Spiral-flow sectional tube type liquid stirring device

A stirring device and tube-type technology, which is applied in the direction of liquid fuel supply/distribution, fluid mixer, combustion method, etc., can solve environmental pollution and other problems, achieve the effect of reducing cost, reducing raw material cost, and improving environmental protection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] According to the technical means of the present invention, the implementation modes suitable for the present invention are listed below, and are described as follows in conjunction with the drawings:

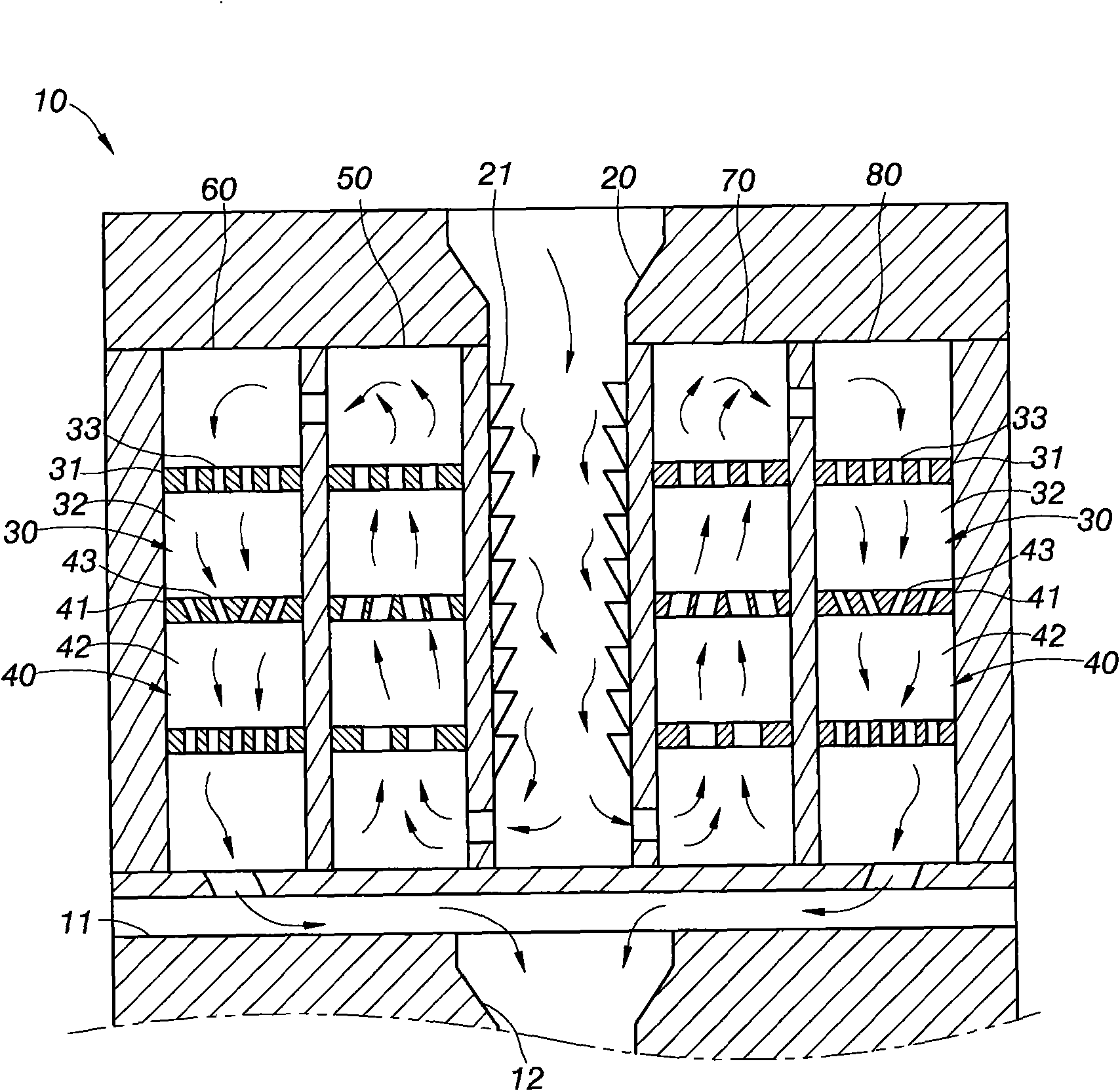

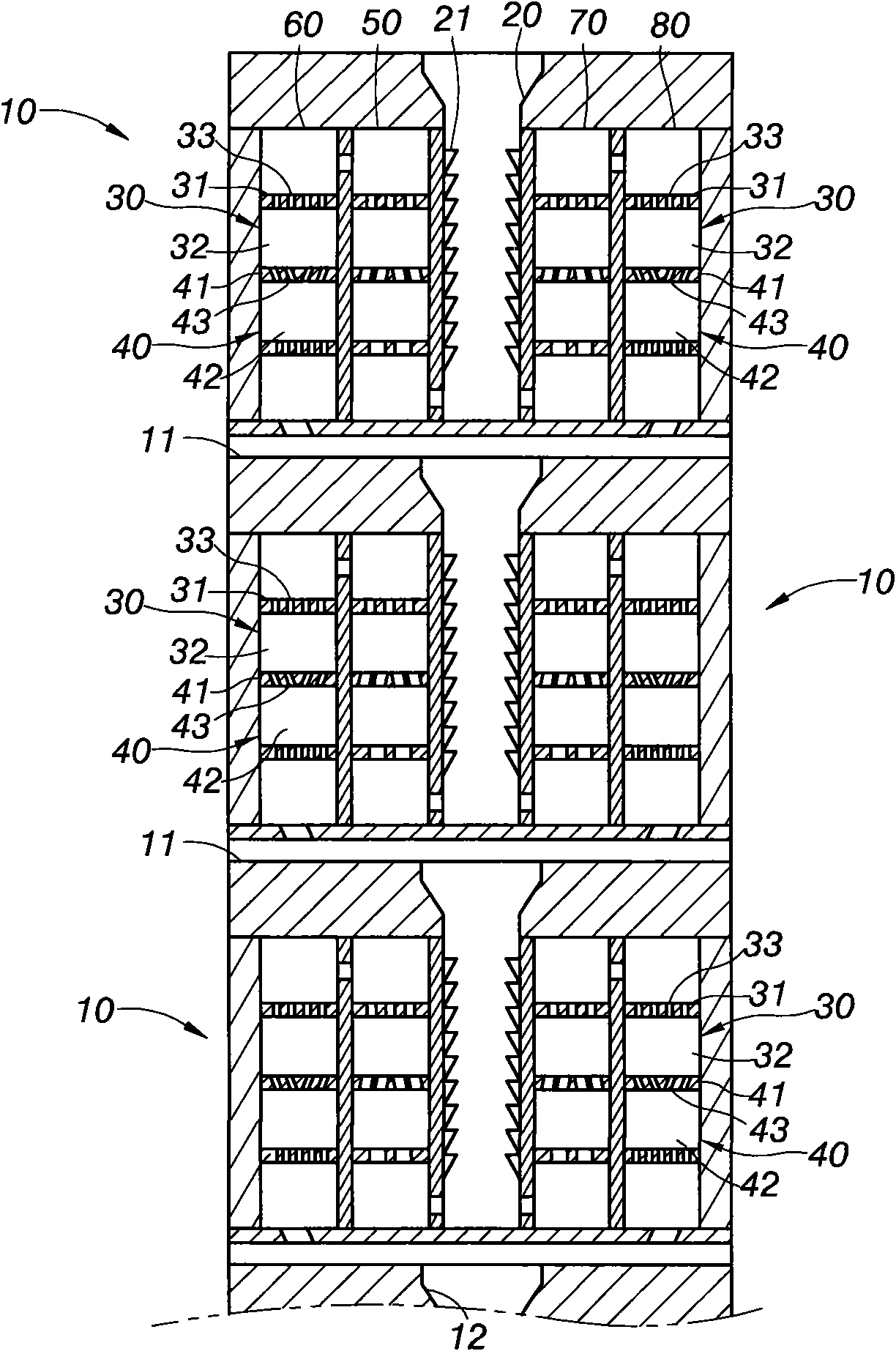

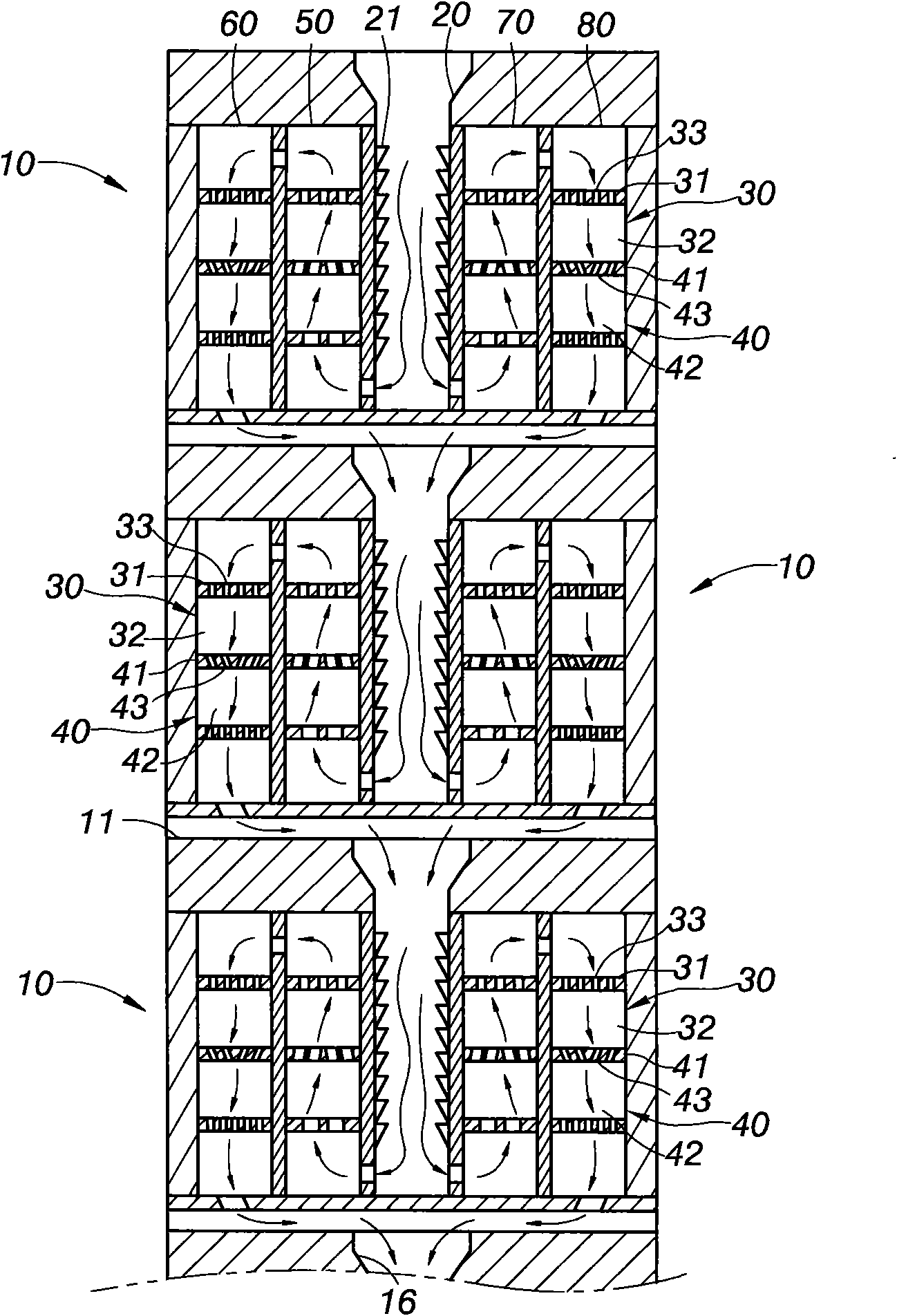

[0030] Such as figure 1 As shown, in the present invention, a swirl joint-type liquid stirring device is provided with a rectifying tube 20 in a holding tank 10, and a plurality of turbulent flow layers 30 and rectifying mixing layers 40 arranged alternately are arranged on the side of the rectifying tube, wherein :

[0031] When the above-mentioned accommodation tank 10 is implemented, the outer shape can be generally barrel-shaped, and the top of the accommodation tank 10 is provided with an aforementioned rectifying tube 20, and the rectifying tube 20 is connected to the bottom of the housing tank 10 by the top of the housing tank 10, and is stacked with the aforementioned The first layer of the turbulence layer 30 and the rectification and mixing layer 40 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com