Method for preparing stannic oxide nanocrystalline thin film with honeycomb structure by using hydrothermal method

A technology of nano-crystals and tin oxide, which is applied in the direction of coating, etc., can solve the problems of low purity of tin oxide thin film materials, difficult shape, high cost, etc., and achieve the effects of easy control, simple operation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

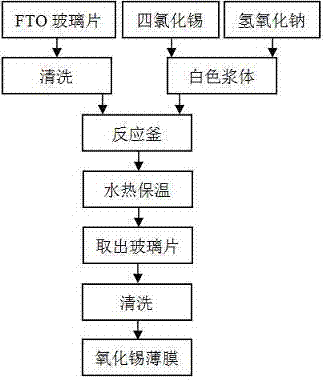

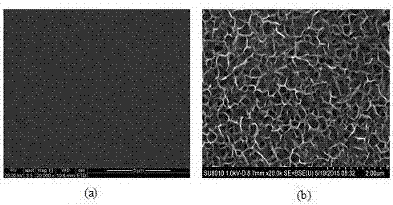

[0014] First, clean the surface of the FTO conductive glass sheet with deionized water and put it into the reaction kettle. Add the prepared tin tetrachloride solution with a concentration of 0.01mol / L into the beaker, add distilled water, and stir until the concentration is 0.04mol / L. Drop the sodium hydroxide solution in the beaker containing the tin tetrachloride solution to form a white slurry, keep the pH value of the slurry at 9, continue stirring for 1 hour, pour the slurry in the beaker into the FTO conductive glass Put the reaction kettle into the oven, raise the temperature of the oven to 200°C and keep it warm for 5 days, take out the FTO conductive glass piece and wash it with distilled water for 3 times, then wash it with absolute ethanol once, and dry it. A tin oxide nanocrystal thin film material with a honeycomb structure is prepared. as attached figure 2 The front and back comparison diagrams (scanning electron micrographs) of the shown FTO glass sheet surfa...

Embodiment 2

[0016] First, clean the surface of the FTO conductive glass sheet with deionized water and put it into the reaction kettle. Add the prepared tin tetrachloride solution with a concentration of 1mol / L into the beaker, add distilled water, stir, and oxidize the solution with a concentration of 4mol / L. The sodium solution is dripped into the beaker containing the tin tetrachloride solution to form a white slurry, and the pH value of the slurry is maintained at 9, and the stirring is continued for 0.5 hours, and the slurry in the beaker is poured into the reaction reaction of the FTO conductive glass sheet. put the reaction kettle into an oven, raise the temperature of the oven to 200°C and keep it warm for 7 days, take out the FTO conductive glass sheet and wash it with distilled water for 3 times, then wash it with absolute ethanol once, and dry it to obtain a Tin oxide nanocrystal thin film material with honeycomb structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com