Wind driven generator blade deicing equipment and wind driven generator blade deicing method

A technology of wind generators and blades, which is applied in the direction of wind power generators, monitoring of wind power generators, control of wind power generators, etc., and can solve problems such as complex blade structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

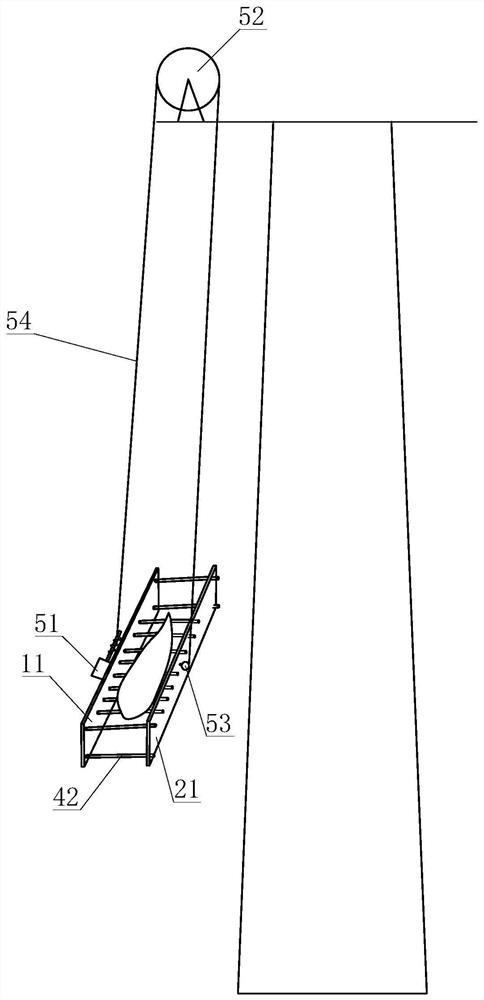

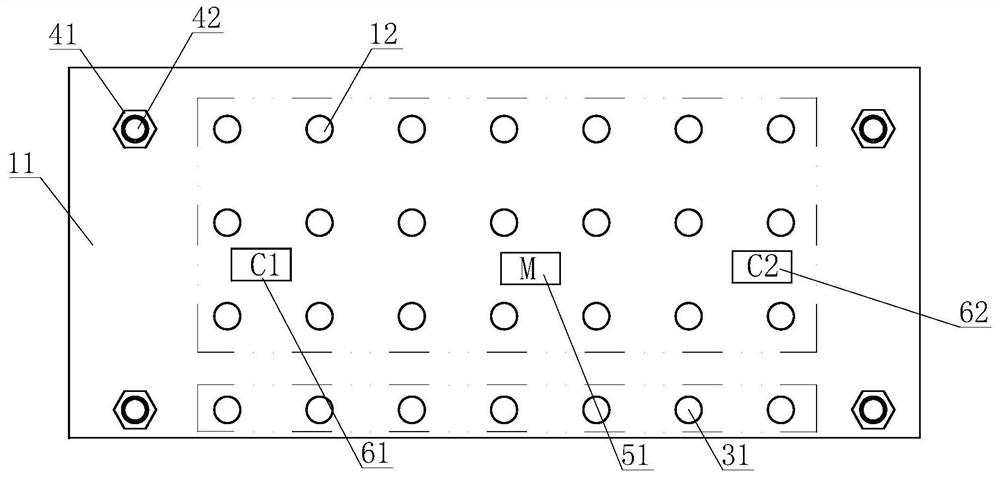

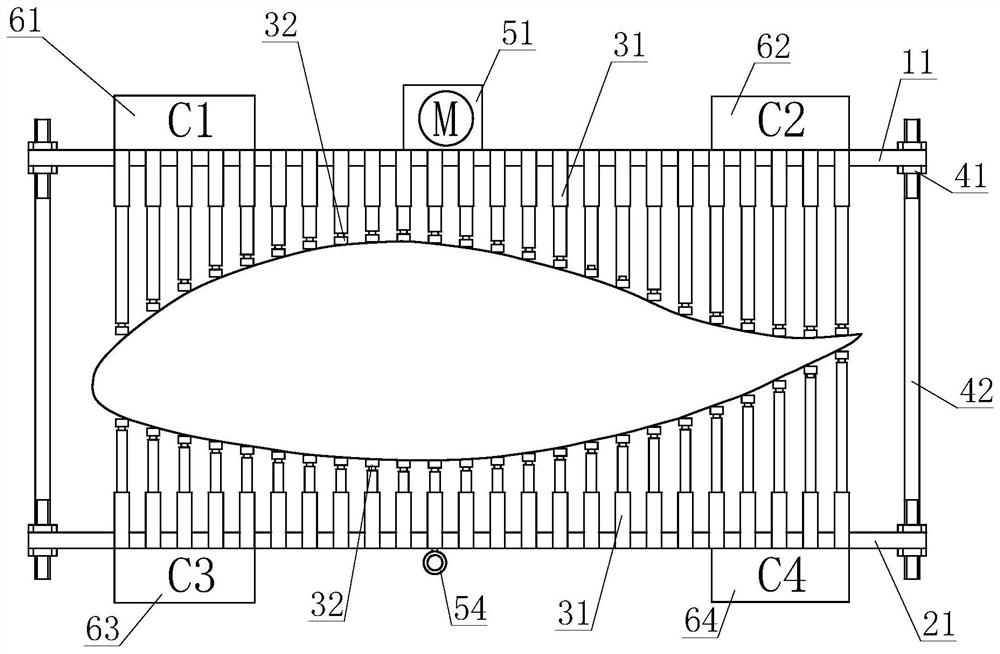

[0054] like Figure 1-Figure 4 As shown, the deicing equipment for wind turbine blades provided in this embodiment includes a deicing device, which is used for detachable connection with the wind turbine blades, and the deicing device has a mechanical deicing head of the first category and a mechanical deicing head of the second category. De-icing head, the first type of mechanical de-icing head is used to install on the windward side of the wind turbine blade, the second type of mechanical de-icing head is used to be installed on the leeward side of the wind turbine blade, the first type of mechanical de-icing The head is connected to the output end of the first type of deicing drive, the second type of mechanical deicing head is connected to the output end of the second type of deicing drive, the fixed end of the first type of deicing device is connected to the second type of deicing drive The fixed end of the device is relatively fixedly arranged.

[0055] By setting the f...

Embodiment 2

[0076] like Figure 5 shown, refer to Figure 1-Figure 4 The method for deicing wind turbine blades provided in this embodiment uses any of the wind turbine blade deicing equipment described above, including a positioning step, a control step, a deicing step, and a lifting step:

[0077] In the positioning step, the positioning drive device drives the positioning sensor to contact the surface of the wind turbine blade, and transmits a contact signal to the control system; specifically, the positioning hydraulic cylinder 31 drives the pressure sensor 32 to move toward the wind turbine blade, and the pressure sensor located at the front end 32 will be in contact with the blades of the wind power generator first, and when the pressure value borne by the pressure sensor 32 reaches the set value, it means that the blades have been clamped, and the positioning driving device stops working.

[0078] In the control step, the control system receives the signal of the positioning senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com