy to store and transportFacilitate automated mass productionPeptide/protein ingredientsViral antigen ingredientsSide effectT lymphocyte

A polypeptide drug or bacterin for curing tumor caused by Human Papillomavirus Type 18 is characterized in that the aminophenol order is amido end- VAWDSVYYM- carboxyl end, which is a multi-copy serial structure with lysine as a joint and a plurality of aminophenol orders connected. The present invention has the advantages of convenient transport and storage as well as automatic mass production. The present invention also has the capacity of activating specific cytotoxic T lymphocytes (CTL) and the specific CTL cell can kill, damage and dissolve target cells with the relative tumor sign Human Papillomavirus Type 18. The present invention has obvious effect and no side effect.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

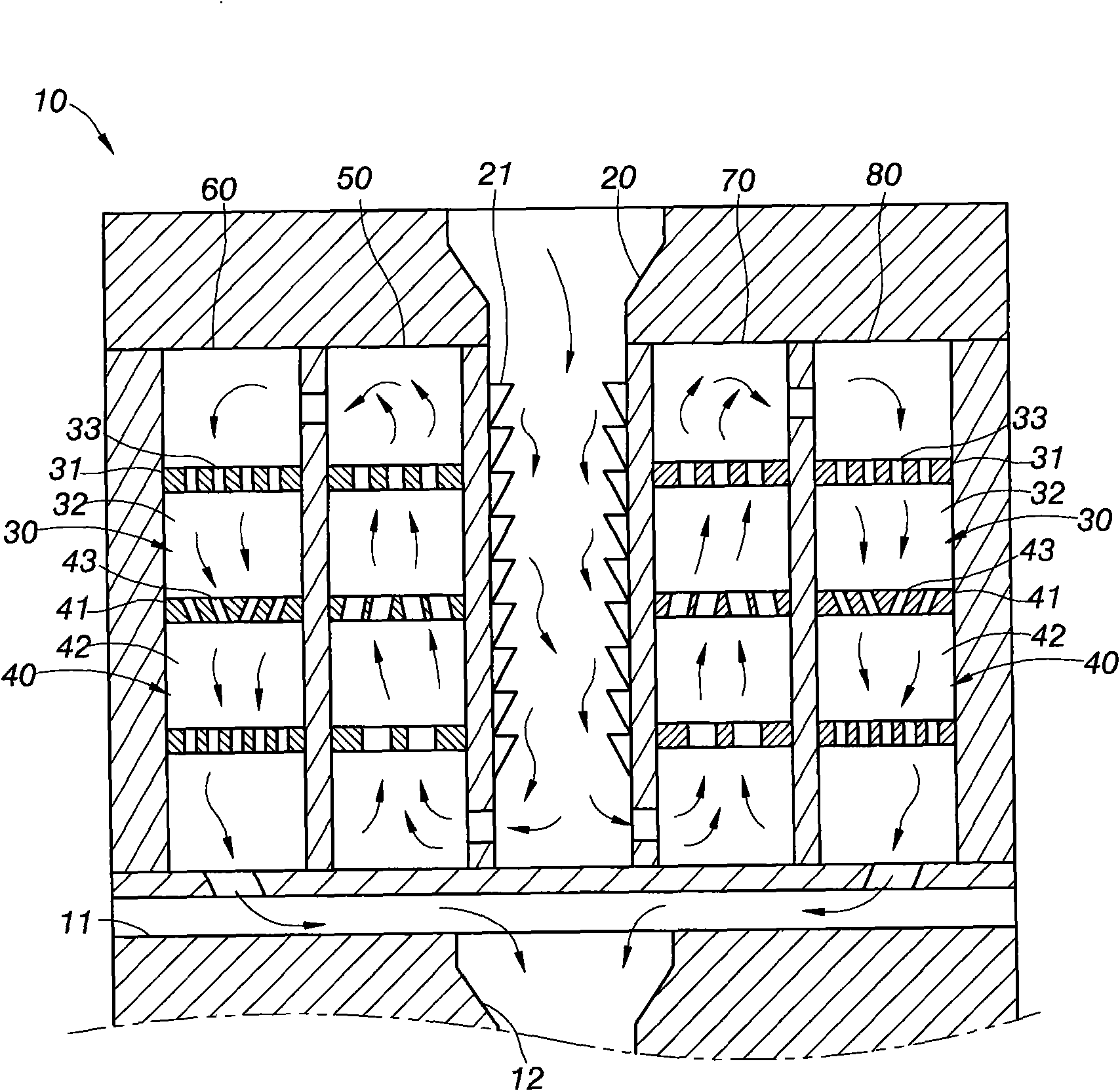

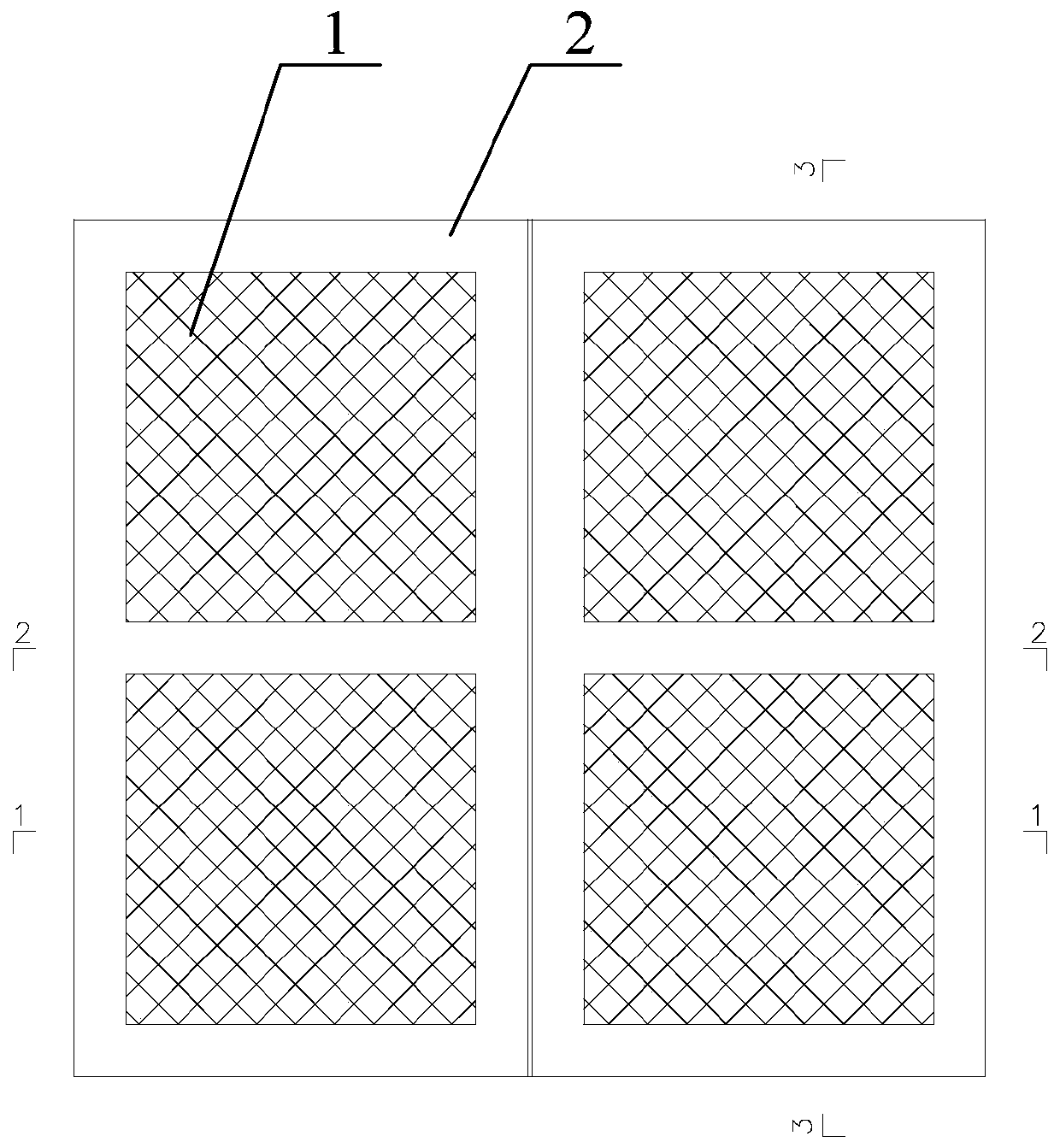

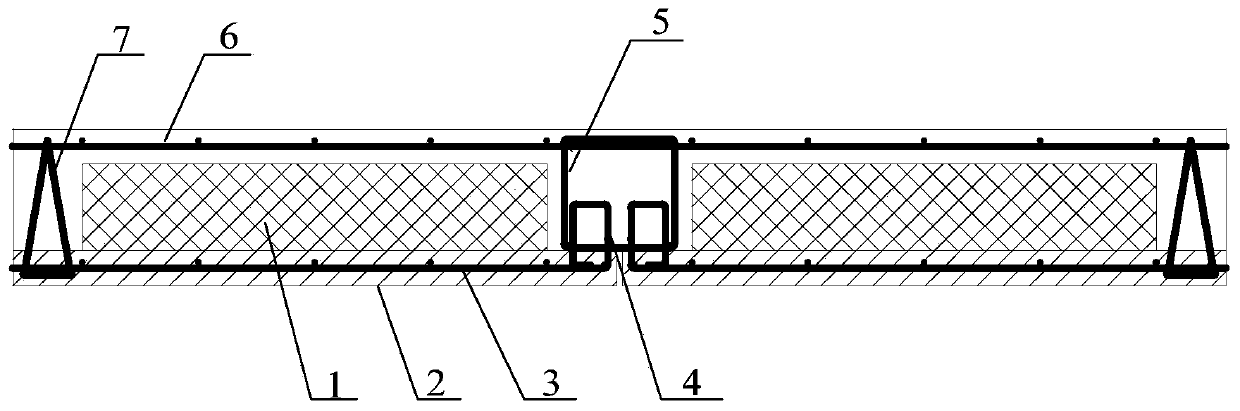

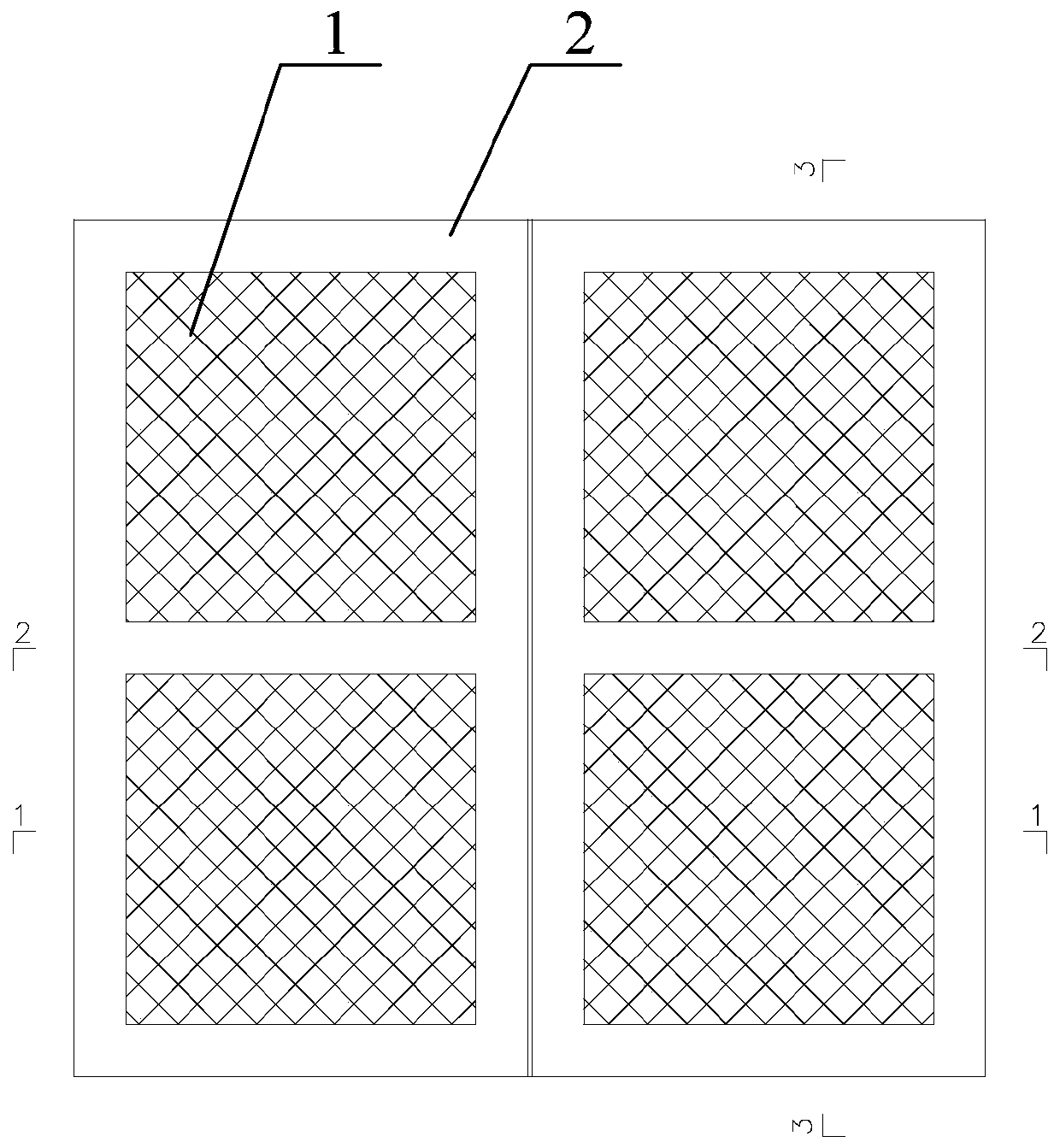

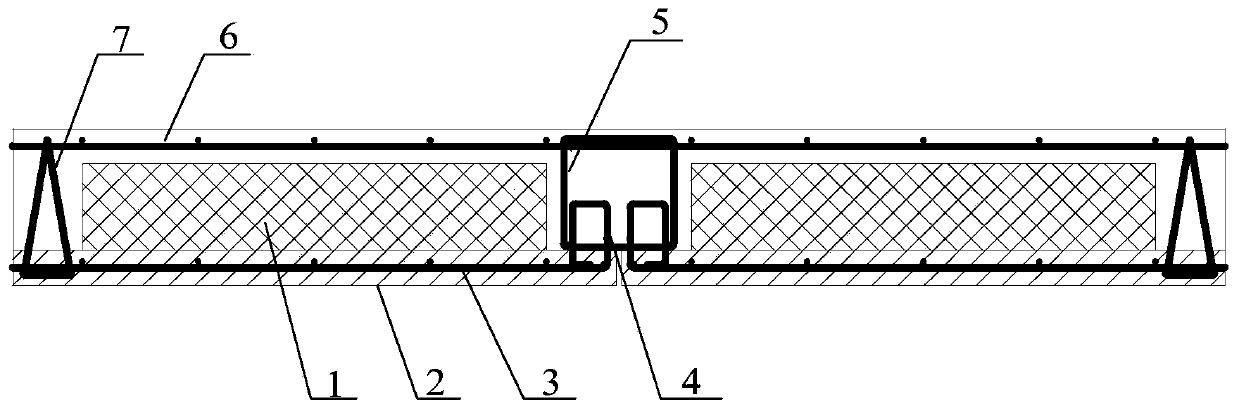

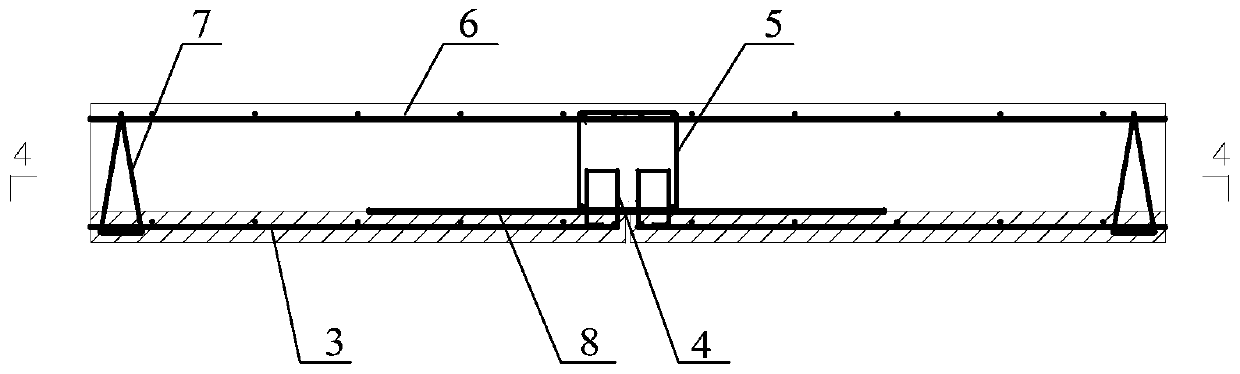

Composite floor slab splicing structure and construction method thereof and composite structure residential system

The invention relates to the technical field of buildings, in particular to a composite floor slab splicing structure and a construction method thereof and a composite structure residential system. The composite floor slab splicing structure comprises a reinforcement cage and two floor slabs arranged at an interval, wherein a mounting gap is formed in the end, positioned at a splicing surface, ofeach of the floor slabs; floor slab ring ribs are sequentially and vertically fixed at the bottom of the mounting gap at intervals; the reinforcement cage comprises a connecting horizontal rib and a plurality of connecting ring ribs; the connecting ring ribs and a plurality of floor slab ring ribs on the two floor slabs are arranged in a staggered manner; and concrete is poured in the connecting ring ribs and the floor slab ring ribs. The composite floor slab splicing structure greatly increases the onsite construction speed, lowers the construction difficulty and is simple in construction process; ribs do not go out of four sides of a prefabricated slab, so that factory automatic mass production is facilitated, and the production cost is greatly lowered; the composite floor slab splicingstructure is excellent in mechanical property, high in integrality, and also high in assembling integral type structural integrity; and onsite prefabricated construction is realized, the constructionefficiency is high, and dense rib construction greatly lowers the floor dead weight and concrete quantity to lower the cost.

Owner:SHENZHEN YJY BUILDING TECH +2

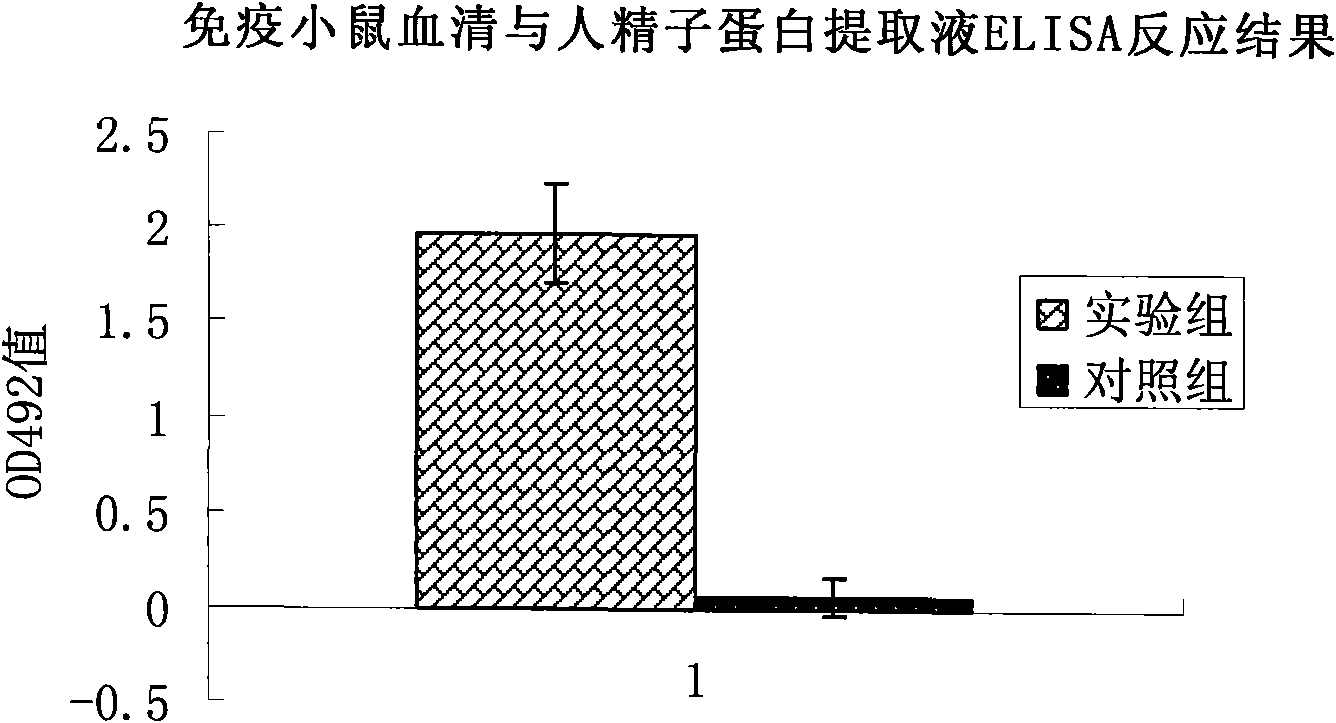

Human epididymis protease profilin immunological contraception polypeptide

InactiveCN101638438ANo side effectsEasy to transportPeptide/protein ingredientsProtease inhibitorsSide effectProfilin

A human epididymis protease profilin immunological contraception polypeptide is characterized in that the basic amino acid sequence of the polypeptide is amino terminal-LSEIKGVIVHRLEGVGGGMFVYGGCQGNNNN-carboxyl terminal; lysine can be used as linker to combine a plurality of the basic amino acid sequences together to compose multiple copies of series connection structure. The invention has the advantages that the product is easy to transport and preserve and the automated production of the product can be realized; the invention has effective immunogenicity and antigenicity, obvious immune effect, high effective and reversible contraceptive effect, safe use and no side effect.

Owner:ARMY MEDICAL UNIV

Production process of dielectric isolation type pressure sensor based on flip welding chip

ActiveCN109534282ASimple production processLess investmentDecorative surface effectsFluid pressure measurement by electric/magnetic elementsMems pressure sensorFlexible circuits

The invention discloses a production process of a dielectric isolation type pressure sensor based on a flip welding chip. The pressure sensor comprises a shell and a ceramic substrate arranged on theinner side of the shell. The production process of the dielectric isolation type pressure sensor comprises the following specific steps: printing a thick film circuit on the bottom of the ceramic substrate; brushing glass glaze on the thick film circuit, so that the glass glaze covers the thick film circuit to protect the thick film circuit on the ceramic substrate from being eroded when being applied to various media; flip welding an MEMS pressure sensitive chip on the bottom of the ceramic substrate; and welding a welding point of the thick film circuit on the bottom of the ceramic substratetogether with a flexible circuit board at the top of the ceramic substrate to realize an electrical connection of the MEMS pressure sensitive chip and the flexible circuit board. The purpose of the invention is to provide a pressure sensor with a simple process, to realize the application of the sensor in a harsh environment and a medium, and to realize the stable and reliable work of the MEMS pressure sensor in the harsh environment and the medium with high cost performance.

Owner:江西新力传感科技有限公司

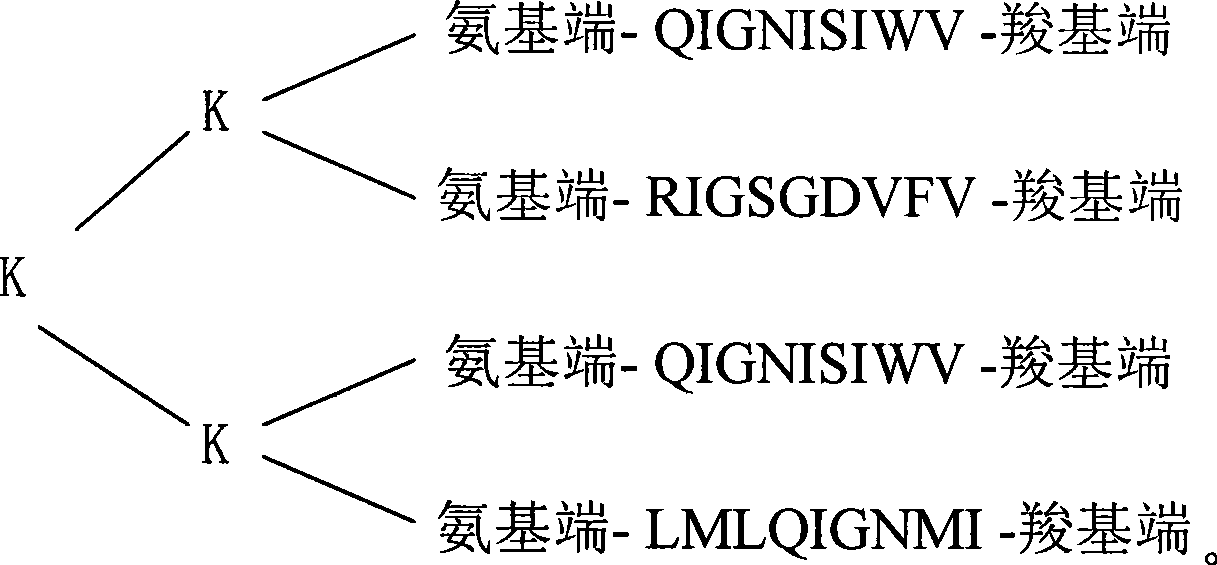

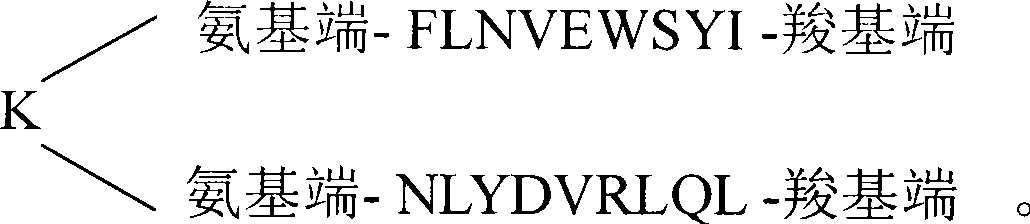

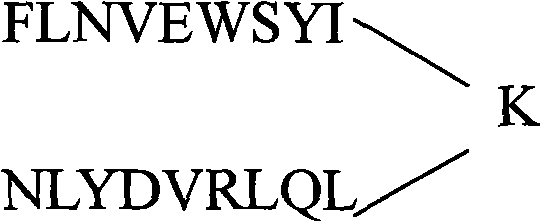

Polypeptide medicament for treating highly pathogenic bird flu virus H5N1induced disease

InactiveCN101411866AEasy to store and transportFacilitate automated mass productionPeptide/protein ingredientsAntiviralsDiseaseBird flu

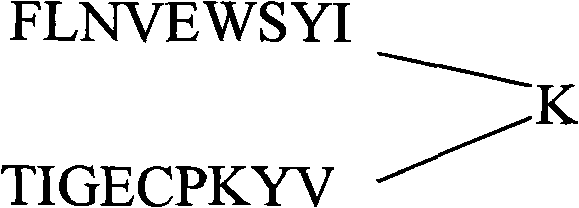

The invention provides a polypeptide drug for treating diseases initiated by highly pathogenic bird flu virus H5N1. The polypeptide drug is characterized in that the amino acid sequence of the polypeptide drug is amino terminal-FLNVEWSYI-carboxyl terminal; a plurality of the amino acid sequences form a multicopy serial structure by using lysine as a joint. The polypeptide drug has the advantages of convenient transportation and storage and automatic batch production, and has the capability of activating specificity cytotoxicity T lymphocyte (CTL). The specificity CTL has a target cell which kills and dissolves H5 albumen with the highly pathogenic bird flu virus H5N1 with obvious effect without toxic side effect.

Owner:ARMY MEDICAL UNIV

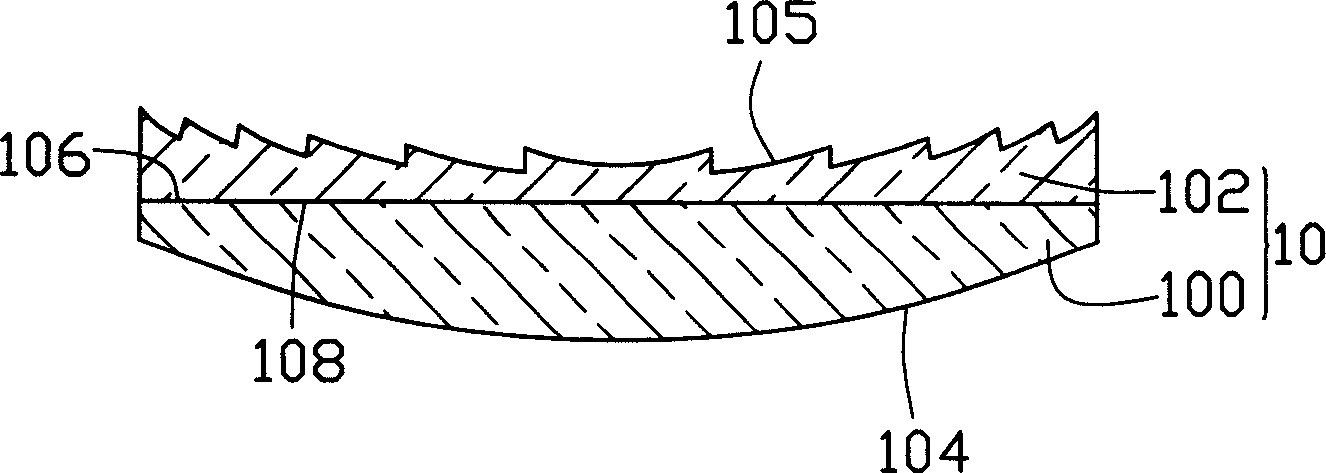

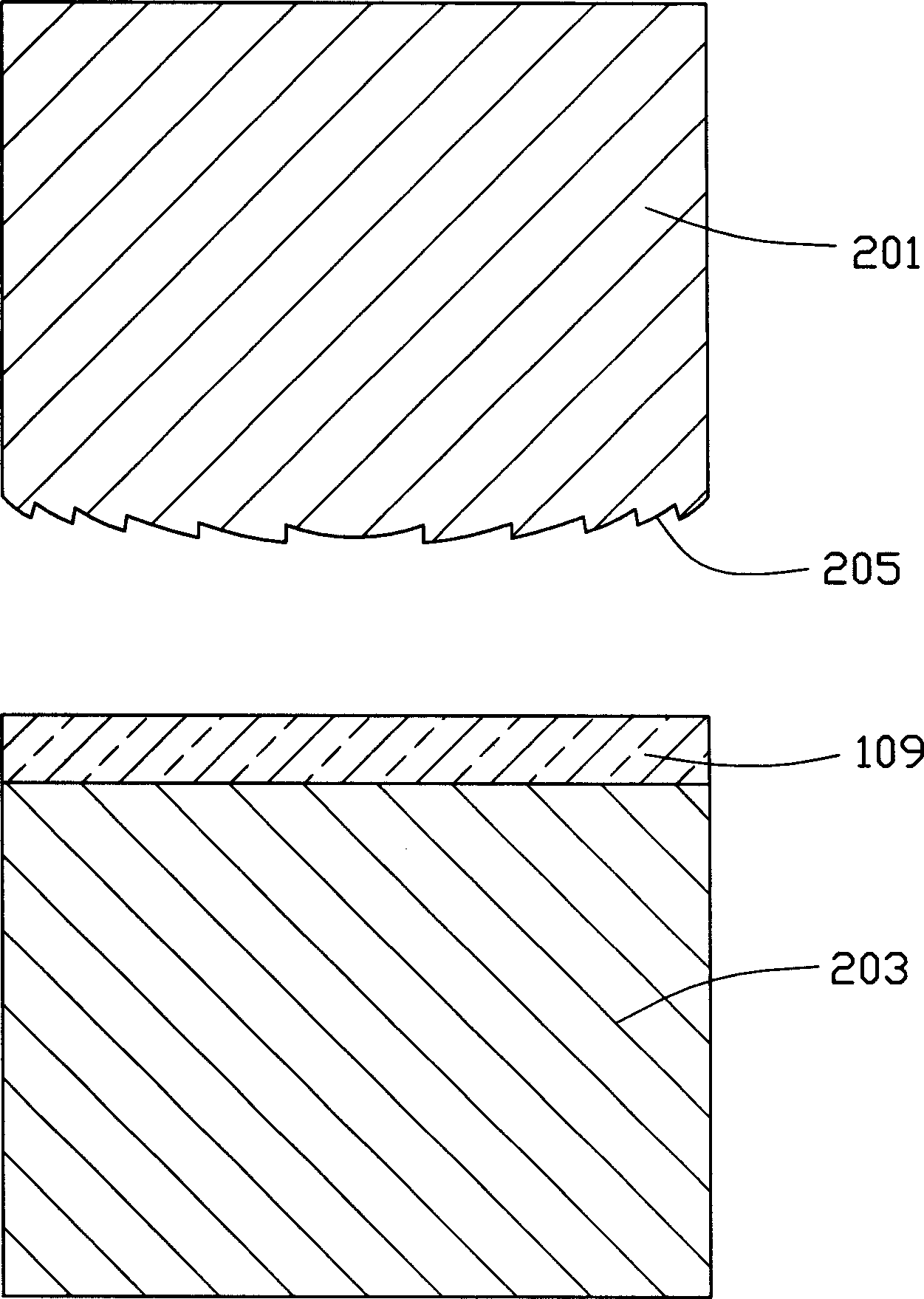

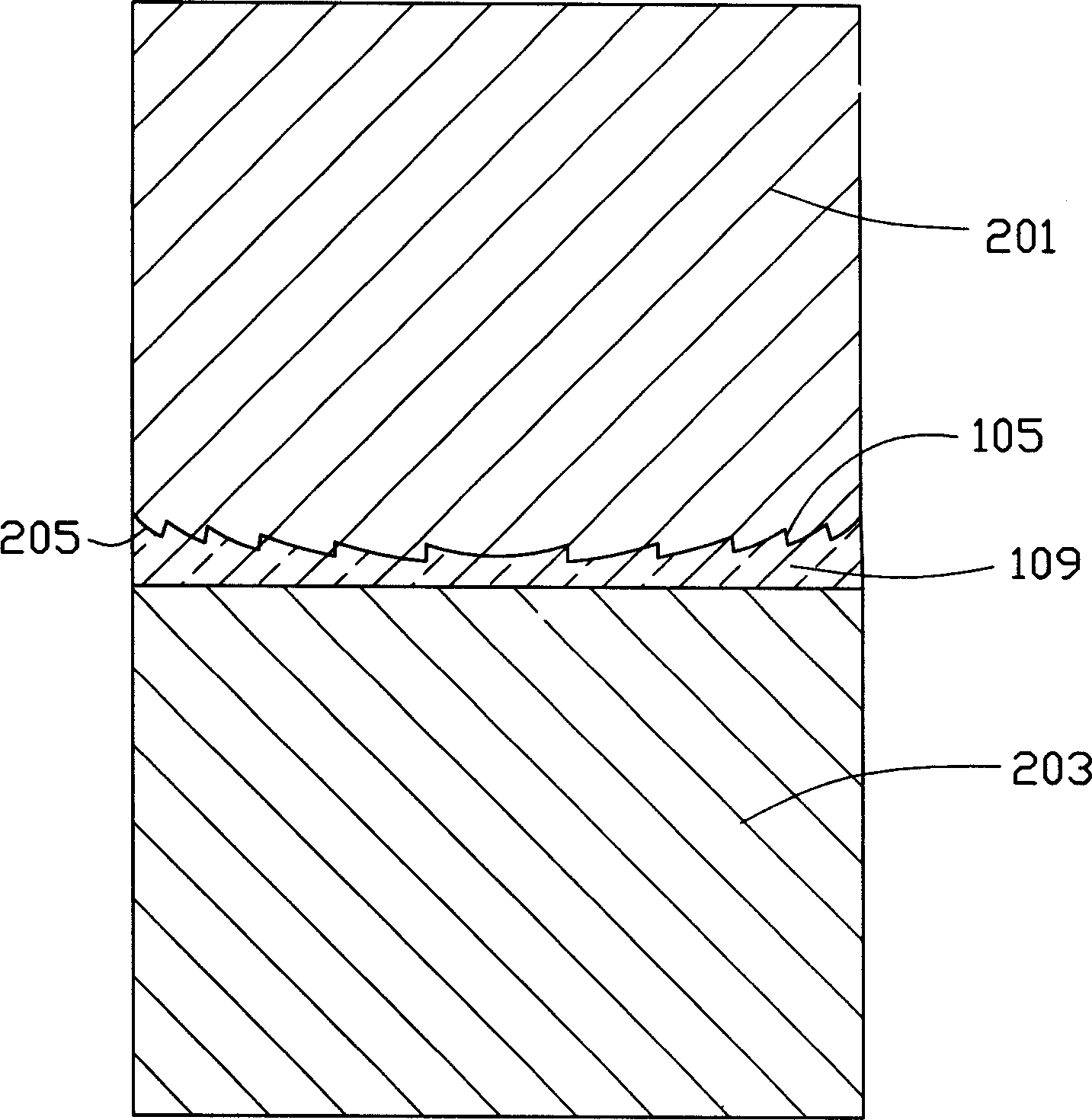

Diffraction optical component and its production

InactiveCN1854812APrecise structureImprove yieldDiffraction gratingsOptical diffractionDiffraction optics

An optical diffraction element consists of a lens and a diffraction grating being stuck on said lens. Its preparing method including providing a lens with the first surface and a diffraction grating with the second surface and diffraction surface in opposite to the second surface, setting diffraction structure on said diffraction surface and sticking the first surface of lens on the second surface of diffraction grating to let diffraction surface with diffraction be set towards outside.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

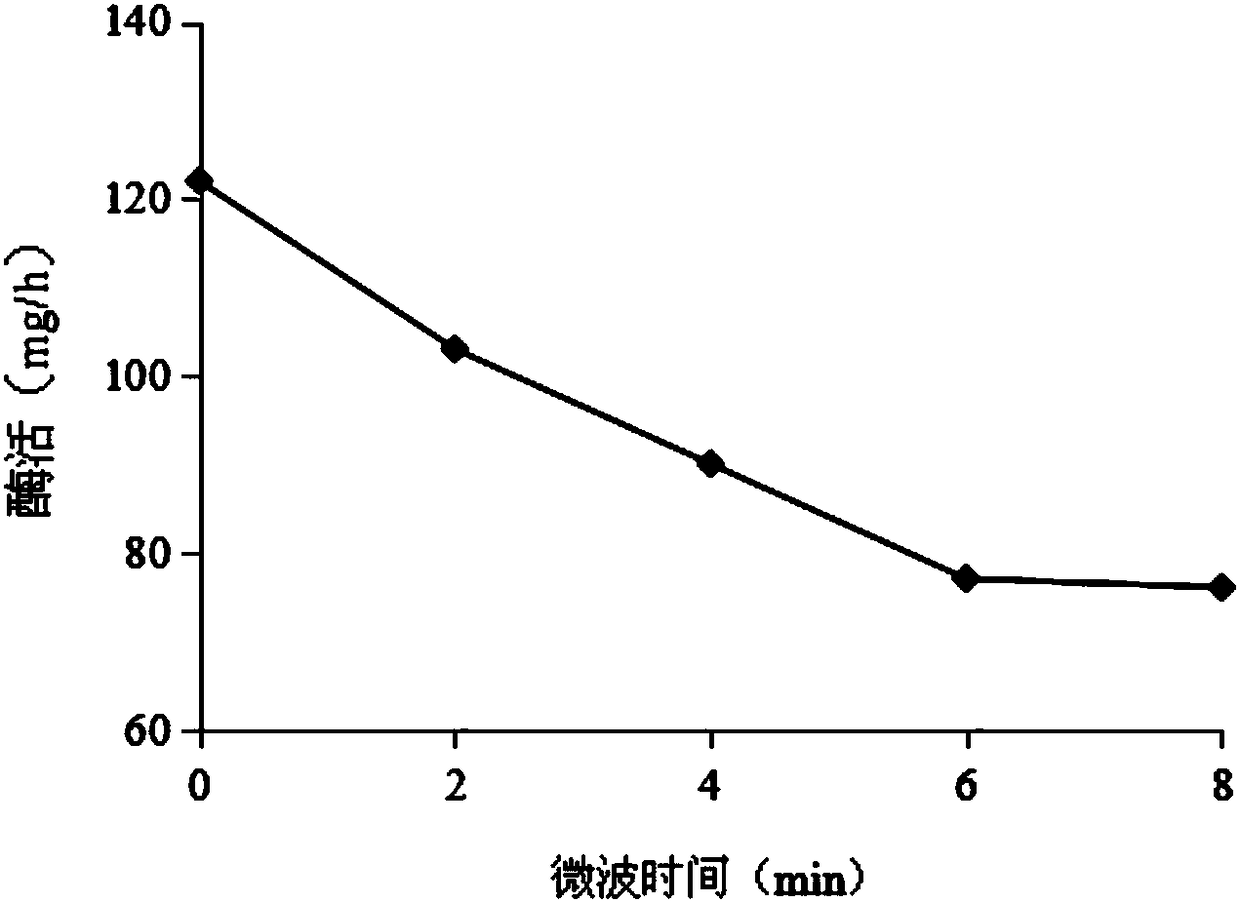

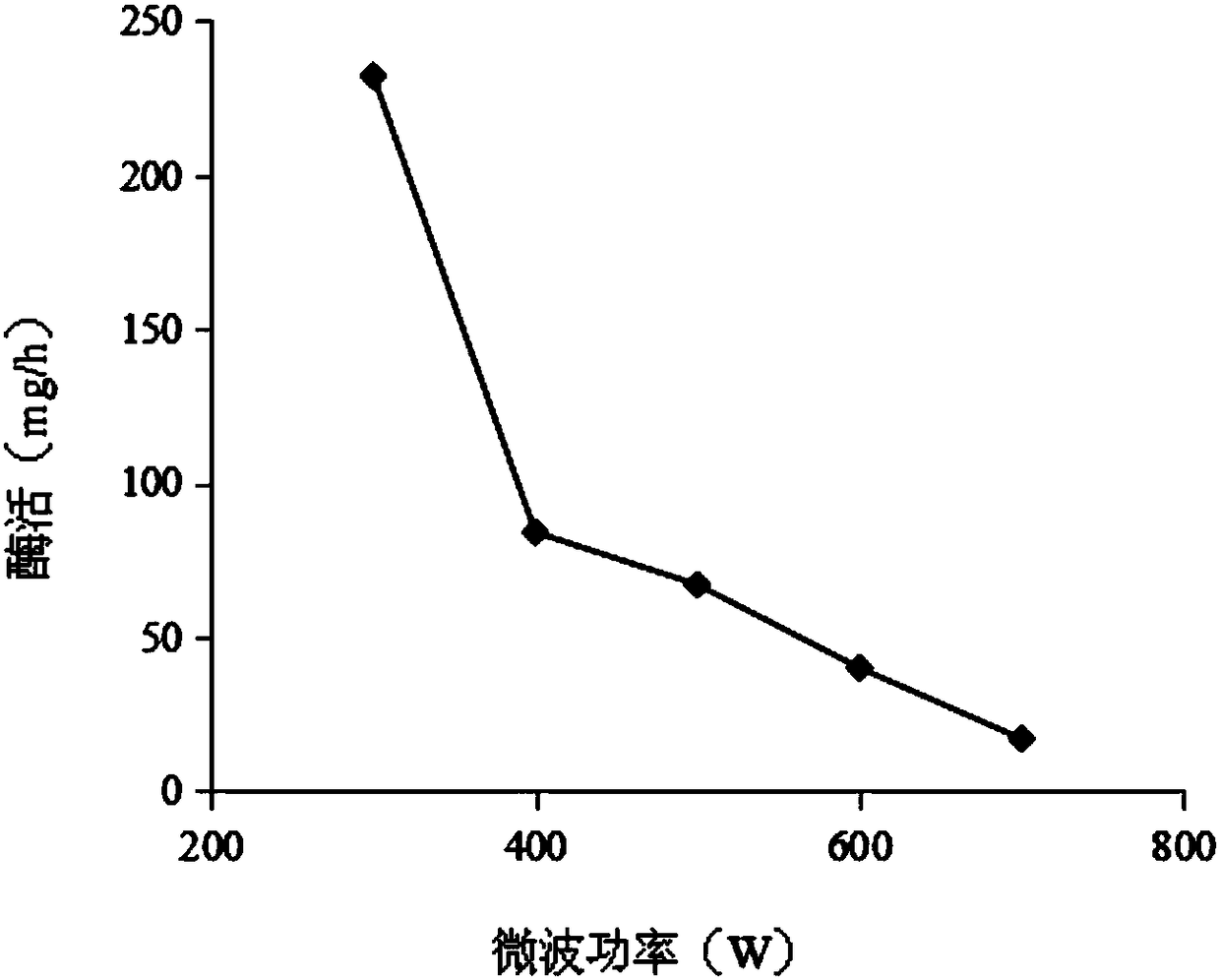

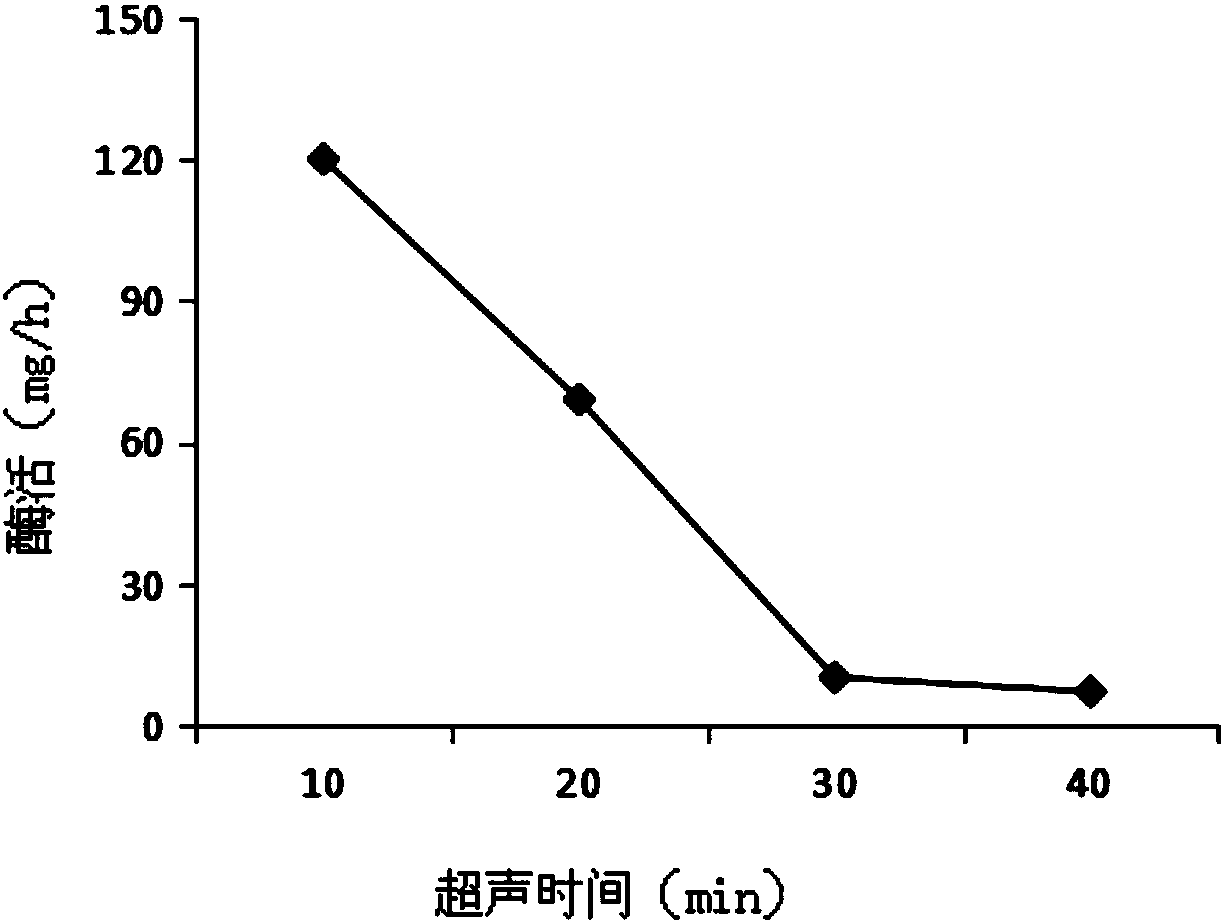

Method for treating passivated citrus ball surface residual enzyme activity by jointly utilizing ultrasonic-microwaves

InactiveCN108175029AQuality is not affectedEasy to operateFood thermal treatmentFood mechanical treatmentFood industryFruit juice

The invention discloses a method for treating passivated citrus ball surface residual enzyme activity by jointly utilizing ultrasonic-microwaves. An enzymatic method and a gap vacuum method are combined to peel the citrus fruit balls and remove segment membrane of citrus fruit balls, and the enzyme remaining on the surface of the citrus ball is passivated firstly by adopting ultrasonic way and then a microwave treatment way. The specific method is as follows: at the temperature of 20 to 30 DEG C, the ultrasonic frequency is 25kHz, the power is 500 to 750 w, and the ultrasonic time is 25 to 40min; and then the microwave treatment is carried out, the microwave power is 400 to 700 w, and the time is 4 to 8 min. The method provided by the invention is simple in operation, low in cost and highin efficiency, not only can effectively passivate the enzyme remaining on the surface of the passivated citrus ball, but also does not damage the citrus ball and does not influence the quality of thecitrus ball, sets a foundation for the automatic mass production of the enterprises in the industries such as RTU food industry, fruit juice industry, and fruit can, and can promote the automatic production of the industries and can boom the economy.

Owner:SOUTHWEST UNIVERSITY

Split type diamond grinding wheel and manufacturing technology thereof

ActiveCN103659626AReduce processing difficultySave raw materialsBonded abrasive wheelsManufacturing technologyStructural engineering

The invention discloses a split type diamond grinding wheel which comprises a grinding ring tightly clamped between a pressing plate and a base plate. The grinding ring is composed of a plurality of singe teeth in a splicing mode, an anti-flying mechanism which limits the radial direction, the axial direction and the circumferential degree of freedom of each single tooth is arranged between each single tooth and the pressing plate and the base plate. Each anti-flying mechanism comprises a clamping embedded structure which is formed by matching of a convex strip and a concave groove and an embedded body with moderate hardness and deformation, the convex strips and the concave grooves are placed between the single teeth and the pressing plate or / and the base plate, the embedded bodies are arranged between the splicing grinding ring and the clamping face of the pressing plate or the clamping face of the base plate or between the clamping face of the pressing plate and the clamping face of the base plate in squeezed and deformed modes. A manufacturing technology of the diamond grinding wheel comprises the steps that all the single teeth with equiform abrasion structures are manufactured first, then all the single teeth are spliced into the grinding ring, at last the spliced grinding ring is tightly clamped between the pressing plate and the base plate, and the anti-flying mechanisms are arranged to limit the radial direction, the axial direction and the circumferential degree of freedom of each single tooth. According to the split type diamond grinding wheel and the manufacturing technology thereof, the equiform abrasion structures which are difficult to machine on the entire grinding ring are machined conveniently by being split into single teeth to be spliced.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

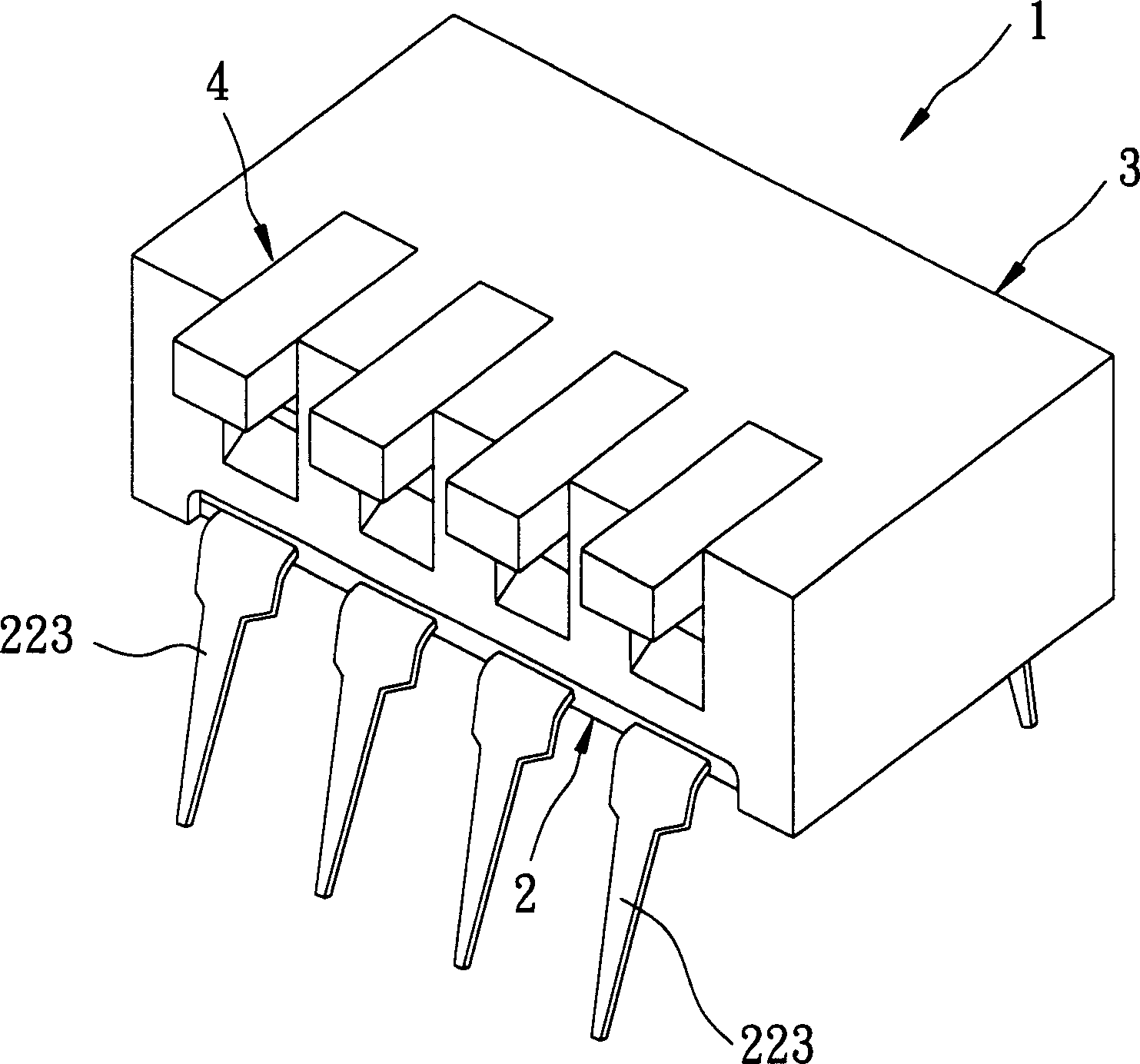

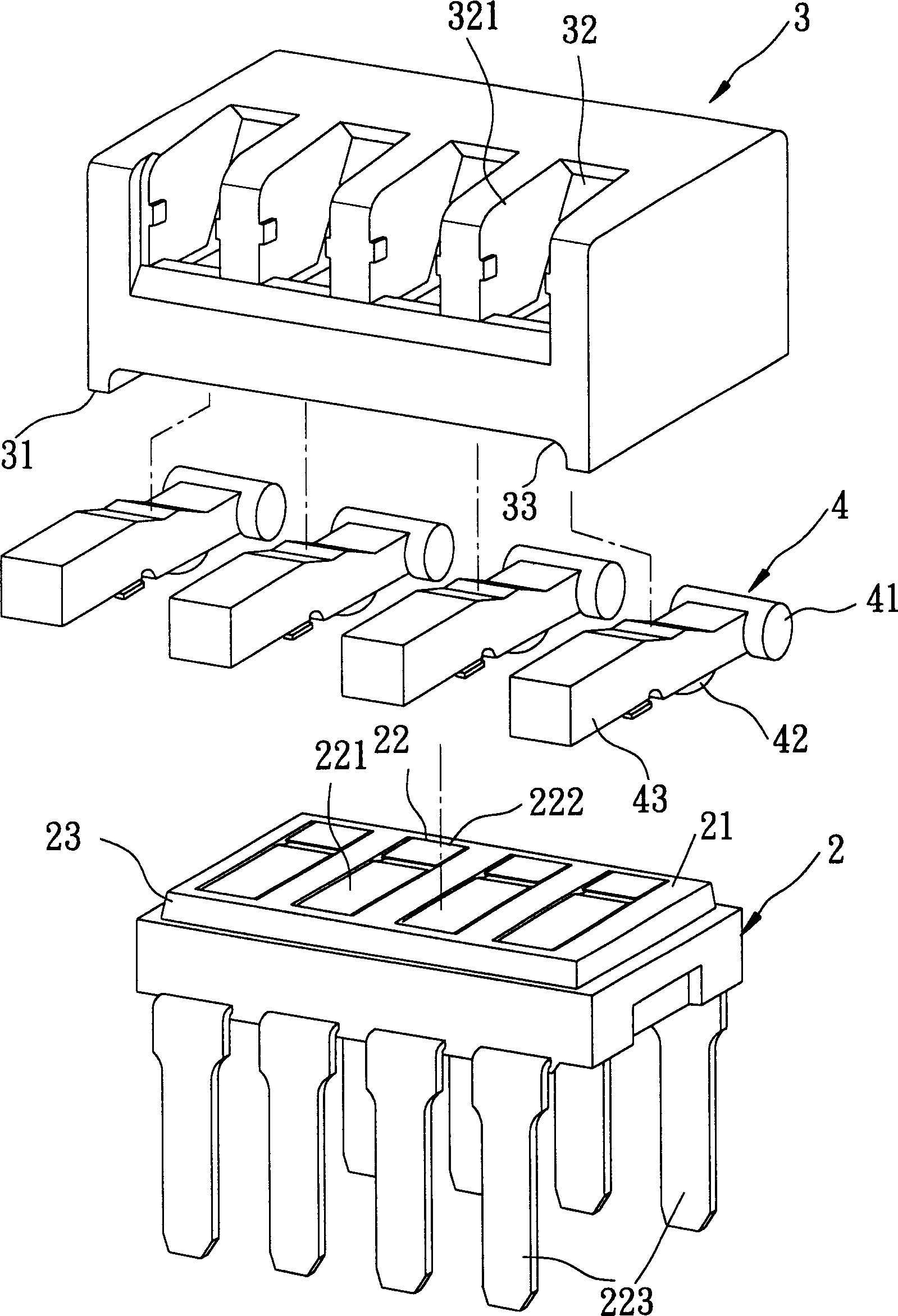

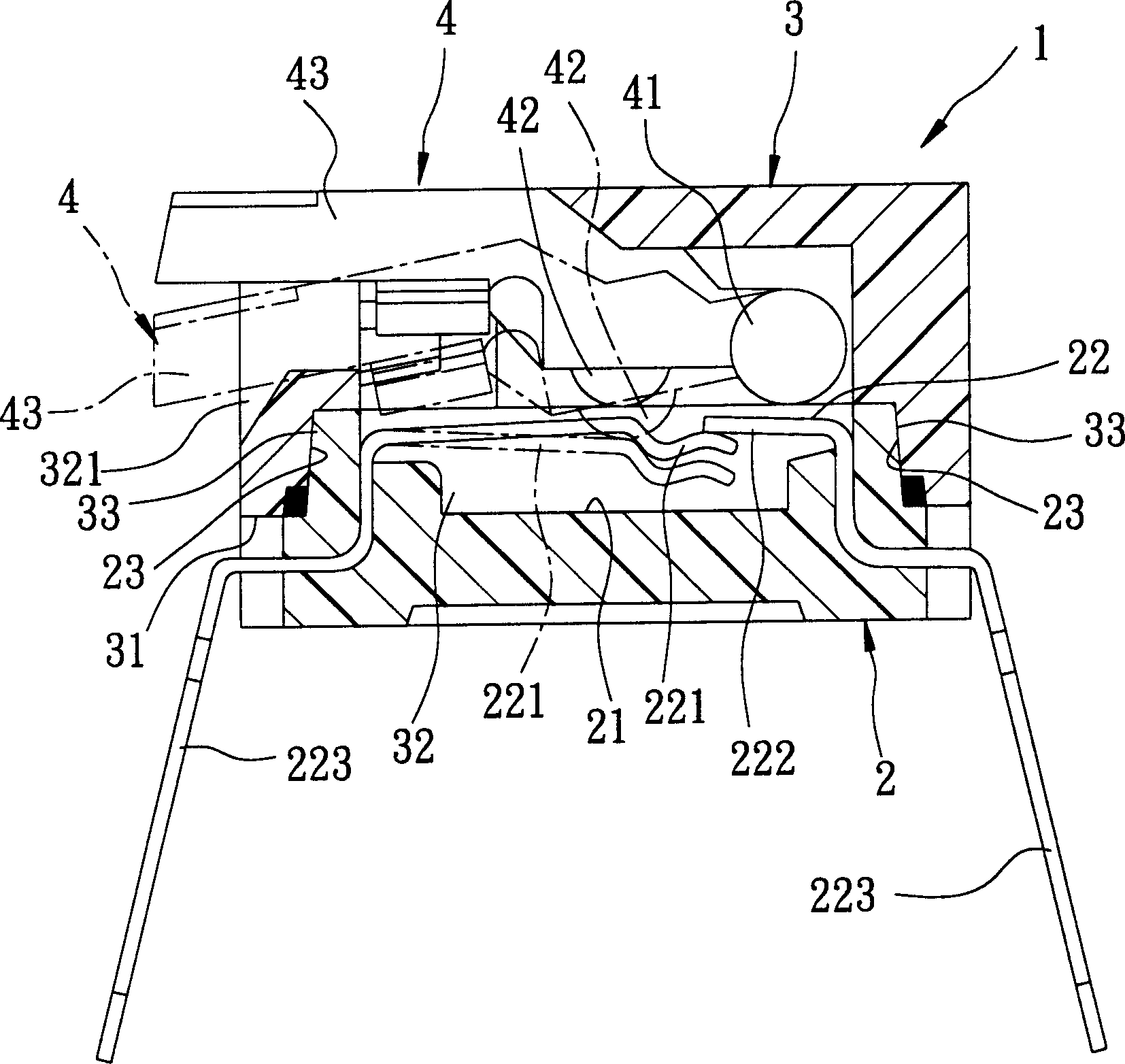

Program switch

InactiveCN1459814AExtended service lifeAvoid deformationElectric switchesElectrical and Electronics engineering

A programming switch is composed of a base with several recesses having parallel but non-contact two metallic sheets for each recess, a top cover embedded to the base, several metallic elastic pieces fixed to said base, and several toggle parts pivoted in the top cover and with a convex block for touching with said metallic elastic piece. When said toggle part moves up and down, a metallic elastic piece is driven to touch with one or both side metallic sheets. Its advantages are long service life, and low cost.

Owner:EXCEL CELL ELECTRONICS

Cleaning liquid applied to optical glass substrate and preparation method

InactiveCN110387292ANo smellNon-irritatingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsActive agentPhysical chemistry

The invention provides a cleaning liquid applied to an optical glass substrate. The cleaning liquid comprises the following components in percentages by weight: 3 to 20% of an inorganic alkaline substance, 1 to 4% of potassium salt and 0.01 to 0.05% of a non-ionic surfactant, with the balance being deionized water, wherein the above-mentioned deionized water is prepared by an RO reverse osmosis method, is pure water with impurities removed in an ion form, and is also called as ultrapure water and pure water and high-purity water. The invention provides a preparation method for the cleaning liquid applied to the optical glass substrate. The cleaning liquid provided by the invention has the following positive effects: fingerprints, stains and fine particles remaining on the optical glass substrate can be effectively removed, and no corrosion to the optical glass substrate is generated at the same time; meanwhile, the cleaning liquid is free of high requirements on a temperature and equipment of a use environment, has simple and convenient operation, and is safe and environmentally friendly.

Owner:苏州芯显微电子有限公司

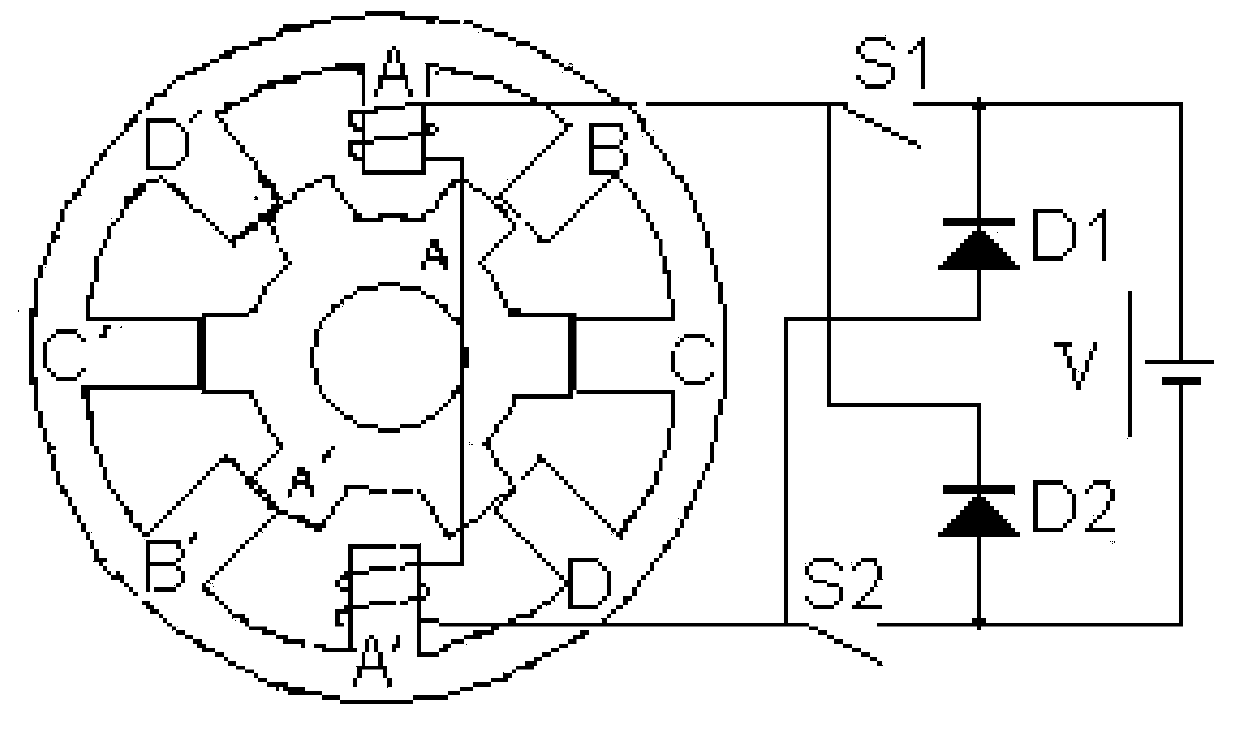

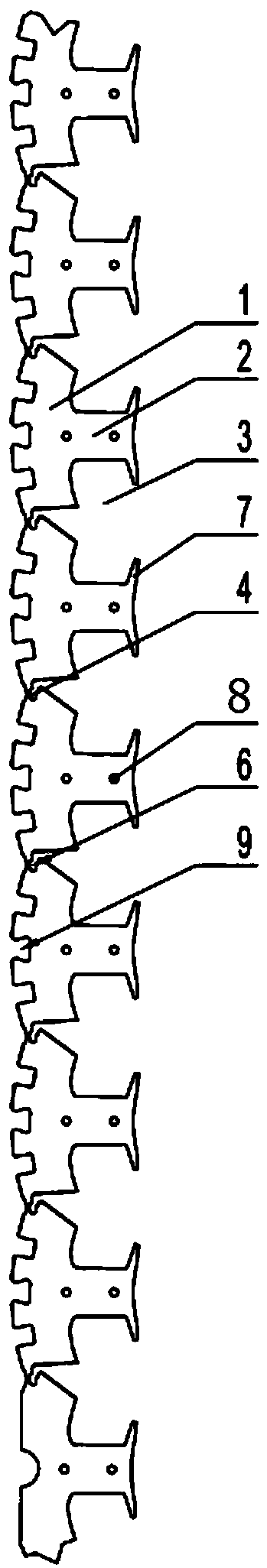

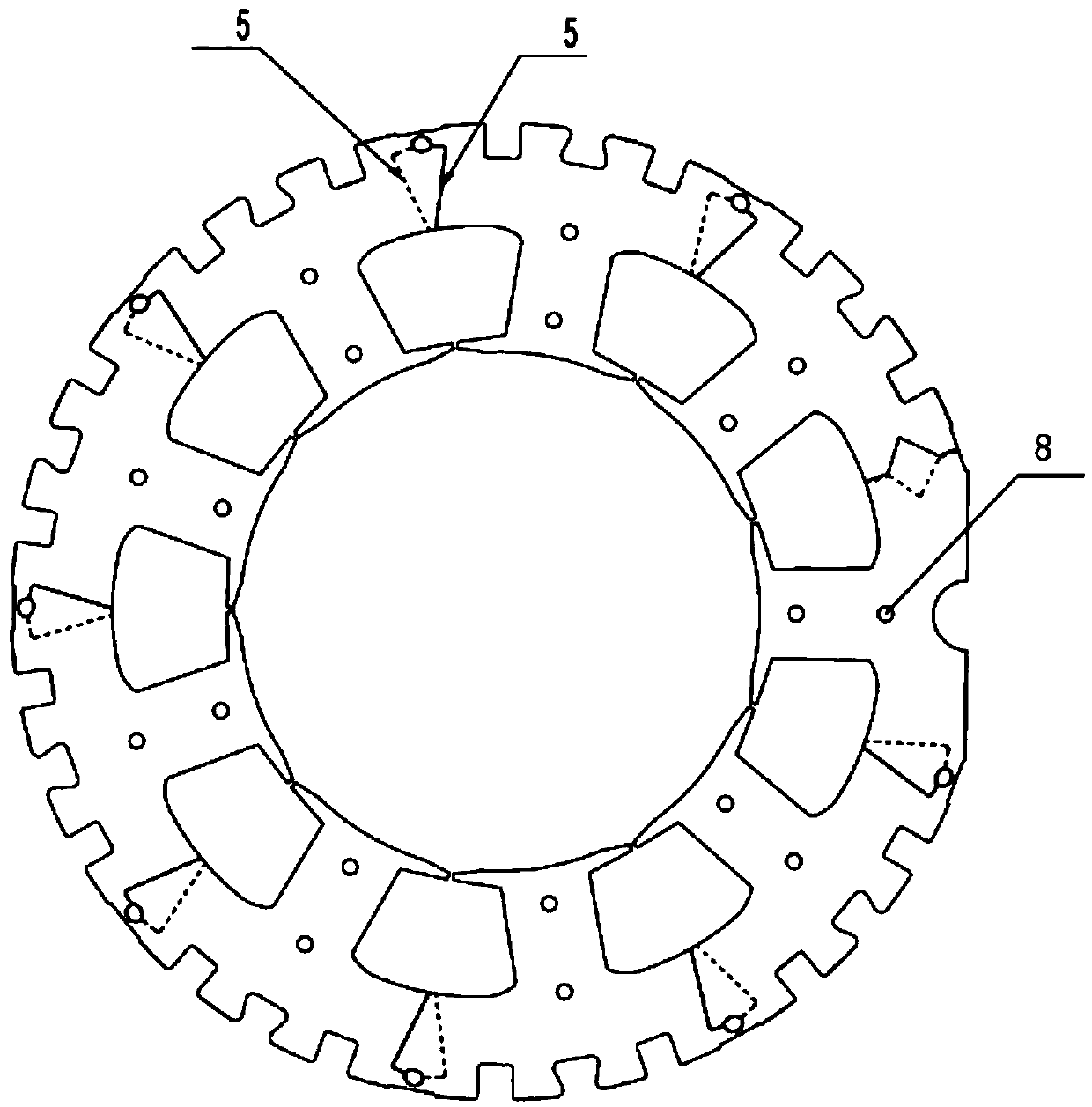

Reluctance machine with laminated connection type stators and fabrication method of reluctance machine

InactiveCN109617271AIncrease profitReduce manufacturing costMagnetic circuit stationary partsManufacturing stator/rotor bodiesConnection typePunching

The invention discloses a reluctance machine. The reluctance machine comprises multiple layers of stator cores and multiple layers of rotor cores which are formed in a lamination way, the reluctance machine is characterized in that each stator core is formed by laminating a first punching sheet and a second punching sheet in a staggered way, the first punching sheet and the second punching sheet are inserted to each other and are cut in a suit way, the first punching sheet and the second punching sheet respectively comprises N punching sheet units which are connected by connection parts, eachpunching sheet unit comprises a yoke part and a tooth part, mutual surfaces of adjacent yoke parts after ring formation are in contact to form a gap, gaps of adjacent layers are not in the same axialcross section, and a salient pole of a rotor is made of a magnetic conduction material of which the quality is lower than that of a stator. The reluctance machine is good in manufacturing process andhas the advantage of automatic manufacturing on a large scale; and moreover, the performance of the reluctance machine is improved, the material utilization rate is improved, and the motor cost is reduced.

Owner:ZHEJIANG SPECIAL ELECTRIC MOTOR CO LTD

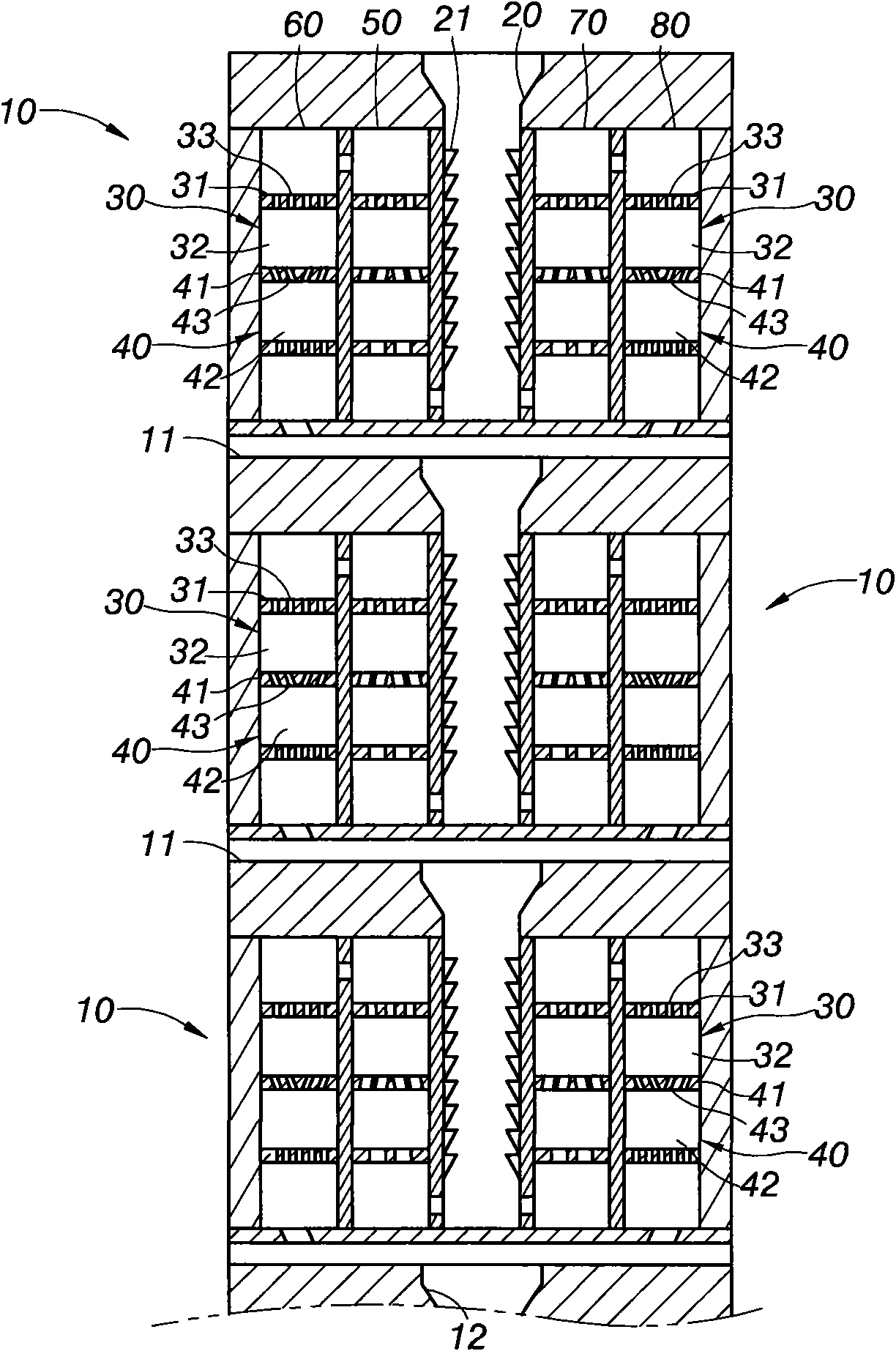

Floor structure and combined structure residential system with same

PendingCN111173122AEasy constructionReduce on-site workloadClimate change adaptationFloorsFloor slabArchitectural engineering

The invention relates to a floor structure and a combined structure residential system with the same. The floor structure comprises floor slabs and cantilever slabs; a steel reinforcement framework isarranged in the space between every two adjacent floor slabs; floor ring ribs are sequentially and vertically fixed at intervals along the length direction of the floor slab splicing surface at the bottom of an installation notch; each steel reinforcement framework comprises a connecting horizontal rib arranged along the length direction of the splicing surface and a plurality of connecting ringribs fixed to the connecting horizontal rib; the connecting ring ribs are parallel to the floor ring ribs; concrete is poured into the connecting ring rib sand the floor ring ribs; and the floor slabsand the cantilever slabs are connected through cold-hot-proof bridge nodes. According to the structure, the on-site construction speed is greatly improved, the construction difficulty is reduced, theconstruction process is simple, the four sides of a prefabricated plate are free of reinforcement rib exposing, the automatic batch production of factories is facilitated, and the production cost isgreatly reduced; the stress performance is good, the integrity is strong, and the structural integrity in the assembly integral mode is strong; and on-site assembly construction is realized, the construction efficiency is high, the self weight and the concrete consumption of a floor are greatly reduced by the multi-rib structure, and the cost is reduced.

Owner:SHENZHEN YJY BUILDING TECH +2

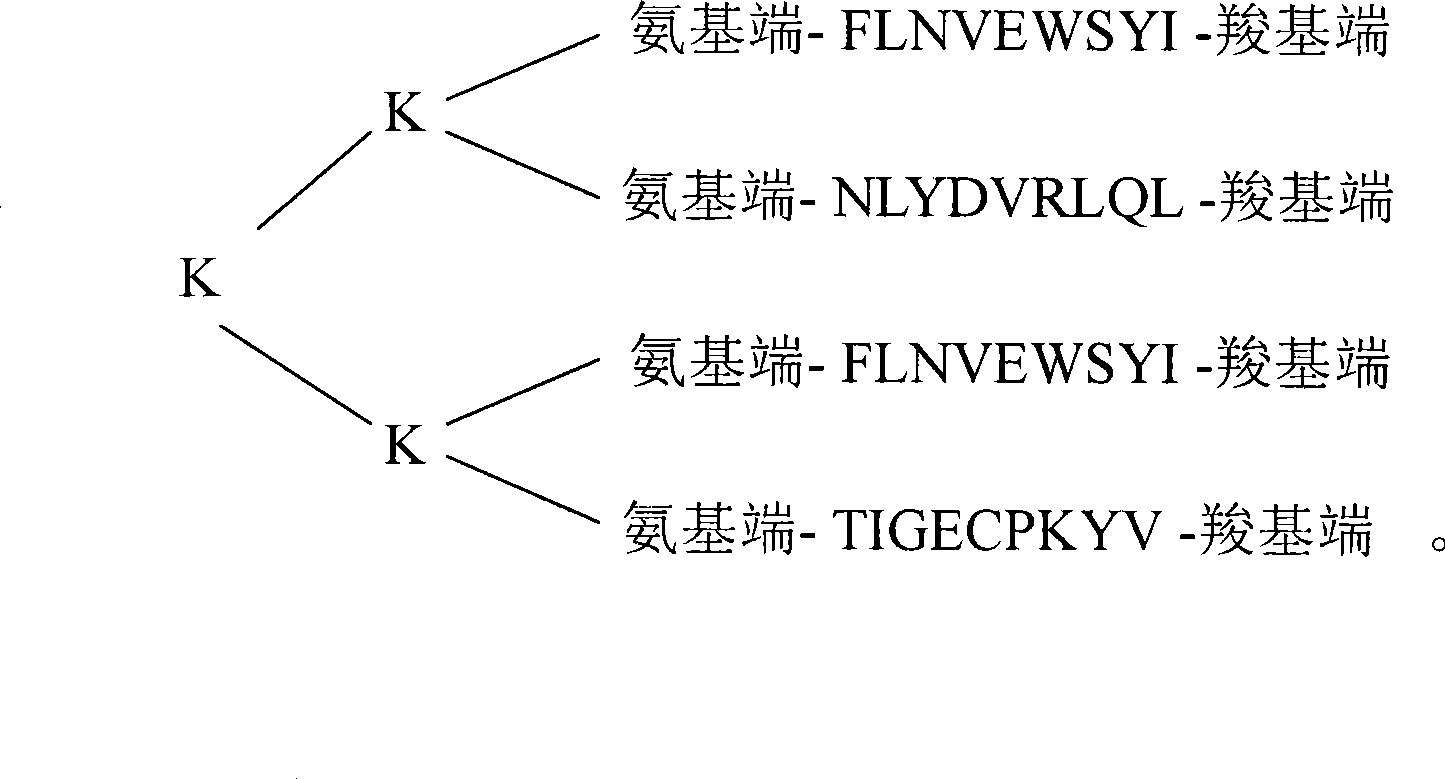

Polypeptide drug for treating diseases caused by highly pathogenic avian influenza virus H5N1

InactiveCN102058873AEasy to store and transportFacilitate automated mass productionPeptide/protein ingredientsAntiviralsDiseaseSide effect

The invention relates to a polypeptide drug for treating diseases caused by highly pathogenic avian influenza virus H5N1, in particular to a polypeptide drug about diseases caused by highly pathogenic avian influenza virus H5N1, belonging to the field of biomedicine. The polypeptide drug is characterized in that the amino acid sequence of the polypeptide drug is amido-FLNVEWSYI-carboxyl, which is a special connection mode formed by using the characteristic that lysine has two amidoes and one carboxyl and using the lysine as a joint. The invention has the advantages of convenience for transportation and preservation and automated batch production; the polypeptide drug has the capacity of activating specific cytotoxicity T lymphocyte (CTL); and the specific CTL cells have target cells for killing and dissolving H5 protein having the highly pathogenic avian influenza virus H5N1, with obvious effects but without toxic or side effects.

Owner:CHONGQING UNIV

Plate lifting device for PCB plate

InactiveCN101296572ASimple structureFacilitate automated mass productionPrinted circuit assemblingSolderingMotherboard

The invention relates to a device of a solder pot, in particular to a PCB board removing device which comprises a clamp used for clamping the PCB board, and a support used for supporting the clamp. The support is fixedly mounted on a motherboard at the lower part; a board removing cylinder is fixedly mounted at one side of the motherboard; when the mandril of the board removing cylinder is upraised, the mandril is butted against the lower edge of one side of the clamp; a lifting cylinder is arranged at the lower part of the clamp, and a cylinder mounting base is fixedly arranged on the motherboard; the board removing cylinder is connected with the cylinder mounting base. The PCB board removing device of the invention has simple structure, by imitating the welding process of WAVE SOLDING, a side angle is generated when removing the PCB board so that detinning is carried out at one angle when tin-soldering is finished by the PCB elements, thus solving the phenomena of poor welding such as icicles, insufficient solder and missing solder, etc. The PCB board removing device of the invention is beneficial to automated large scale production.

Owner:SUZHOU MINGFU AUTOMATIC SCI & TECH

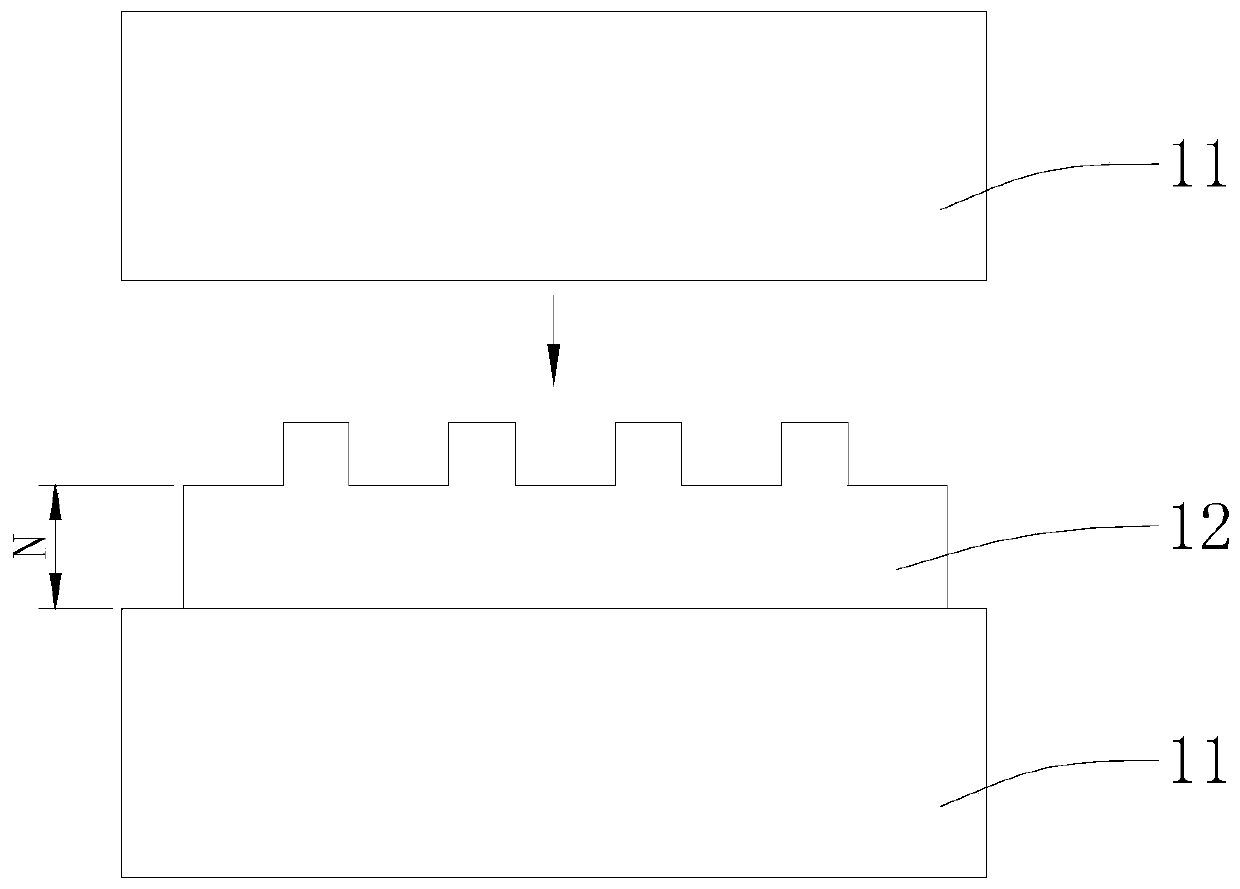

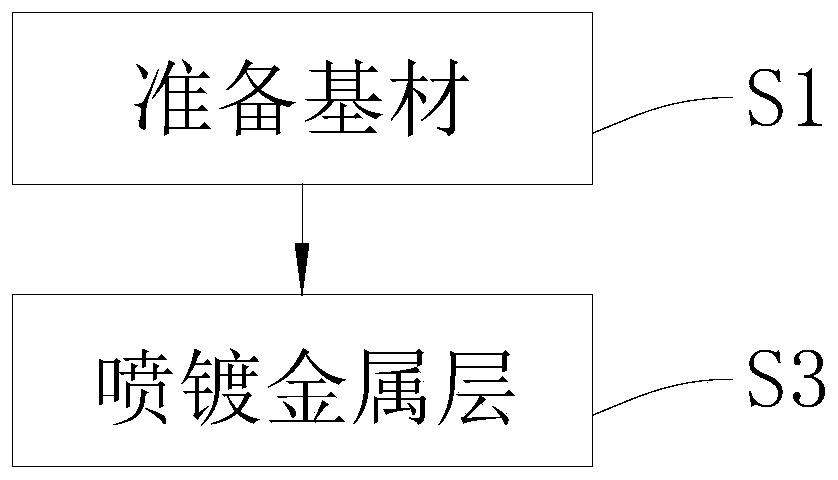

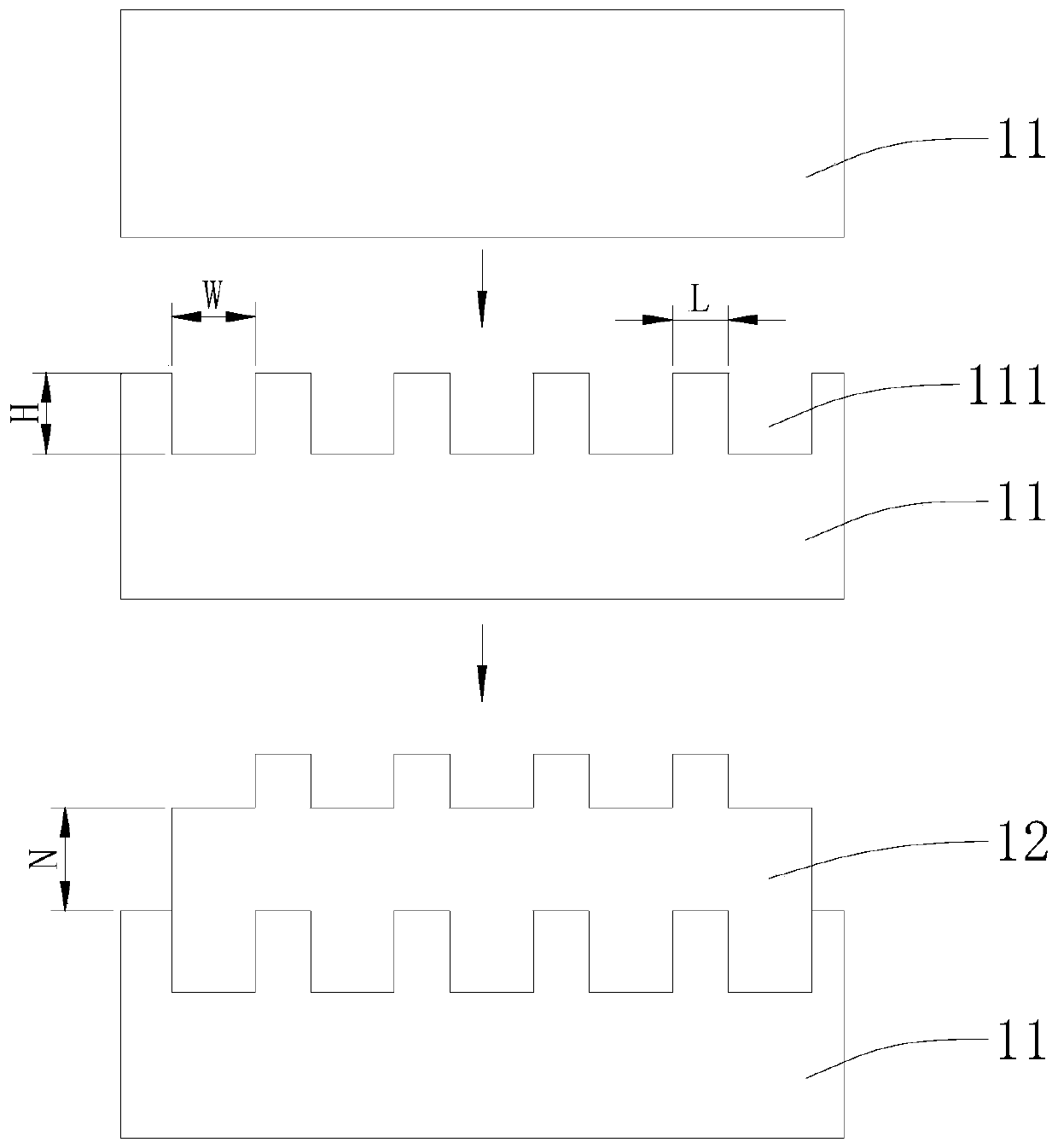

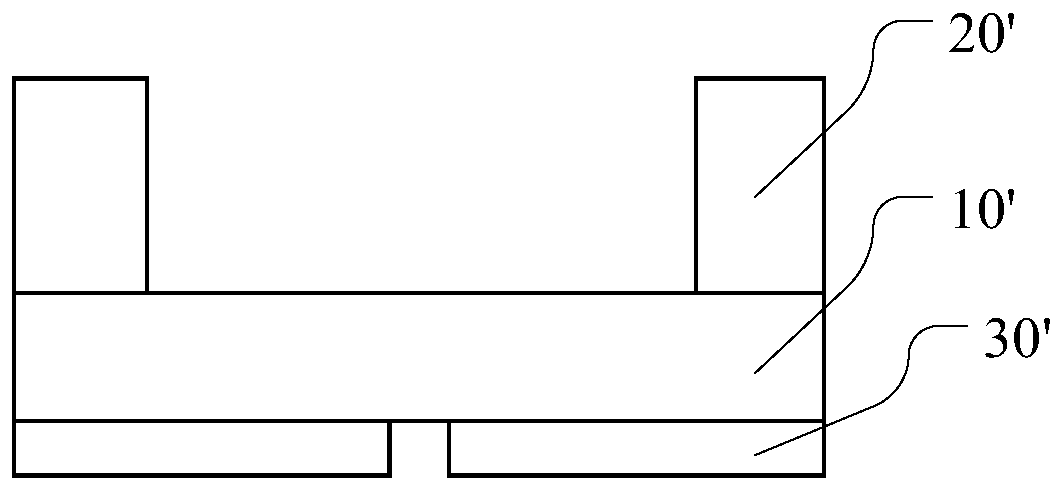

Anti-electromagnetic interference substrate and preparation method thereof, and electronic equipment

InactiveCN110331361AQuality assuranceGood electromagnetic shielding protectionMolten spray coatingMagnetic/electric field screeningGold particlesElectromagnetic interference

The invention provides an anti-electromagnetic interference substrate and a preparation method thereof, and electronic equipment. The preparation method of the anti-electromagnetic interference substrate comprises the following steps that a base material is provided, and a shielding area needing to be provided with electromagnetic shielding on the base material is determined; metal particles are sprayed on the shielding area of the base material, and thus a metal coating is formed on the shielding area; and the metal particles are one of copper particles, silver particles, gold particles, copper alloy, silver alloy or gold alloy. The metal coating on the shielding area of the base material by spraying one of copper particles, silver particles, gold particles, copper alloy, silver alloy orgold alloy, so that the shielding area can provide good electromagnetic shielding protection; moreover, the quality of the metal coating can be ensured, automatic mass production can be conducted conveniently, manual sticking is not needed, abnormal fitting is avoided, and waste is reduced; and the method is particularly applicable to a substrate with a complicated and sharp surface, and the adaptability is good.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

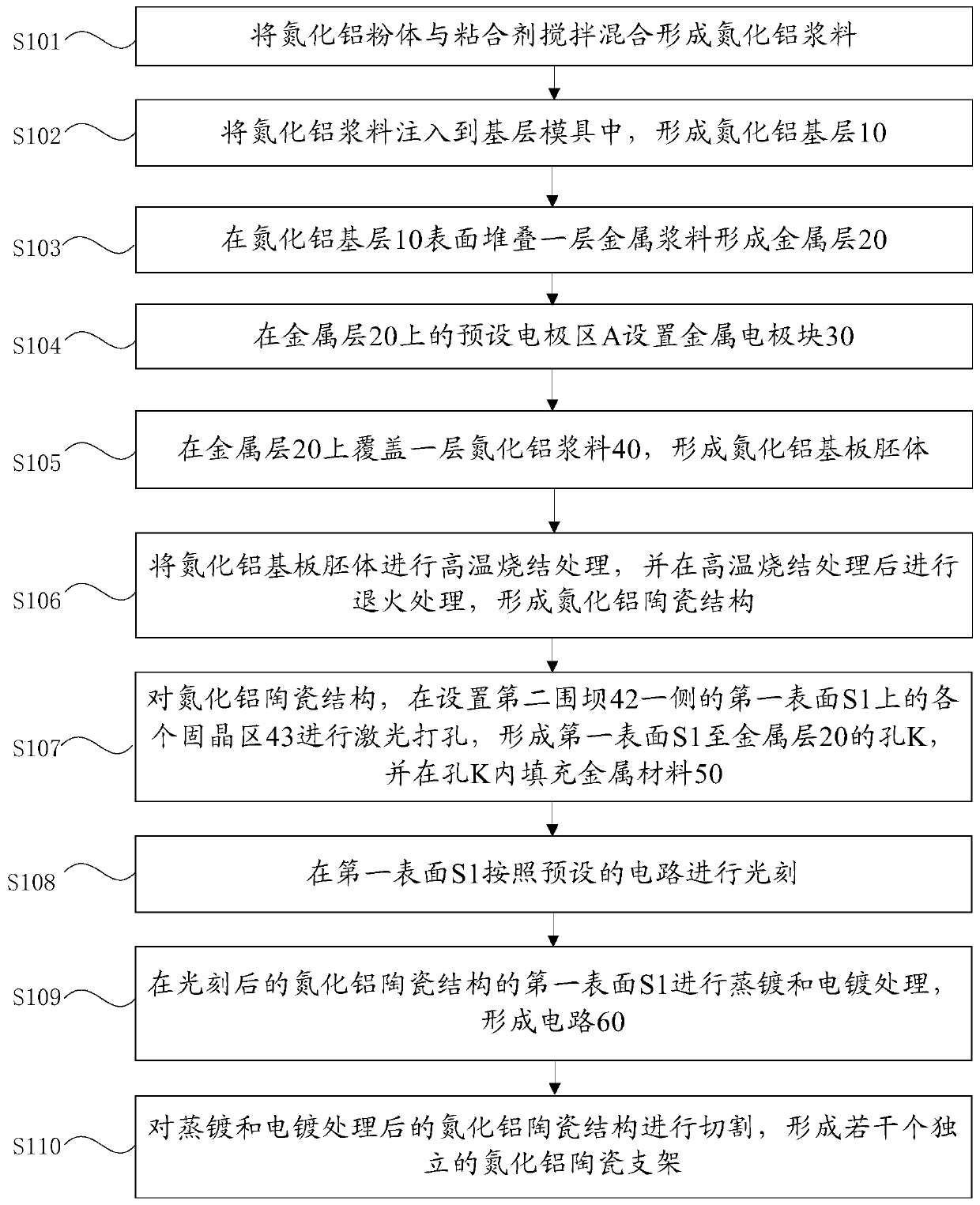

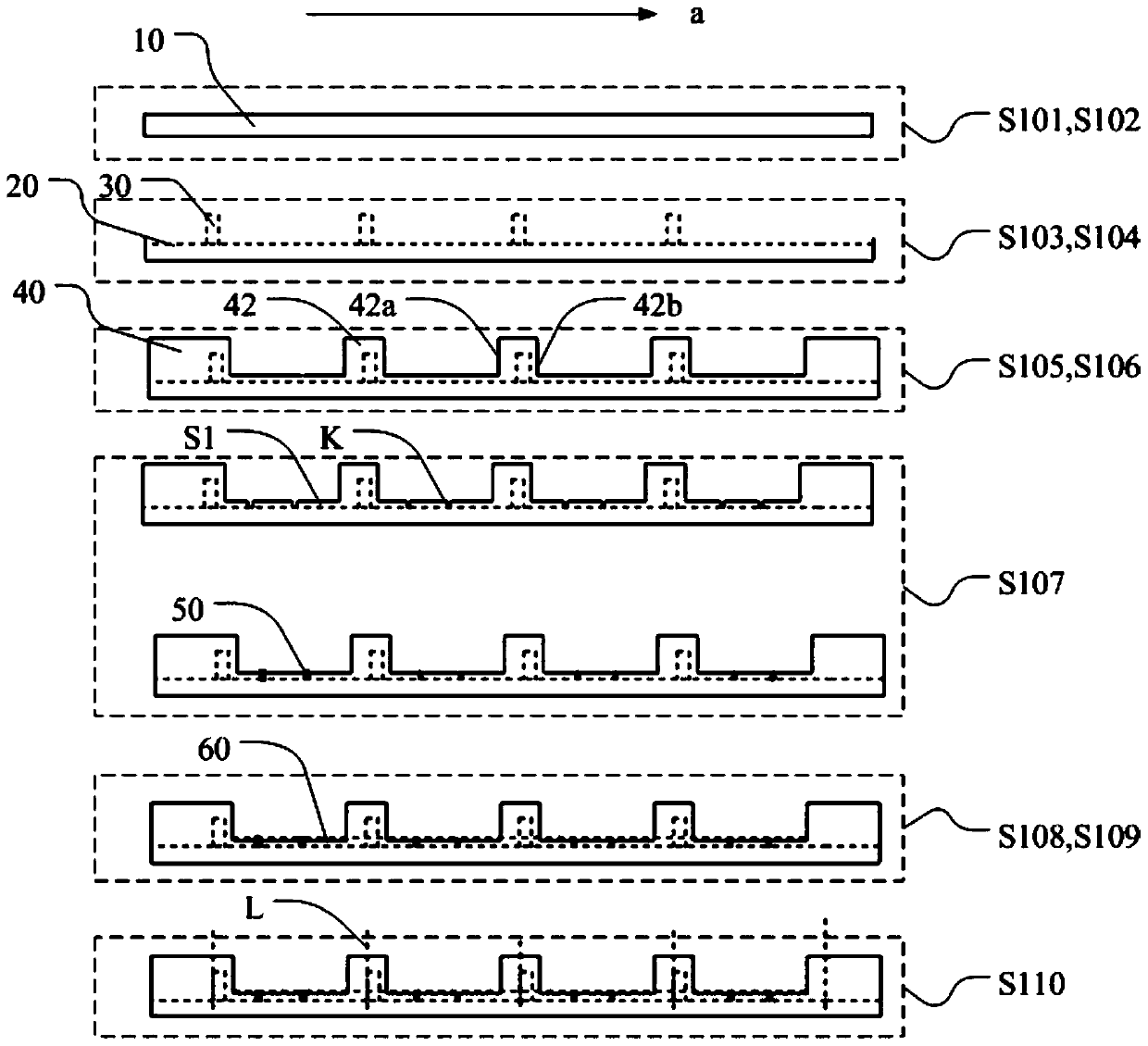

A package bracket suitable for side-emitting deep ultraviolet LEDs and its production process

The invention discloses a side light-emitting deep ultraviolet LED packaging bracket and a production process thereof, the production process includes forming aluminum nitride slurry, injecting it into a base layer mold to form an aluminum nitride base layer; forming a metal layer on the surface of the aluminum nitride base layer; arranging a metal electrode block in a preset electrode region on the metal layer; covering layer of aluminum nitride paste on the metal layer to form an aluminum nitride substrate embryo body; The aluminum nitride substrate embryo is sintered and annealed at high temperature to form an aluminum nitride ceramic structure; The aluminum nitride ceramic structure is laser drilled in each die bonding region on the first surface on the side of the second enclosure damto form a hole from the first surface to the metal layer, and the hole is filled with a metal material; A circuit is formed by photolithography on the first surface according to a preset circuit, anda plurality of independent aluminum nitride ceramic supports are formed after cutting. By the invention, the deep ultraviolet LED lateral light emission can be realized.

Owner:江西力特康光学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com