Irregular fracture surface vibration and noise reduction damping steel rail

A technology of vibration reduction and noise reduction and steel rails, which is applied in the field of rail transit, can solve problems such as unimaginable consequences, high cost, and the inability to use high-speed railway rails to reduce vibration and noise, and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

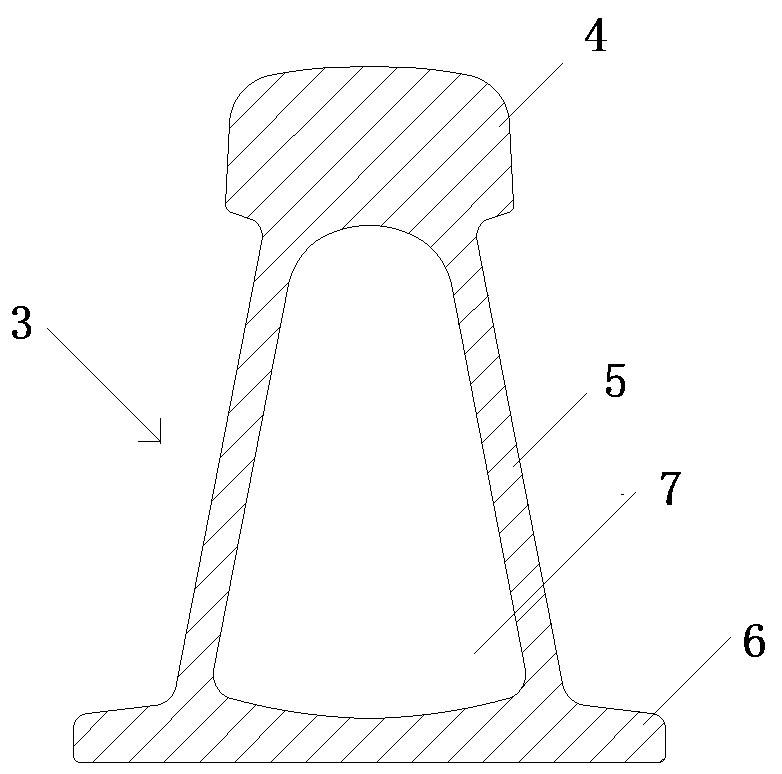

[0021] Example: such as Figure 1-6 As shown, this embodiment specifically relates to a vibration-reducing and noise-reducing damping rail with a special-shaped section. The damping rail 3 has a hollow cavity 7 inside, and the cavity 7 is filled with an intracavity damping material 8, so that no additional damping material is required. The unique restraint and protection structure, while achieving effective vibration and noise reduction, reduces the construction cost and difficulty, and is suitable for various types of running tracks.

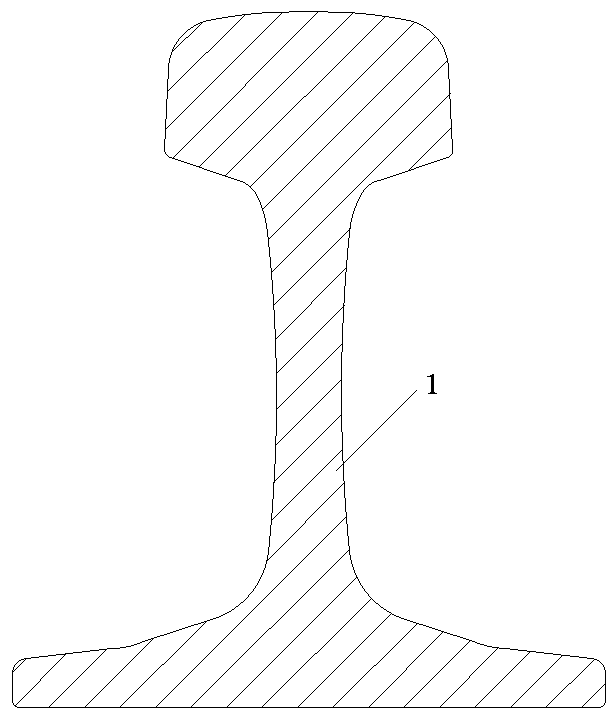

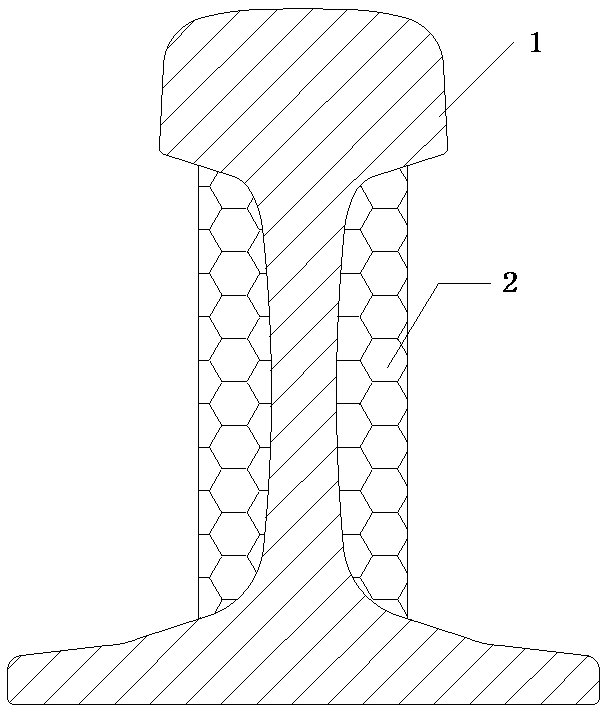

[0022] like Figure 1-2 As shown, in order to reduce the vibration and noise of the rail, the method of pasting the rail waist damping material 2 on both sides of the rail waist of the existing rail 1 is currently used. However, the surface of the rail waist damping material 2 needs to be provided with another constraining layer And the protective layer, the cost is high, and the strength, reliability, durability, etc. of the paste are difficu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com