Ultra-thin asphalt wearing layer structure and construction method thereof

A construction method and wear layer technology, which can be applied to cohesive pavement paved on site, roads, road repairs, etc., can solve the problems of poor overall performance of the road, poor adhesion than hot asphalt, and no time to volatilize, so as to eliminate poor integrity , low-cost repair, and the effect of disease prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

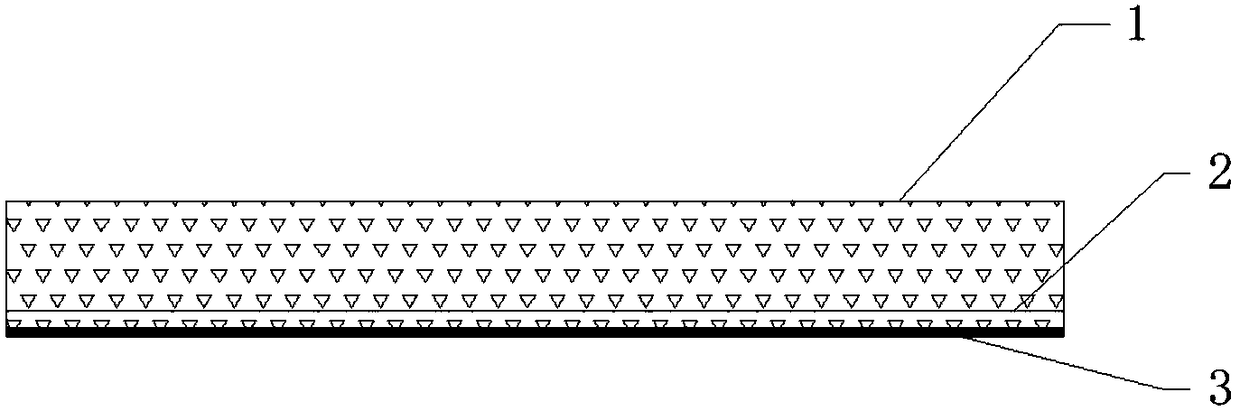

[0029] An embodiment of the ultra-thin asphalt wearing layer structure described in the present invention, the ultra-thin asphalt wearing layer structure described in this embodiment is as attached figure 1 As shown, it includes an ultra-thin asphalt wearing layer 1, an adhesive layer 2, and a pavement 3 from top to bottom. The thickness of the adhesive layer 2 is 8 mm, and the thickness of the adhesive layer 2 is 3 mm, wherein the adhesive layer 2 is a continuous-phase thermal asphalt film, and the continuous-phase thermal asphalt film bonds the ultra-thin asphalt wearing layer 1 and the road surface 3 into a whole.

[0030] A construction method of the ultra-thin asphalt wear layer structure described in this embodiment is as follows:

[0031] Step 1: Preparation Process

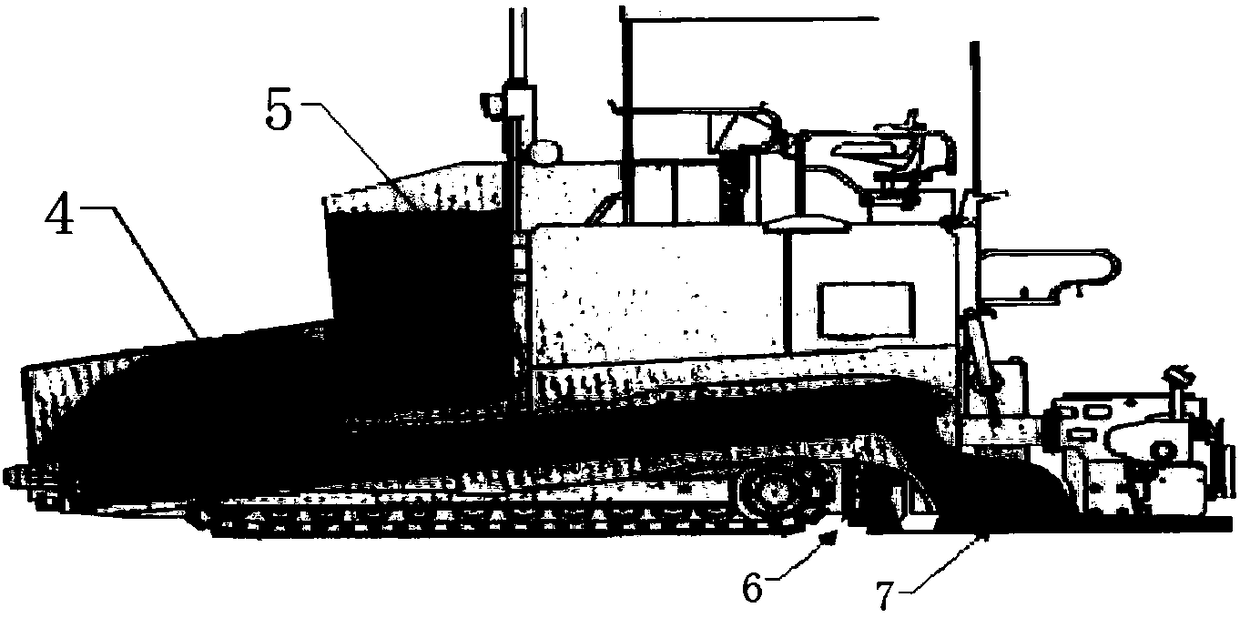

[0032] 1. Heat the hot asphalt to 130°C with a kinematic viscosity of 2.3 Pa.s to reach a sprayable viscosity, and then inject it into the hot asphalt tank 5 of the integrated paver, wherein the hot aspha...

Embodiment 2

[0039] An embodiment of the ultra-thin asphalt wearing layer structure described in the present invention, the ultra-thin asphalt wearing layer structure described in this embodiment is as attached figure 1 As shown, it includes an ultra-thin asphalt wearing layer 1, an adhesive layer 2, and a pavement 3 from top to bottom. The thickness of the adhesive layer 2 is 12 mm, and the thickness of the adhesive layer 2 is 5 mm, wherein the adhesive layer 2 is a continuous-phase thermal asphalt film, and the continuous-phase thermal asphalt film bonds the ultra-thin asphalt wearing layer 1 and the road surface 3 into a whole.

[0040] A construction method of the ultra-thin asphalt wear layer structure described in this embodiment is as follows:

[0041] Step 1: Preparation Process

[0042] 1. Heat the hot asphalt to 180°C with a kinematic viscosity of 0.8 Pa.s to reach a sprayable viscosity, and then inject it into the hot asphalt tank 5 of the integrated paver, wherein the hot asph...

Embodiment 3

[0049] An embodiment of the ultra-thin asphalt wearing layer structure described in the present invention, the ultra-thin asphalt wearing layer structure described in this embodiment is as attached figure 1 As shown, it includes an ultra-thin asphalt wearing layer 1, an adhesive layer 2, and a pavement 3 from top to bottom. The thickness of the adhesive layer 2 is 10 mm, and the thickness of the adhesive layer 2 is 4 mm, wherein the adhesive layer 2 is a continuous-phase thermal asphalt film, and the continuous-phase thermal asphalt film bonds the ultra-thin asphalt wearing layer 1 and the road surface 3 into a whole.

[0050] A construction method of the ultra-thin asphalt wear layer structure described in this embodiment is as follows:

[0051] Step 1: Preparation Process

[0052] 1. Heat the hot asphalt to 160°C with a kinematic viscosity of 1.2 Pa.s to reach a sprayable viscosity, and then inject it into the hot asphalt tank 5 of the integrated paver, wherein the hot asph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com