Reluctance machine with laminated connection type stators and fabrication method of reluctance machine

A reluctance motor and manufacturing method technology, applied in the manufacture of stator/rotor bodies, magnetic circuits, electromechanical devices, etc., can solve the problems of blocked electromagnetic field circuits, low material utilization, and reduced motor efficiency, so as to achieve smooth magnetic circuits and reduce Production cost, effect of improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

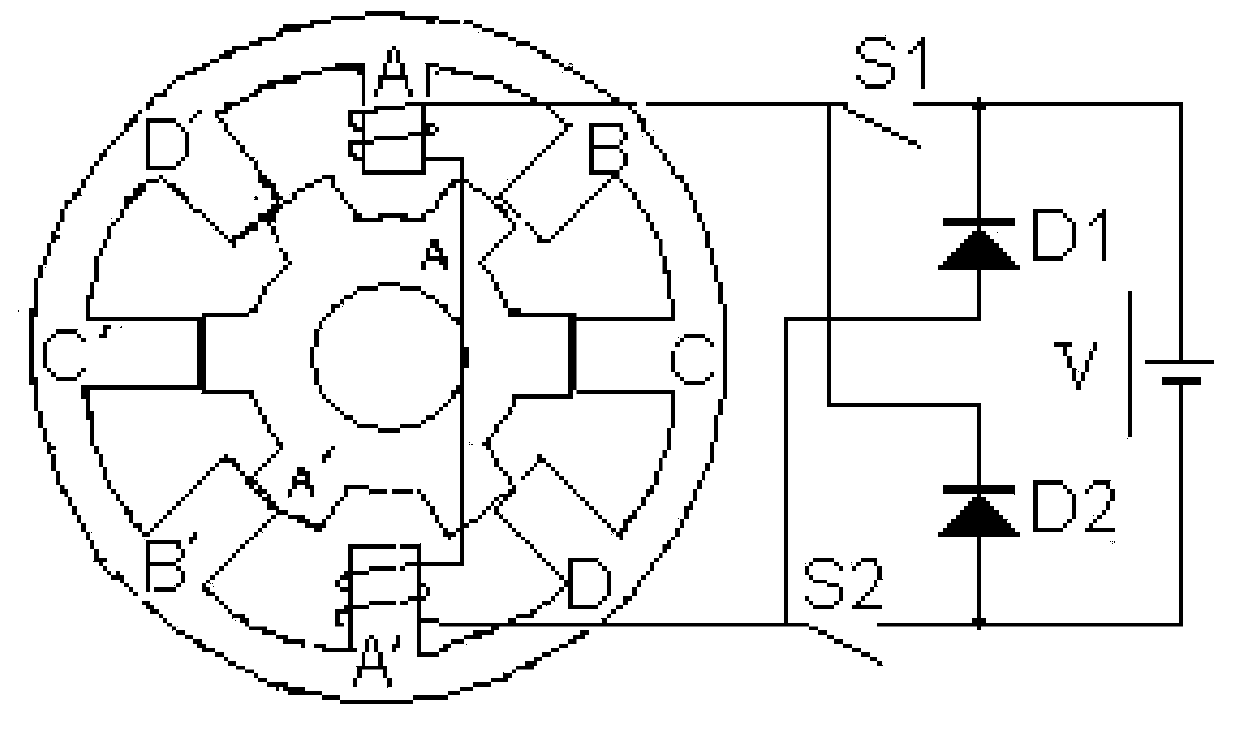

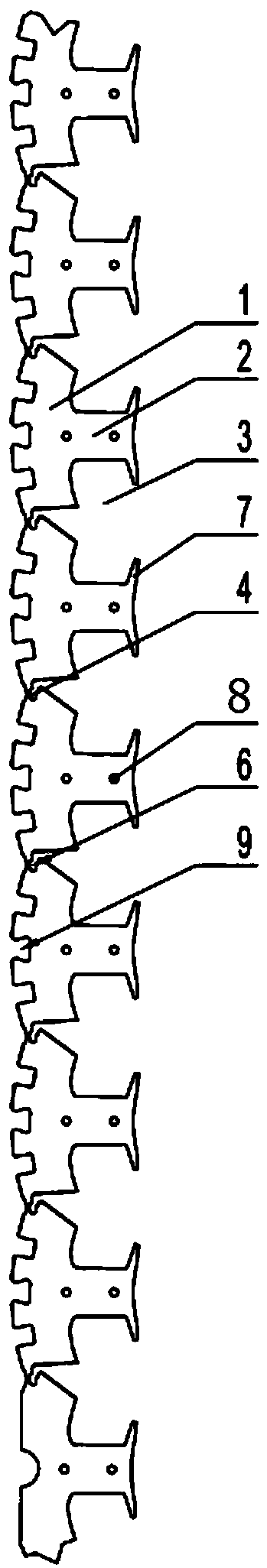

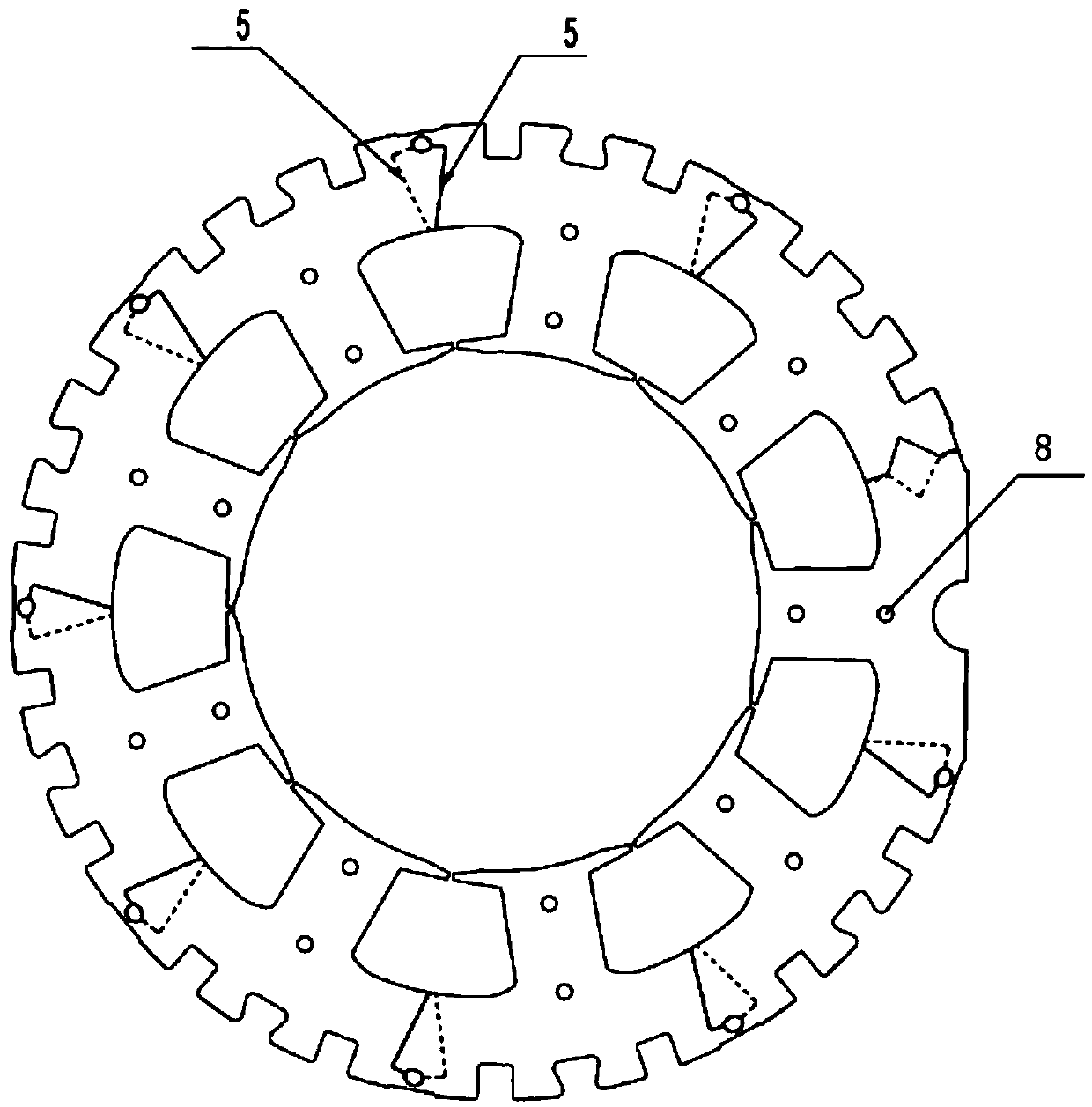

[0031] In a specific embodiment, the reluctance motor of the present invention may be a double-salient pole variable reluctance motor, and the salient poles of the rotor are formed by laminating ordinary silicon steel sheets of a lower grade. The rotor has neither windings nor permanent magnets. The stator poles are wound with concentrated windings. The two radially opposite windings are connected together, which is called "one phase". The switched reluctance motor can be designed into a variety of different phase structures, and the fixed , There are many different collocations for the number of poles of the rotor. The number of phases is large and the step angle is small, which is beneficial to reduce torque ripple, but the structure is complex, and there are many main switching devices, and the cost is high. Nowadays, the four-phase 8 / 6 structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com