Patents

Literature

85results about How to "No risk of shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

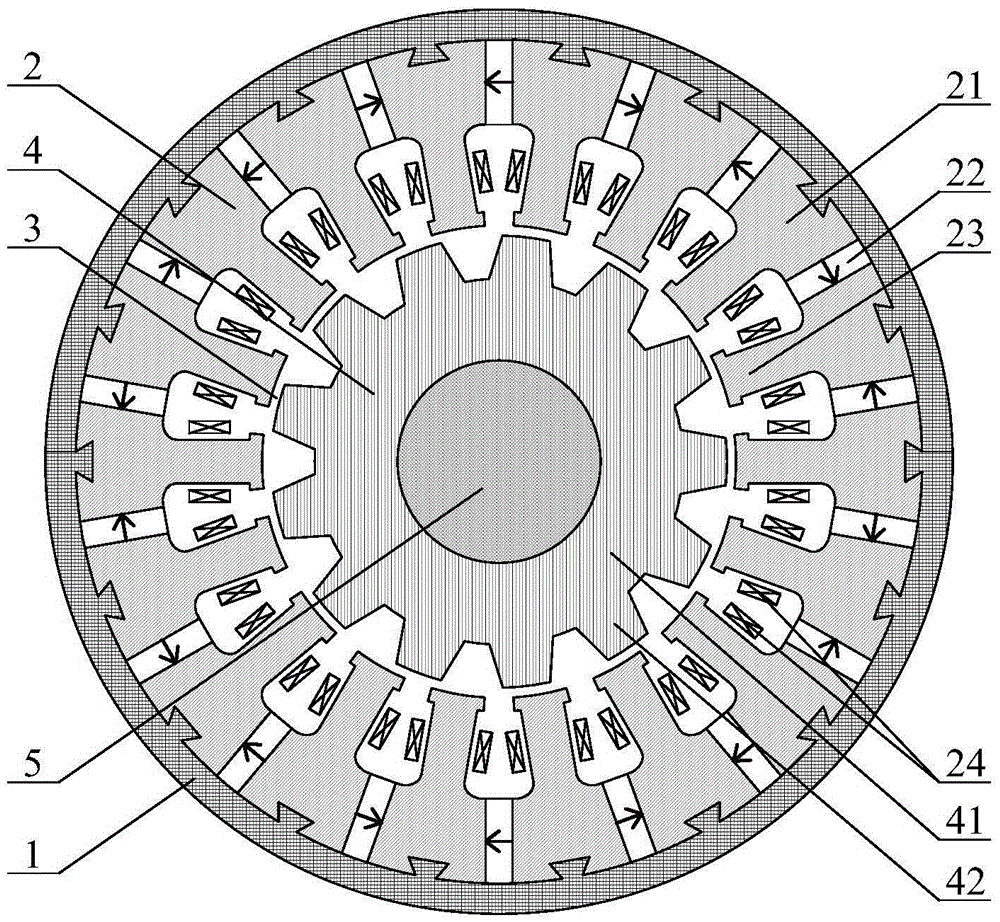

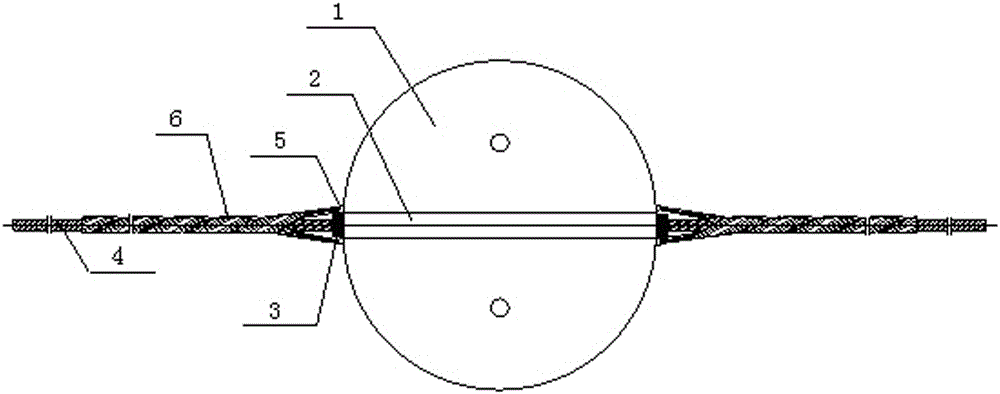

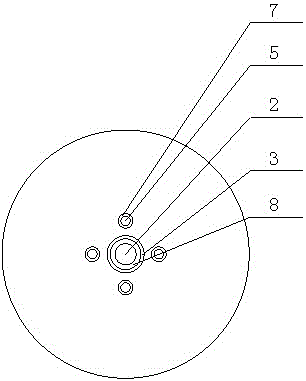

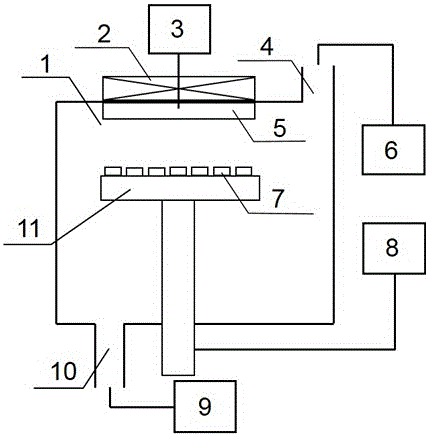

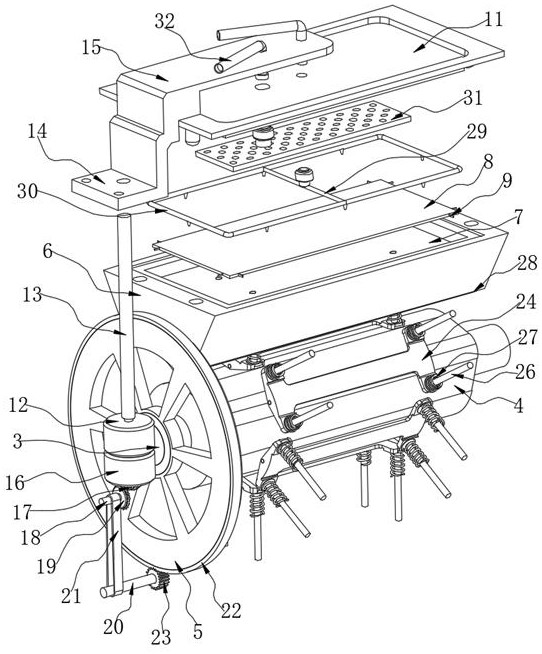

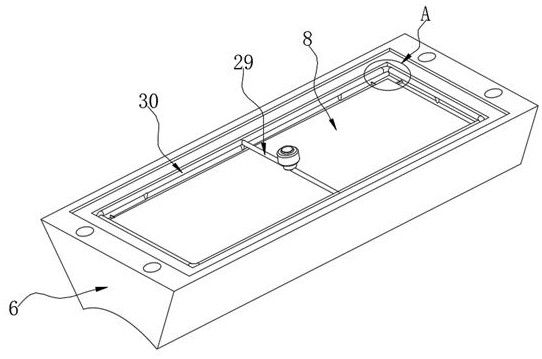

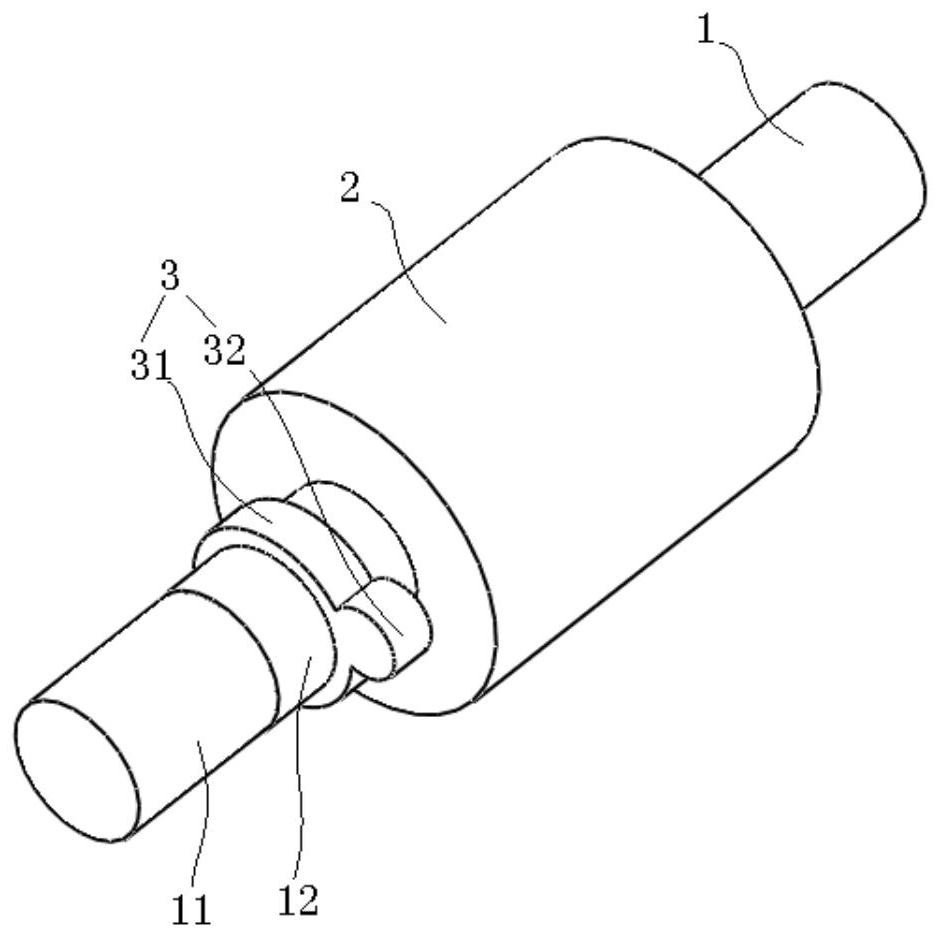

Stator permanent magnet type field modulation motor

InactiveCN105071562ASolid structureEasy to dissipate heatMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsStator

The invention discloses a stator permanent magnet type field modulation motor. The motor comprises a housing, a stator, an air gap, a rotor and a rotating shaft from outside to inside. The housing, the stator, the air gap, the rotor and the rotating shaft are coaxially arranged. The stator is fixed in the housing through a dovetail groove. The air gap is arranged between the stator and the rotor. The rotor is fixed outside the rotating shaft. The stator comprises a plurality of stator iron cores which are arranged at equal intervals along the circumference, stator permanent magnets embedded between adjacent stator iron cores, stator teeth extending out of the inner circumferences of the stator iron cores, and multiphase symmetric armature windings embedded between adjacent stator teeth. The rotor comprises an annular rotor iron core, and a plurality of rotor salient poles extending out of the outer peripheries of the rotor iron cores. According to the invention, the armature windings and the permanent magnets are arranged on the stator side; the air-gap magnetic permeance change caused by the rotor salient pole is utilized to modulate the stator magnetic field, so as to achieve electromechanical energy conversion; and the stator permanent magnet type field modulation motor is characterized in that the rotor structure is simple, the mechanical reliability is high, the heat radiation of the permanent magnets is easy, and the processing and manufacturing is convenient.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

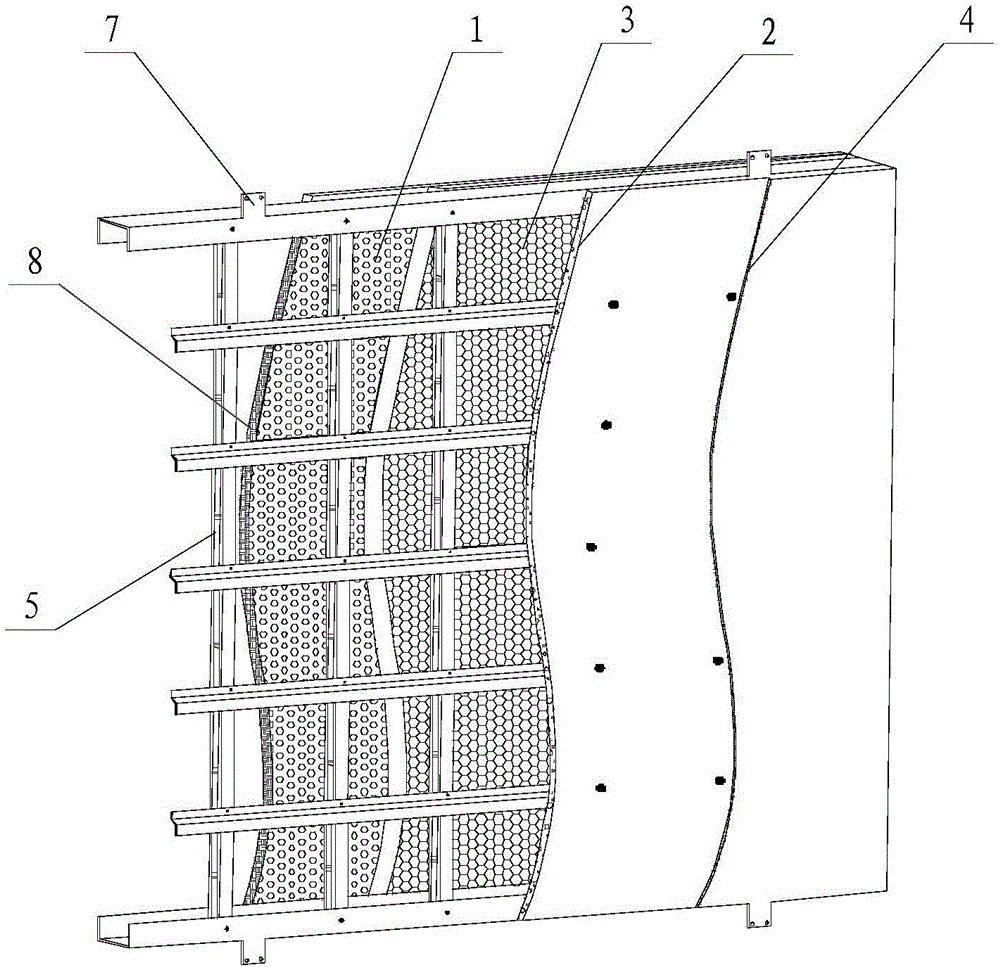

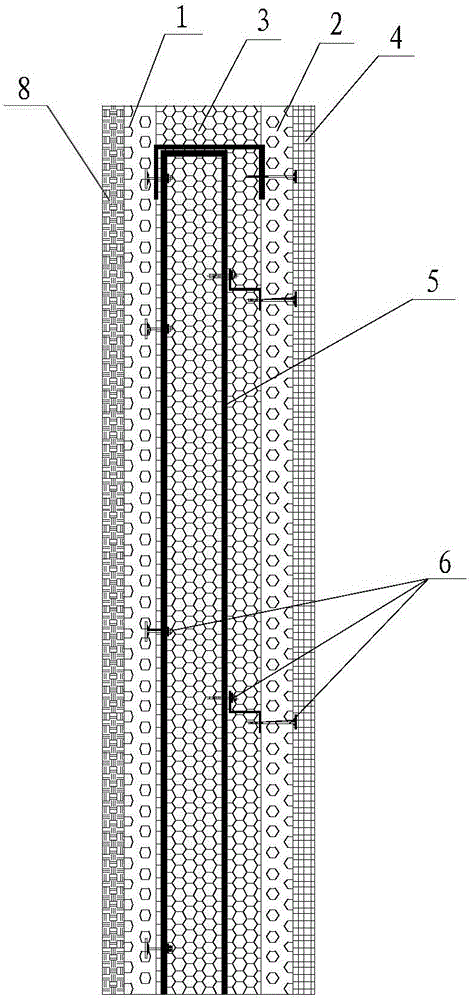

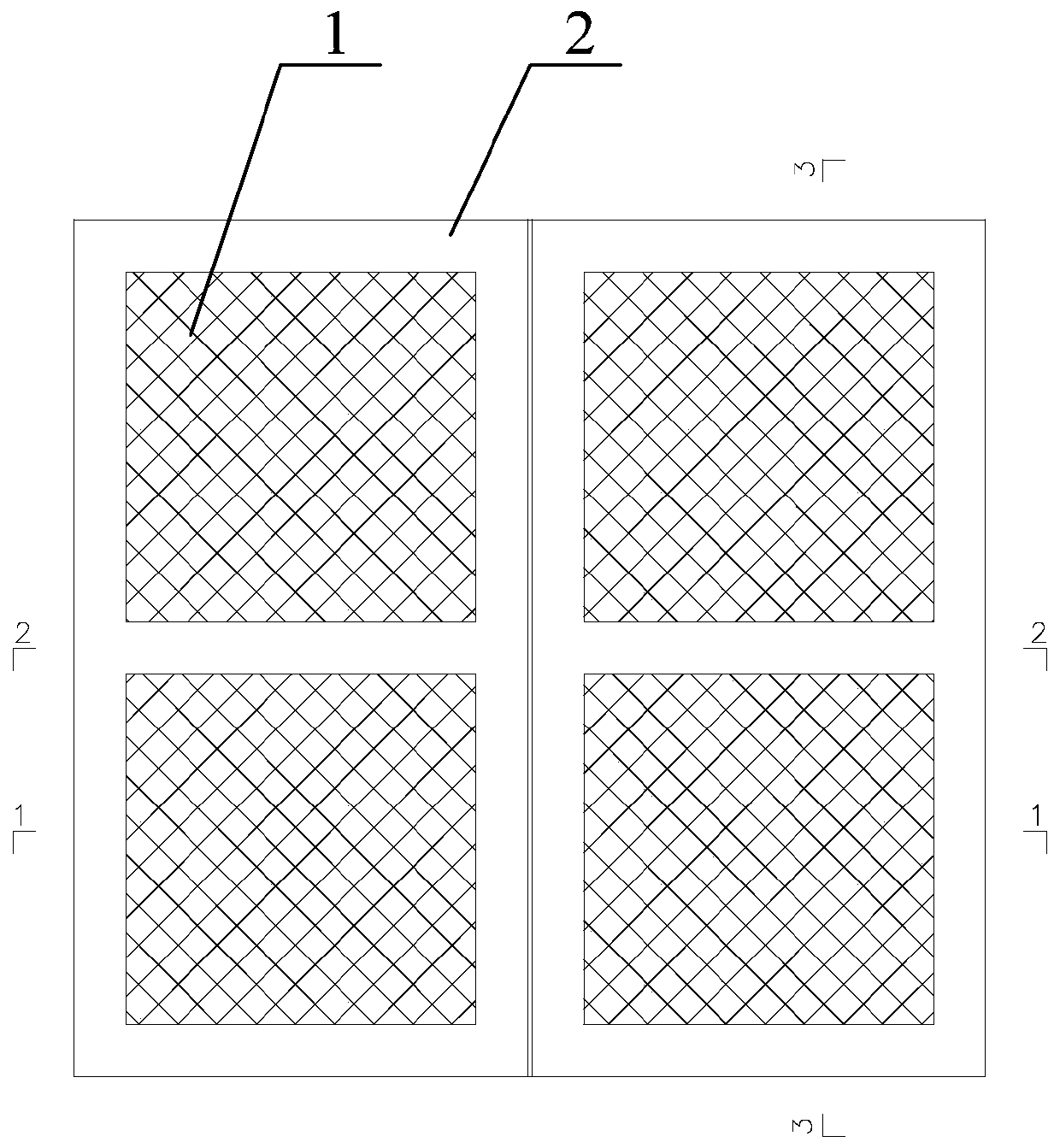

Foamed ceramic compound wallboard

InactiveCN106284828AImprove insulation effectImprove sound insulationBuilding componentsCalcium silicateFiber

The invention relates to a foamed ceramic compound wallboard which comprises an outer panel and an inner main board. The outer panel is a foamed ceramic plate, and the outer side of the outer panel is provided with an outer veneer. The inner main board is a foamed ceramic board or an autoclaved aerated concrete board or a calcium silicate board or a cement fiber board or a gypsum plasterboard, and the inner side of the inner main board is provided with an inner veneer. The outer panel and the inner main board are connected and fixed through a support assembly, and through the support assembly, a cavity is formed between the outer panel and the inner main board. The interior of the cavity is coated with rigid foam polyurethane. According to the technical scheme, the integrated wallboard meets the requirements of a building external wall for the required strength and impact resistance, has the characteristics of water prevention, seepage prevention, heat preservation, good weather resistance and low comprehensive cost, and is combined with a decorative layer.

Owner:谢自强

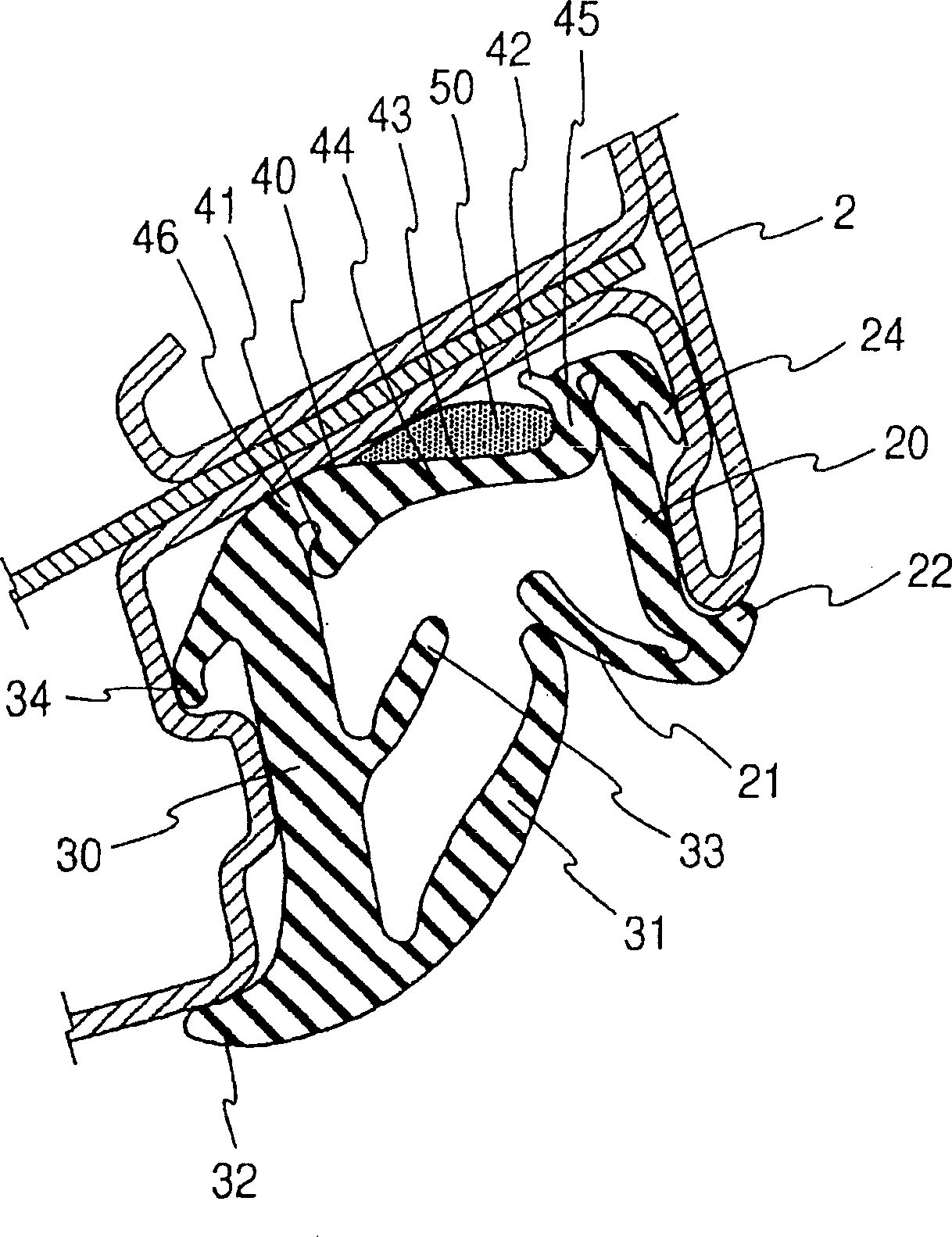

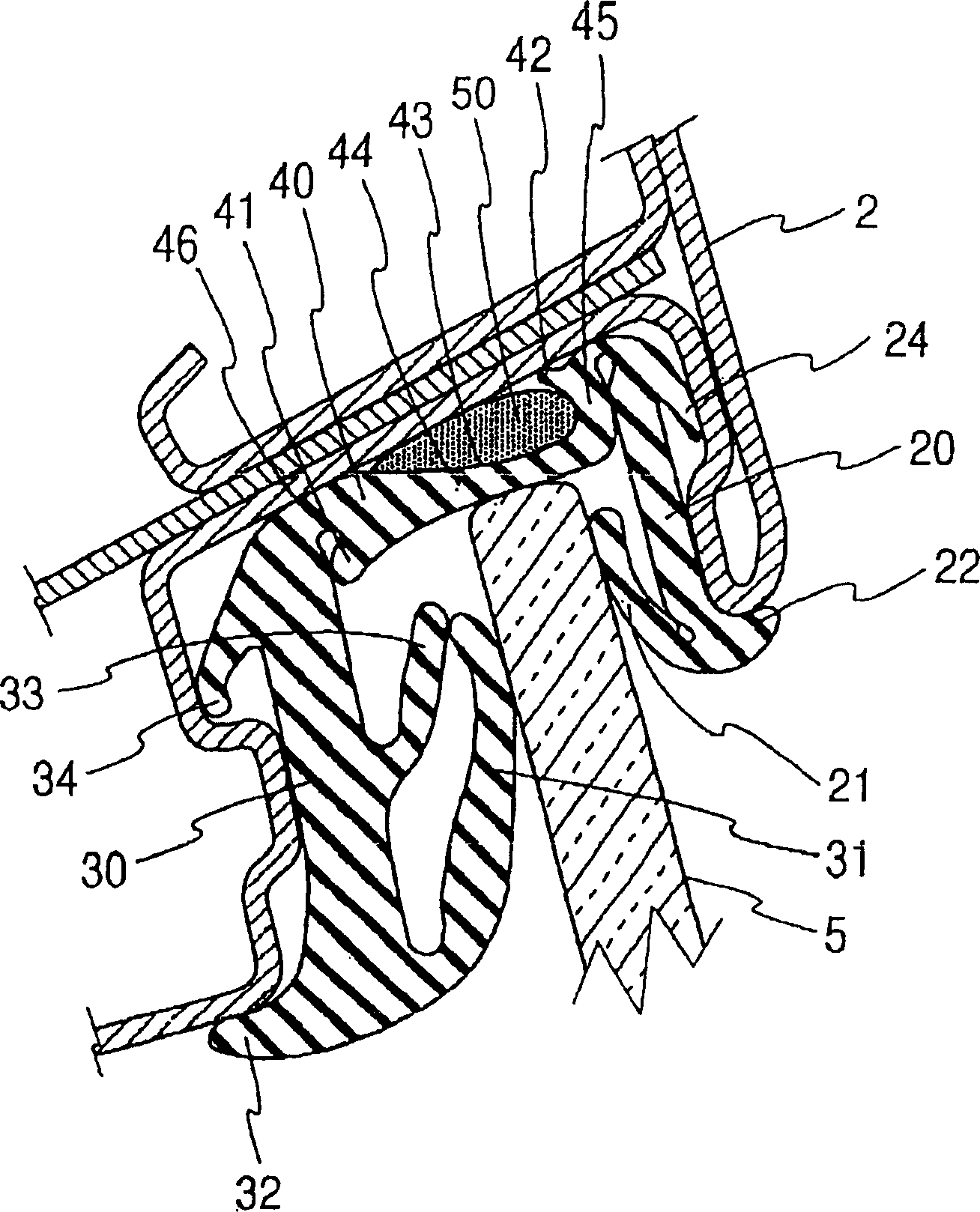

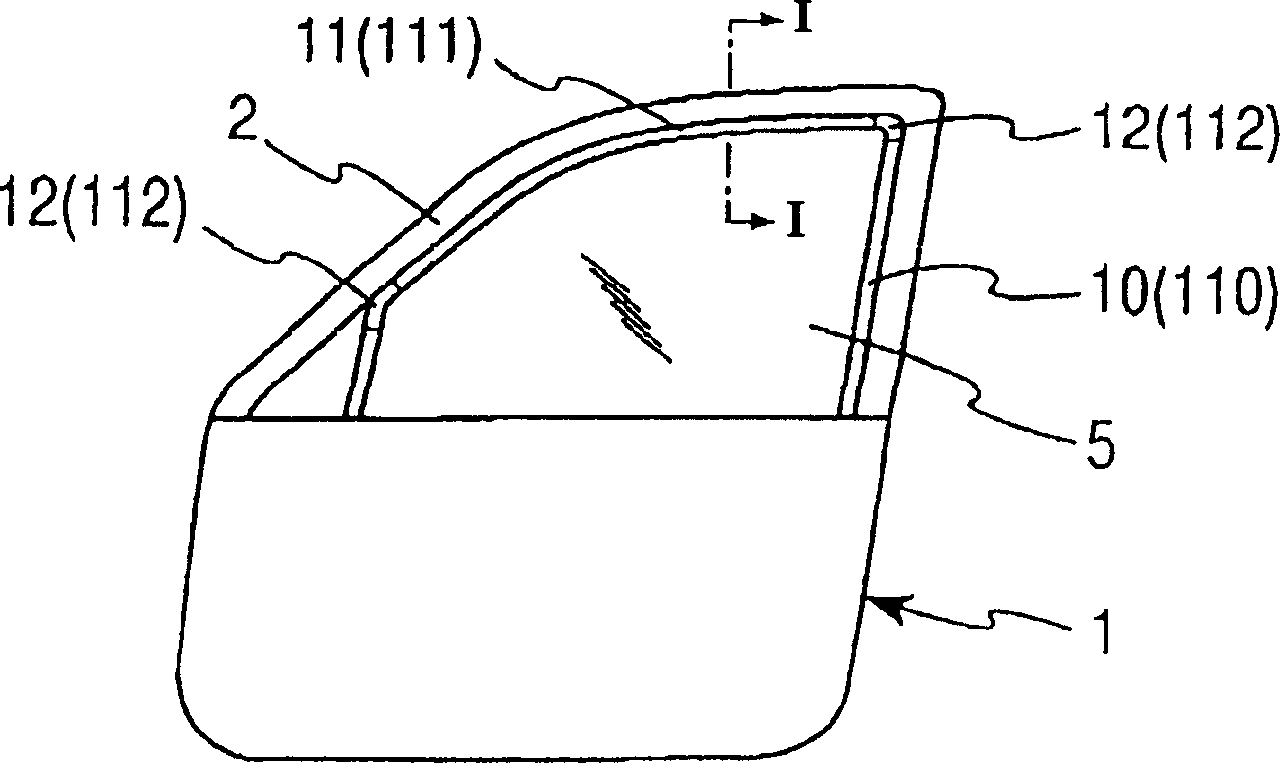

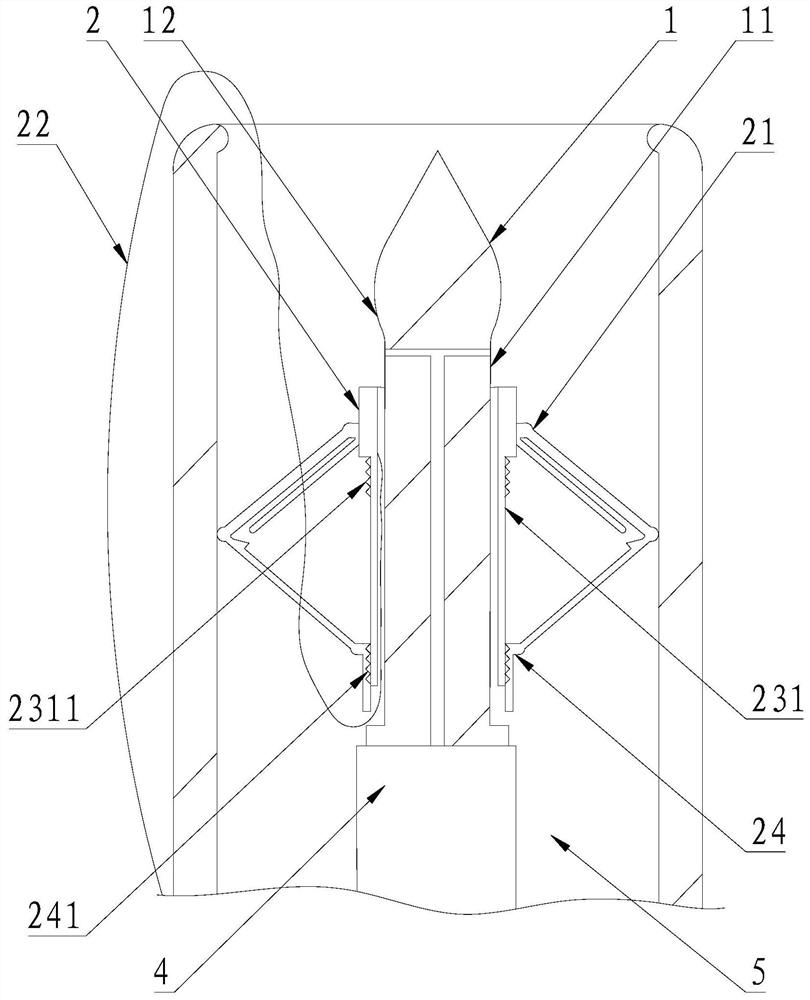

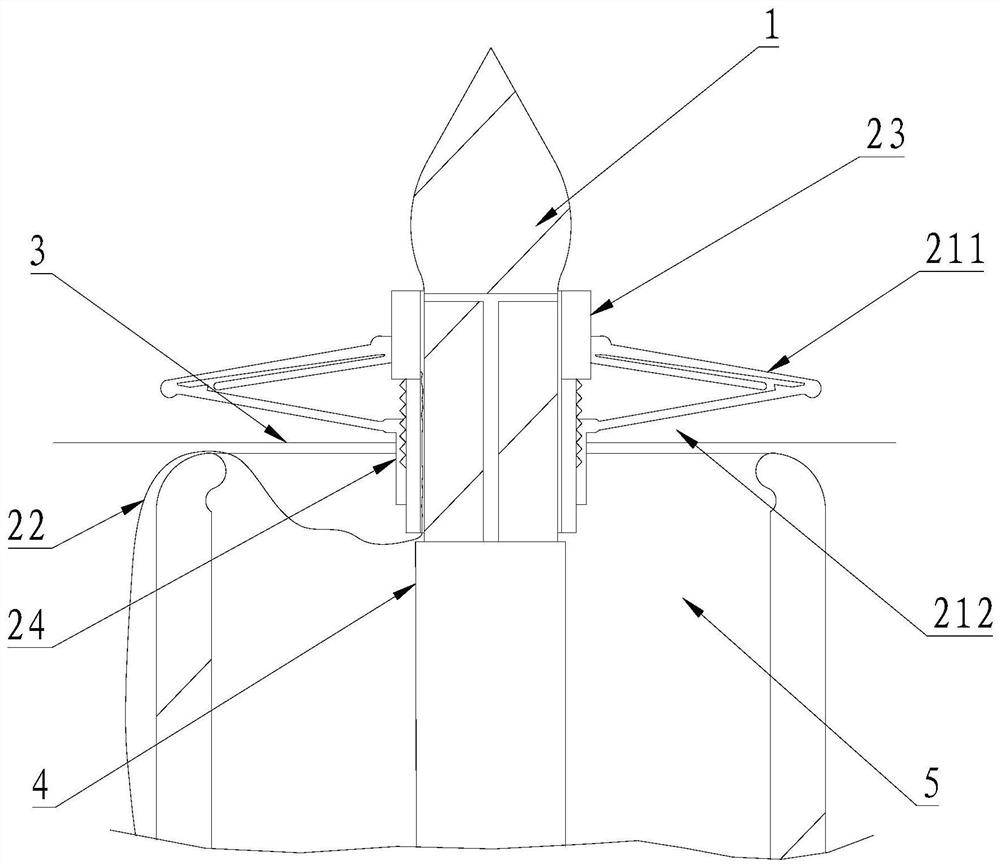

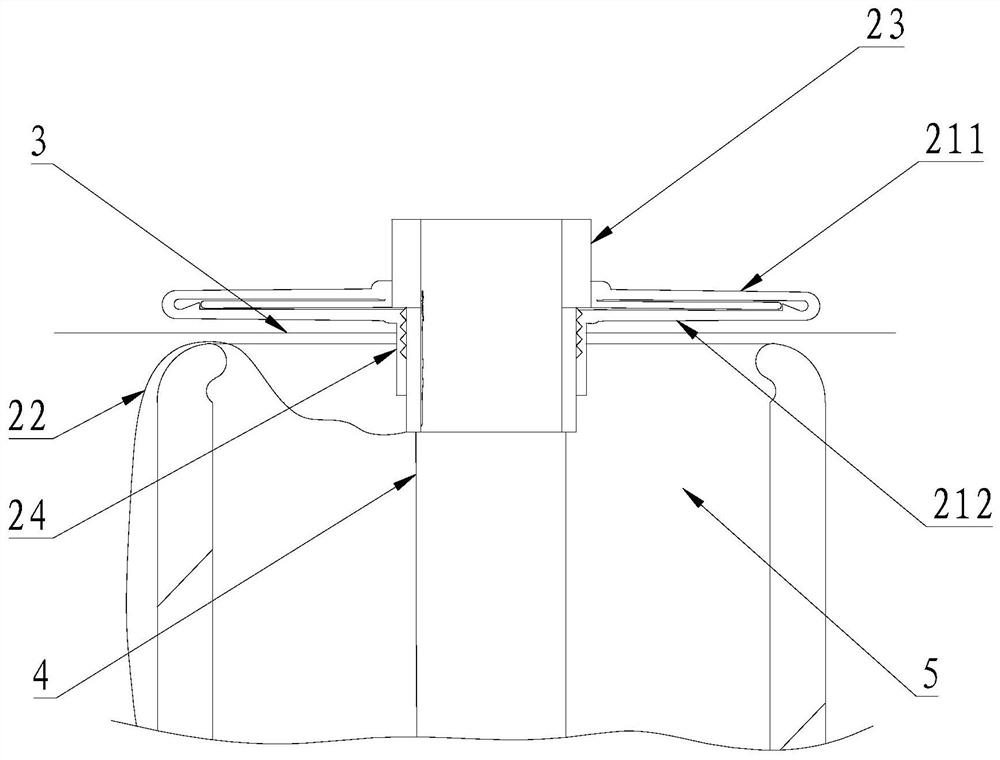

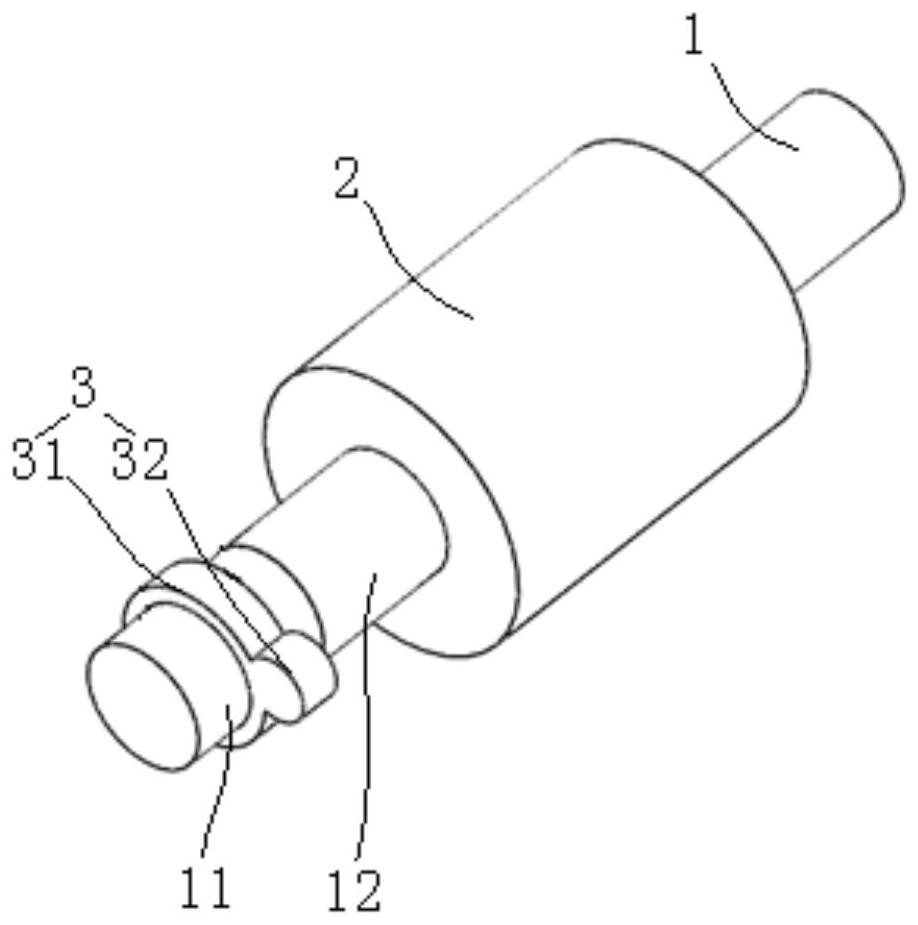

Glass run for automobile

A glass run mounted along an inner part of a door frame of a vehicle door to guide a window glass which moves up and down within the door frame. A main body portion of the glass run is provided with an exterior side wall, an interior side wall and a bottom wall, thereby formed into a shape having a substantially U-shaped cross section. An exterior seal lip and an interior seal lip are provided so as to extend into an inside of the substantially U-shaped cross section from distal portions of the exterior side wall and the interior side wall, respectively. The bottom wall has a bottom wall damping lip which is formed so as to be inclined inwardly from one of side end portions of an inner surface of the bottom wall. A space which is provided between an outer surface of the bottom wall portion and a door frame. A cushion material is provided in the space.

Owner:TOYODA GOSEI CO LTD +1

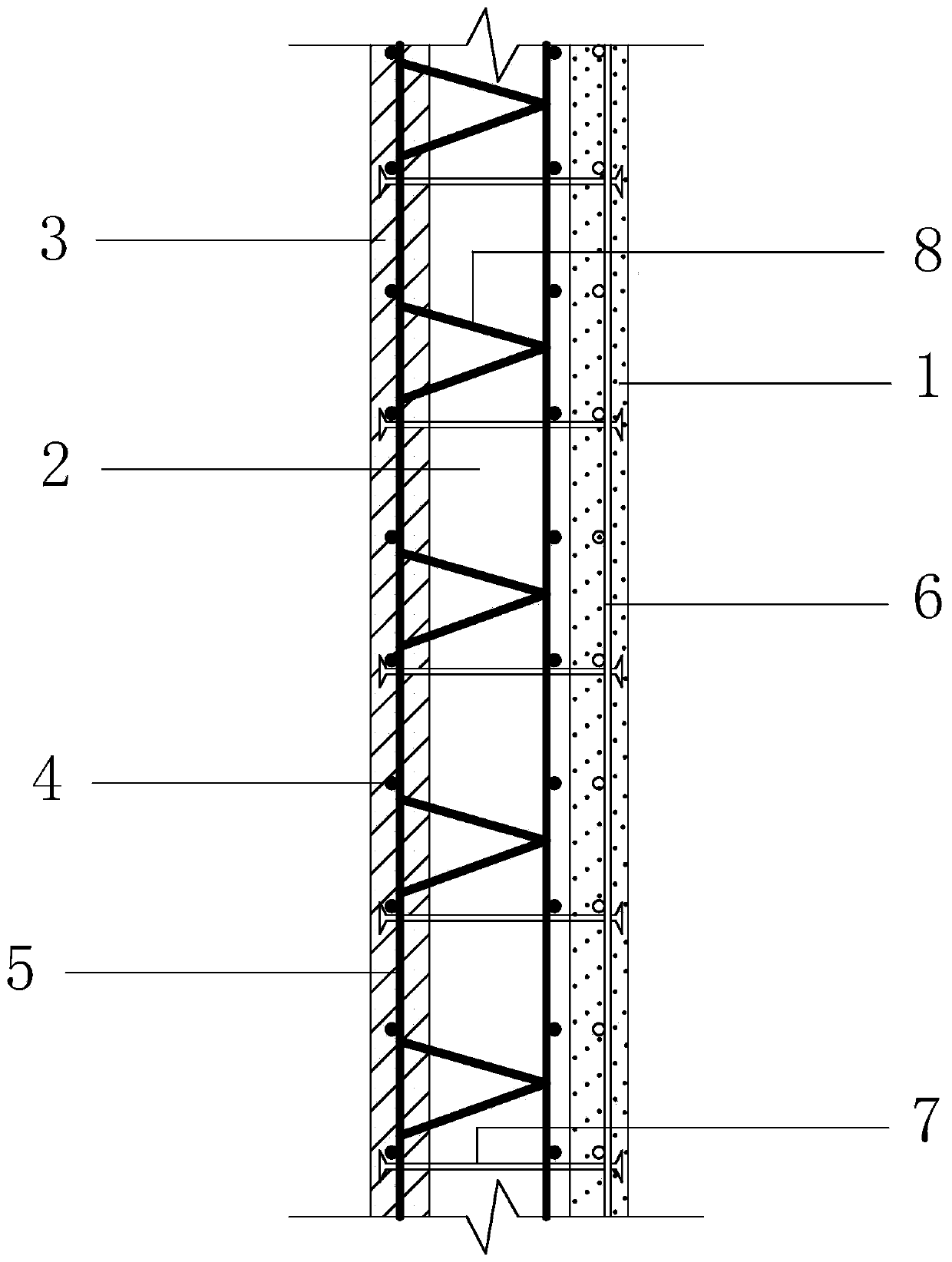

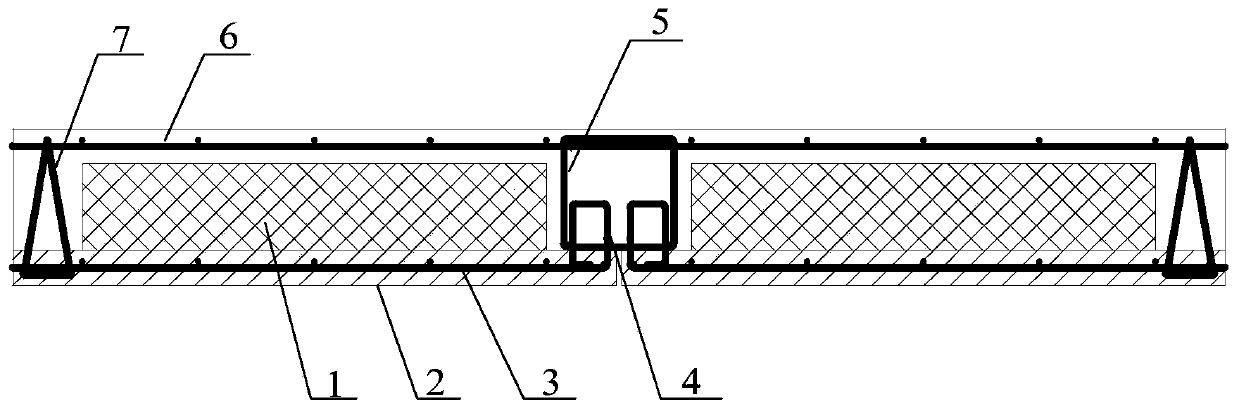

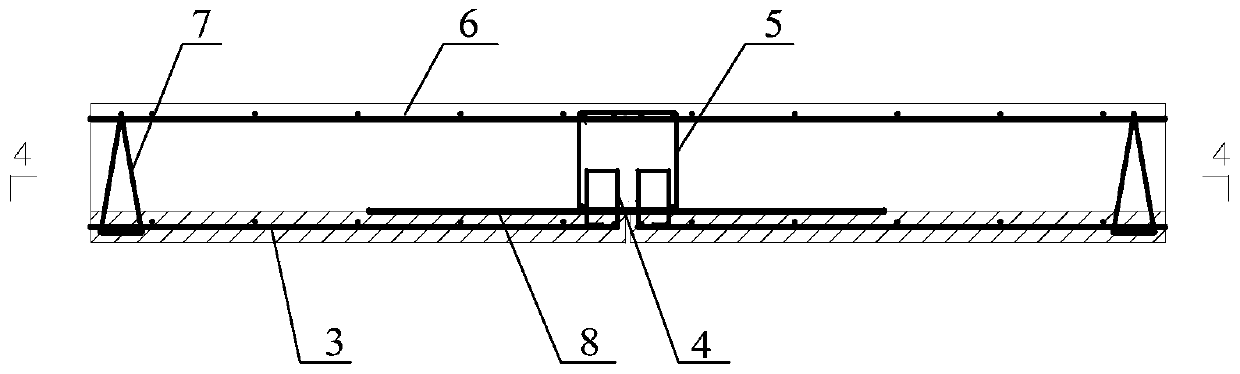

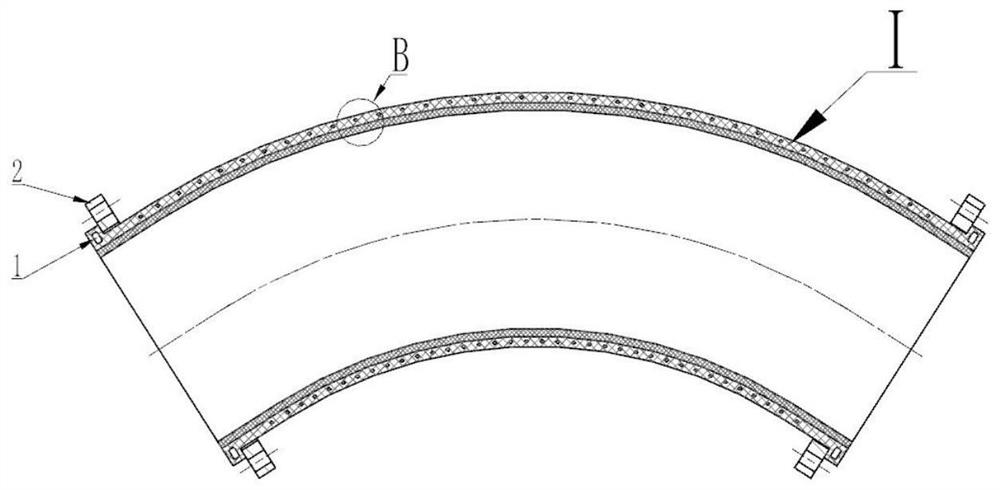

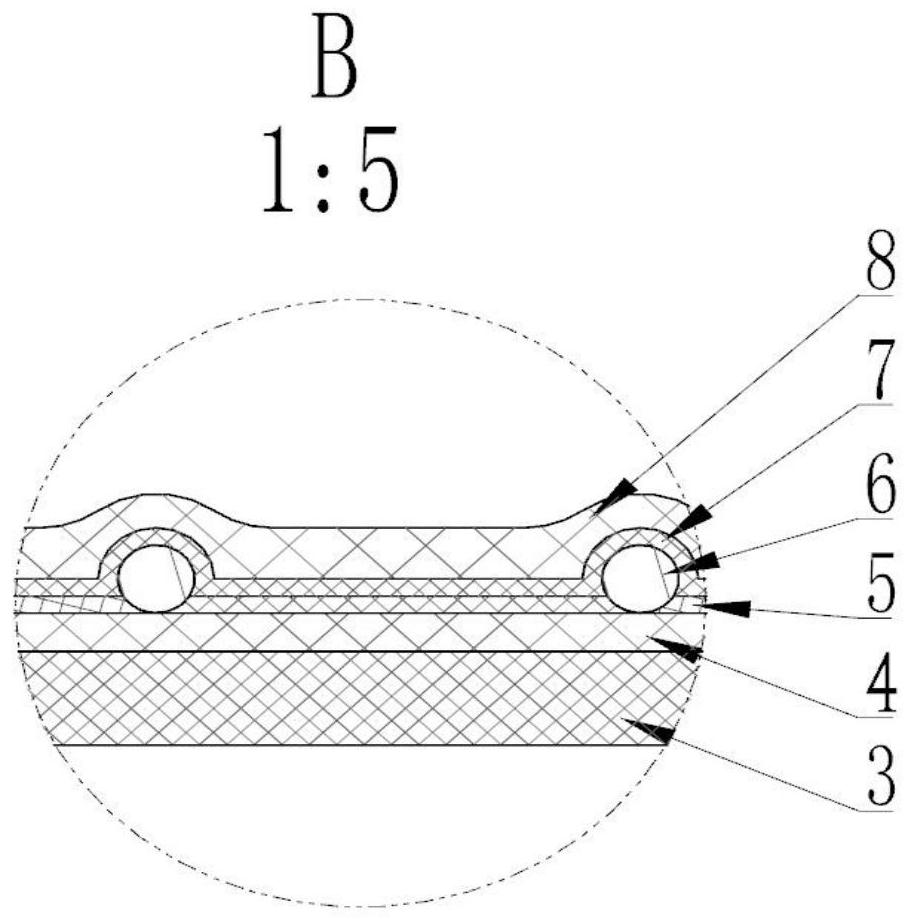

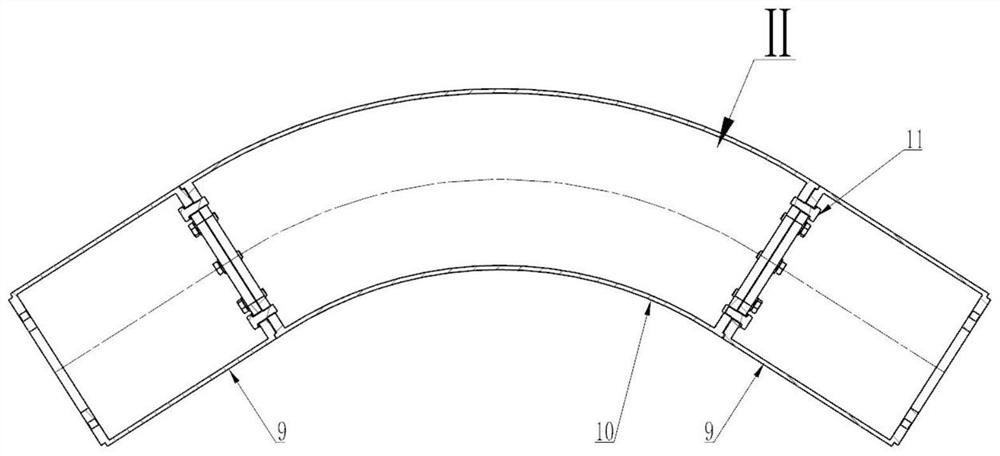

Fabricated self-insulation single face laminated shearing force wall board and casting method thereof

InactiveCN109866315AImprove performanceNot easy to damageDischarging arrangementWallsFoam concreteThermal insulation

The invention relates to a fabricated self-insulation single face laminated shearing force wall board and a casting method thereof. The casting method includes the steps that a laminated shearing force wall rebar framework and a basalt fiber reinforced polymer (BFRP) rib mesh piece in an outer wythe precast wall board are correspondingly bonded and manufactured, and insulation connecting parts arefixedly bonded on the rebar framework; and the rebar framework is placed on a protective layer cushion block of a casting framework platform, inner wythe wall board concrete is cast, the inner wytheprecast wall board after the inner wythe wall board concrete is cured to design strength is overturned by 180 degrees and moves to the upper part of another casting framework platform, the BFRP rib mesh piece is placed on a protective layer cushion block of another casting framework platform, outer wythe foam concrete is casted, the insulation connecting parts are pressed into the outer wythe concrete before initial set of the outer wythe foam concrete, and formwork stripping is conducted when the strength is reached. According to the fabricated self-insulation single face laminated shearing force wall board and the casting method thereof, a BFRP is treated as a bar material of the built-in mesh piece in the outer wythe wall board and a material of the connecting parts, the good thermal insulation performance of outer wythe foam concrete boards can be guaranteed, and stress requirements of the laminated wall board can also be met.

Owner:WUHAN UNIV OF TECH

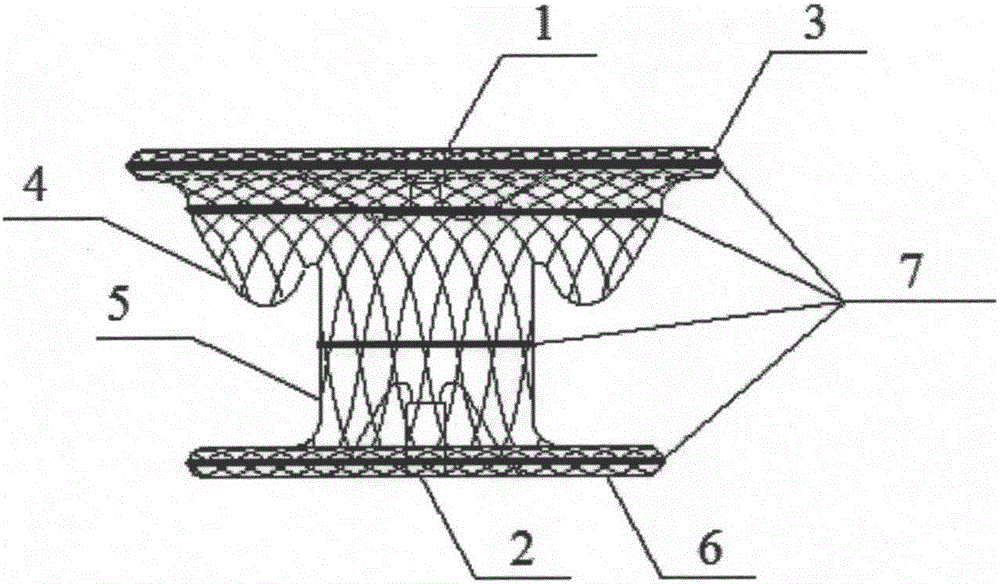

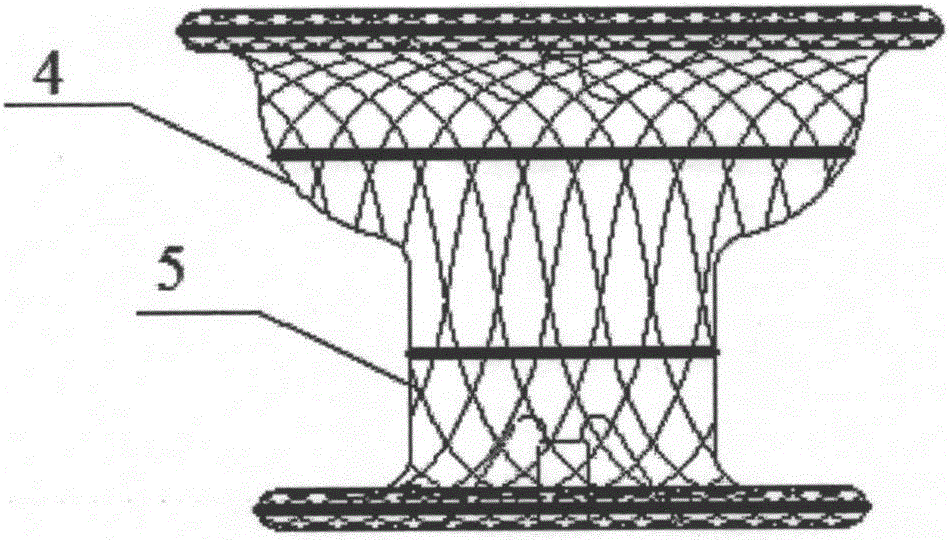

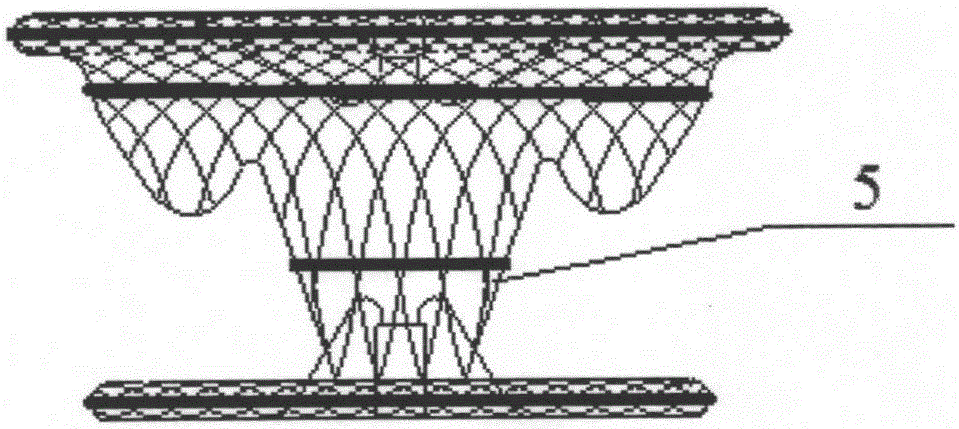

Waist-bendable left atrial appendage occlusion apparatus

The invention discloses a waist-bendable left atrial appendage occlusion apparatus, which comprises a fixing tray and an occlusion tray, wherein flow blocking films are arranged in both the fixing tray and the occlusion tray; an upper steel cover is arranged on the occlusion tray and a lower steel cover is arranged on the fixing tray; the occlusion apparatus is characterized in that the fixing tray is connected to one end of a waist part; the other end of the waist part is connected to one end of a conical body in which the waist part can sink; the other end of the conical body is connected to the occlusion tray; and flocculent skirt hems are arranged around the occlusion tray. The occlusion apparatus disclosed by the invention is simple in structure, convenient to use and low in operating difficulties; in addition, in accordance with the specific circumstances of a left atrial appendage and the left atrial appendage occlusion apparatus which is attached to the inner wall of the left atrial appendage, the occlusion apparatus can be effectively fixed, the occurrence of residual shunts can be effectively relieved and an additional perforating event of the left atrial appendage can be avoided, and the occlusion apparatus is simple to repeatedly recovery and release.

Owner:SHANGHAI SHAPE MEMORY ALLOY

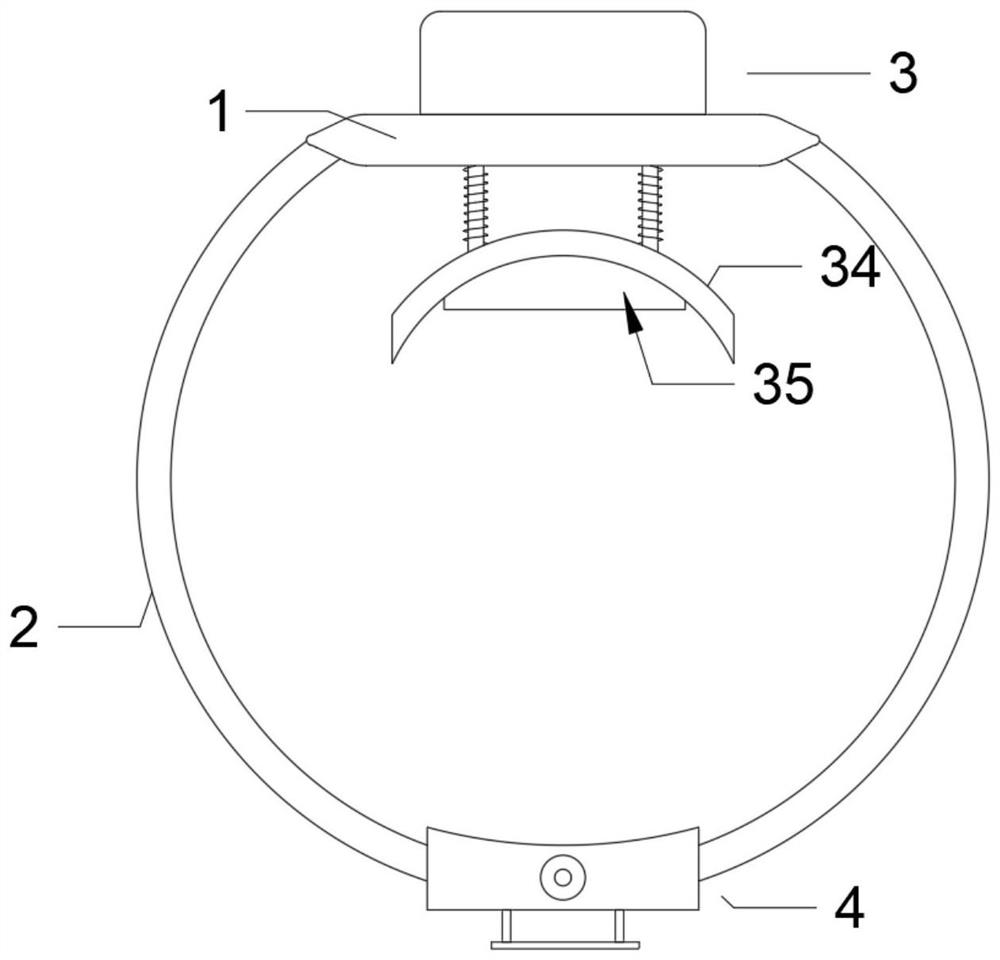

Pre-twisted aviation alerting ball

InactiveCN105047075AHigh elastic modulusNot easily deformedOverhead installationApparatus for overhead lines/cablesElastic modulusGrip strength

The invention discloses a pre-twisted aviation alerting ball. The pre-twisted aviation alerting ball comprises a ball body, a through hole is formed in the ball body, a cable penetrates through the ball body through the through hole, and a protection sleeve is arranged inside the through hole. The pre-twisted aviation alerting ball is characterized in that the ball body is fixed to the cable through a pre-twisted wire amour rod. The elasticity modulus is large, the pre-twisted aviation alerting ball can provide sufficient holding force and is not prone to deforming after installing, and the ball body can be well fixed.

Owner:JIANGDONG FITTINGS EQUIP

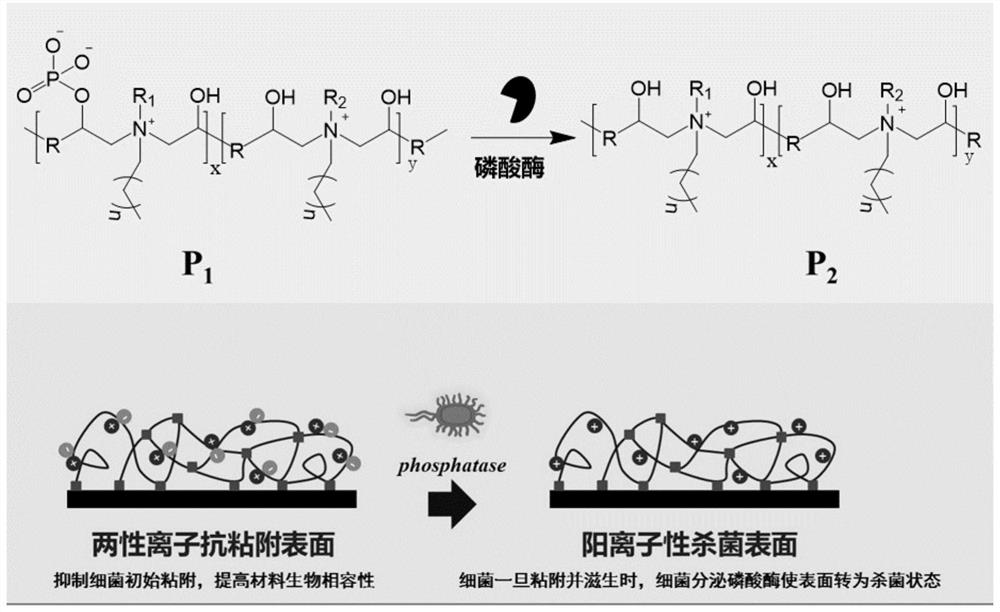

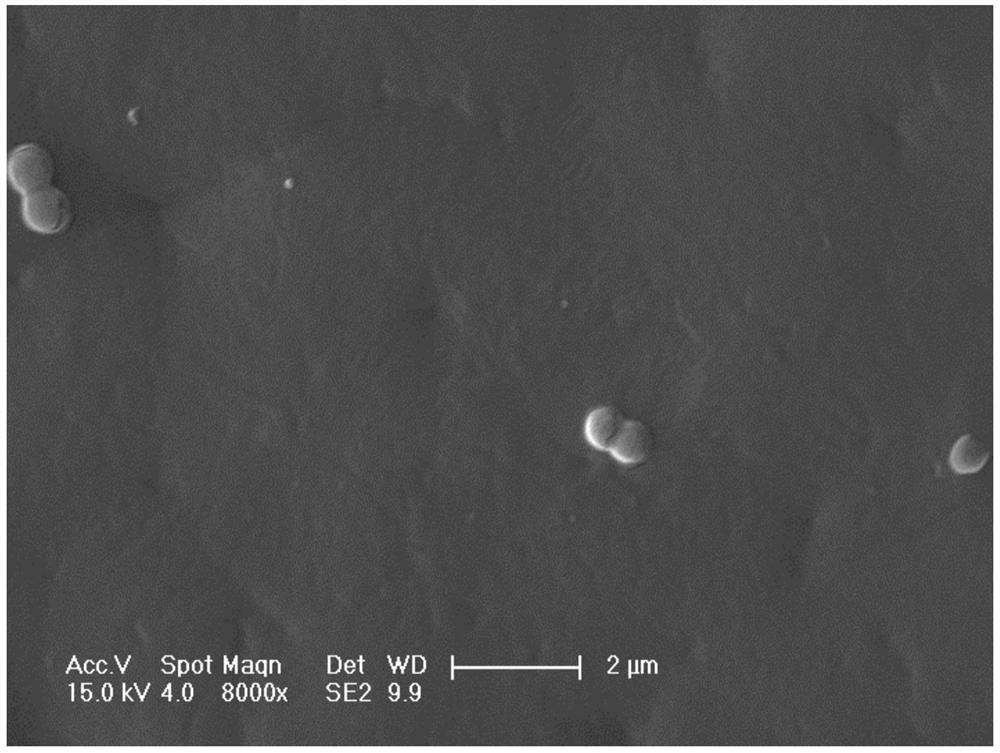

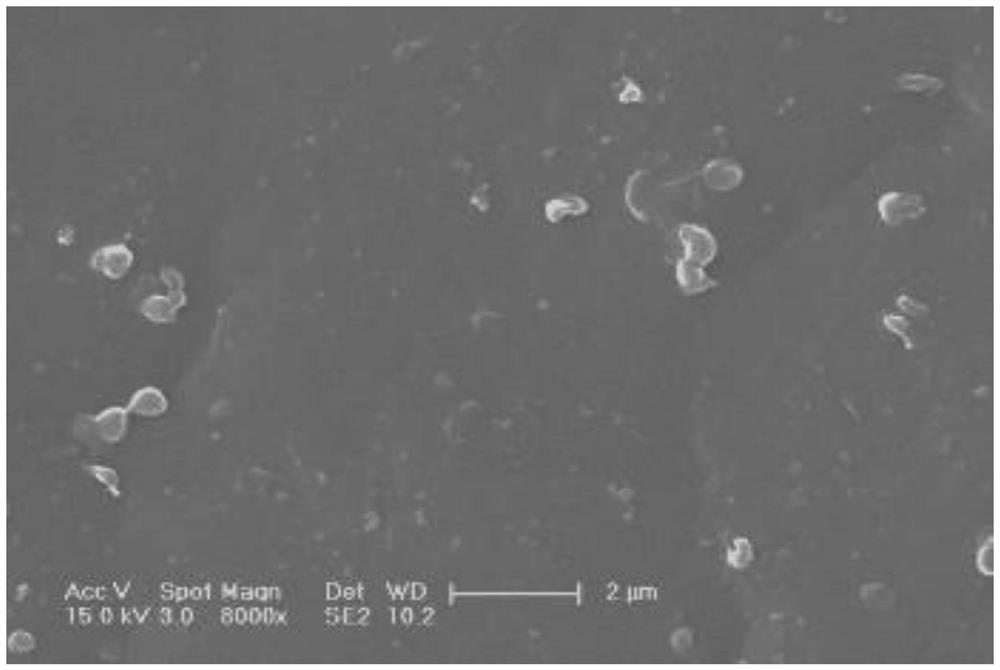

Antibacterial coating with bacterial enzyme response function, functional material with antibacterial coating and preparation method of functional material

ActiveCN112126311ANo risk of sheddingAchieve adaptive antibacterialAntifouling/underwater paintsPaints with biocidesBacterial AdhesionsMicrobiology

The invention provides an antibacterial coating. The antibacterial coating comprises a zwitterionic polymer with a structure shown in a formula (I) or a formula (II). The zwitterionic polymer designedby the invention can conform to the development process of bacteria, a quaternary ammonium salt group with positive electricity and a phosphate radical group with negative electricity exist on the zwitterionic polymer to form a zwitterionic surface, and when the surface of a material is infected by bacteria, the surface of the material is an anti-adhesion surface initially, so that the function of bacterial adhesion resistance is achieved. Once phosphate radicals on the surface are easily released by bacterial enzymes generated by metabolism of bacteria growth and propagation, the surface isimmediately converted into a cationic sterilization surface. The construction of the surface not only effectively prevents the initial adhesion of bacteria, but also has good biocompatibility to organisms, and more importantly, when the initial defensiveness is broken through, the surface can be converted into an excellent sterilization function. The preparation process is simpler, the equipment requirement is low, the operation is easy, and the feasibility is high.

Owner:WEIGAO HLDG +2

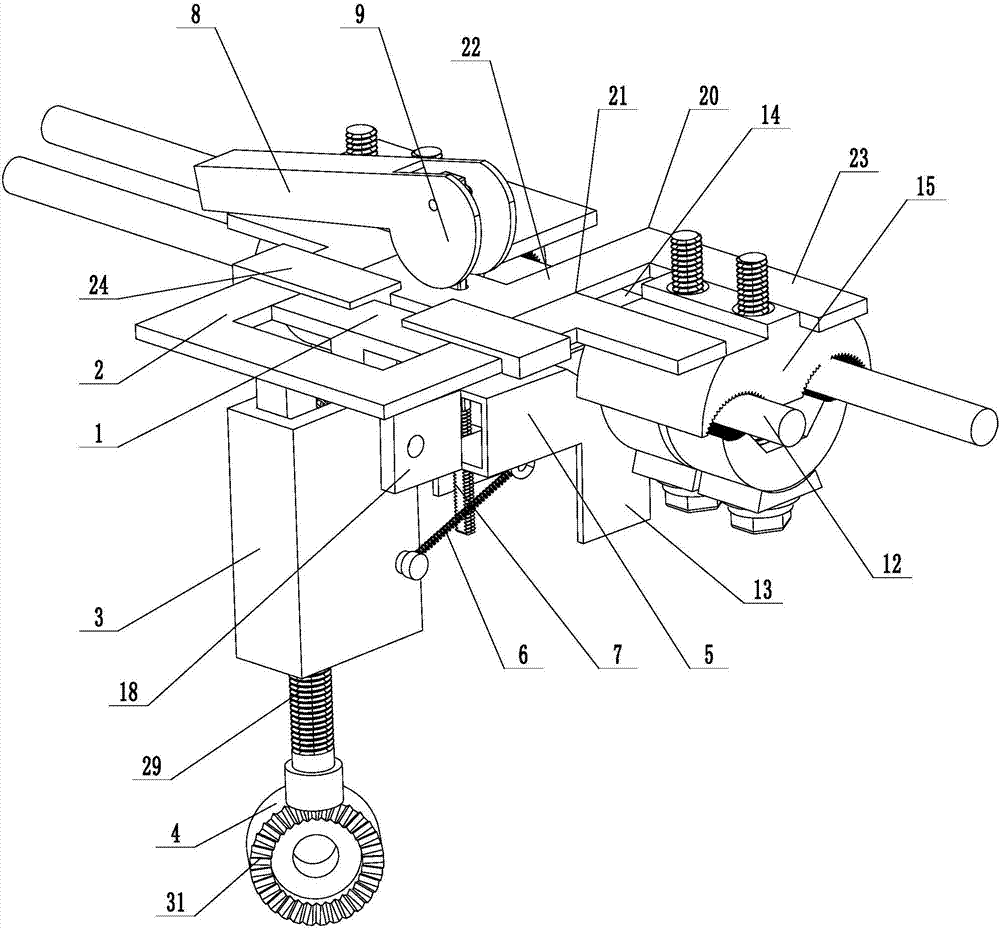

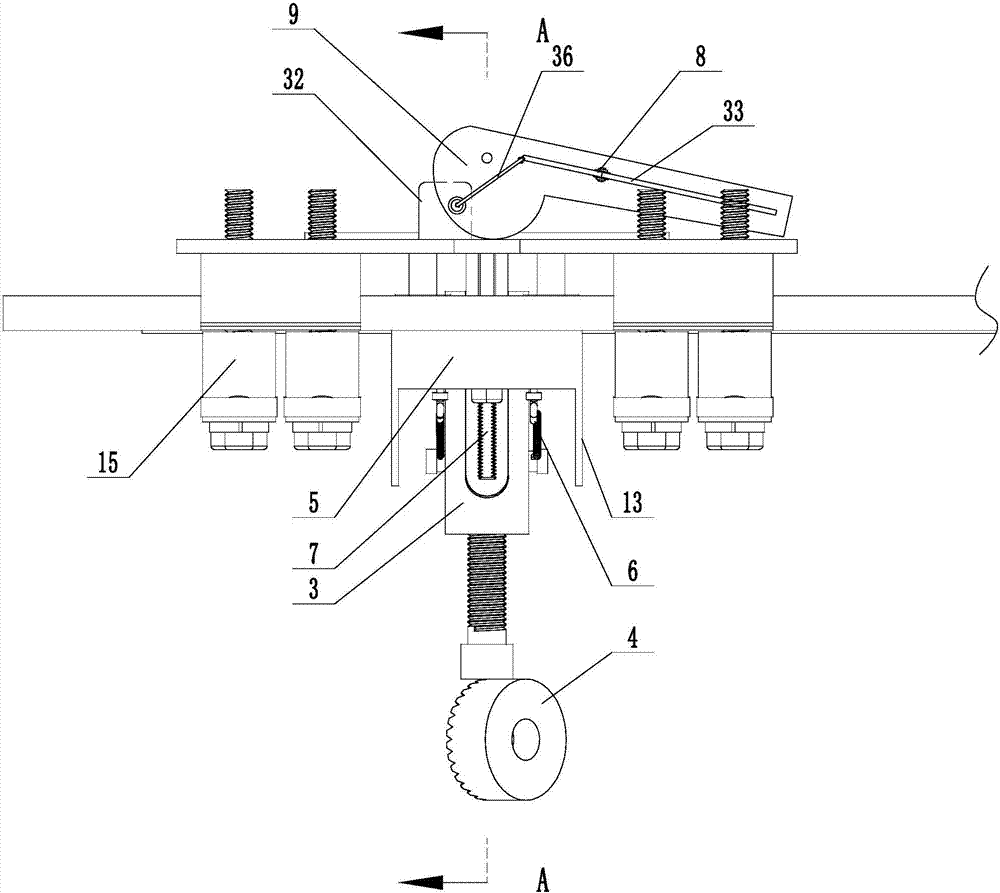

Lead overhead apparatus

ActiveCN107123942AEasy to controlEasy loading and unloadingApparatus for overhead lines/cablesLap jointEngineering

The invention discloses a lead overhead apparatus, and aims to overcome the shortcomings that only one wire clamp can be assembled or disassembled in one time in an electrified operation lead lap joint operation and it is not easy to determine the distance between adjacent two wire clamps, and the shortcomings of inconvenient assembling and disassembling of the wire clamp, high labor intensity, time consumption and labor consumption in the lead overhead operation, poor lead locking effect and risk of easy falling off. The lead overhead apparatus comprises a fixed clamping plate and a push clamping plate; the fixed clamping plate is connected with a mounting base; the mounting base is rotationally connected with a pressing base; the pressing base is connected with a locking rod; the end part of the locking rod is rotationally connected with a handle; eccentric locking plates are arranged at the connecting end between the handle and the locking rod; each eccentric locking plate tightly props against the fixed clamping plate; a locking clamping groove is formed in the pressing base; a plurality of pressing plates are arranged in the positions, opposite to the locking clamping groove, of the fixed clamping plate; a lead is mounted between the pressing plates and the locking clamping groove; a positioning and clamping groove used for mounting and clamping a wire clamp is formed between the push clamping plate and the fixed clamping plate and on each of the two sides of the pressing base; the wire clamp is mounted in each positioning and clamping groove; and the wire clamp is connected with the lead.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD QUZHOU POWER SUPPLY CO +3

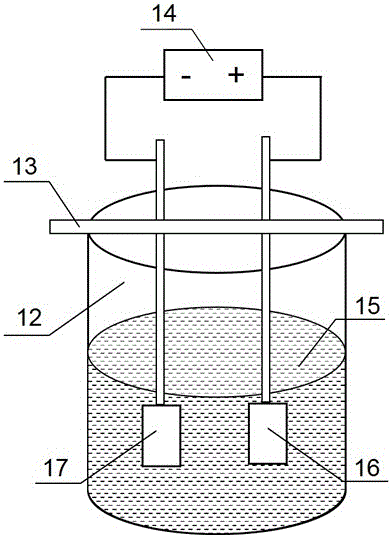

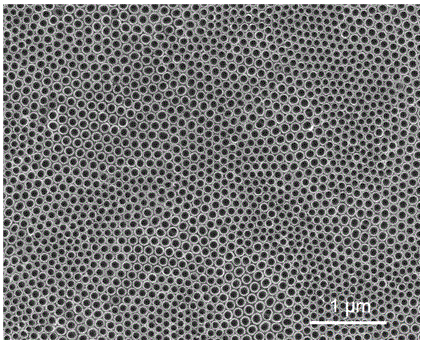

Method for preparing zinc oxide-doped titanium dioxide nanotube on pure titanium surface

InactiveCN104988557AEvenly distributedControlled releaseSurface reaction electrolytic coatingVacuum evaporation coatingTitanium surfaceTio2 nanotube

The invention discloses a method for preparing a zinc oxide-doped titanium dioxide nanotube on a pure titanium surface, and belongs to the technical field of material surface modification. The method comprises the following steps: a pretreated pure titanium sample is put on a sample table of magnetron sputtering equipment, and a titanium zinc alloy target is placed opposite to the sample; after the vacuumizing is performed, argon is fed in a vacuum chamber, certain voltage is applied to the alloy target and the sample, and titanium and zinc elements are deposited on the pure titanium surface to form a titanium zinc composite film layer under the effect of plasma bombardment; and then, the anodic oxidation treatment is performed for the composite film layer to prepare the zinc oxide-doped titanium dioxide nanotube. The nanotube, prepared by the method, has excellent infection resistance and osseointegration capacity.

Owner:TAIYUAN UNIV OF TECH

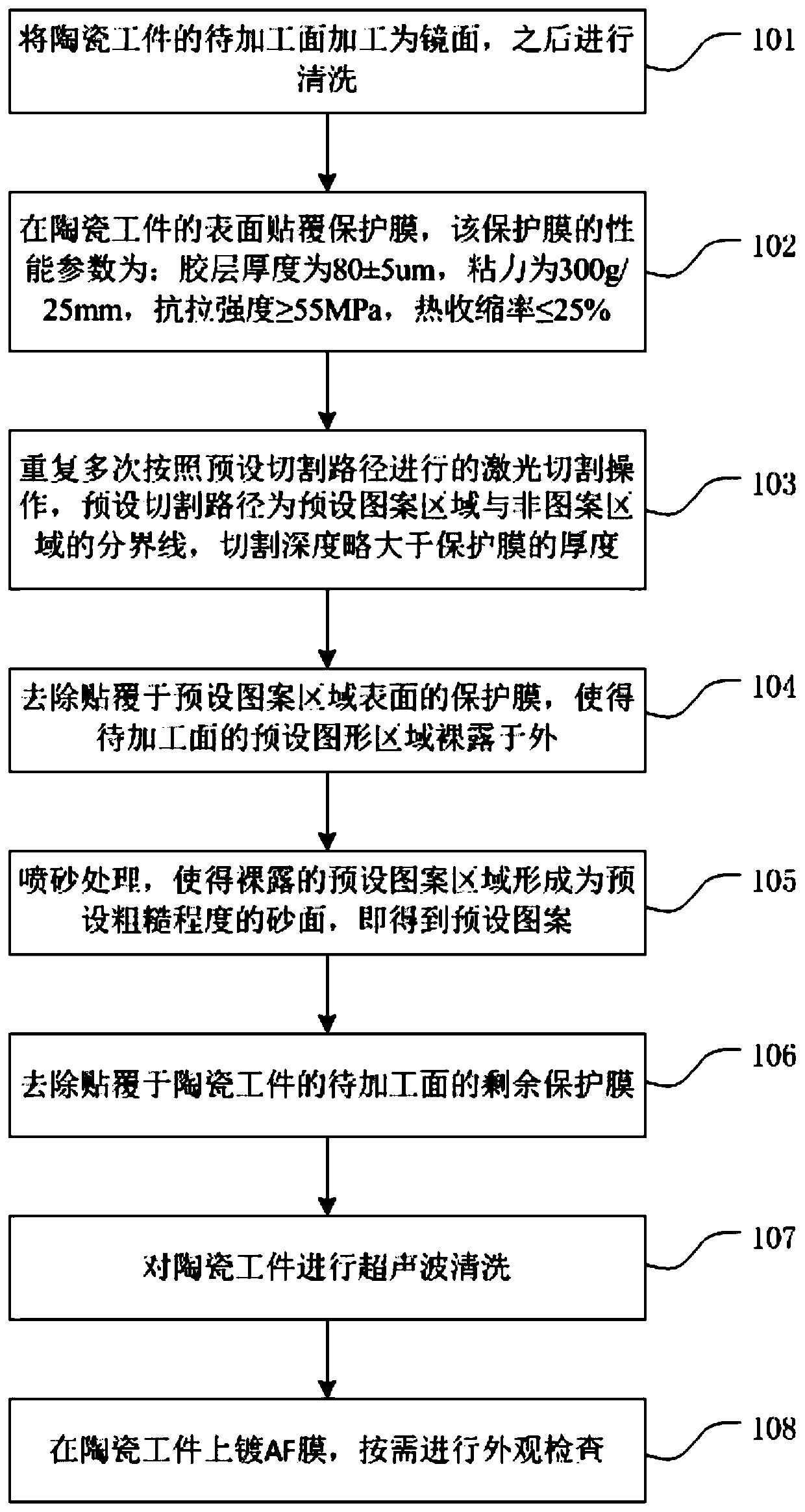

Ceramic surface pattern machining method, ceramic and electronic equipment shell

ActiveCN110919203AExcellent hardnessExcellent wear resistanceDecorative surface effectsLaser beam welding apparatusSurface patternSand blasting

The invention relates to the field of ceramic and discloses a ceramic surface pattern machining method, ceramic and an electronic equipment shell. The method comprises the steps that a protecting filmis attached to the surface of a ceramic workpiece, and performance parameters of the protecting film include the thickness being 80+ / -5 micrometers, viscous force being 300 g / 25 mm, the tensile strength being larger than or equal to 55 MPa, and the hot-shrinkage rate being smaller than or equal to 25%; on the to-be-machined face, laser cutting operation is carried out according to a preset cutting path, the preset cutting path is a boundary of a pattern area and a non-pattern area, and the cutting depth is no smaller than the thickness of the protecting film; the protecting film covering thepreset pattern area is removed; the to-be-machined face is subjected to sand blasting treatment until the preset pattern area is formed into a sand face with the preset roughness; and the remaining protecting film is removed. According to the method, the protecting film applied to the ceramic workpiece is designed and manufactured according to the special performance parameters, meanwhile, the laser cutting and sand blasting technology is utilized, pattern manufacturing of high-hardness ceramic surfaces is achieved, and higher machining precision and machining quality are achieved.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

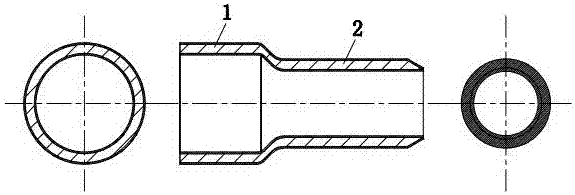

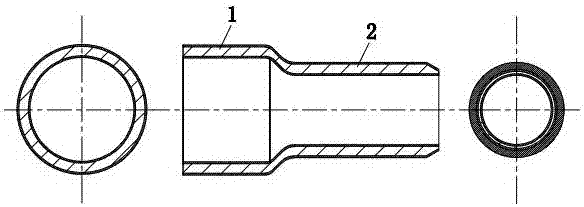

Production technology for connecting pipe of compressor

InactiveCN107009101ARealize environmentally friendly manufacturingImprove assembly stabilityEnvironmental resistancePunching

The invention relates to the technical field of connecting pipes of compressors, in particular to a production technology for a connecting pipe of a compressor. The production technology for the connecting pipe of the compressor includes the steps that firstly, material selecting is conducted; and secondly, continuous multistage punching stretching forming or pipe machining technology forming is adopted, wherein firstly continuous multistage punching stretching forming is adopted includes the first step of blanking, the second step of multistage stretching, the third step of trimming, the fourth step of punching and the fifth step of shaping, and secondly, pipe machining technology forming is adopted; thirdly, polishing cleaning is conducted; and fourthly, drying is conducted. The production technology for the connecting pipe of the compressor has the beneficial effects of environment friendliness and energy conservation, due to the fact that the end portion of a diffusionless pipe end portion is covered with a red copper plate layer, assembling stability and sealing performance of the connecting pipe of the compressor can be improved, deformation of pump body parts can be reduced, the production efficiency can be greatly improved, and the quality reject ratio is greatly reduced.

Owner:DONGGUAN JINRUI HARDWARE PROD

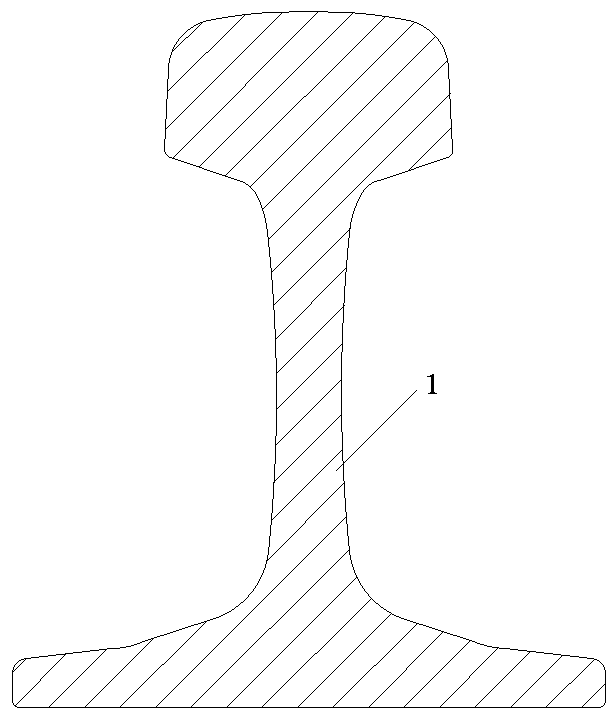

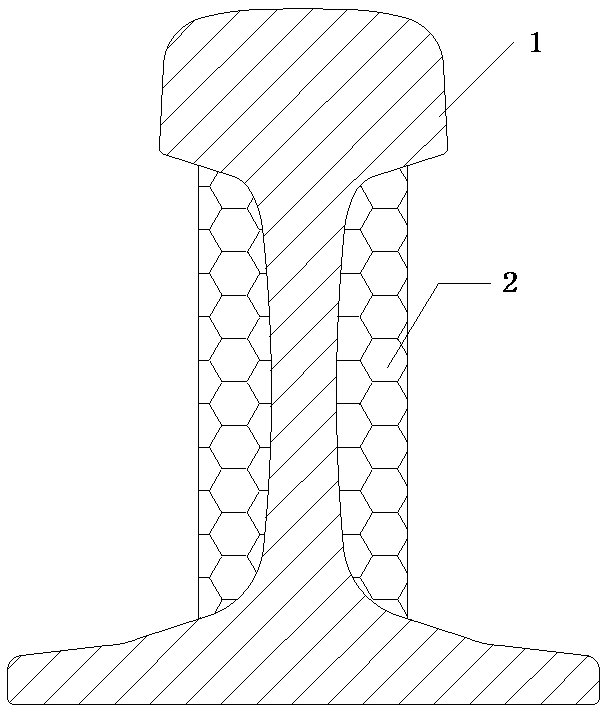

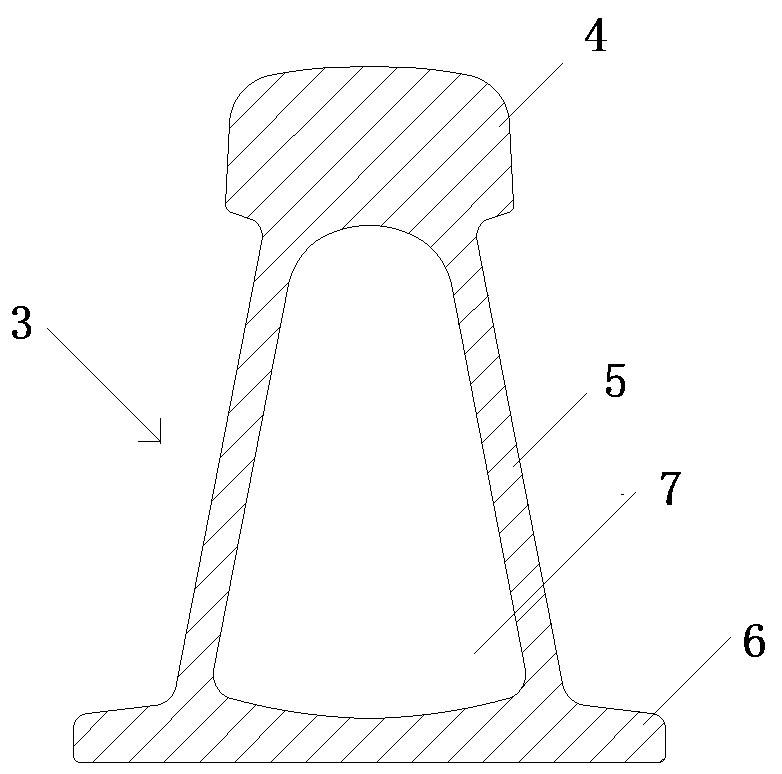

Irregular fracture surface vibration and noise reduction damping steel rail

The invention discloses an irregular fracture surface vibration and noise reduction damping steel rail. The irregular fracture surface vibration and noise reduction damping steel rail is characterizedby comprising a rail head, a rail base, and a rail web connected between the rail head and the rail base; a surrounding region among the rail head, the rail base and the rail web forms a hollow cavity; and a damping material is filled in the cavity. The damping steel rail disclosed by the invention has the advantages as follows: (1) compared with an operation of adhering the damping material at the rail web, a constraint layer and a protective layer on the surface of the damping material can be saved, and the bonding strength and the durability and like problems between the damping material and the rail web are out of consideration; (2) the damping steel rail not only can be used for the vibration and noise reduction of the low-speed rail traffic steel rail, but also can be used for the vibration and noise reduction of the high-speed railway steel rail, and is wide in applicable range; and (3) the damping material in the invention is filled in the steel rail, the damping material falling risk is inexistent, and the damping material cannot cause any barrier for the normal driving of the train.

Owner:EAST CHINA JIAOTONG UNIVERSITY

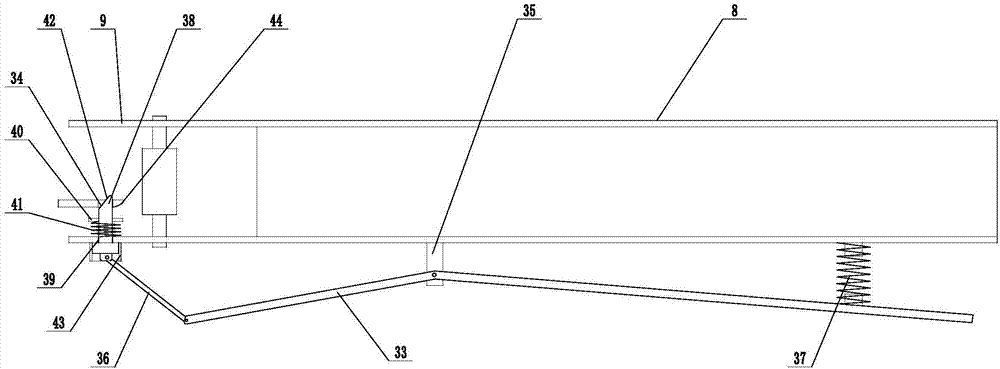

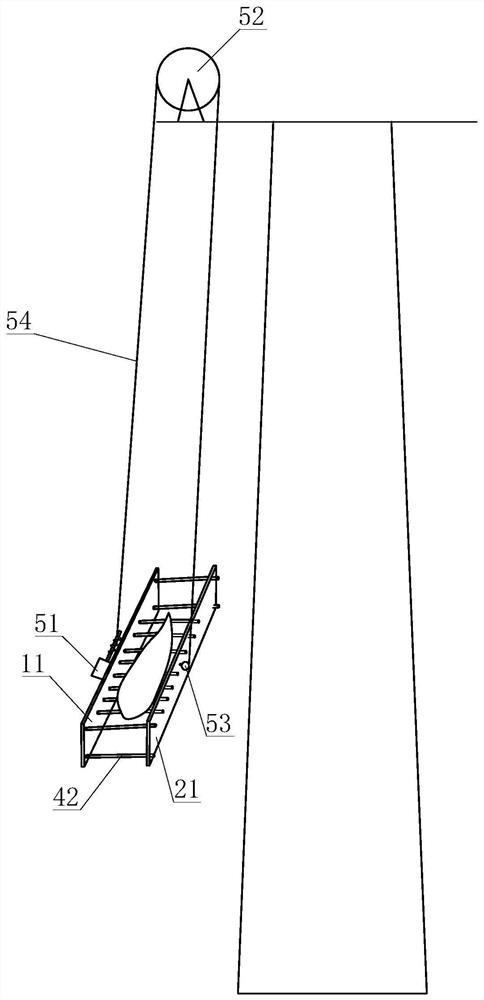

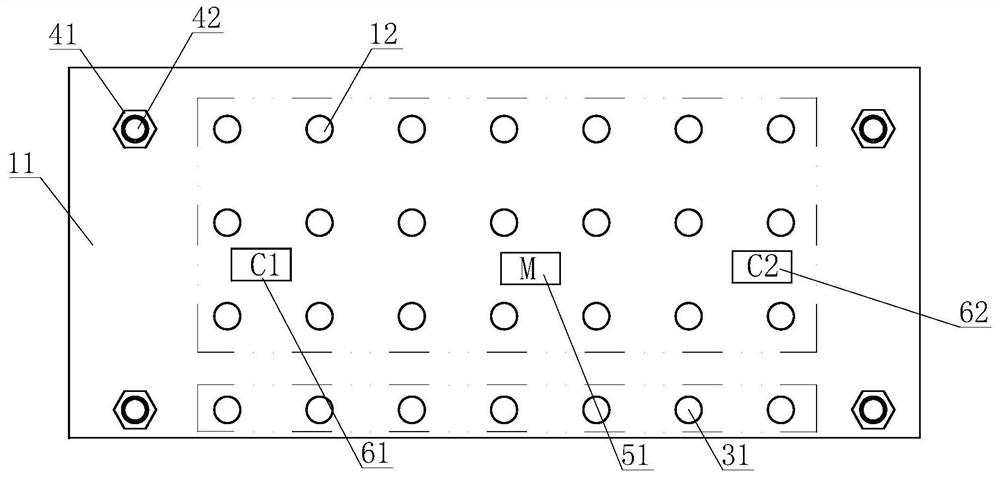

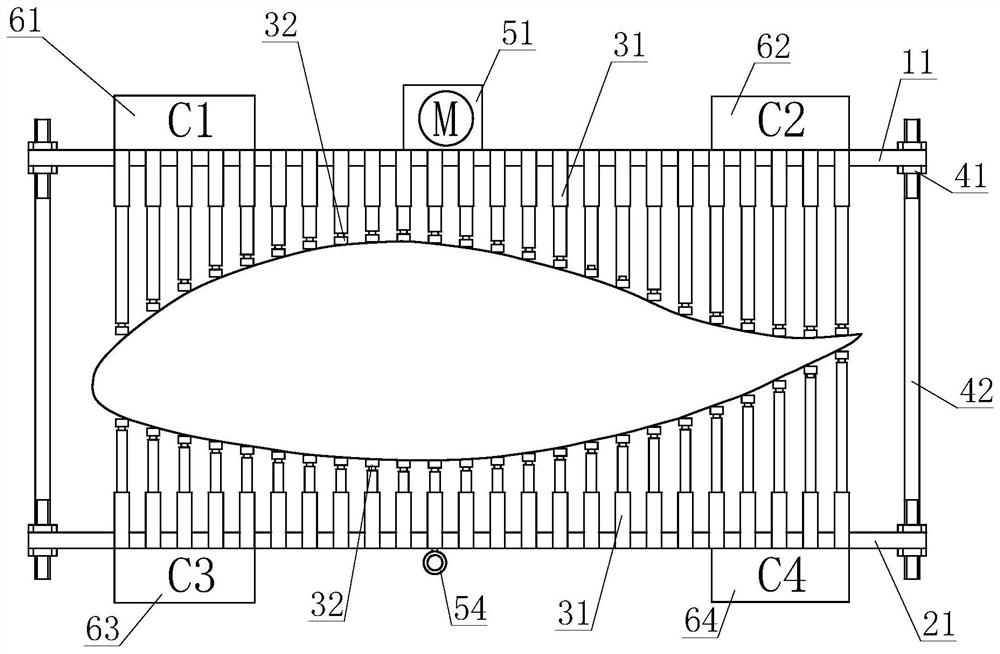

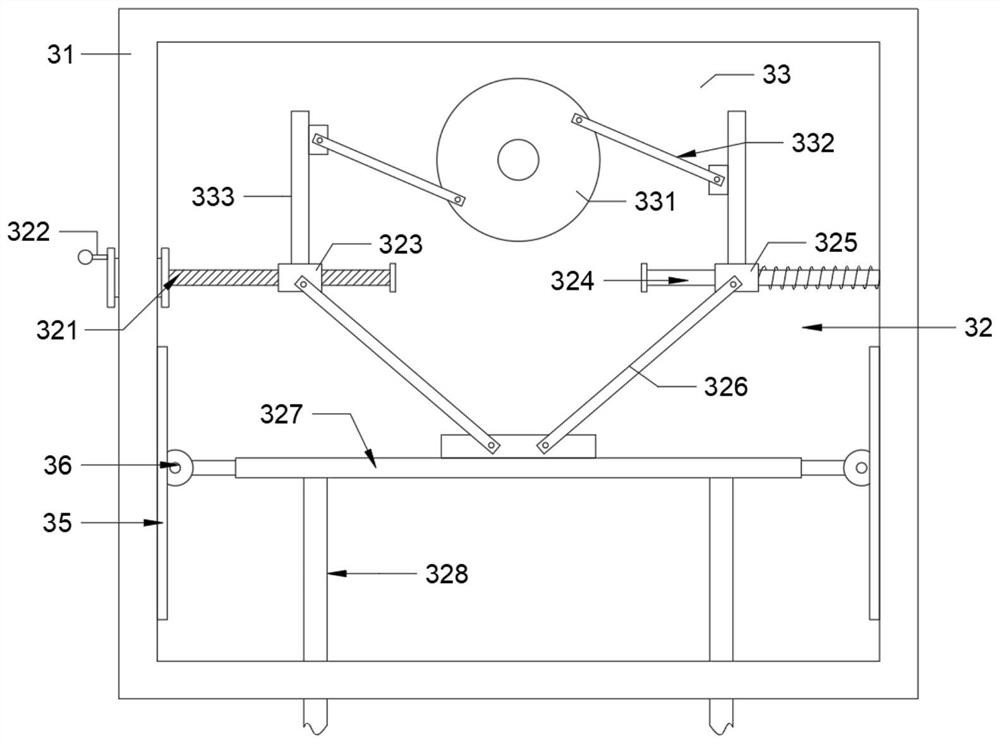

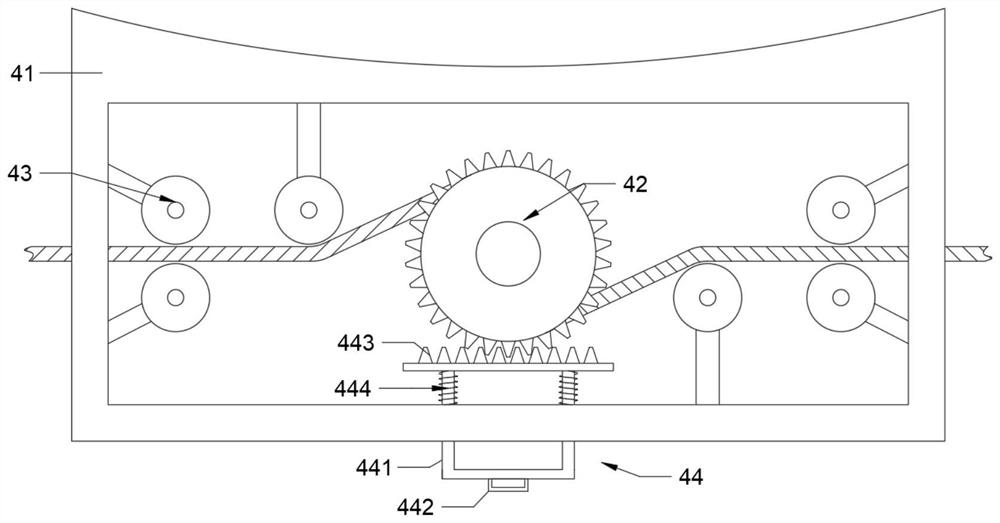

Wind driven generator blade deicing equipment and wind driven generator blade deicing method

ActiveCN111794919ASimple internal structureReduce weightWind motor controlMachines/enginesMarine engineeringStructural engineering

The invention belongs to the technical field of deicing of wind driven generator blades, and relates to wind driven generator blade deicing equipment and a wind driven generator blade deicing method.The wind driven generator blade deicing equipment comprises deicing equipment body, the deicing equipment body is used for being detachably connected with a wind driven generator blade, the deicing equipment body is provided with a first-class mechanical deicing head and a second-class mechanical deicing head, the first-class mechanical deicing head and the second-class mechanical deicing head areused for being arranged outside the windward side and the leeward side of the blade correspondingly, the first-class mechanical deicing head is connected with the output end of the first-class deicing driving device, the second-class mechanical deicing head is connected with the output end of the second-class deicing driving device, and the fixing end of the first-class deicing device and the fixing end of the second-class deicing driving device are oppositely and fixedly arranged. According to the wind driven generator blade deicing equipment and the wind driven generator blade deicing method, the technical problem that in the prior art, a fixing deicing equipment body needs to be additionally arranged inside the blade, and consequently an internal structure of the blade is caused to becomplex is solved, and the technical effect of simplifying the internal structure of the blade of the wind driven generator is achieved.

Owner:SANY ELECTRIC CO LTD

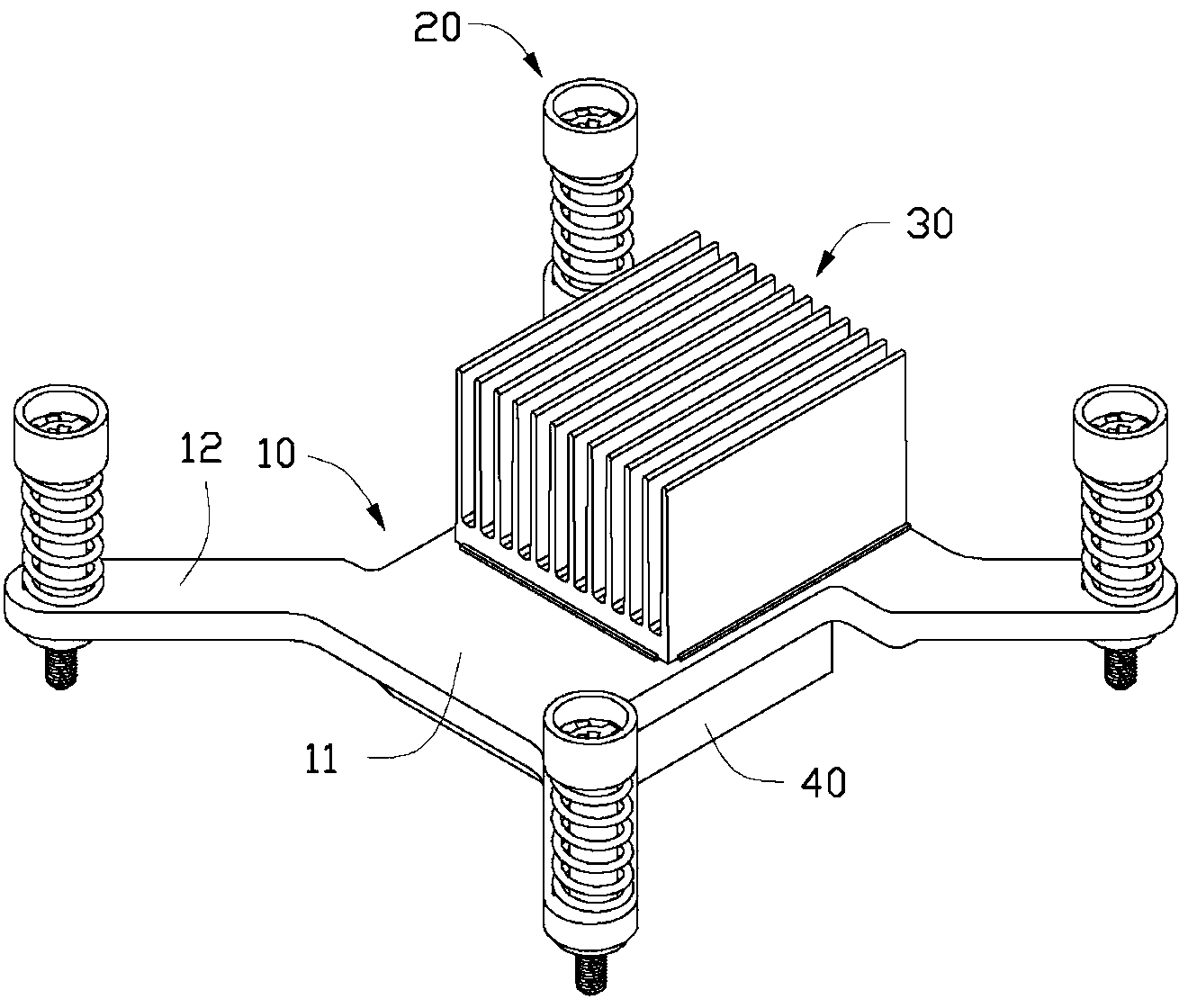

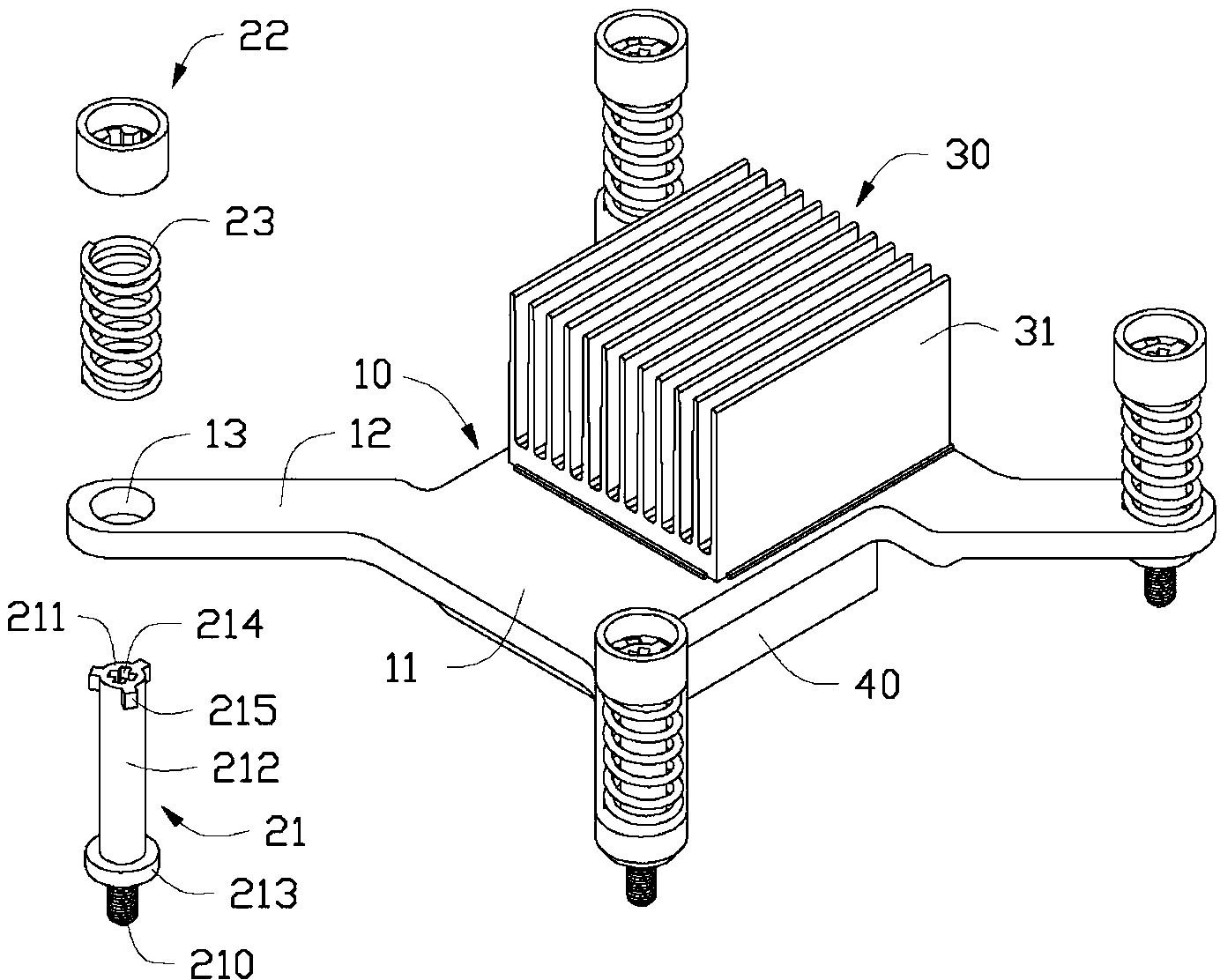

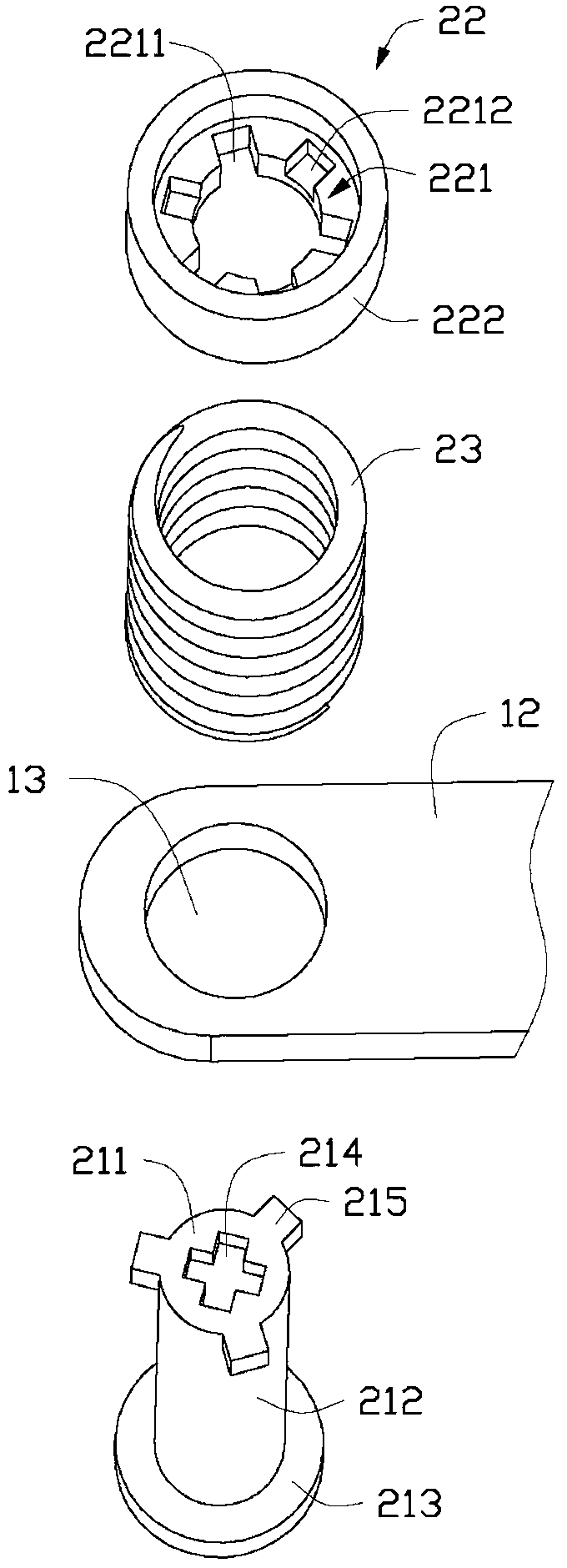

Heat dissipation device and fastening structure thereof

InactiveCN102832184ACompact and stable structureInstalled and disassembledSemiconductor/solid-state device detailsSolid-state devicesEngineeringFastener

The invention relates to a fastening structure for fixing a heat dissipation device, which comprises a fixing element as well as an elastic element and a fastener which are sleeved at the fixing element, wherein the fixing element comprises an operating part arranged at one end and a fixing part arranged at the other opposite end, the fixing part is provided with a buckle, the elastic element is arranged between the buckle and the fastener, several buckles extend out from the operating part, the fastener is provided with a through hole for the buckles to pass through and a retaining slot for retaining the buckles, the fastening structure is compact and stable in structure, convenient in installation and dismounting, and has no risk of falling from the heat dissipation device in the transportation process. The invention also relates to a heat dissipation device providing with the fastening structure.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

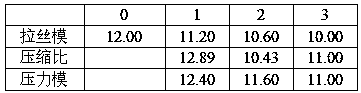

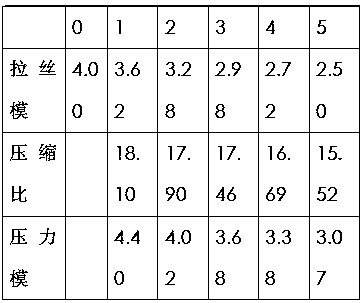

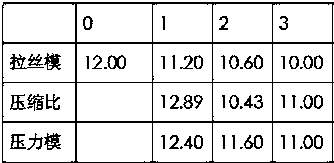

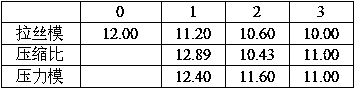

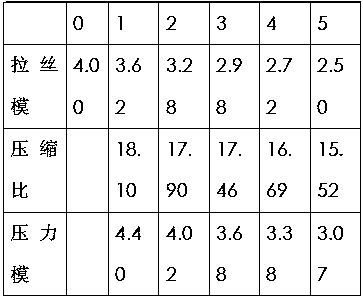

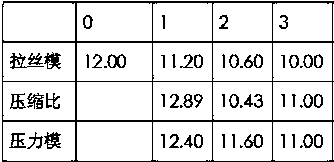

Manufacturing method of multi-purpose zinc clad steel

The invention belongs to the technical field of electric power, and particularly relates to a manufacturing method of multi-purpose zinc clad steel. The manufacturing method comprises the following steps that chemical-free environment-friendly treatment is performed on the surfaces of steel wires; surface cleaning treatment is performed on the steel wires by the aid of a belt sander; the cleaned steel wires are heated by an intermediate-frequency furnace, then the steel wires and two zinc rods enter a continuous cladding machine simultaneously for extruding, the zinc clad steel is obtained, the heating temperature of the intermediate-frequency furnace is controlled to range from 200 DEG C to 250 DEG C, an extruding mold and a guiding mold are assembled on the cladding machine according tothe product requirements, the nasal fossa sizes for mold assembly are controlled to range from 3 mm to 6 mm according to the diameters of the steel wires, the mold cavity temperatures are controlled to range from 150 DEG C to 250 DEG C, the rotating speed of an extruding wheel is controlled to range from 3 rpm to 7 rpm, and the extruding speed is controlled to range from 70 m / min to 120 m / min; andcomposite metal drawing is performed on zinc clad steel busbars after cladding. According to the method, the whole production process is free of chemical pollution, the method is different from all existing zinc clad steel technologies, and flexible production is realized.

Owner:HENAN TONG CABLE

Waterproof lettering zipper and manufacturing method thereof

InactiveCN107348628ANo risk of sheddingMeets production test requirementsSlide fastenersLaminationEngineeringHot melt

The invention relates to a waterproof lettering zipper and a manufacturing method thereof. The problem that lettering patterns on waterproof zippers in the prior art are easy to fall off is solved. The invention discloses the waterproof lettering zipper. The zipper comprises a zipper cloth tape and zipper teeth, and is characterized in that a waterproof lettering film is arranged on the zipper cloth tape; the waterproof lettering film comprises a first transparent film, a font pattern layer and a second film; the first transparent film is arranged on the zipper cloth tape in a hot-melt mode, the font pattern layer is printed on the transparent film layer, and the font pattern layer is coated with the second film. According to the waterproof lettering zipper, the font pattern layer on the waterproof lettering film is printed between the first transparent film and the second film, lettering patterns cannot be touched during drying washing and wear resistance tests, the lettering patterns are free of the fall-off risk, and production test requirements of the garment industry are met.

Owner:深圳市联星服装辅料有限公司

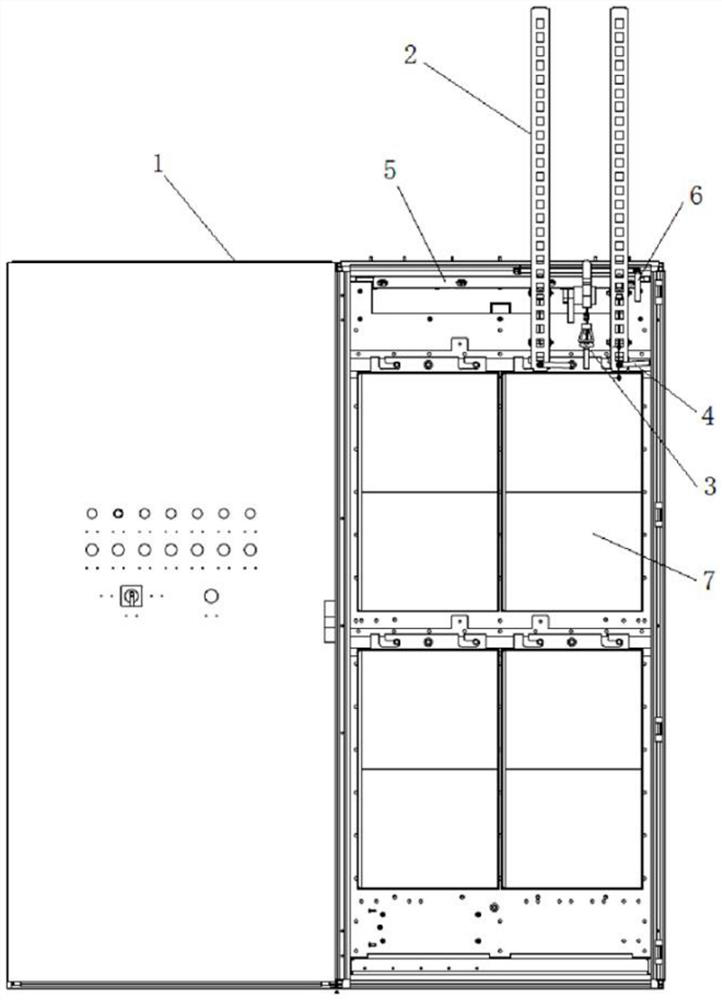

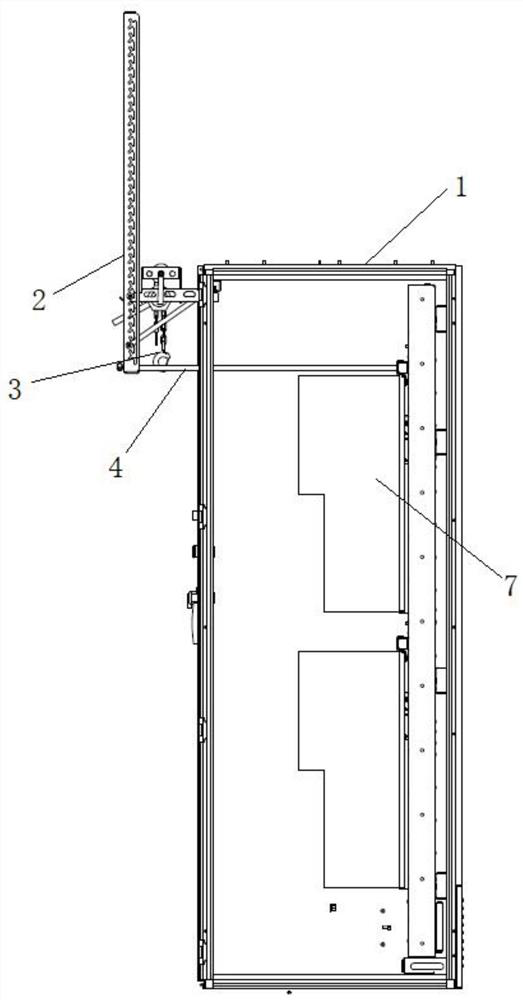

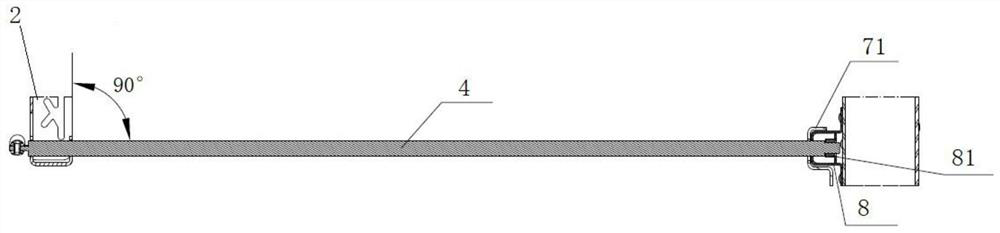

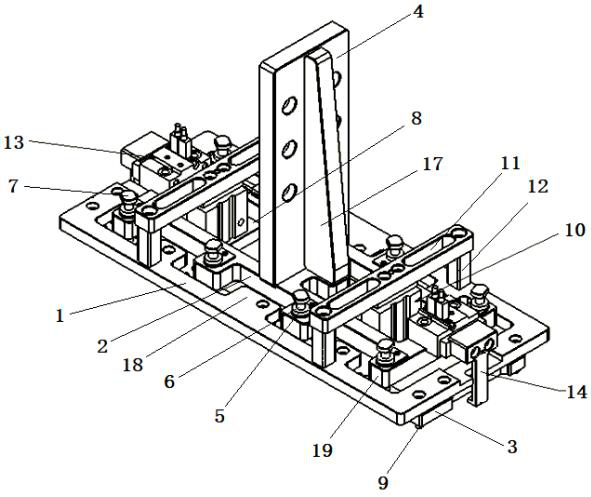

Equipment hoisting structure

ActiveCN112591643AEasy to assemble and disassembleEasy to operatePortable liftingEngineeringIndustrial engineering

The invention discloses an equipment hoisting structure. The equipment hoisting structure comprises a cabinet used for installing equipment, two sets of movable stand column assemblies, an equipment lifting device, two sliding rod assemblies, a top clamping base and a hanging rod assembly are arranged on the cabinet, the top clamping base is installed at the top of the cabinet, the movable stand column assemblies are installed on the top clamping base, the hanging rod assembly is installed on the movable stand column assemblies, one end of the equipment lifting device is connected with the hanging rod assembly, the other end of the equipment lifting device can be connected with the equipment to realize lifting of the equipment, the front ends of the sliding rod assemblies penetrate throughthe movable stand column assemblies, the rear ends of the sliding rod assemblies are fixed in the cabinet, and two L-shaped clamping notches are formed in an equipment hanging frame on the equipment.The structure is simple in structural form, high in expandability and adjustability, and light in weight, is portable, safe, reliable, and is capable of being operated by a single person and installed without auxiliary tools such as a sleeve and a wrench, and rapid disassembly and assembly are realized by adopting the clamping type installation concept.

Owner:NANJING HUASHI ELECTRONICS SCI

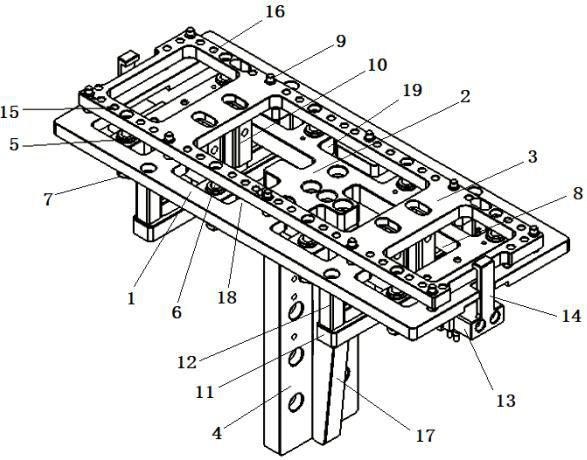

Jig cover plate disassembling and assembling mechanism of chip assembling feeding and discharging machine

PendingCN112382593AQuick changeQuick numberSemiconductor/solid-state device manufacturingStructural engineeringChipset

The invention discloses a jig cover plate disassembling and assembling mechanism of a chip assembly feeding and discharging machine, which comprises an ejector pin mounting plate. A linear bearing mounting plate is arranged in the ejector pin mounting plate, a cover plate fitting plate is arranged below the ejector pin mounting plate, and the linear bearing mounting plate is connected with the cover plate fitting plate through a linear bearing and a guide shaft. The cover plate fitting plate is connected with the ejector pin mounting plate through an ejector pin cylinder and a connecting block. A mechanism mounting plate is arranged in the middle of the linear bearing mounting plate, cover plate clamping jaws are arranged at the left end and the right end of the linear bearing mounting plate through clamping jaw opening and closing air cylinders, and ejector pins are arranged at the bottom of a frame of the ejector pin mounting plate and penetrate through ejector pin through holes in the cover plate attaching plate. And a magnet is arranged at the bottom of the frame of the cover plate fitting plate through an iron mounting groove. The type and number of the magnets can be quicklyreplaced, the suction efficiency of the cover plate is greatly improved, the risk that the cover plate falls off can be avoided through the cover plate clamping jaws on the two sides, reliability is improved, the cover plate can be smoothly separated from the mechanism through the ejector pins at the bottom, and the position of the cover plate is guaranteed.

Owner:苏州茂特斯自动化设备有限公司

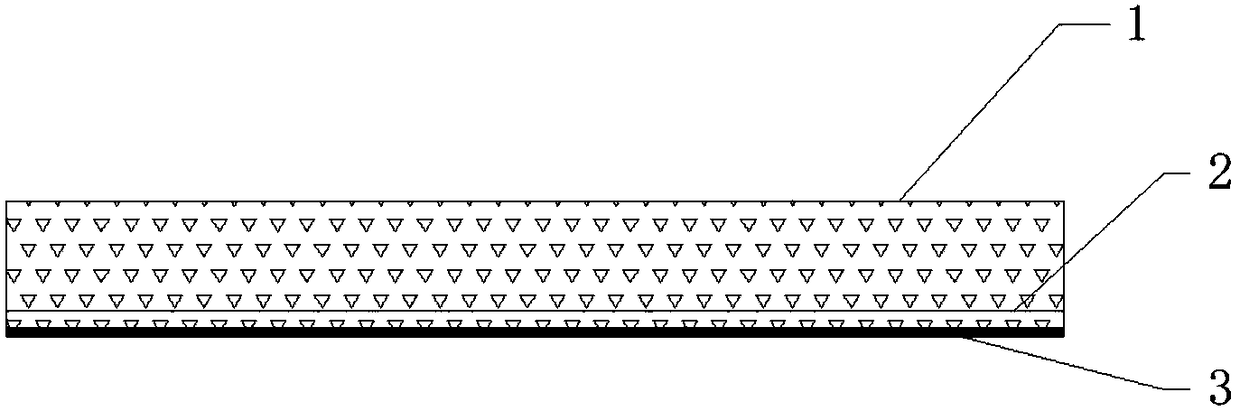

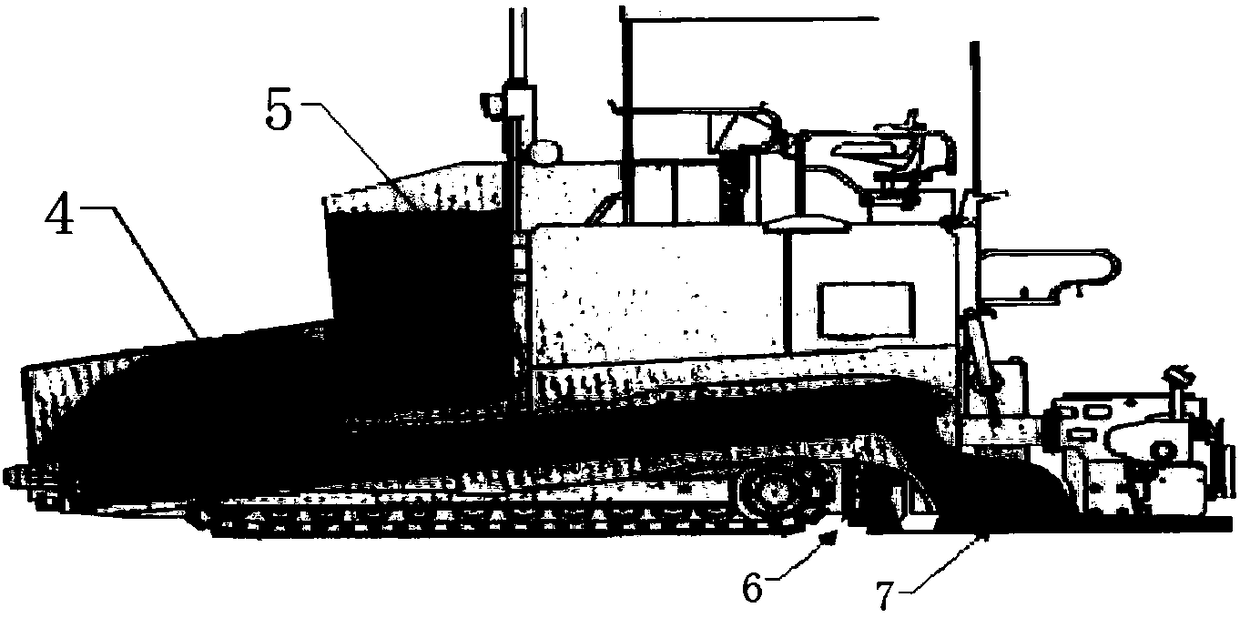

Ultra-thin asphalt wearing layer structure and construction method thereof

PendingCN108221540APoor eliminationEliminate riskIn situ pavingsRoads maintainenceWhole bodyThin layer

The invention discloses an ultra-thin asphalt wearing layer structure. The structure comprises an ultra-thin asphalt wearing layer, a bonding layer and a pavement from the upper part to the lower partin sequence, wherein the bonding layer is arranged in a gap at the lower part of the ultra-thin asphalt wearing layer in an embedded extruding manner; the thickness of the ultra-thin asphalt wearinglayer is 8 to 12 mm. The formed ultra-thin asphalt wearing layer is bonded with the pavement in the lower layer through hot asphalt at the bottom to form a firm whole body, and poor integrality and delaminating risks caused by thin layers are eliminated. The ultra-thin asphalt wearing layer structure belongs to a novel technology for preventive maintenance of asphalt pavements; after an asphalt pavement is subjected to a quantity of years of traffic use, surface function problems, such as degenerative skid resistance function, poor flatness, big noise and slight pit slots, occur, and the structure can rapidly, simply and effectively repair surface functions of the asphalt pavement at low cost, and prevent further occurrence of diseases. The invention further discloses a construction methodof the ultra-thin asphalt wearing layer structure.

Owner:广东华起建设工程有限公司

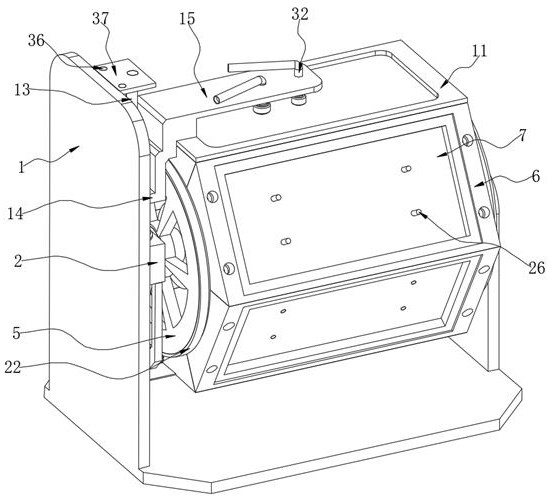

A glue-iron integrated vehicle backlight processing device

The invention discloses a rubber-iron integrated vehicle-mounted backlight processing device, which relates to the technical field of rubber-iron integrated vehicle-mounted backlight processing. A cam column is fixedly arranged on the outer side of the fixed shaft. The positioning and fixing sheet of the present invention not only plays the role of positioning and limiting the position of the back plate into the placement cavity, but also during the injection molding process of the plastic frame, the molten plastic frame solution can wrap multiple sets of positioning and fixing sheets, so that the plastic frame and the The connection between the backplanes is more stable, and there is no risk of falling off. When one set of plastic frames is solidified, multiple sets of lower mold bases rotate at a certain angle. At this time, the cam column will push the ejector rod to push out the backplane and plastic frame together. The placement cavity and injection cavity can not only push out the injection molded back plate and plastic frame, but also make a new set of lower mold bases rotate to the injection molding position, and the overall injection molding efficiency is high.

Owner:惠州市瀚达美电子有限公司

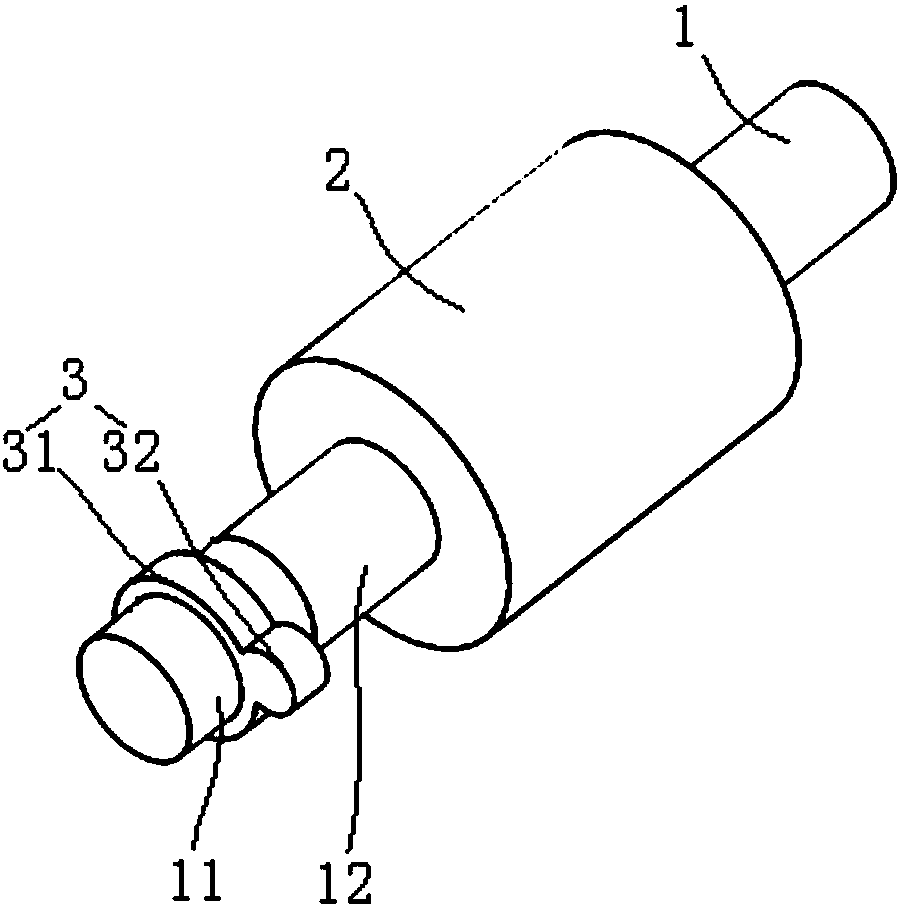

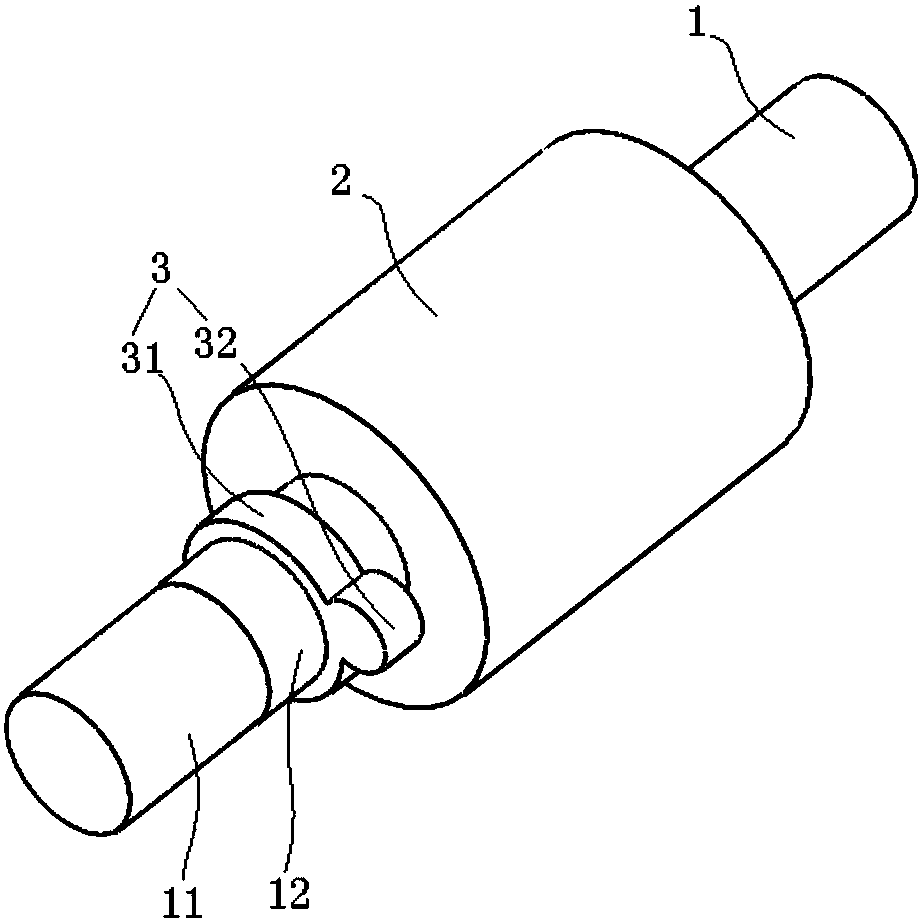

Electric power steering system, motor and rotor dynamic balancing method thereof

ActiveCN110417142ANo risk of sheddingEasy to fixMagnetic circuit rotating partsElectrical steeringElectric power steeringBalancing machine

The invention discloses an electric power steering system, a motor and a rotor dynamic balancing method thereof. The rotor dynamic balancing method comprises the following stepsofS1, determining the unbalanced position of a rotor according to a dynamic balancing machine; S2, pressing a dynamic balancing block onto a first shaft segment of a motor shaft in a sleeving mode; S3, rotating the dynamicbalancing block around the first shaft segment until the dynamic balancing block can balance the dynamic unbalanced position of the rotor; and S4, pressing the dynamic balancing block onto a second shaft segment of the motor shaft in the sleeving mode. The first shaft segment and the second shaft segment have magnitudes of interference relative to the dynamic balancing block, and the magnitude ofinterference of the first shaft segment relative to the dynamic balancing block is smaller than that of the second shaft segment relative to the dynamic balancing block. According to the rotor dynamicbalancing method provided by the invention, the operational reliability of the motor is not damaged in the process of amending dynamic unbalance of the rotor, and the method is simple, convenient andflexible to operate and easy to generalize.

Owner:SAIC MOTOR

Preparation method of electrostatic spinning fibrous membrane

InactiveCN112516806AHigh porosityLarge specific surface areaSemi-permeable membranesElectro-spinningFiberPolymer science

The invention discloses a preparation method of an electrostatic spinning fibrous membrane. The preparation method is characterized by comprising the following steps: (1) preparing a spinning solution, namely dissolving polymer resin, an additive and a mineralizing material into a solvent to prepare the spinning solution; and (2) preparing an electrostatic spinning mineralized nanofiber membrane,namely mounting a substrate on a receiving device of electrostatic spinning equipment, defoaming the spinning solution obtained in the step (1), injecting the defoamed spinning solution into an electrostatic spinning device, carrying out electrostatic spinning and air curing, and carrying out curing forming in a coagulating bath to obtain the mineralized electrostatic spinning nanofiber membrane.The mineralization material is combined with the electrostatic spinning nanofibers, the specific surface area is increased, inflow water can be fully mineralized when passing through the membrane, andthe mineralization efficiency is improved; and the mineralized material is fixed on the nanofibers, so that the risk of falling off is avoided, and the drinking water is safer.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Internal medicine pressing hemostasis device for internal medicine

InactiveCN113616265ANo risk of sheddingEasy to installSurgeryMechanical engineeringBiomedical engineering

The invention relates to the field of medical internal medicine, and particularly relates to an internal medicine pressing hemostasis device for internal medicine. The device comprises a fixing plate, a pressing mechanism and a control mechanism, wherein through holes penetrating through the fixing plate are formed in the two sides of the fixing plate, and tightening belts used for fixing a device body and a human body are fixedly arranged at the two ends of the fixing plate; the pressing mechanism is fixedly installed on the fixing plate, penetrates through the through holes formed in the fixing plate, extends to the inner sides of the tightening belts and is used for conducting pressing hemostasis on a wound; and the control mechanism is connected with the ends, away from the fixing plate, of the tightening belts and used for controlling the tightening belts to be contracted or released. According to the internal medicine pressing hemostasis device for internal medicine, the hemostasis belts can be firmly pressed on the skin, the risk of falling is avoided, installation is easy, and the practicability is high.

Owner:李贤

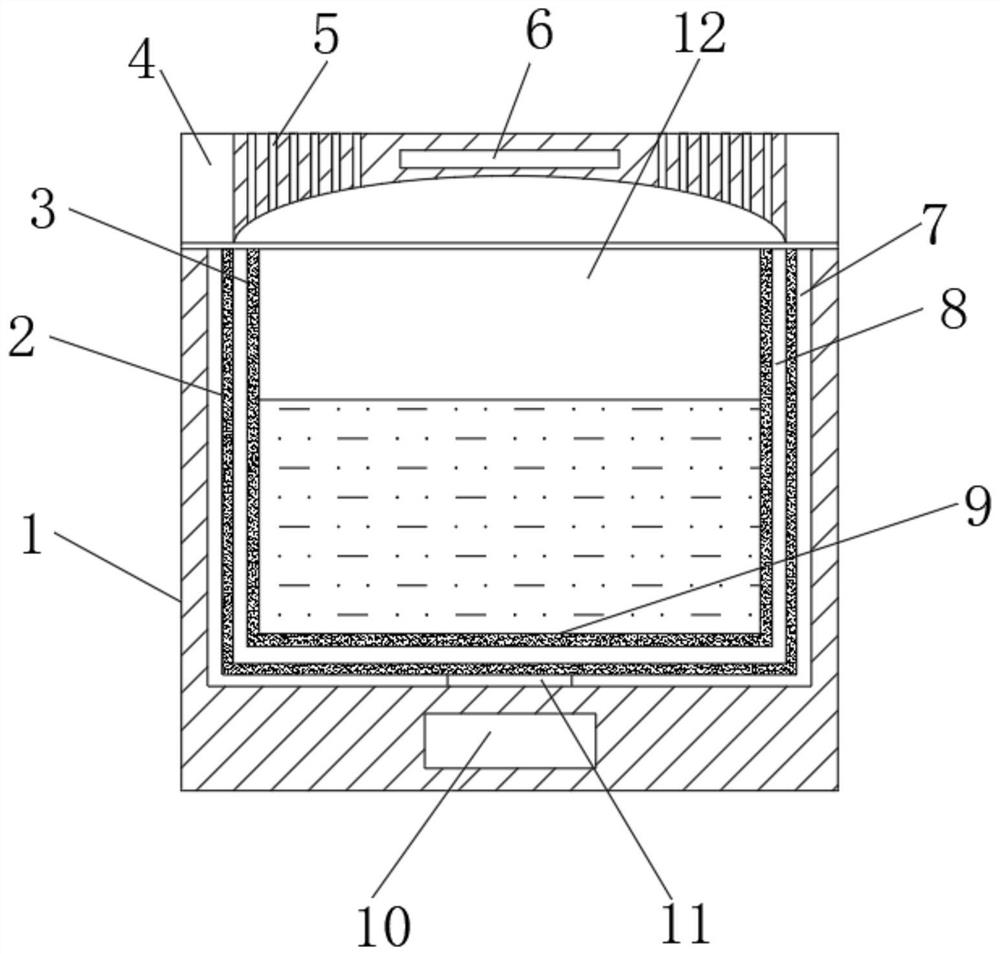

Novel electric cooker and cooking method thereof

InactiveCN111920294AFlexible enoughChewy enoughCooking-vessel materialsWarming devicesRice dishesCooking methods

The invention discloses a novel electric cooker and a cooking method thereof. The invention relates to the technical field of electric cookers. The electric cooker comprises an electric cooker body, wherein the electric cooker body comprises an outer pot, a first cavity is formed in the outer pot, an outer container is mounted in the first cavity, an inner container is mounted in the outer container, a second cavity is formed between the outer container and the inner container, a third cavity is formed in the inner side of the inner container, a humidity sensor is arranged at the bottom of theinner container, an intelligent control circuit board is installed on the inner side of the bottom of the electric cooker body, an electric heating plate rotating disc is connected to the center of the bottom of the first cavity, and an upper cover is connected to the top of the electric cooker body. According to the invention, each rice grain can be uniformly and fully cooked, so that each ricegrain has enough elasticity and chewiness; during cooking, the rice cooker is naturally not stuck, and the risk that a chemical coating falls off does not exist; and in the cooking process, time and electricity are saved, and operation is convenient.

Owner:章小林

an esd surgical tool

ActiveCN110974355BStable excision strippingPrecise excision and strippingEndoscopic cutting instrumentsLesion siteApparatus instruments

The present invention relates to the field of medical devices, in particular to an ESD surgical tool, comprising a needle and a detachable supporting member arranged on the needle, the supporting member is gathered on the outer wall of the needle when the needle is inserted into the needle, and the supporting member is The needle unfolds as it withdraws and remains below the layer to be peeled. The ESD surgical tool provided by the present invention is more convenient and faster to operate than the conventional method of fixing the lesion with titanium clips or separating the lesion layer by injecting physiological saline, without frequent replacement and use of different instruments, which reduces the cost of surgery. Under the support of the support, the lesion can be resected and stripped more stably and accurately, which improves the quality of the operation, helps reduce the postoperative pain of the patient, improves the recovery rate of the patient and reduces the occurrence of complications Rate.

Owner:郑由周

Electric power steering system, motor and rotor dynamic balancing method thereof

ActiveCN110417142BNo risk of sheddingEasy to fixMagnetic circuit rotating partsElectrical steeringElectric power steeringElectric machine

The invention discloses an electric power steering system, a motor and a rotor dynamic balancing method thereof. The rotor dynamic balancing method includes the following steps: S1, determining the unbalanced position of the rotor according to a dynamic balancing testing machine; S2, pressing the dynamic balancing block into the sleeve on the first shaft section of the motor shaft; S3, rotating the dynamic balance weight around the first shaft section to a position where the dynamic balance weight can balance the dynamic unbalance of the rotor; S4, turning the dynamic balance weight The balance weight is pressed onto the second shaft section of the motor shaft. Wherein, both the first shaft section and the second shaft section have interference with respect to the dynamic balance weight, and the interference of the first shaft section with respect to the dynamic balance weight is smaller than that of the second shaft The interference of the segment relative to the dynamic balance block. The rotor dynamic balancing method provided by the invention does not endanger the operation reliability of the motor during the process of correcting the dynamic unbalance of the rotor, and is simple and flexible in operation and easy to popularize.

Owner:SAIC MOTOR

Quick processing method of internal nut stage hole PCB

ActiveCN108617099AIncrease productivityShorten the timePrinted circuit manufactureDrill bitContinuous production

The invention discloses a quick processing method of an internal nut stage hole PCB. The quick processing method comprises the following steps of S1, preparing a base material based on specificationsto complete a cutting operation, and performing manufacturing until electroplating according to the normal processing process of the internal nut stage hole PCB, after a pattern tin electroplating iscompleted, performing a drilling procedure to drill an internal nut stage hole; S2, designing of the internal nut stage hole: measuring the upper diameter, length of inclined edges and height of an internal nut, working out an angle at the bottom of a drill bit, selecting a drill bit according to the upper diameter of the nut and the angle at the bottom of the drill bit, and setting the depth of the internal nut stage hole according to the height of the nut; S3, processing of internal nut stage hole: selecting a drill with depth finding and finding functions to complete drilling according to the designed parameters of the internal nut stage hole designed in the step S2; and S4, after drilling of the internal nut stage hole is completed, performing an electroplating etching procedure to perform continuous production to prepare a finished product. The quick processing method has the advantages of improvement of production efficiency, lowering of production cost, improvement of processingprecision and the like.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

Floor structure and combined structure residential system with same

PendingCN111173122AEasy constructionReduce on-site workloadClimate change adaptationFloorsFloor slabArchitectural engineering

The invention relates to a floor structure and a combined structure residential system with the same. The floor structure comprises floor slabs and cantilever slabs; a steel reinforcement framework isarranged in the space between every two adjacent floor slabs; floor ring ribs are sequentially and vertically fixed at intervals along the length direction of the floor slab splicing surface at the bottom of an installation notch; each steel reinforcement framework comprises a connecting horizontal rib arranged along the length direction of the splicing surface and a plurality of connecting ringribs fixed to the connecting horizontal rib; the connecting ring ribs are parallel to the floor ring ribs; concrete is poured into the connecting ring rib sand the floor ring ribs; and the floor slabsand the cantilever slabs are connected through cold-hot-proof bridge nodes. According to the structure, the on-site construction speed is greatly improved, the construction difficulty is reduced, theconstruction process is simple, the four sides of a prefabricated plate are free of reinforcement rib exposing, the automatic batch production of factories is facilitated, and the production cost isgreatly reduced; the stress performance is good, the integrity is strong, and the structural integrity in the assembly integral mode is strong; and on-site assembly construction is realized, the construction efficiency is high, the self weight and the concrete consumption of a floor are greatly reduced by the multi-rib structure, and the cost is reduced.

Owner:SHENZHEN YJY BUILDING TECH +2

Manufacturing method of high-wear-resistance rubber steel wire hose and mold forming device

PendingCN113211836AHigh bonding strengthImprove performanceNon-macromolecular adhesive additivesTubular articlesMoulding deviceManufacturing engineering

The invention relates to the field of mine pipelines, and discloses a manufacturing method of a high-wear-resistance rubber steel wire hose and a mold forming device. The method comprises the following steps: A, preprocessing a film; B, calendering the film; C, carrying out rubber material splicing pipe body forming; D, forming a pipe orifice check ring; E, carrying out product vulcanization; and F, demolding and polishing to obtain a finished product. According to the manufacturing method, the thickness of each layer can be effectively controlled, so that easy-to-fail points are controlled in a targeted manner, and the wear resistance and the stability of the hose are improved.

Owner:JIANGXI NAIPU MINING MASCH CO LTD

A kind of manufacturing method of multi-purpose zinc-clad steel

The invention belongs to the technical field of electric power, and particularly relates to a manufacturing method of multi-purpose zinc clad steel. The manufacturing method comprises the following steps that chemical-free environment-friendly treatment is performed on the surfaces of steel wires; surface cleaning treatment is performed on the steel wires by the aid of a belt sander; the cleaned steel wires are heated by an intermediate-frequency furnace, then the steel wires and two zinc rods enter a continuous cladding machine simultaneously for extruding, the zinc clad steel is obtained, the heating temperature of the intermediate-frequency furnace is controlled to range from 200 DEG C to 250 DEG C, an extruding mold and a guiding mold are assembled on the cladding machine according tothe product requirements, the nasal fossa sizes for mold assembly are controlled to range from 3 mm to 6 mm according to the diameters of the steel wires, the mold cavity temperatures are controlled to range from 150 DEG C to 250 DEG C, the rotating speed of an extruding wheel is controlled to range from 3 rpm to 7 rpm, and the extruding speed is controlled to range from 70 m / min to 120 m / min; andcomposite metal drawing is performed on zinc clad steel busbars after cladding. According to the method, the whole production process is free of chemical pollution, the method is different from all existing zinc clad steel technologies, and flexible production is realized.

Owner:HENAN TONG CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com