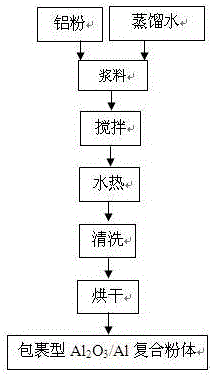

Method for preparing coated Al2O3/Al composite powder through hydrothermal method

A composite powder and packaged technology, which is applied in transportation and packaging, metal processing equipment, etc., can solve the problems of uneven distribution of reinforcement phase and performance degradation, and achieve the effects of easy control, low energy consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] First add 10 grams of aluminum powder into the beaker, add 10 ml of distilled water, stir to form a slurry, drop 0.01mol / L aluminum nitrate solution and ammonia solution into the aluminum powder slurry at the same time, let the pH of the slurry Keep the value at 7, continue to stir for 0.5 hours, pour the slurry in the beaker into the reactor, put the reactor into the oven, raise the temperature of the oven to 100°C and keep it warm for 1 hour, and wash the slurry 3 times with distilled water , then washed once with absolute ethanol, and dried to obtain the wrapped Al 2 o 3 / Al composite powder.

Embodiment 2

[0016] First add 10 grams of aluminum powder into the beaker, add 50 ml of distilled water, stir to form a slurry, drop 1mol / L aluminum nitrate solution and ammonia solution into the aluminum powder slurry at the same time, let the pH of the slurry Keep at 11, continue to stir for 3 hours, pour the slurry in the beaker into the reactor, put the reactor into the oven, raise the temperature of the oven to 300°C and keep it warm for 200 hours, wash the slurry 3 times with distilled water, Then wash with absolute ethanol once, and then dry to obtain the wrapped Al 2 o 3 / Al composite powder.

Embodiment 3

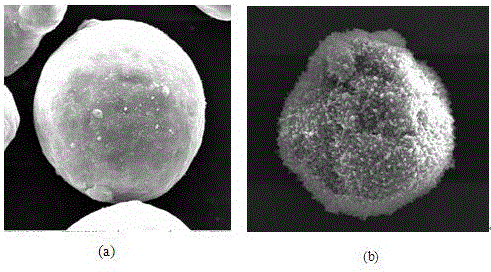

[0018] First add 10 grams of aluminum powder into the beaker, add 30 ml of distilled water, stir to form a slurry, drop 0.5 mol / L aluminum nitrate solution and ammonia solution into the aluminum powder slurry at the same time, let the pH of the slurry Keep the value at 9, continue to stir for 1 hour, pour the slurry in the beaker into the reaction kettle, put the reaction kettle into the oven, raise the temperature of the oven to 200°C and keep it warm for 100 hours, and wash the slurry with distilled water for 3 times , then washed once with absolute ethanol, and dried to obtain the wrapped Al 2 o 3 / Al composite powder, such as figure 2 shown. In the figure (a) is aluminum powder (b) is wrapped Al 2 o 3 / Al composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com