Moving iron receiver with novel magnetic conduction structure

A receiver and magnetic guide technology, applied in the directions of loudspeakers, sensors, electrical components, etc., can solve the problems of complicated assembly process of magnetic circuit system and difficult processing of magnetic yokes, and is conducive to automated large-scale production, simplified product design, The effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

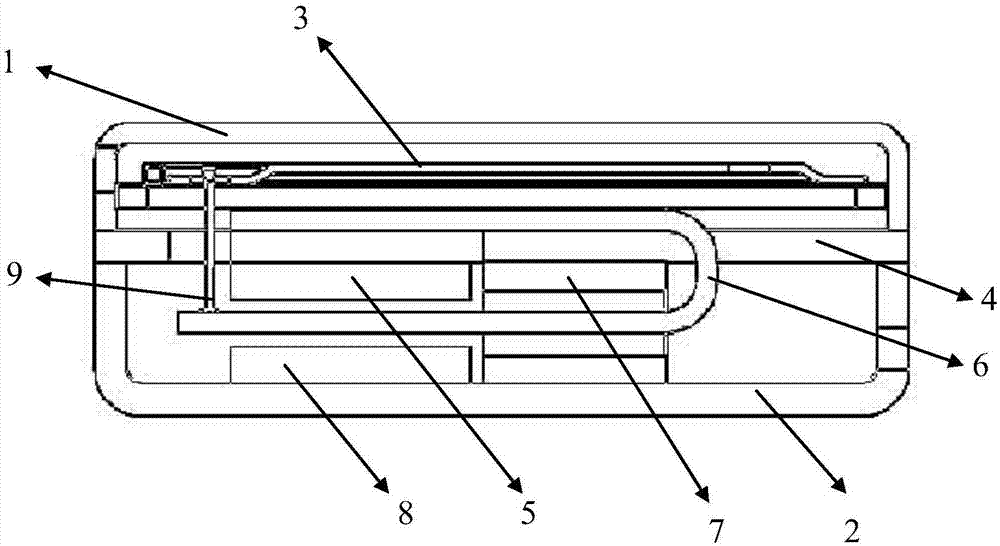

[0023] like figure 1 and figure 2 As shown, a moving iron receiver with a new magnetic permeation structure, including the shell formed by the upper shell 1 and the lower shell 2, the diaphragm 3 is fixed in the upper shell 1 and the inner space of the shell is divided into a front cavity and a rear cavity Cavity, the space between the diaphragm 3 and the upper shell 1 is the front cavity, the space between the diaphragm 3 and the lower shell 2 is the rear cavity, the reed, the magnetic plate, the upper magnet, the coil, the driving rod, the lower magnet.

[0024] Specifically, the magnetic guide plate 4 is in the shape of a sheet and is arranged in the rear cavity, the edges of the magnetic guide plate are fixed to the upper and lower housings, and the upper surface of the upper magnet 5 and the lower surface of the magnetic guide plate 4 are fixed together by welding or bonding. . The U-shaped reed 6 includes a fixed portion and a vibrating portion, the fixed portion of ...

Embodiment 2

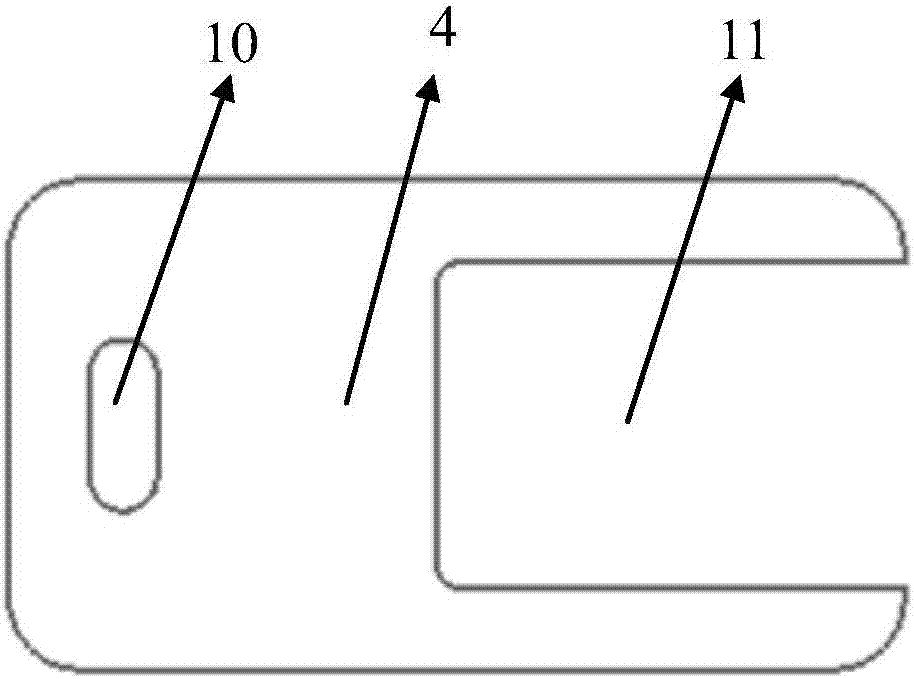

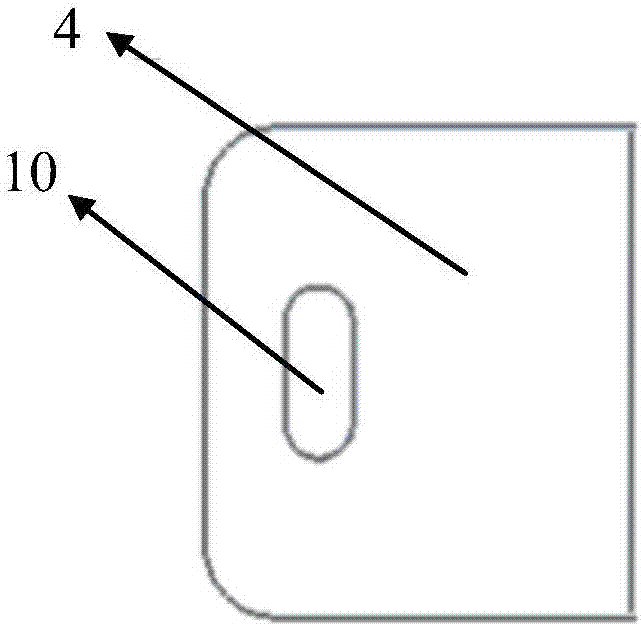

[0029] The structure is similar to that of Embodiment 1, the difference is that the magnetic guide plate 4 is a half-piece, the lower housing 2 has a step surface 12 matched with the magnetic guide plate, and the upper housing, the magnetic guide plate and the lower housing form a closed shell, such as image 3 , 4 As shown, the structure is more simplified, and the use of magnetic plate materials is saved.

Embodiment 3

[0031] The structure is similar to Embodiment 1, the difference is that the magnetic guide plate 4 is a small piece, that is, it is only arranged on the fixed part of the U-shaped reed 6 and corresponds to the upper magnet and the lower magnet, and the middle part of the lower housing has a magnetic guide plate. The groove 13, the upper shell, the magnetic guide plate, and the lower shell form a closed shell, such as Figure 5 , 6 As shown, the structure is more simplified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com