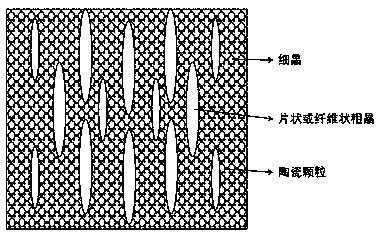

Preparation method of hierarchically-structured composite material with nano-ceramic particle reinforced metal matrix

A technology of nano-ceramic particles and composite materials is applied in the field of preparation of nano-ceramic particles reinforced metal matrix graded configuration composite materials, which can solve the problems of low efficiency, high cost, poor plasticity and toughness, etc. Good density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a nano-ceramic particle-reinforced metal matrix hierarchical configuration composite material, the specific steps are as follows:

[0025] (1) First select SiC ceramic powder with a size of 50nm and 7075 aluminum alloy powder with a size of 30μm, wherein the mass ratio of SiC ceramic powder and 7075 aluminum alloy powder is 1:2, add 1.5% stearic acid in total, and the ball-to-material ratio is 10 : 1, the rotating speed is 1000 rpm, and finally the high-energy ball mill mixes the powder evenly.

[0026] (2) Then, the 7075 aluminum alloy was melted to prepare molten metal, the melting temperature was 750°C, and then kept at 660°C for 30 minutes, and the molten metal was stirred.

[0027] (3) Add the uniformly mixed SiC ceramic powder and 7075 aluminum alloy metal powder in step (1) into the molten metal in step (2), so that the mass ratio of the final SiC ceramic powder to 7075 aluminum alloy metal is 1:19, And stir to disperse the ceramic powder ...

Embodiment 2

[0031] A preparation method of the nano-ceramic particle reinforced metal matrix hierarchical configuration composite material, the specific steps are as follows:

[0032] (1) First select Al with a size of 100nm 2 o 3 Ceramic powder and 5μm cast aluminum alloy (ZAlSi7Mg) powder, where Al 2 o 3 The mass ratio of ceramic powder and cast aluminum alloy (ZAlSi7Mg) powder is 1:4, a total of 1% stearic acid is added, the rotation speed is 500 rpm, the ball-to-material ratio is 10:1, and finally the powder is mixed evenly by high-energy ball milling.

[0033] (2) Then melt the cast aluminum alloy (ZAlSi7Mg) to prepare molten metal at a melting temperature of 720°C, then keep it at 650°C for 50min, and stir the molten metal.

[0034] (3) Mix the Al powder evenly in step (1) 2 o 3 Ceramic powder and cast aluminum alloy (ZAlSi7Mg) metal powder are added to the molten metal in step (2), so that the final Al 2 o 3 The mass ratio of ceramic powder to cast aluminum alloy (ZAlSi7Mg) ...

Embodiment 3

[0038] A preparation method of the nano-ceramic particle reinforced metal matrix hierarchical configuration composite material, the specific steps are as follows:

[0039] (1) First select TiO with a size of 50nm 2 Ceramic powder and 1μm cast copper alloy (ZCuZn38Mn2Pb2) powder, in which TiO 2 The mass ratio of ceramic powder and cast copper alloy (ZCuZn38Mn2Pb2) powder is 1:4, a total of 1% stearic acid is added, the ball-material ratio is 20:1, the speed is 700 rpm, and finally the powder is mixed evenly by high-energy ball milling.

[0040] (2) Then melt the cast copper alloy (ZCuZn38Mn2Pb2) to prepare molten metal, the melting temperature is 990°C, and then keep it at 890°C for 20min, and stir the molten metal.

[0041] (3) Mix the TiO powder uniformly in step (1) 2 Ceramic powder and cast copper alloy (ZCuZn38Mn2Pb2) metal powder are added to the molten metal in step (2), so that the final TiO 2 The mass ratio of ceramic powder to cast copper alloy (ZCuZn38Mn2Pb2) is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com