Porous hydroxy calcium phosphate nanometer particle-modified titanium-based titanate nanowire biologic support material and preparation method thereof

A technology of calcium hydroxyphosphate and titanium-based titanate, which is applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problems of incomplete surface pores, low mechanical properties, difficult forming and processing, etc. The effect of easy operation, low equipment investment and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The present embodiment carries out according to the following steps:

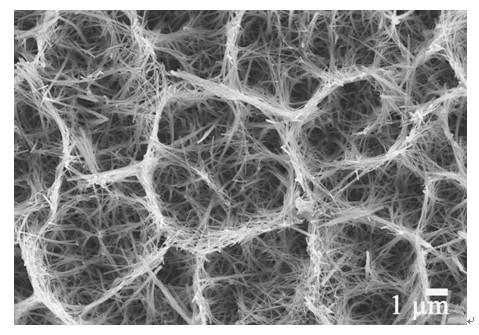

[0034] (1) Preparation of titanium-based titanate nanowires with grid-like microporous structure by dissolved salt method. The specific preparation method is as follows: the titanium metal substrate is ultrasonically cleaned in acetone and absolute ethanol solutions at room temperature for 20 minutes, and then rinsed with distilled water for 4 times. Ba(OH) 2 ﹒ 8H 2 The mixed solution of O was sealed in a polytetrafluoroethylene reactor, and after reacting at 280 °C for 16 h, a titanium-based titanate nanowire with a grid-like microporous structure was obtained, and the titanium-based titanate nanowire was used Rinse with deionized water until neutral, and air dry.

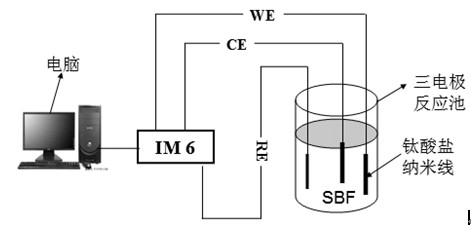

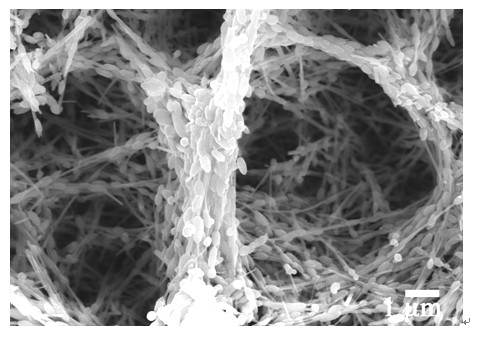

[0035] (2) Porous calcium hydroxyphosphate nanoparticles modified titanium-based titanate nanowire bioscaffolds were prepared by electrochemical deposition. The specific preparation process is as follows: In the three-...

Embodiment 2

[0051] Embodiment 2: The present embodiment carries out according to the following steps:

[0052] (1) Titanium-based titanate nanowires with grid-like microporous structure prepared by dissolved salt method. The specific preparation method is as follows: the titanium metal substrate is ultrasonically cleaned in acetone and absolute ethanol solutions at room temperature for 20 min, and then rinsed with distilled water for 4 times. Ba(OH) 2 ﹒ 8H 2 The mixed solution of O was sealed in a polytetrafluoroethylene reactor, and after reacting at 200 °C for 8 h, a titanium-based titanate nanowire with a grid-like microporous structure was obtained, and the titanium-based titanate nanowire was used Rinse with deionized water until neutral, and air dry.

[0053] (2) Porous calcium hydroxyphosphate nanoparticles modified titanium-based titanate nanowire bioscaffolds were prepared by electrochemical deposition. The preparation process is as follows: in the three-electrode reaction c...

Embodiment 3

[0057] Embodiment 3: the present embodiment carries out according to the following steps:

[0058] (1) Titanium-based titanate nanowires with grid-like microporous structure prepared by dissolved salt method. The specific preparation method is as follows: the titanium metal substrate is ultrasonically cleaned in acetone and absolute ethanol solutions at room temperature for 20 min, and then rinsed with distilled water for 4 times. Ba(OH) 2 ﹒ 8H 2 The mixed solution of O was sealed in a polytetrafluoroethylene reactor, and after reacting at 100 °C for 1 h, a titanium-based titanate nanowire with a grid-like microporous structure was obtained, and the titanium-based titanate nanowire was used Rinse with deionized water until neutral, and air dry.

[0059] (2) Porous calcium hydroxyphosphate nanoparticles modified titanium-based titanate nanowire bioscaffolds were prepared by electrochemical deposition. The preparation process is as follows: in the three-electrode reaction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com