Heat dissipation device and fastening structure thereof

A heat dissipation device and fastener technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of unfavorable disassembly and installation, detachment, flake ring falling off, etc., and achieve the effect of easy installation and disassembly, compact and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

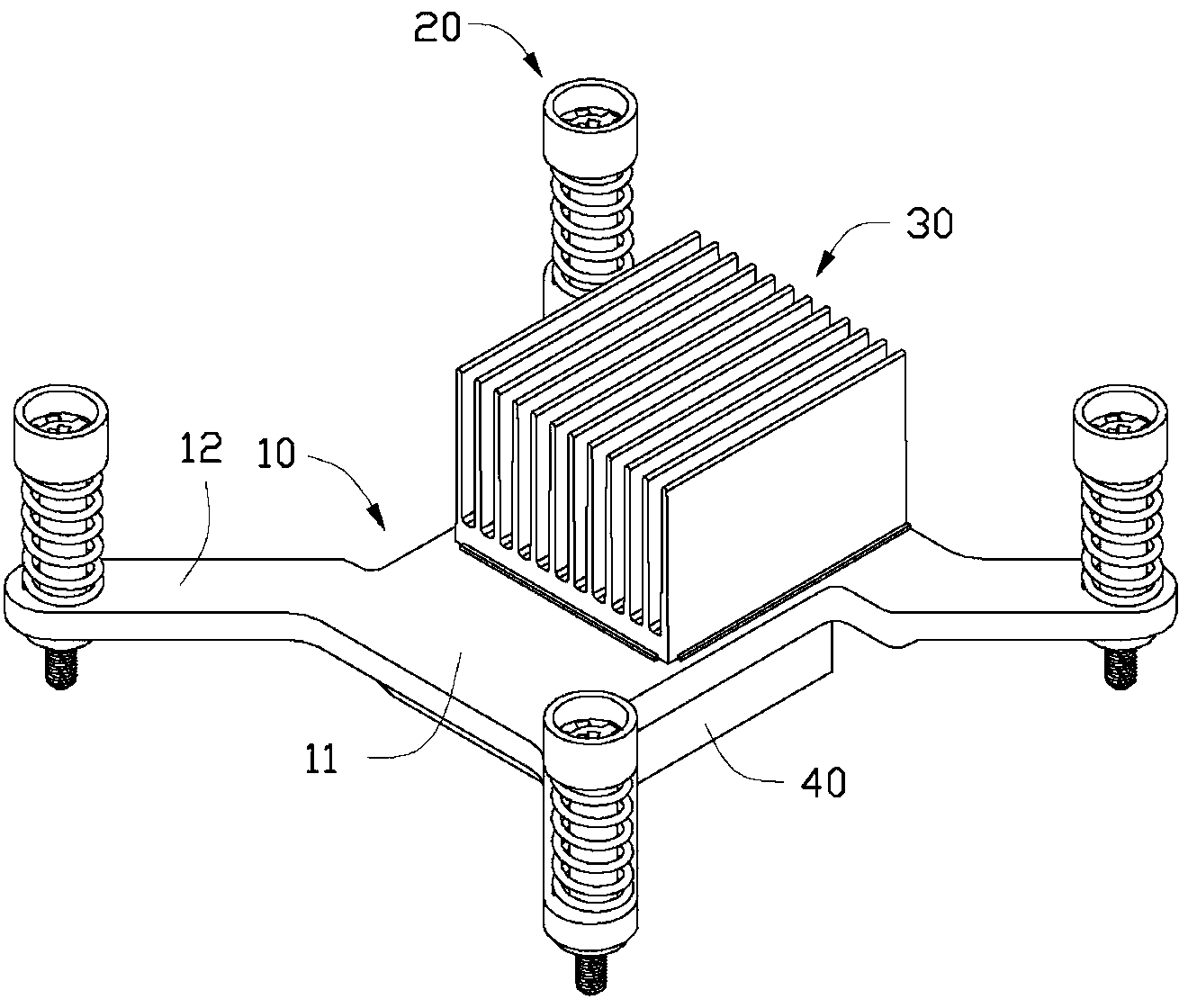

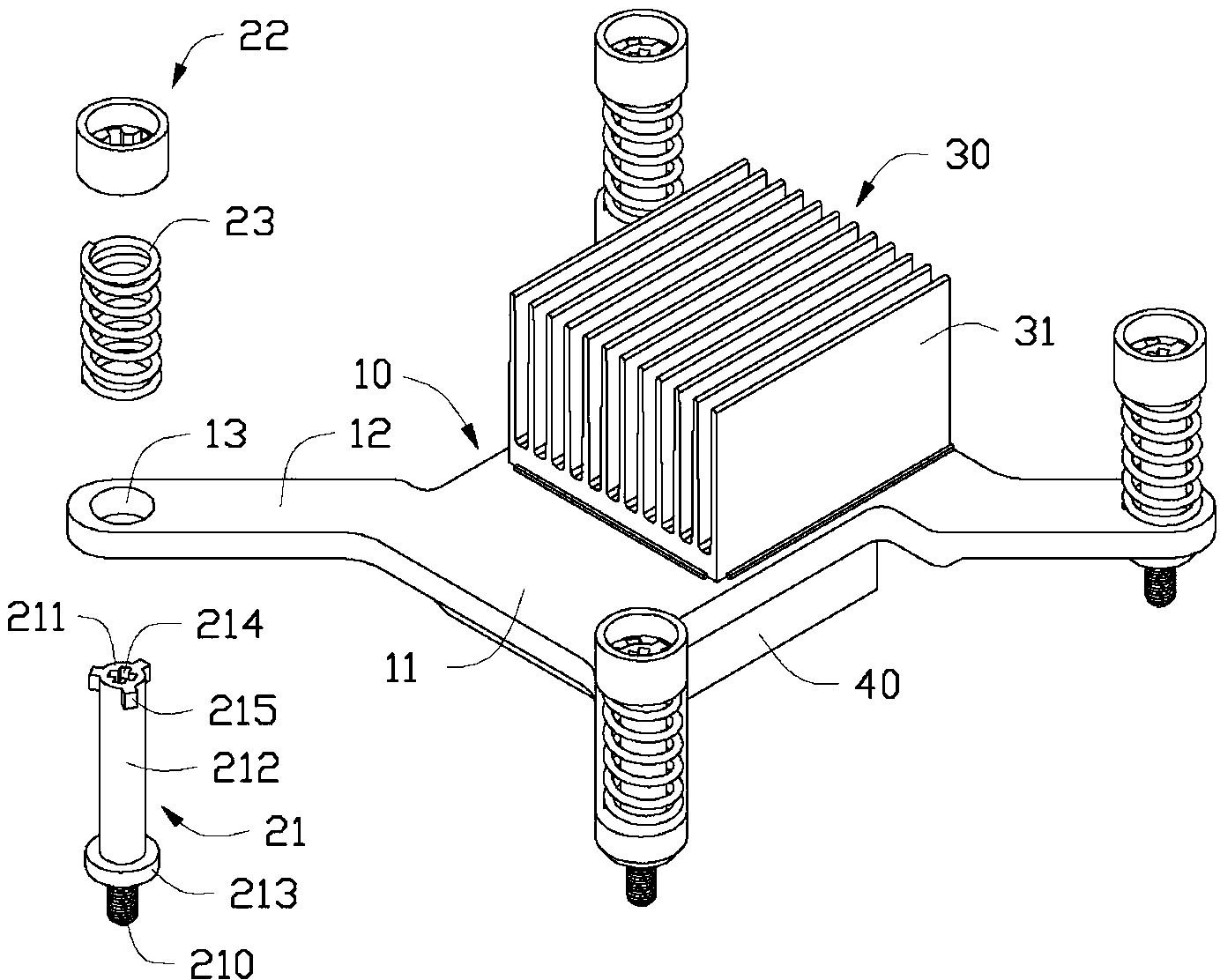

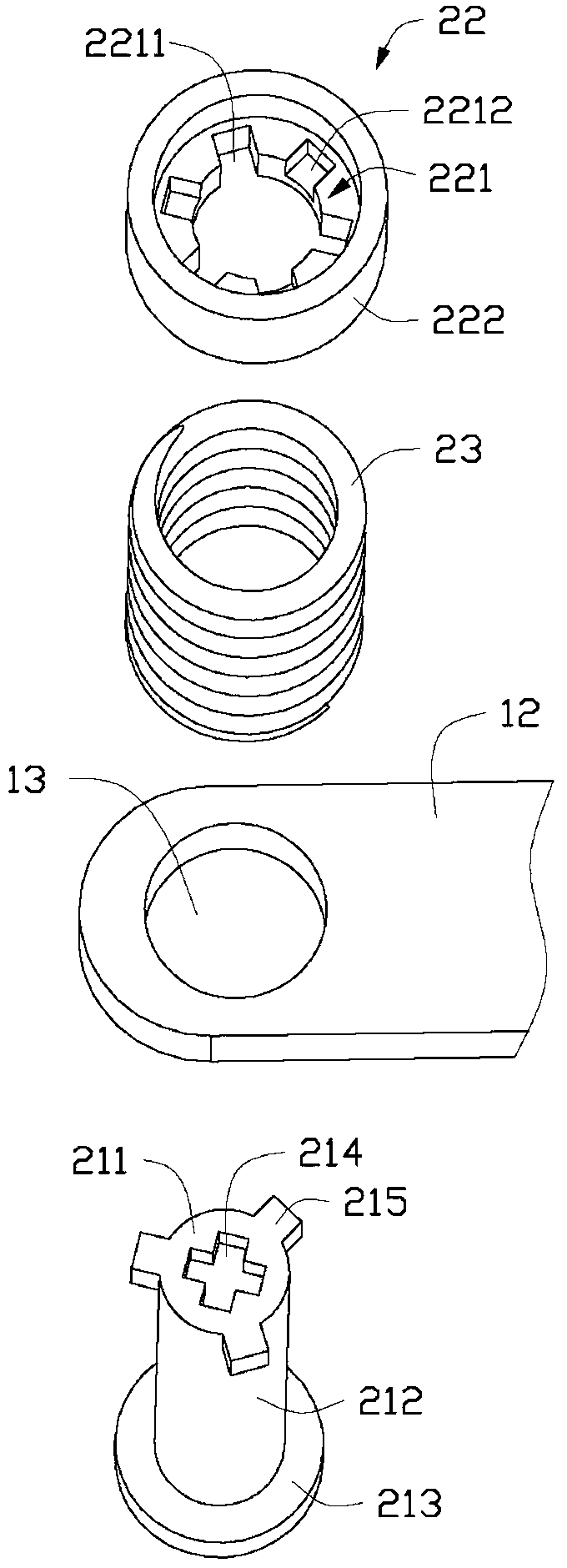

[0016] see figure 1 and figure 2 An embodiment of the heat dissipation device of the present invention includes a heat sink set 30 , a base plate 10 carrying the heat sink set 30 , and a fastening structure 20 disposed on the base plate 10 .

[0017] The base plate 10 includes a body portion 11 and four lugs 12 extending obliquely outward from the four top corners of the body portion 11. The body portion 11 is in a square shape, and the bottom surface of the body portion 11 is attached to the heat conduction element 40. The top surface of the main body 11 is connected to the heat sink set 30; the four lugs 12 are roughly elongated and each lug 12 is provided with a perforation 13, and the perforation 13 is circular to match the buckle structure 20 penetration.

[0018] The heat sink set 30 is disposed on the body portion 11 of the substrate 10 and is formed by a plurality of heat sinks 31 for dissipating heat from the heat conducting element 40 . The heat dissipation devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com