Lead overhead apparatus

A technology of lead wires and wire clamps, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems that the distance between two adjacent wire clamps is not easy to determine, reduce labor intensity, and easily fall off, etc., achieve good locking effect of lead wires and reduce labor intensity , The effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

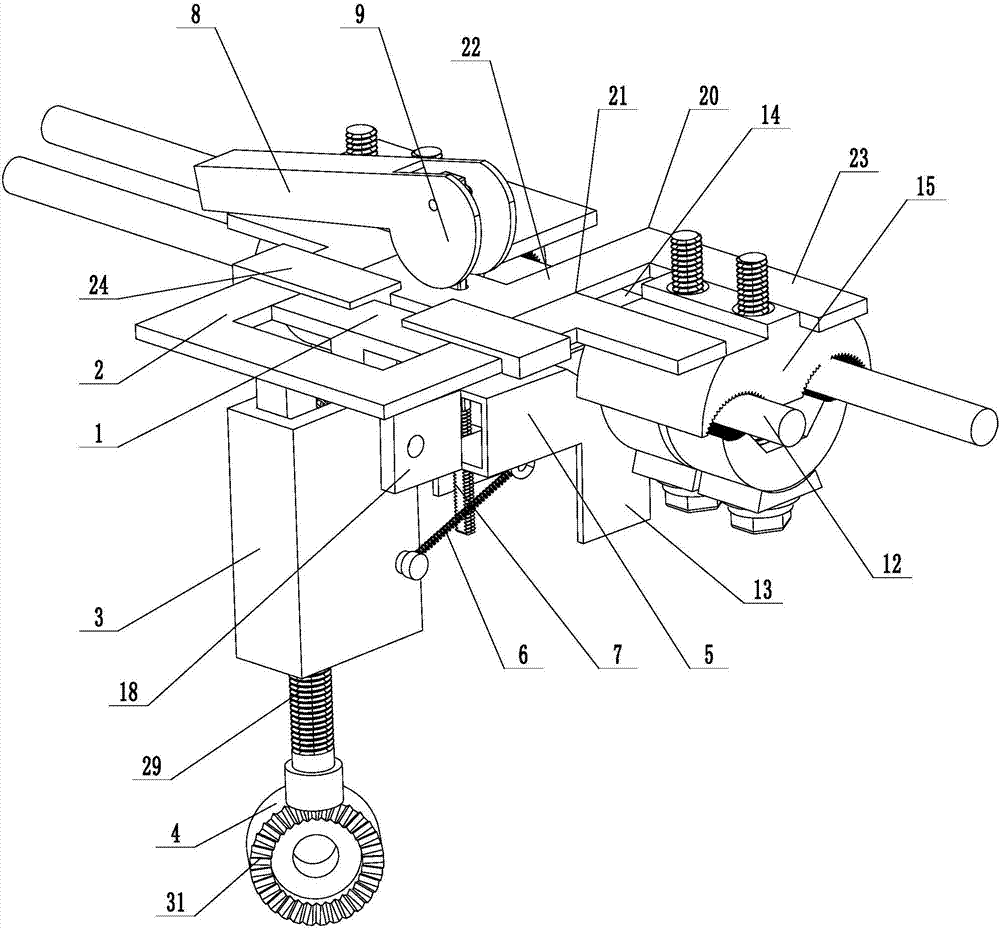

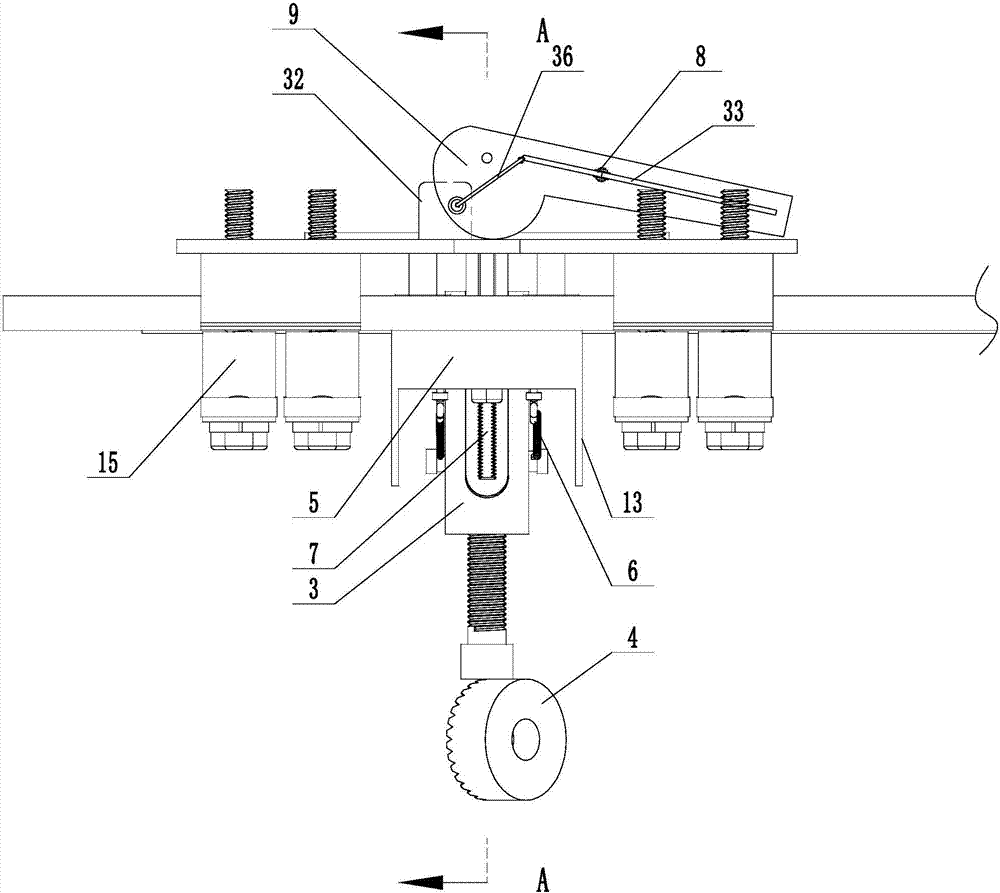

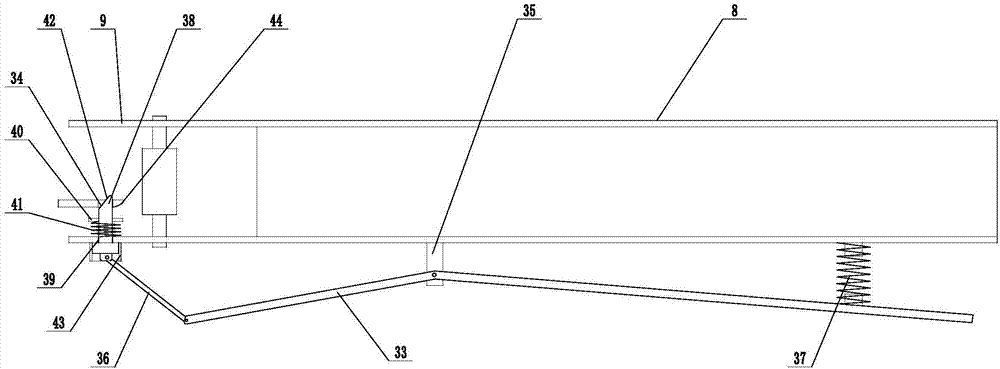

[0023] Embodiment: a kind of lead wire overhead device (see attached Figures 1 to 5), including a fixed splint 1, a push splint 2, a mounting seat 3 connected to the fixed splint, an insulating rod connector 4 connected to the mounting seat, the push splint can be slidably installed on the fixed splint, and a press seat 5 is rotatably connected to the mounting seat. The return spring 6 is connected between the seat and the mounting seat, the locking rod 7 is connected to the pressure seat, the locking rod runs through the fixed splint, the end of the locking rod is rotated and connected to the handle 8, and an eccentric lock is provided on the handle and the connecting end of the locking rod. The tight disk 9, the eccentric locking disk abuts against the fixed splint, and a limit locking mechanism is connected between the eccentric locking disk and the fixed splint. The cross-section of the handle is a rectangular frame structure, two eccentric locking discs are arranged oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com