Plate lifting device for PCB plate

A PCB board and bottom board technology, which is applied in the field of PCB board lifting device, can solve the problems of PCB board soldering quality cannot be guaranteed, sharpening, etc., and achieve the effect of facilitating automatic large-scale production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

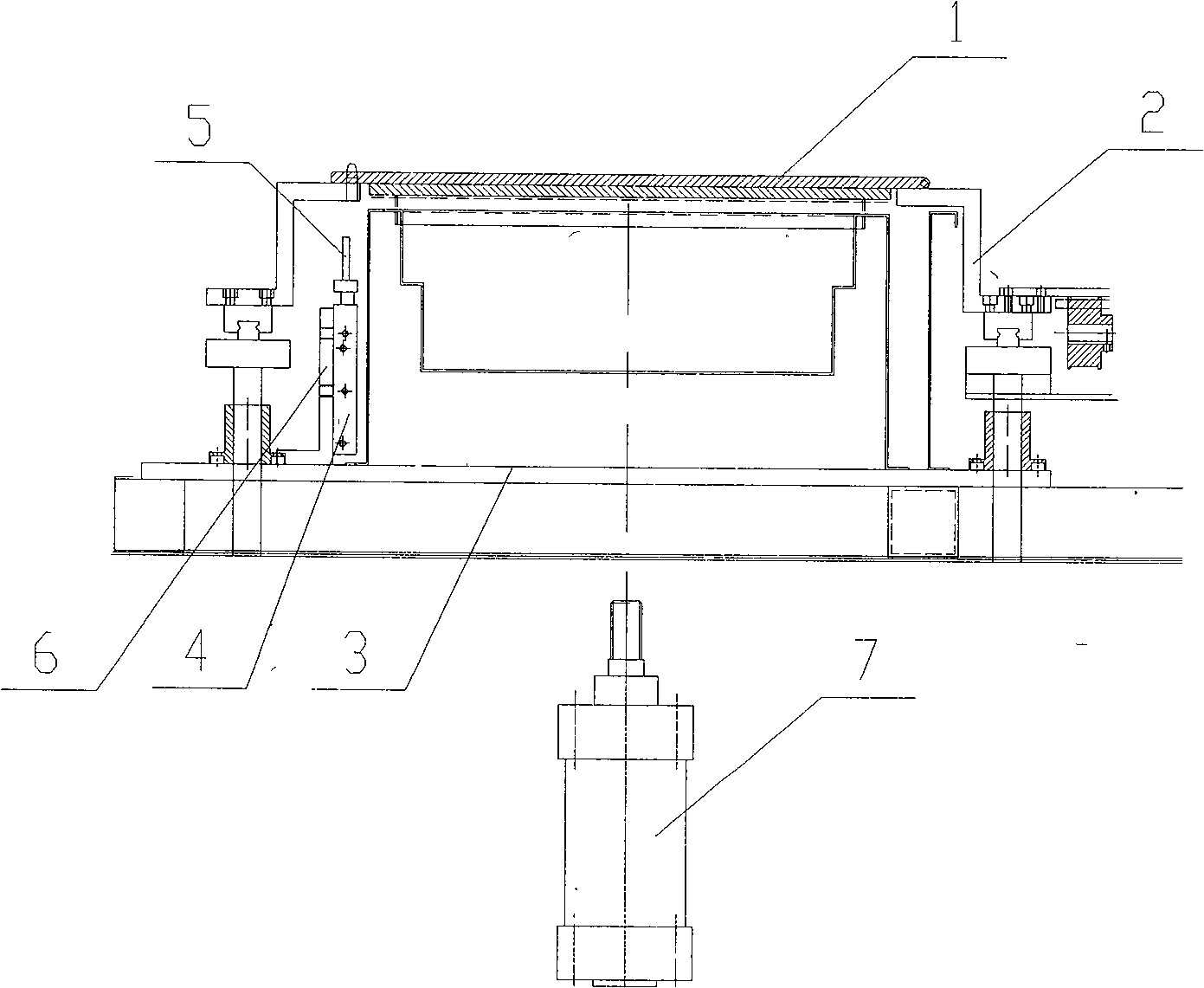

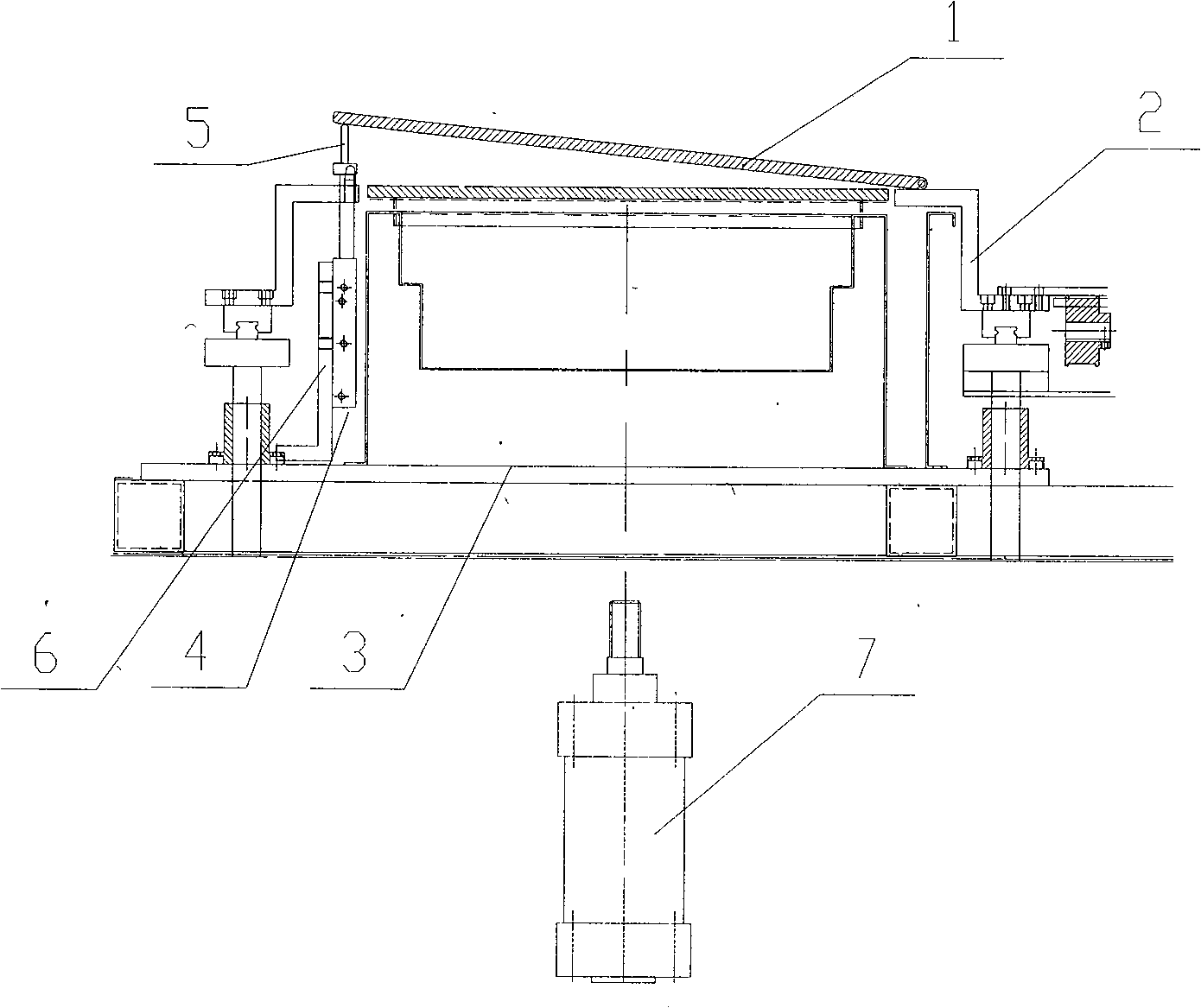

[0012] like figure 1 A PCB board lifting device shown has a jig 1 for clamping the PCB board and a support 2 for supporting the jig 1. The support 2 is fixedly installed on the bottom plate 3 below, on one side of the bottom plate 3 A board lifting cylinder 4 is fixedly installed, and when the push rod 5 of the board lifting cylinder 4 rises, it is offset against the lower edge of one side of the clamp 1, and a jacking cylinder 7 is arranged below the clamp. In addition, in order to facilitate the installation and position adjustment of the lifting cylinder, a cylinder mounting seat 6 is fixedly arranged on the bottom plate 3 , and the lifting cylinder 4 is connected to the cylinder mounting seat 6 .

[0013] When in use, after the PCB board clamped by the fixture 1 has been welded, first start the lifting cylinder 4, and the ejector rod 5 of the lifting cylinder 4 lifts up the lower edge of one side of the fixture 1 to make the fixture 1 tilt, as figure 2 As shown, in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com