Continuous multi-station curved surface polishing machine

A polishing machine, multi-station technology, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problem of low polishing efficiency, improve the grinding and polishing efficiency, and facilitate automated mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

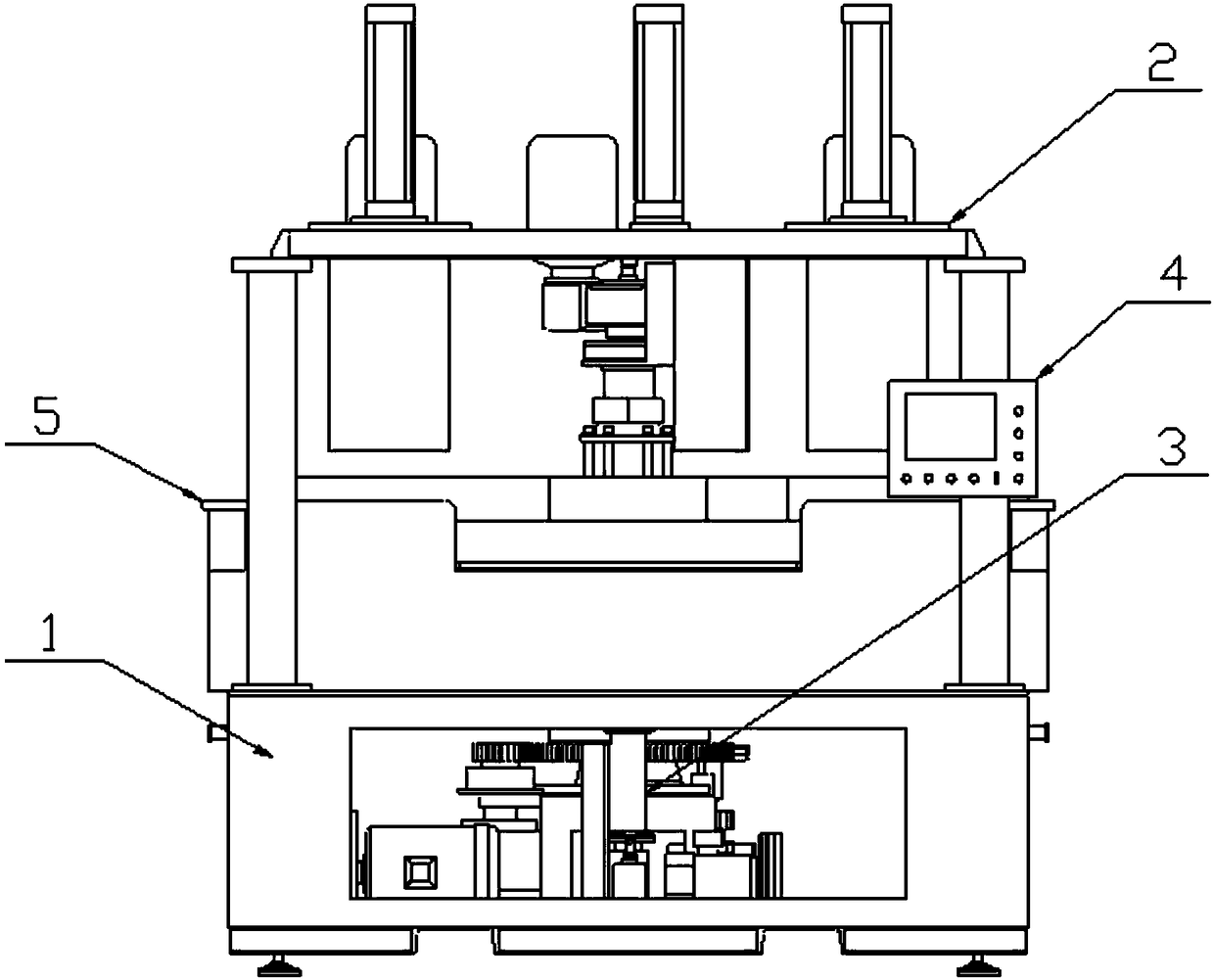

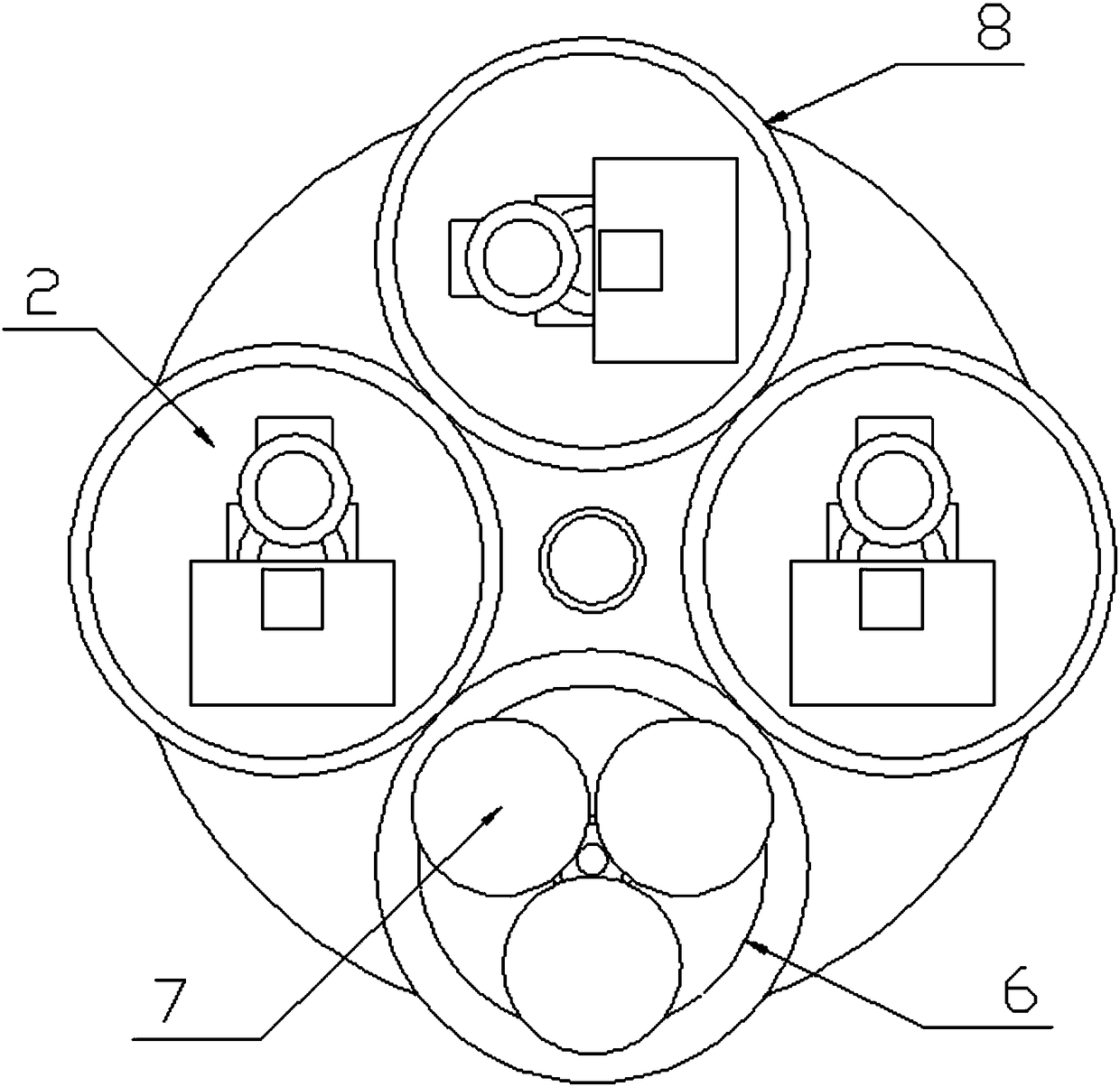

[0029] With reference to the accompanying drawings, a continuous multi-station curved surface polishing machine includes a frame 1, and three groups of upper plate units 2 uniformly distributed on the frame 1 (three groups of upper plate units form the upper plate device), which are located on the frame 1. The transmission main body 3 at the lower end of the interior, the electric control operation box 4 suspended around the frame 1, and the vacuum adsorption device 5.

[0030] The frame 1 is a frame structure, surrounded by four round columns, and the electric control operation box 4 and the vacuum storage tank 5 are respectively fixed on the round columns of the frame 1 .

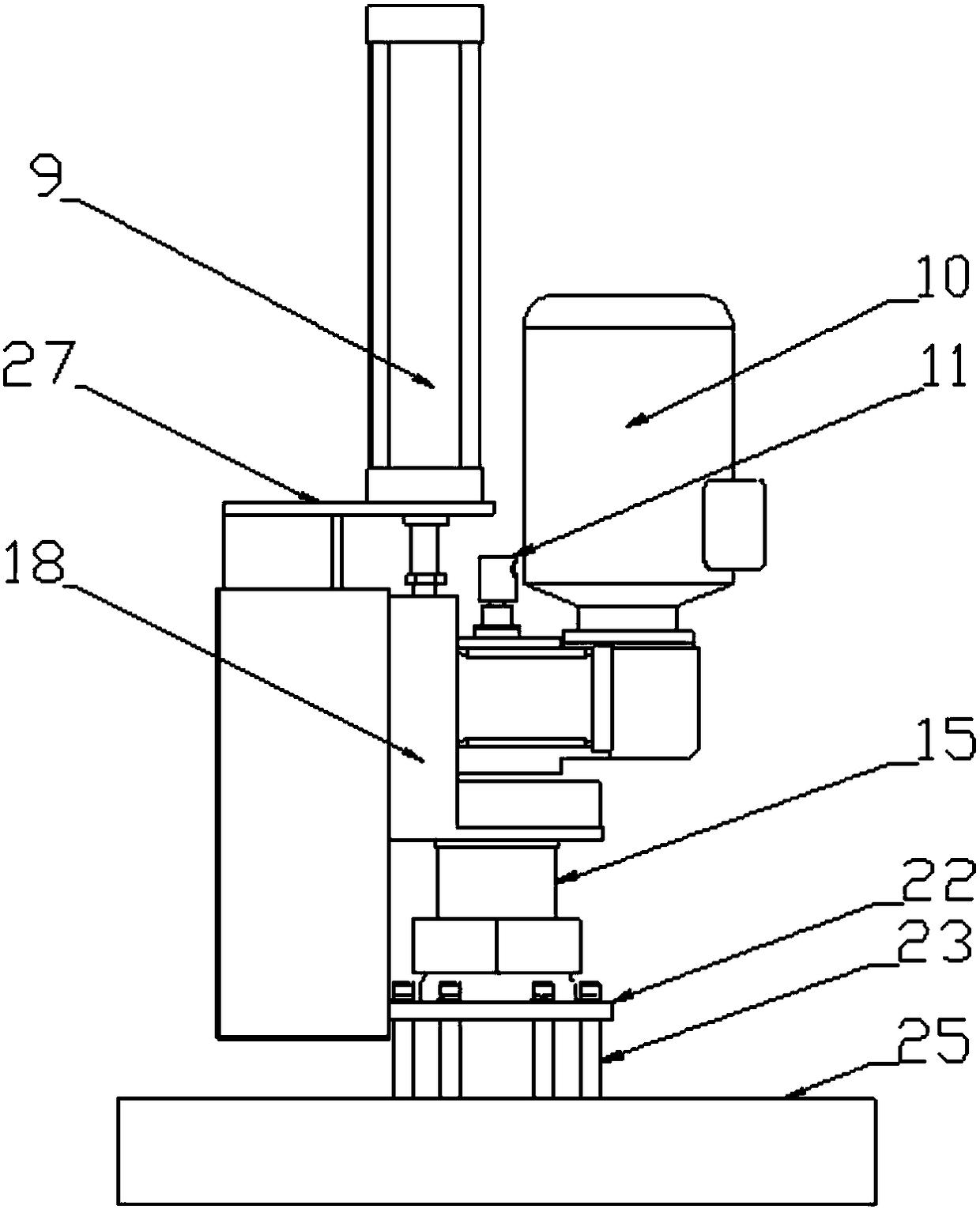

[0031] The upper disk unit 2 is fixed on the top frame of the frame 1, including the upper disk rotation device and the upper disk lifting device; the upper disk rotation device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com