Split type diamond grinding wheel and manufacturing technology thereof

A technology of diamond grinding wheel and manufacturing process, which is applied in the direction of manufacturing tools, bonded grinding wheels, metal processing equipment, etc., which can solve problems such as difficult manufacturing and complex structure, and achieve the effect of reducing processing difficulty and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described below in conjunction with an embodiment and accompanying drawings:

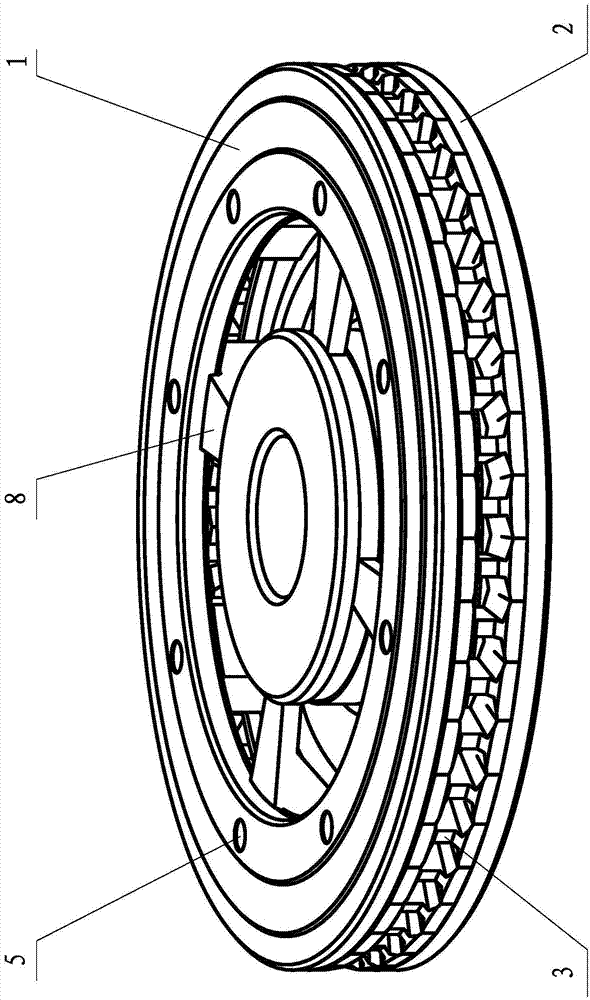

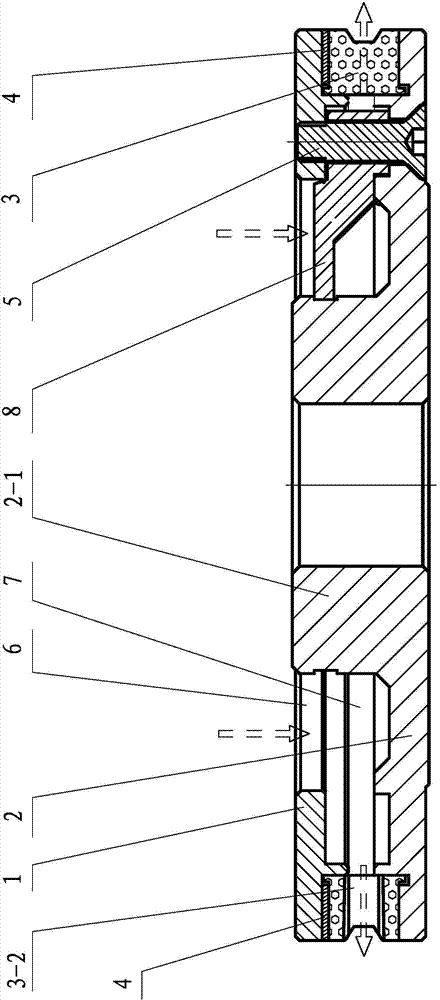

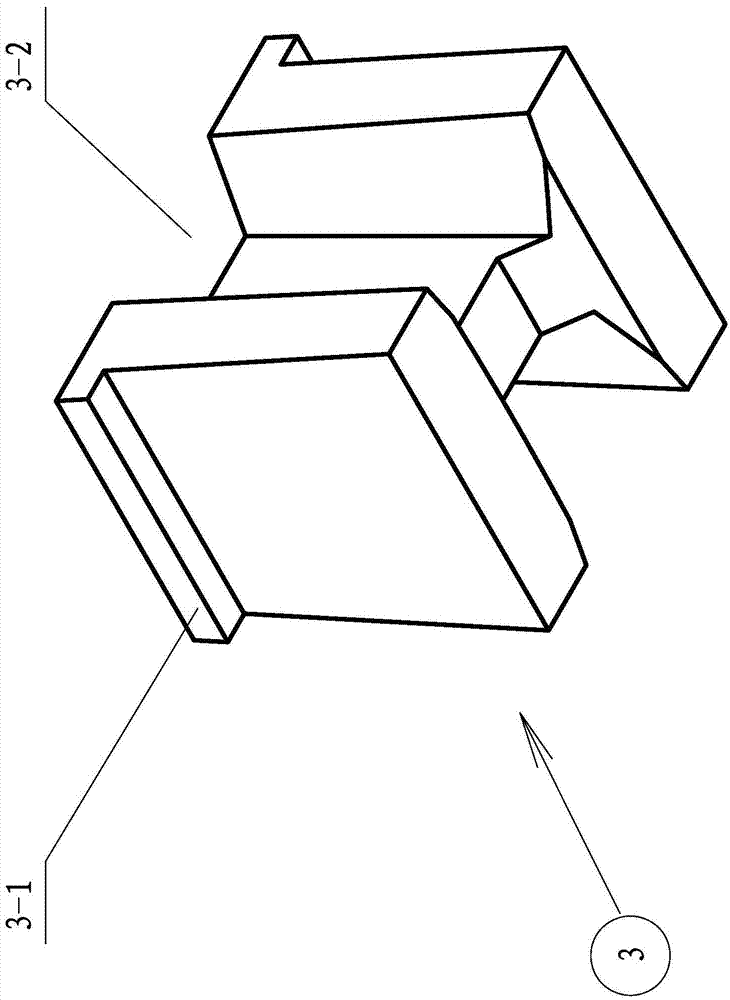

[0038] In this embodiment, the split type diamond grinding wheel of the present invention clamps and solidifies the grinding ring with a uniform wear structure through the base body to form a special-shaped grinding wheel, and the special-shaped grinding surface of the grinding ring is provided with chip grooves and outlets that do not participate in grinding. The nozzle 3-2 is used as the non-solid processing area, and the rest of the special-shaped grinding surface is the solid processing area participating in the grinding. The total length of the circumference of the solid processing area at different axial positions corresponds to that of the workpiece at the same position. The machining allowance, the corresponding relationship is a proportional relationship or an approximately proportional relationship; the base body is asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com