Method for ensuring the axiality of the injection molding cooling deep borehole and the external-molding surface

A manufacturing method and external forming technology are applied in the manufacturing field to ensure the coaxiality between the cooling deep hole of the injection mold and the external forming surface, which can solve the problem of not fully considering the requirements of wall thickness uniformity, excessive dimensional error of the preform wall thickness, Preform deformation and other problems, to achieve the effect of being conducive to automated mass production, simple processing methods, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

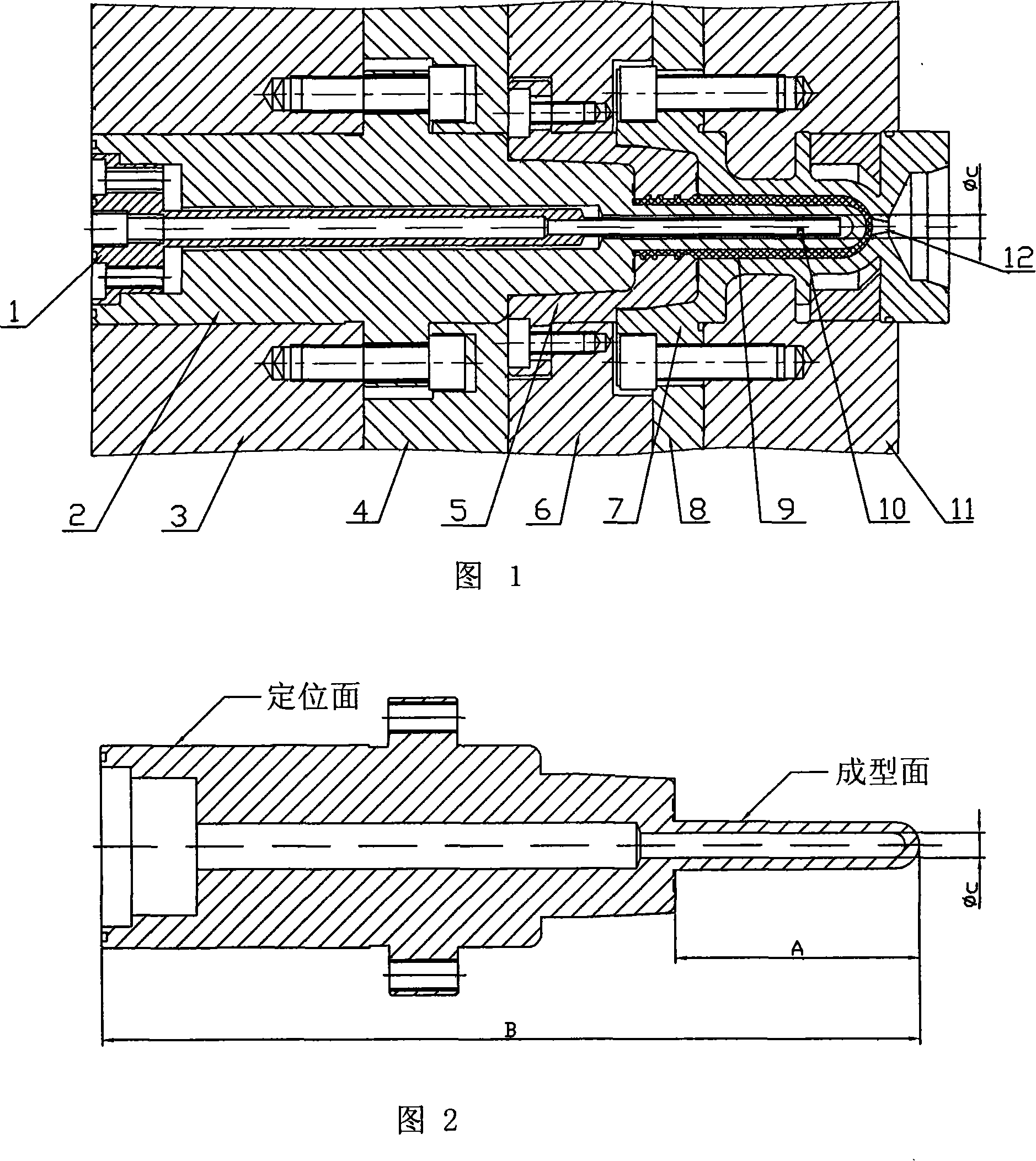

[0024] Embodiment 1: Manufacture of cores in injection molds for one out of sixteen (19g) PET bottles; A=92.58mm, B=239mm, C=9mm.

[0025] In order to ensure the coaxiality of the core cooling deep hole in the injection mold and the outer molding surface, the manufacturing method includes the following steps:

[0026] (1) Rough turning shape: use ordinary lathe CA6140 rough turning to inject the mold shape, and control the surface roughness of the outer cylindrical surface of the mold core to be less than 3.2 microns.

[0027] (2) Drilling water channel holes and adjusting eccentricity: Use a dial indicator to correct the rough-turned outer cylindrical surface on an ordinary lathe to ensure that the radial runout is 0.02. According to the diameter of the rough-turned water channel φ9, use a "twist" drill to drill the cooling water hole ; Measure the thickness difference of the forming channel wall (using an ultrasonic thickness gauge) at a height of 10mm along the two ends of ...

Embodiment 2

[0035] Embodiment 2: one out of twenty-eight (19g) PET bottle injection mold core manufacture; A=89.968mm, B=236mm, C=11mm

[0036] In order to ensure the coaxiality of the core cooling deep hole in the injection mold and the outer molding surface, the manufacturing method includes the following steps:

[0037](1) Rough turning shape: Use an ordinary lathe (CA6140) to rough turn the injection mold shape, and control the surface roughness of the outer cylindrical surface of the mold core to be less than 3.2 microns.

[0038] (2) Drilling water channel holes and adjusting eccentricity: Use a dial indicator to correct the rough-turned outer cylindrical surface on an ordinary lathe to ensure radial runout of 0.02. According to the diameter of the rough-turned water channel φ11, use a "twist" drill to drill the cooling water hole ; Measure the thickness difference of the forming channel wall (using an ultrasonic thickness gauge) at a height of 10mm along the two ends of the forming...

Embodiment 3

[0046] Embodiment 3: one out of eight (100g) PET bottle injection mold core manufacturing; A=168.03mm, B=314.5mm, C=26mm

[0047] In order to ensure the coaxiality of the core cooling deep hole in the injection mold and the outer molding surface, the manufacturing method includes the following steps:

[0048] (1) Rough turning shape: Use an ordinary lathe (CA6140) to rough turn the injection mold shape, and control the surface roughness of the outer cylindrical surface of the mold core to be less than 3.2 microns.

[0049] (2) Drilling water channel holes and adjusting eccentricity: Use a dial indicator to correct the rough-turned outer cylindrical surface on an ordinary lathe to ensure radial runout of 0.02. According to the diameter of the rough-turned water channel φ26, use a "twist" drill to drill the cooling water hole ; Measure the thickness difference of the forming channel wall at a height of 10mm along the two ends of the forming surface (using an ultrasonic thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com