Floor structure and combined structure residential system with same

A floor and floor slab technology, which is applied to floors, building components, building structures, etc., can solve the problems of low production efficiency of four-sided ribs and complex construction of integral joints, so as to facilitate factory automated mass production and high construction efficiency , the effect of reducing the amount of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] The floor structure provided in this embodiment includes: a floor slab and a pick-up plate; in a horizontal projection plane, the floor slab is arranged indoors, and the pick-up plate is arranged outdoors.

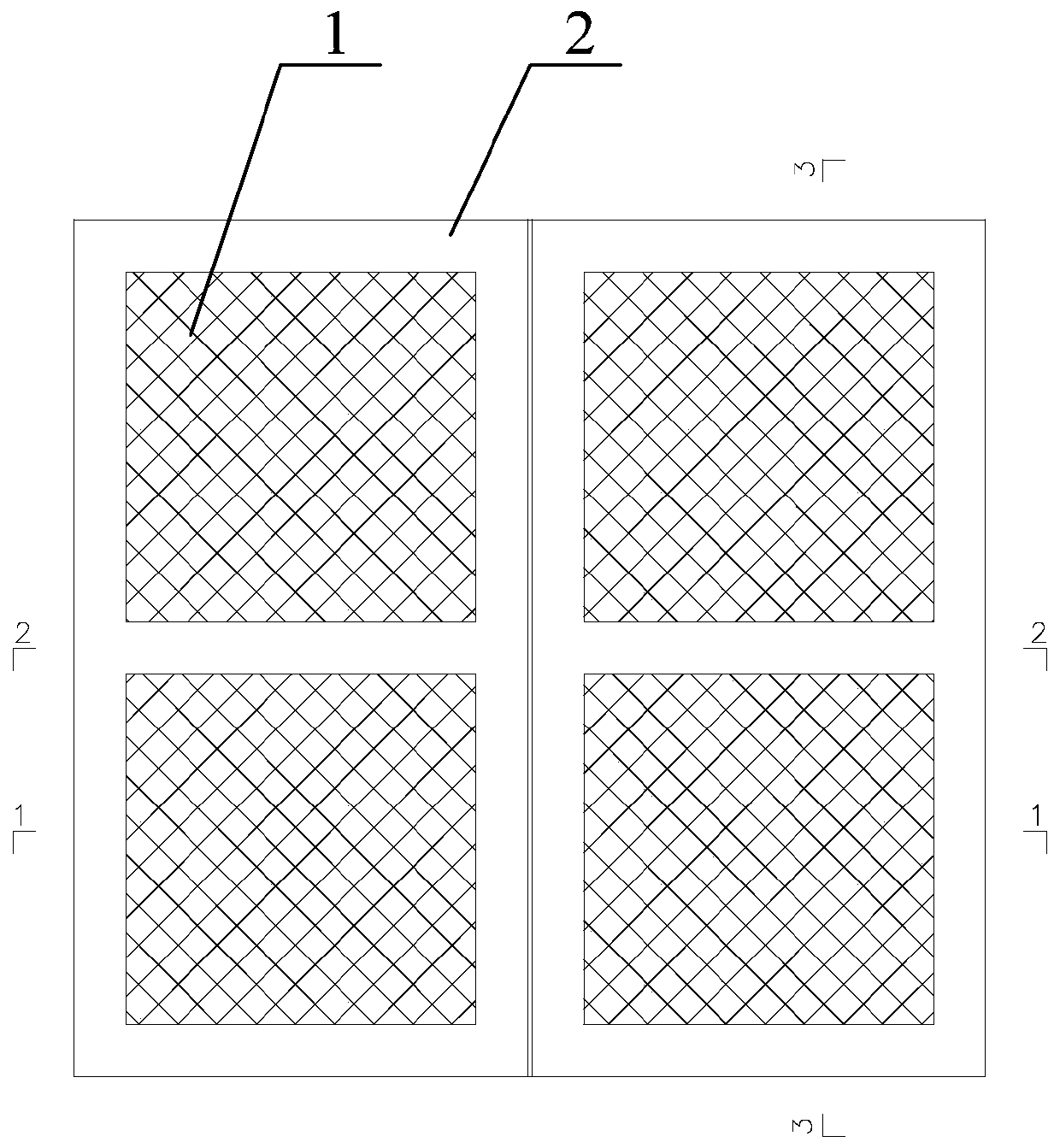

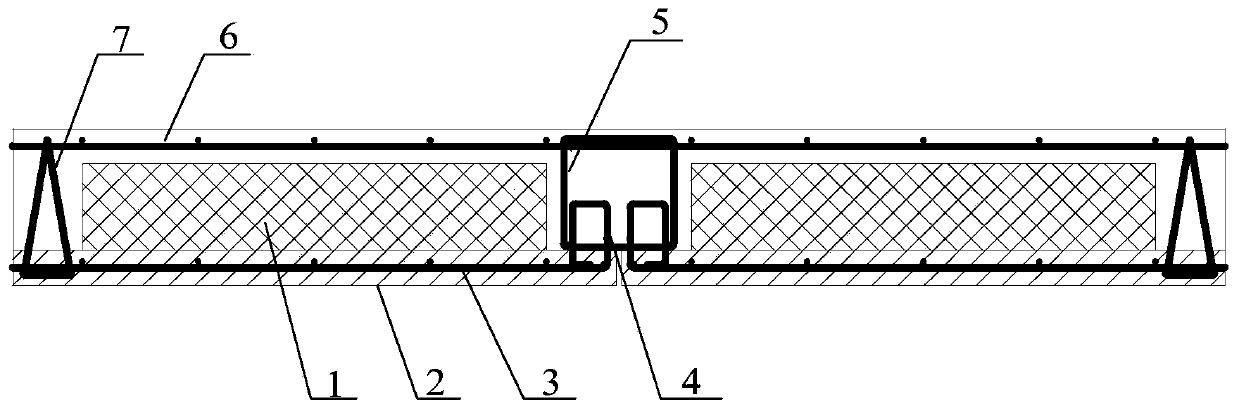

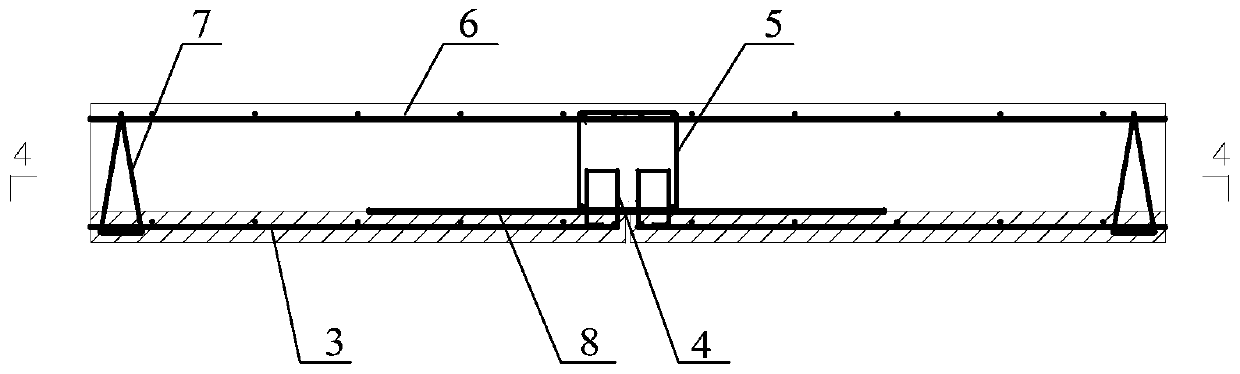

[0098] Such as Figure 1-Figure 7 As shown, it includes a reinforcement skeleton and two floor slabs arranged at intervals; one end of the floor slab located at the splicing surface is provided with an installation gap; the bottom of the installation gap is vertically fixed with floor ring bars 4 at intervals along the length direction of the floor splicing surface; The skeleton includes connecting horizontal ribs 9 arranged along the length direction of the splicing surface and a plurality of connecting ring ribs 5 fixed to the connecting horizontal ribs 9; the connecting ring ribs 5 are parallel to the floor ring ribs 4; A plurality of floor slab ring bars 4 are arranged in a staggered manner; the connecting ring bars 5 and the floor slab ring bars 4 are poured wi...

Embodiment 2

[0151] This embodiment discloses a combined structure housing system. This embodiment is basically the same as Embodiment 2, except that:

[0152] Such as Figure 25 As shown, the combined structure residential system includes a restraint support 60; the two ends of the restraint support 60 are fixedly connected to the middle part of the column and the middle part of the steel beam respectively.

[0153] Such as Figure 26 As shown, the constraining support 60 includes an outer constraining sleeve 61 and an inner core 62 , a constraining ring 63 and a constraining rod 64 all disposed in the outer constraining sleeve.

[0154] The restraint rod 64 and the inner core 62 are all arranged along the length direction of the outer restraint sleeve, and the restraint ring 63 is fixed to the outer restraint sleeve, and is sleeved outside the inner core 62 and the restraint rod 64 to fix the inner core 62 and the restraint rod 64 .

[0155] As shown in 26, the inner core 62 is in the...

Embodiment 3

[0161] This embodiment discloses a combined structure housing system, which is basically the same as Embodiment 2, the difference lies in:

[0162] Such as Figure 29-Figure 32 As shown, a column 30 provided in this embodiment includes a round steel pipe 31 and 2-4 T-shaped steels 32; the round steel pipe 31 is poured with concrete 33, and a plurality of T-shaped steels 32 are spaced along the circumferential direction of the round steel pipe 31. Set, and the opposite end of the T-shaped steel 32 web and the flange is fixedly connected to the outer wall of the round steel pipe 31; the web 32b of the T-shaped steel 32 is located on the extension line of the diameter of the round steel pipe 31, and the flange 32a is provided with bolt holes.

[0163] Among them, several T-shaped steel 32 are arranged in various ways, such as Figure 29 As shown, there are two T-shaped steels 32, and the webs of the two T-shaped steels 32 are located on the same diameter of the round steel pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com