Patents

Literature

39results about How to "Solid structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

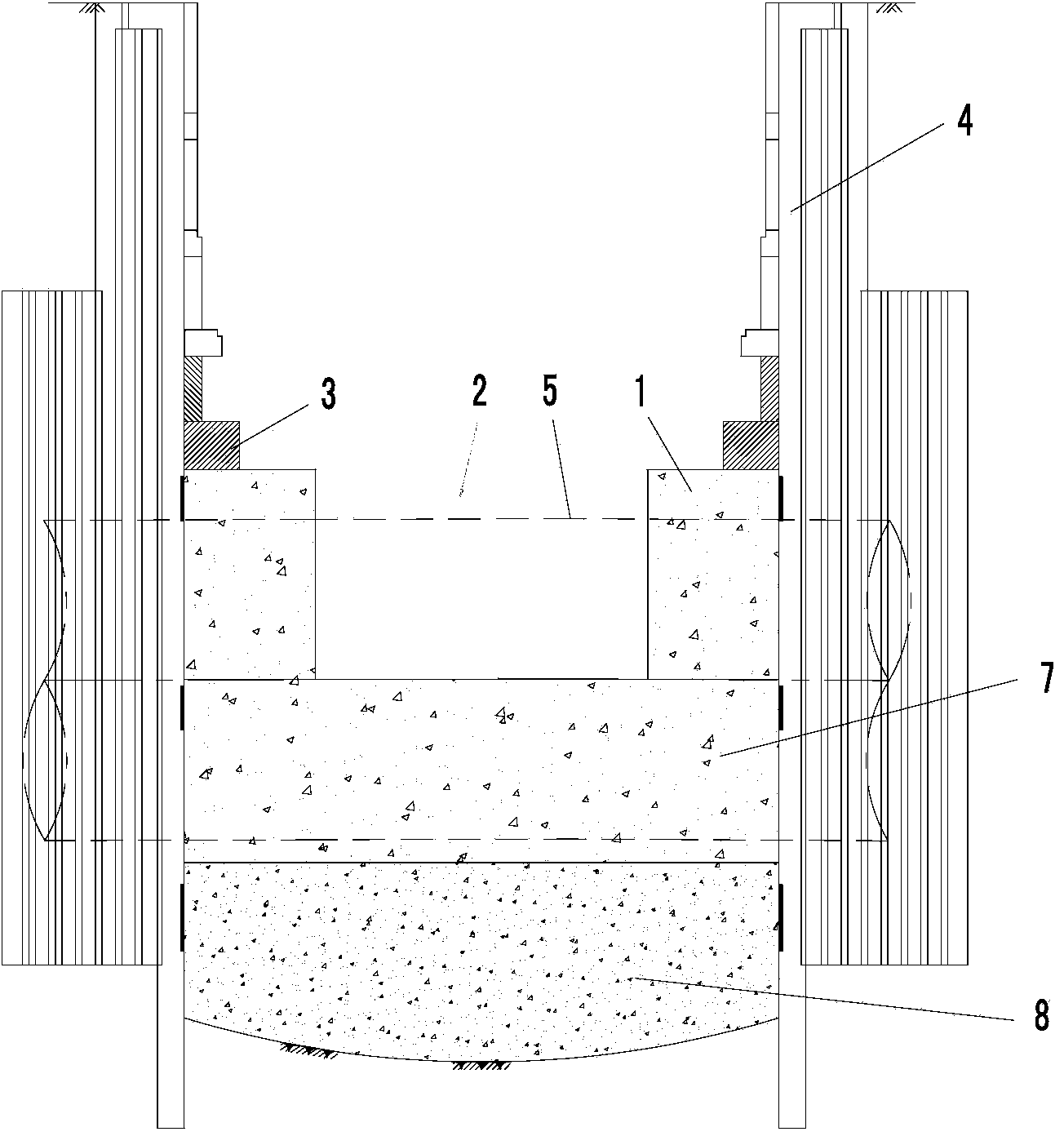

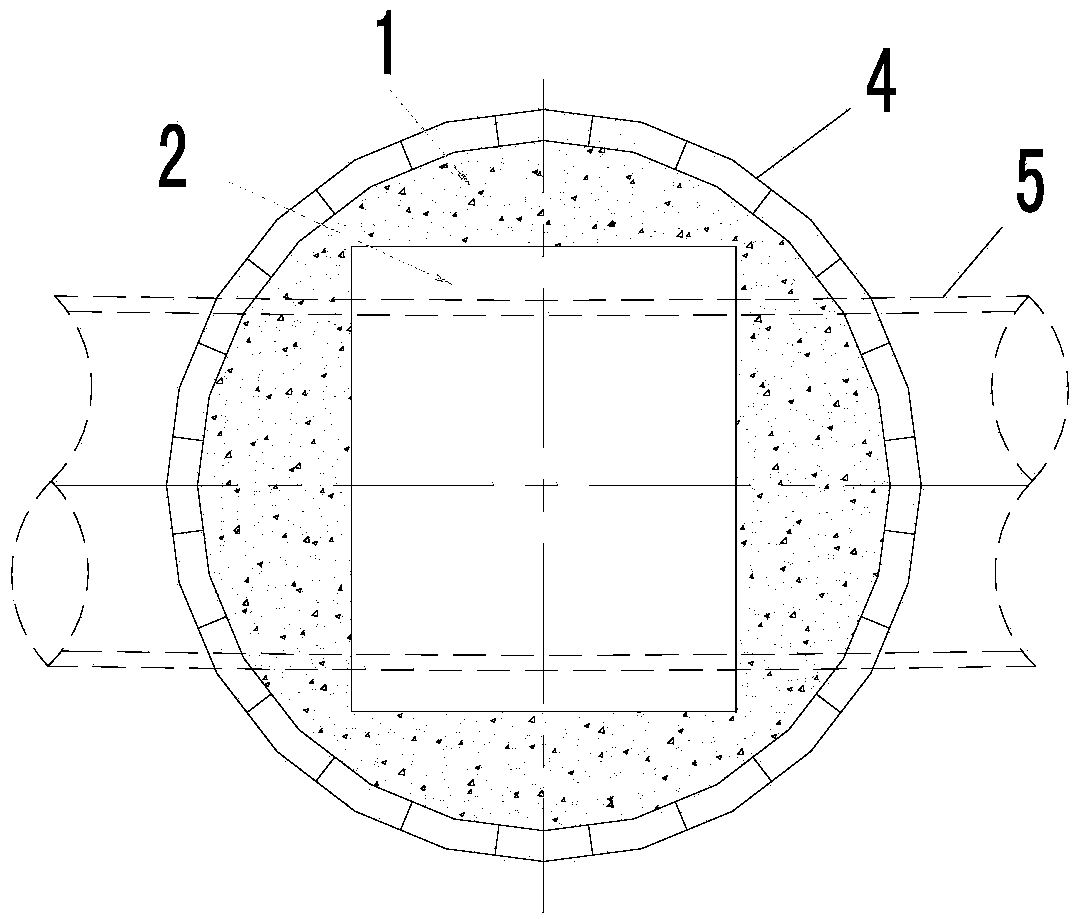

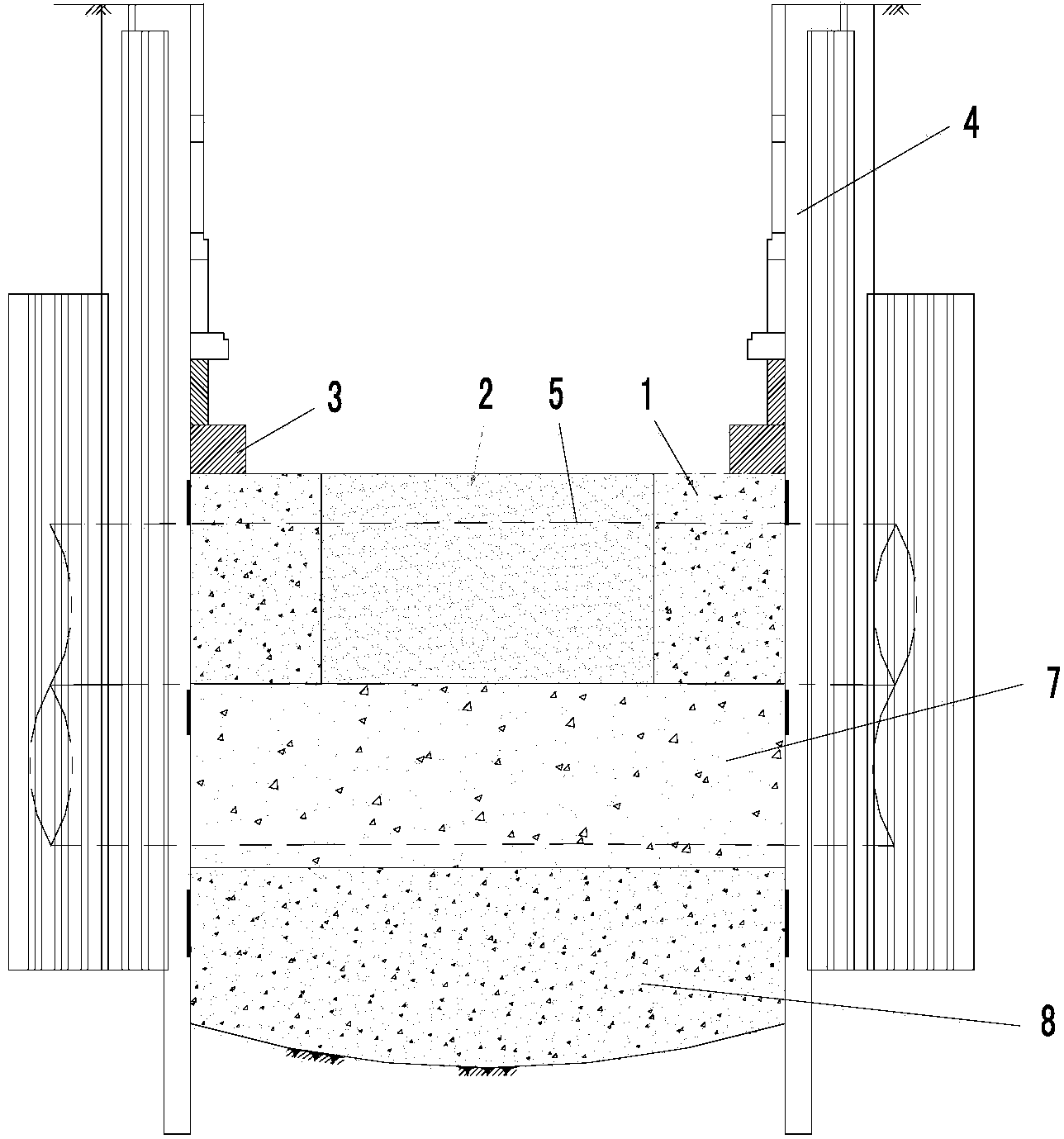

Air shaft shield crossing construction method

ActiveCN104389608AShorten the construction periodSolid structureUnderground chambersTunnel liningArchitectural engineeringTower

The invention discloses an air shaft shield crossing construction method. The construction sequence of firstly performing shield crossing and then performing air tower main body structure construction in the prior art is regulated into the construction sequence of firstly constructing a partial main body structure of an air tower and then performing the shield crossing, so that the air tower construction is not influenced by the shield construction progress; the construction period can be effectively shortened; the smooth proceeding of the later-stage construction is ensured; and the structure is also very firm, reliable and safe.

Owner:CCCC TUNNEL ENG

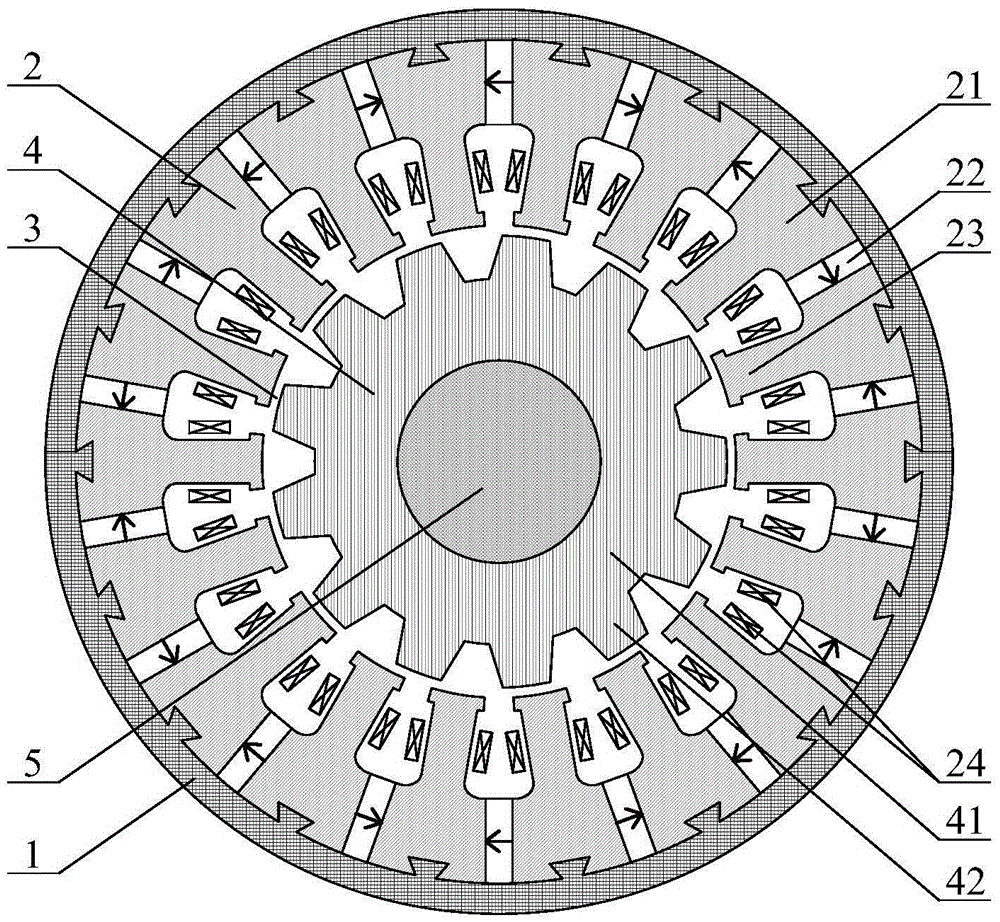

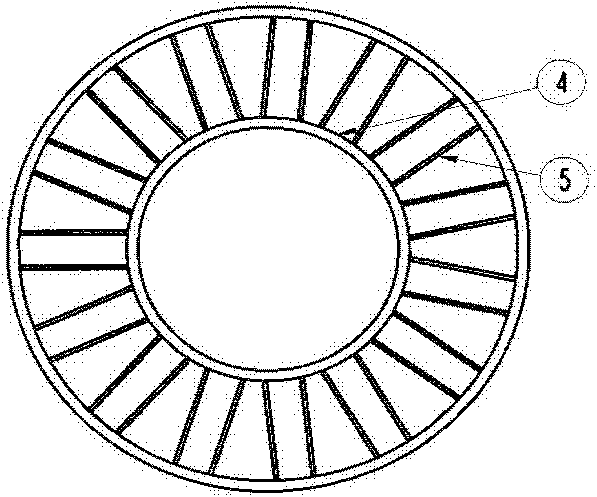

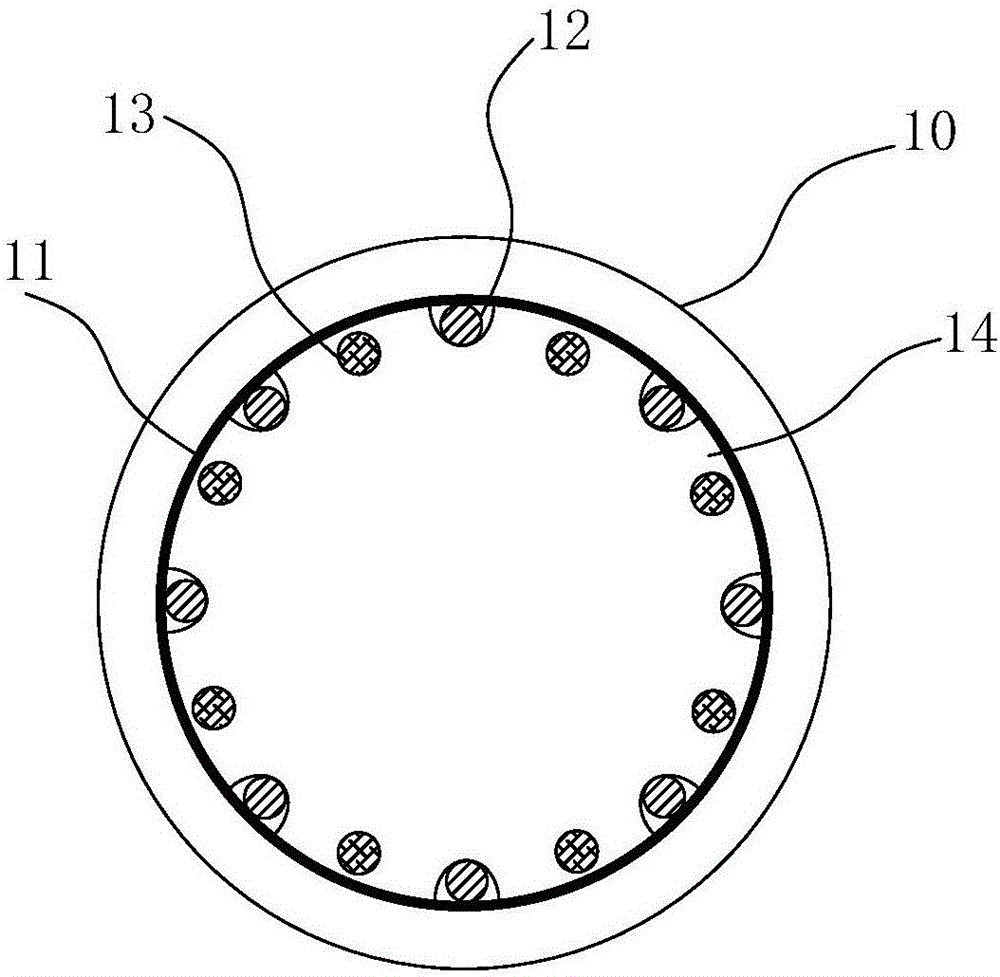

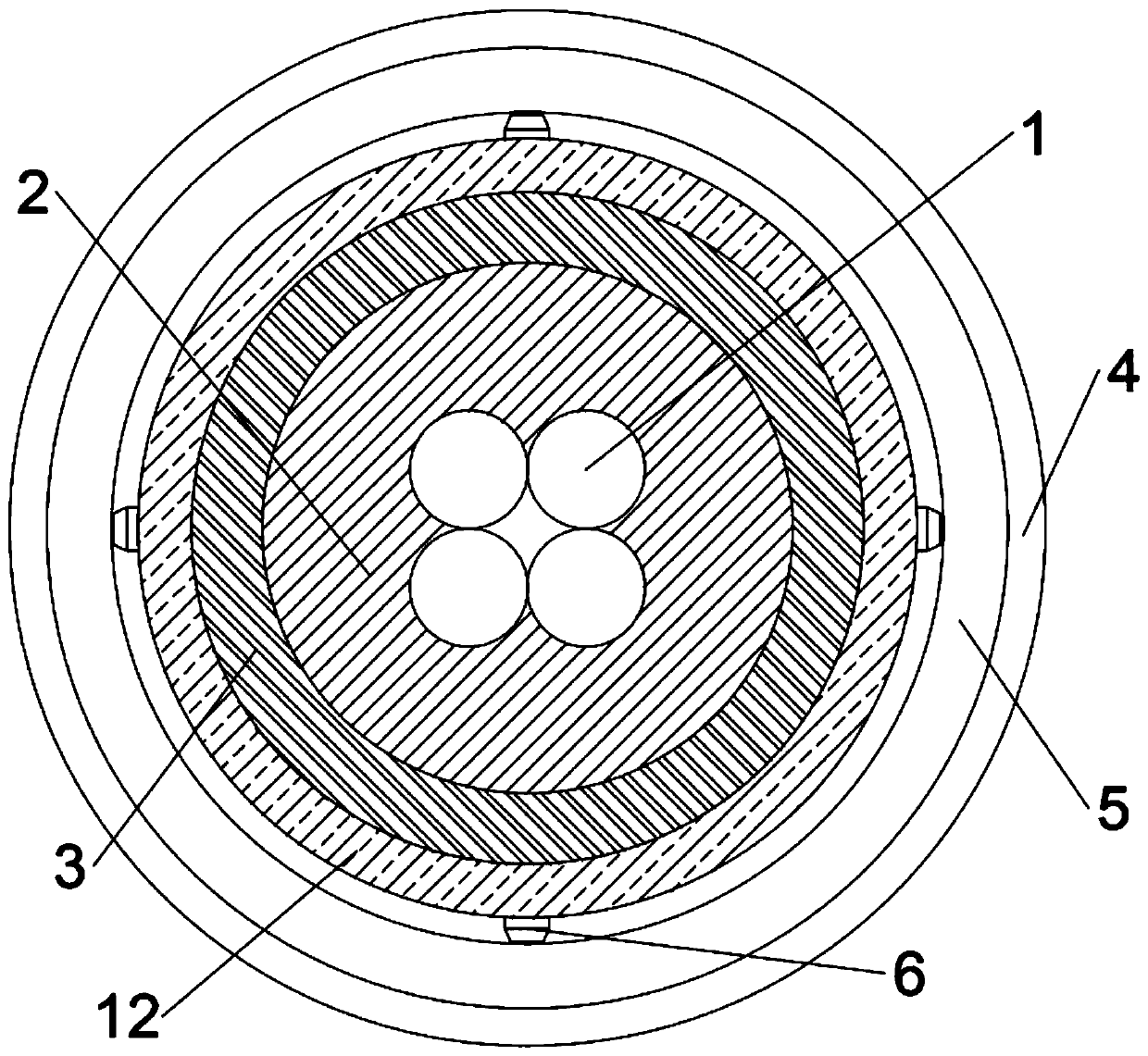

Stator permanent magnet type field modulation motor

InactiveCN105071562ASolid structureEasy to dissipate heatMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsStator

The invention discloses a stator permanent magnet type field modulation motor. The motor comprises a housing, a stator, an air gap, a rotor and a rotating shaft from outside to inside. The housing, the stator, the air gap, the rotor and the rotating shaft are coaxially arranged. The stator is fixed in the housing through a dovetail groove. The air gap is arranged between the stator and the rotor. The rotor is fixed outside the rotating shaft. The stator comprises a plurality of stator iron cores which are arranged at equal intervals along the circumference, stator permanent magnets embedded between adjacent stator iron cores, stator teeth extending out of the inner circumferences of the stator iron cores, and multiphase symmetric armature windings embedded between adjacent stator teeth. The rotor comprises an annular rotor iron core, and a plurality of rotor salient poles extending out of the outer peripheries of the rotor iron cores. According to the invention, the armature windings and the permanent magnets are arranged on the stator side; the air-gap magnetic permeance change caused by the rotor salient pole is utilized to modulate the stator magnetic field, so as to achieve electromechanical energy conversion; and the stator permanent magnet type field modulation motor is characterized in that the rotor structure is simple, the mechanical reliability is high, the heat radiation of the permanent magnets is easy, and the processing and manufacturing is convenient.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Intelligent spiral lifting tower three-dimensional garage

The invention provides an intellectualization spiral lifting tower type stereo garage, belonging to traffic facilities, the stereo garage is provided with a barrel garage body, a vehicle inlet door is disposed at the most lower part of the garage body, the internal of the garage body is provided with a plurality of parking layers in a layered arrangement, each parking layer is provided with a plurality of parking positions in a radial arrangement, the center of the garage body is provided with a vehicle lifting mechanism lifting the vehicle to the parking layer, each parking position is provided with a vehicle parking mechanism. The stereo garage is characterized in that, the vehicle lifting mechanism is provided with a lifting leading screw, a lifting platform is in a rotating sleeve on the lifting leading screw, the lifting platform is fixedly provided with a platform guide rail used for fixing the vehicle during lifting, the lower end of the lifting leading screw is connected with a power mechanism driving rotation of the lifting leading screw; and the vehicle parking mechanism comprises a fixed support body capable of moving on a platform guide rail, and two sides of one end of the fixed support body are fixedly provided with a clamping disc used for clamping the vehicle. The intellectualization spiral lifting tower type stereo garage is not only advantaged by firm structure, and few fault, but also advantaged by greatly improving efficiency and precision, what's more, a hydraulic cylinder is adopted to clamp the vehicle, facilitating intellectualization control, and developing a new way for development of the field.

Owner:李忠礼

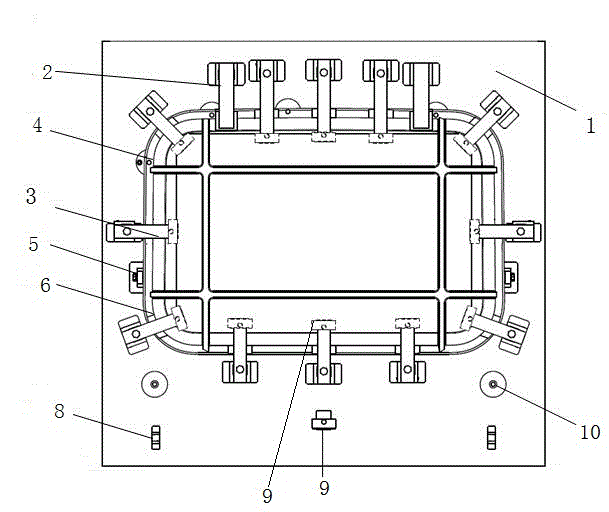

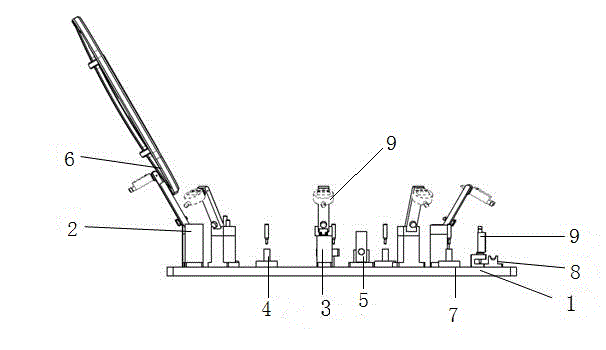

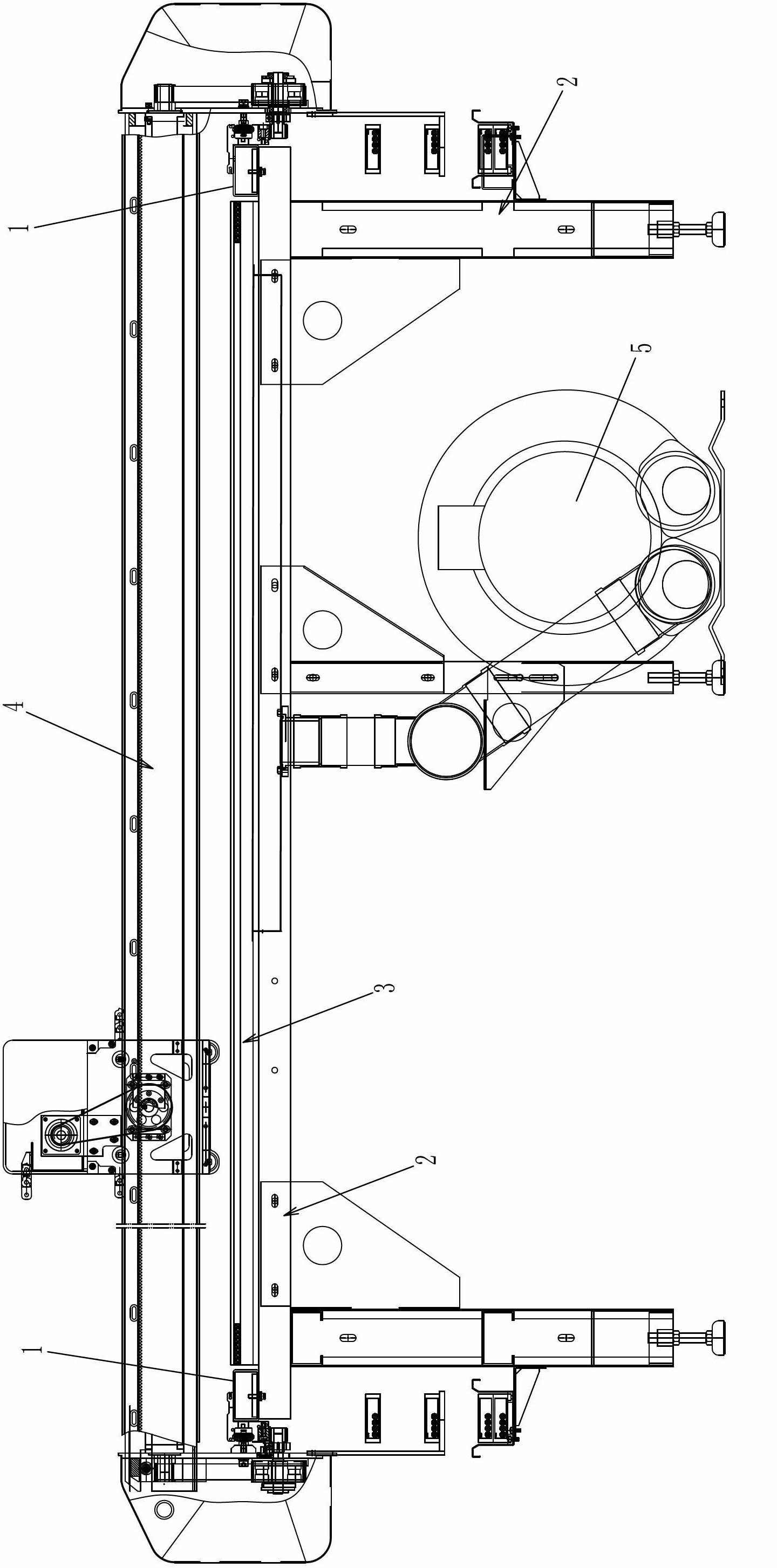

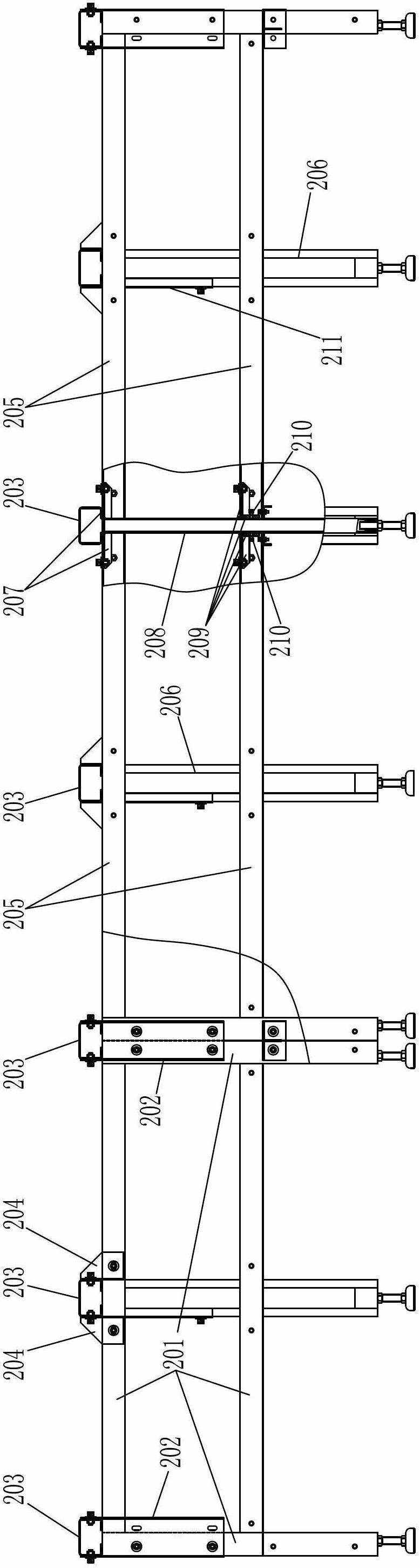

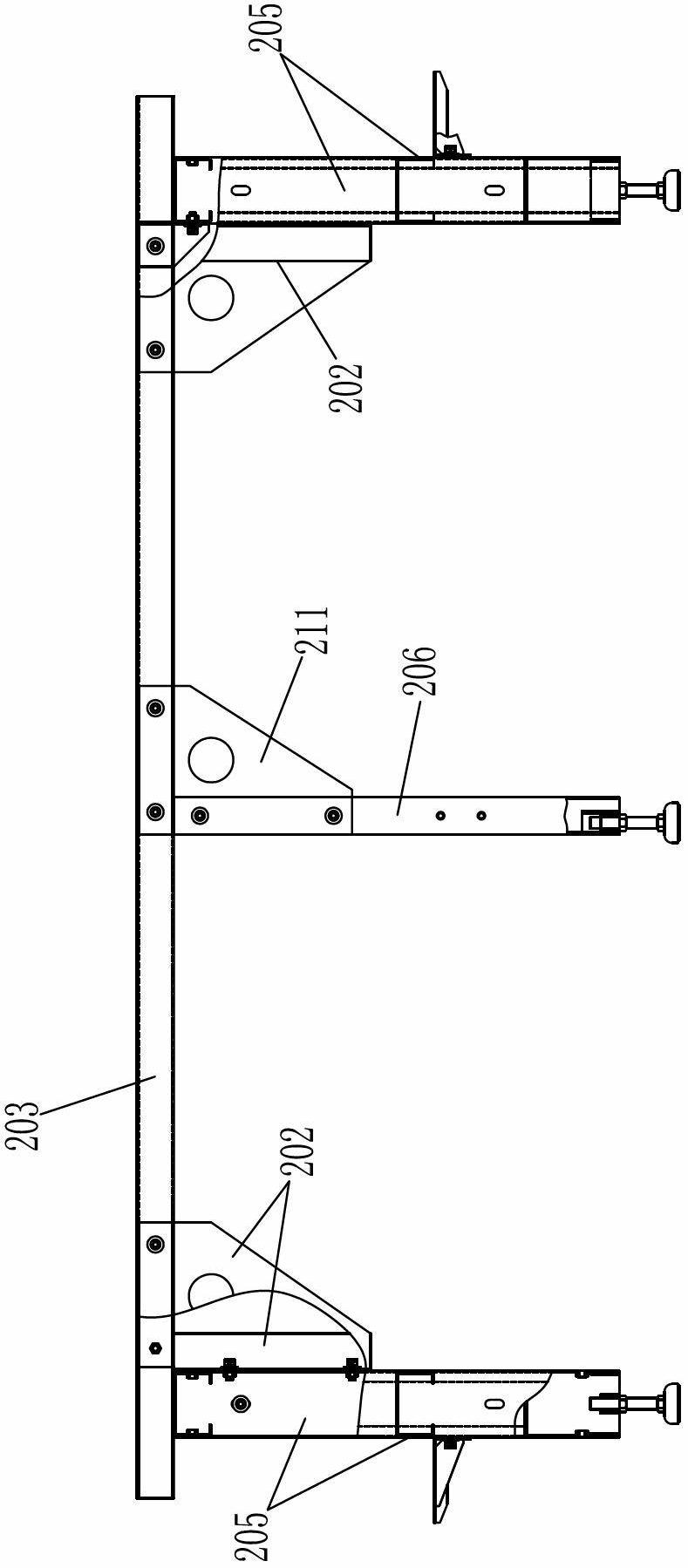

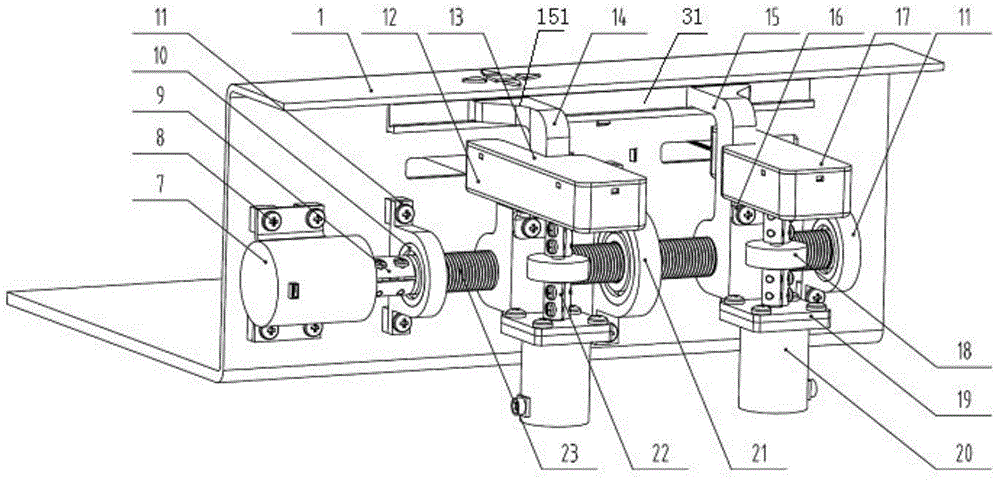

Detection device for profile and hole location of car sunroof

ActiveCN104390546ASolid structurePrevent displacement and movementMechanical counters/curvatures measurementsCushionEngineering

The invention discloses a detection device for the profile and the hole location of a car sunroof. The device comprises a bottom plate on which an overturning mechanism is arranged; the car sunroof is mounted on the overturning mechanism; glass profile difference detecting mechanisms are arranged like a rectangle on the bottom plate; a main positioning pin is arranged beside the glass profile difference detecting mechanism at the left side; profile cushion blocks are arranged inside the glass profile difference detecting mechanism, and while profile blocks are arranged on the glass profile difference detecting mechanism; a hole location detecting pin is arranged on the glass profile difference detecting mechanism at the lower side; a draining port detecting block is arranged at the lower side of the bottom plate; when in use, the glass profile difference detecting mechanisms are opened, the profile blocks are overturned to reach the opening position, then main, secondary positioning pins and the hole location detecting pin are drawn out, the sunroof is positioned to the detecting device, then the main and secondary positioning pins are inserted, and finally the profile difference and the hole location can be detected. The detection device is simple in structure, convenient to mount and dismount, and is able to effectively improve the detection efficiency.

Owner:WUHU MOTIONTEC AUTOMOTIVE

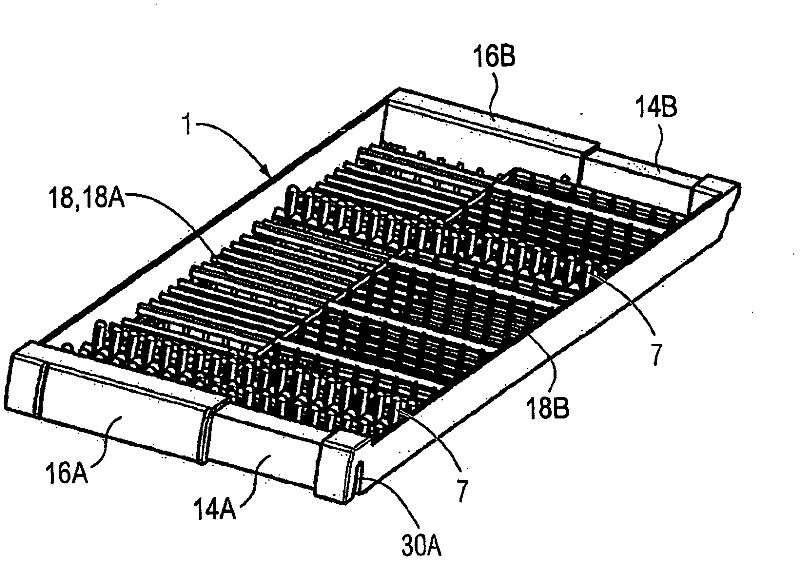

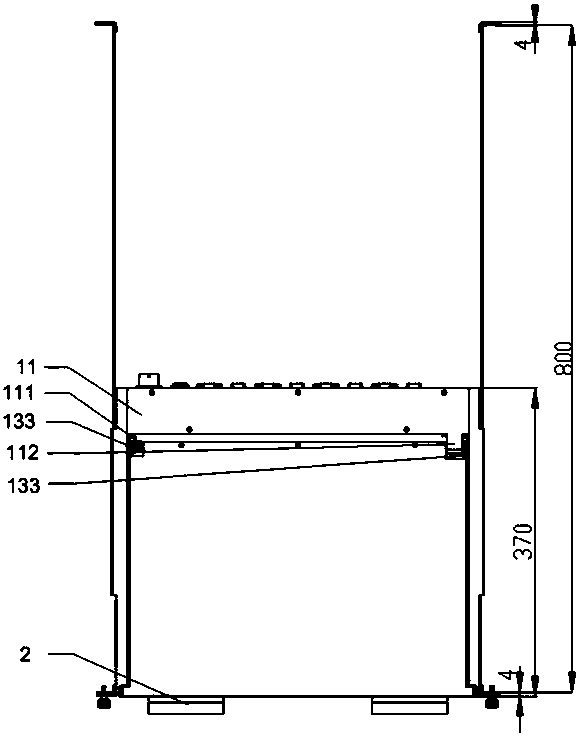

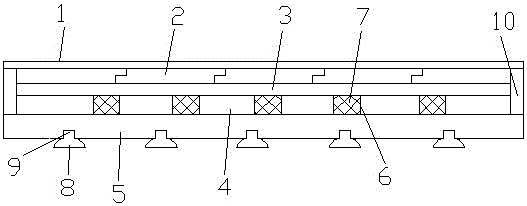

Cutting bed

The invention discloses a cutting bed frame, which comprises a first row of bracket body components, a second row of bracket body components and a plurality of cross rod components, wherein the first row of bracket body components and the second row of bracket body components are formed by parallelly connecting a plurality of bracket bodies; the first row of bracket body components and the second row of bracket body components are arranged in parallel and are connected into a whole through a plurality of cross rod components; a plurality of cross rod components are arranged in parallel and are perpendicular to the two rows of bracket body components; each cross rod component comprises a cross rod; binding faces of bracket legs of two parallel and adjacent bracket bodies are fixedly connected through a fastener; parallel side faces of the bracket legs of two parallel and adjacent bracket bodies are fixedly connected through a first connecting piece; and the first connecting piece is fixedly connected with the cross rod in the cross rod component which is arranged at the joint of the two bracket bodies. By the cutting bed frame, shell fabrics with an ultra-large format can be cut, and the invention has the characteristics that the frame is simple in structure, convenient to splice, convenient to integrally level, high in integral rigidity after being fastened and the like.

Owner:HANGZHOU ECHO SCI TECH

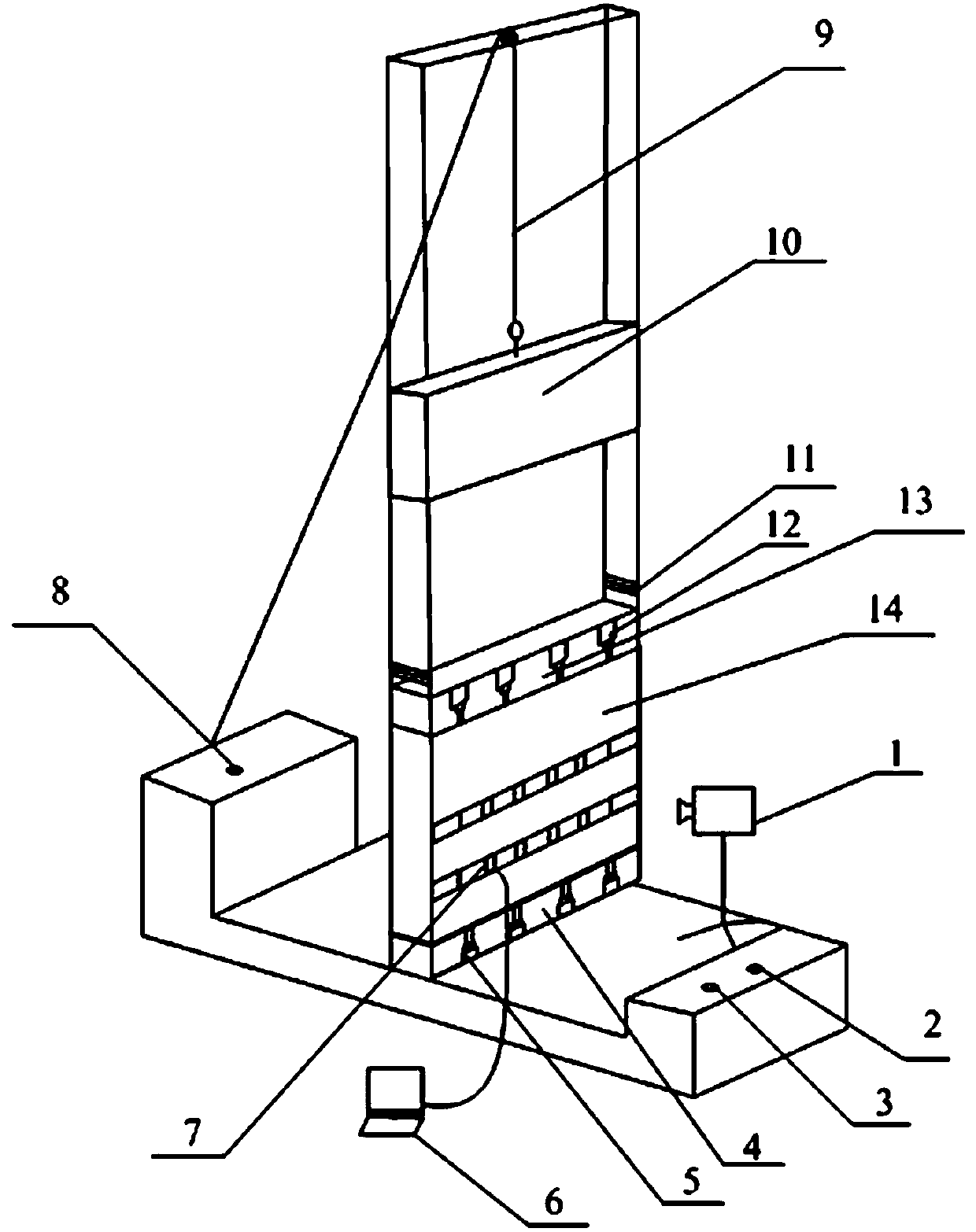

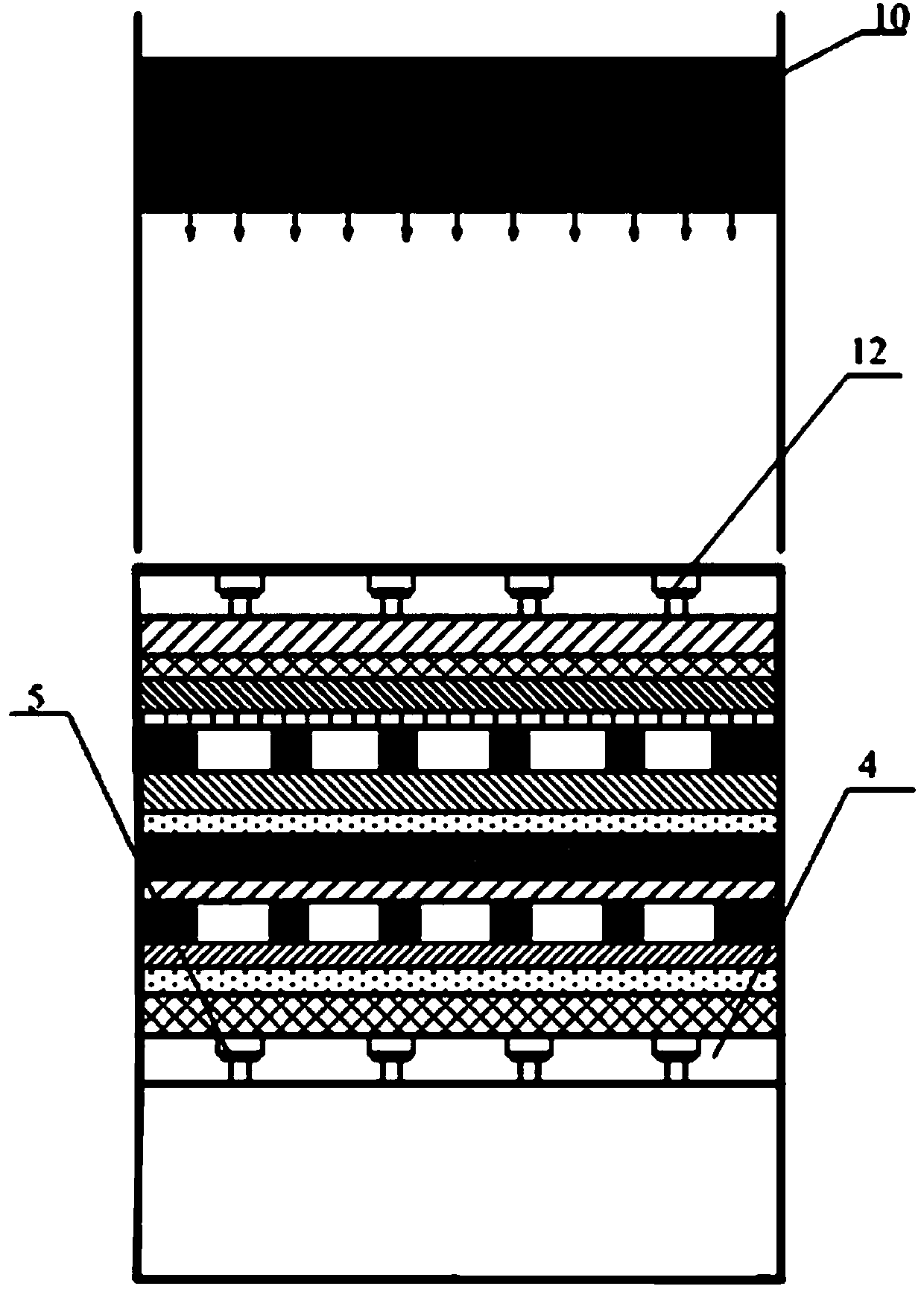

Tester and method for simulating stability of coal pillar group in dynamic load cutter post type residual mining area

Owner:TAIYUAN UNIV OF TECH

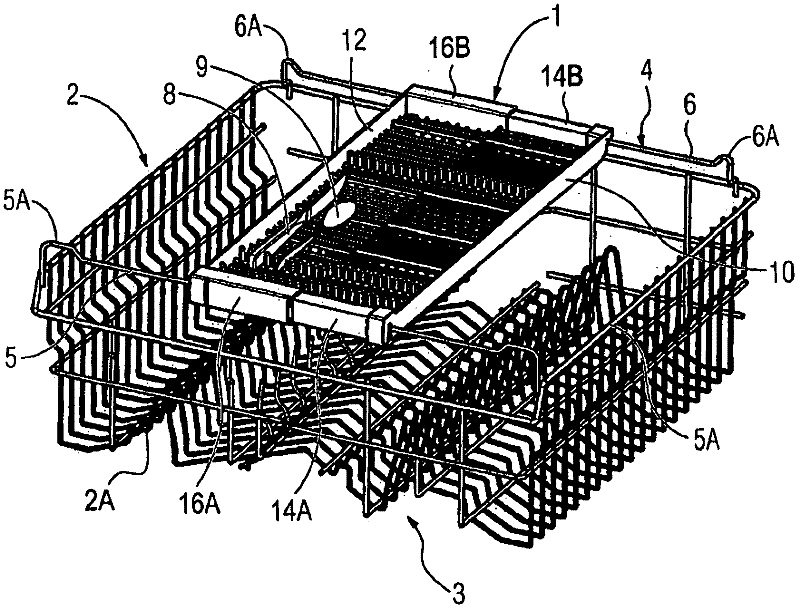

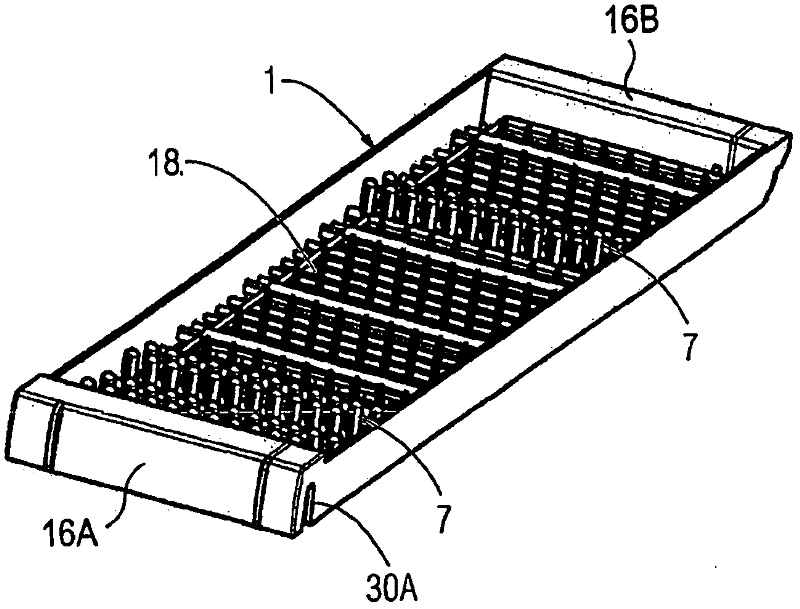

Silverware container, especially silverware tray and/or silverware basket, as well as dishwasher with such a silverware container

ActiveCN102469910ASimple structureSolid structureTableware washing/rinsing machine detailsMechanical engineering

Owner:ELECTROLUX HOME PROD CORP NV

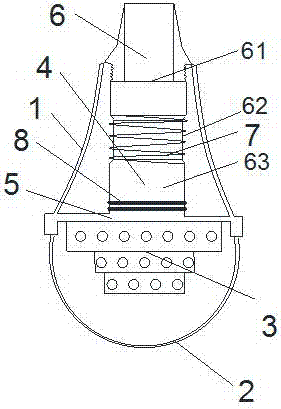

Shockproof projection LED lamp

PendingCN107166192ASolid structureGood shock resistanceLighting heating/cooling arrangementsProtective devices for lightingPotential riskLight source

The invention discloses a shockproof projection LED lamp which comprises a hood, a transparent lampshade, an LED lamp source, a radiator, a base plate and a connector. The top end of the LED lamp is provided with the connector. The connector is arranged at the inner upper end of the hood. The outer wall of the lower end of the connector is further covered with a spring. The hood and the transparent lampshade are fixed through a screw, and the base plate is arranged at the connecting position of the hood and the transparent lampshade. The radiator is arranged on the base plate and in the connector. The LED lamp source is arranged in the middle of the lower portion of the base plate. The shockproof projection LED lamp is firm and reliable in structure, multiple shockproof measures are taken, the whole lamp is good in shockproof performance, the problems that a lamp body falls off and the service life of the lamp is shortened due to violent shaking are effectively solved, and potential risks are low; and the light source is wide in projection range, and application of the shockproof projection LED lamp to wide sites is facilitated.

Owner:广东爱奇光电科技有限公司

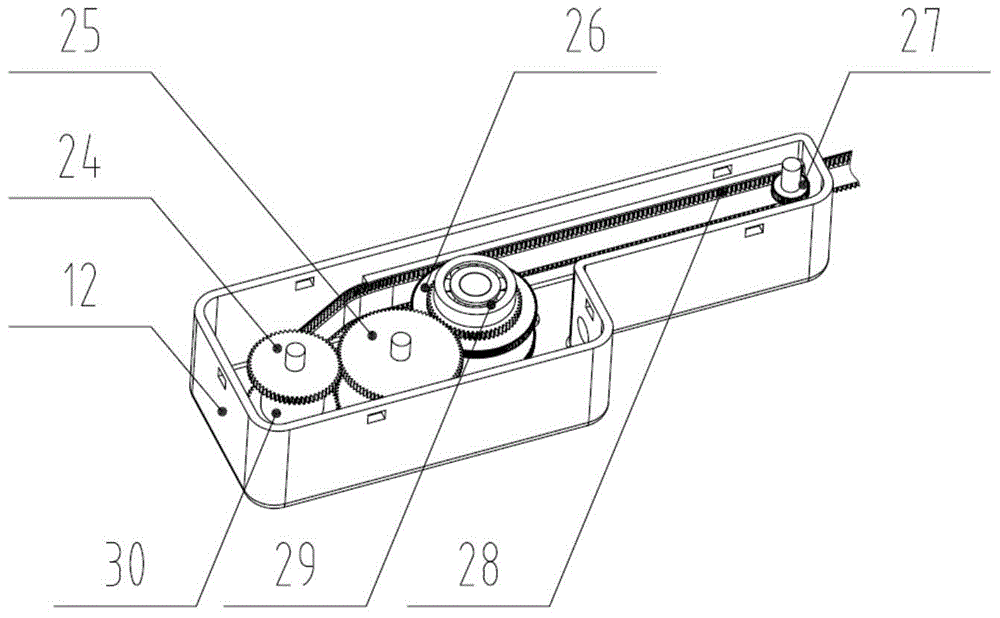

Vehicle saucer device

The invention relates to a vehicle saucer device. The vehicle saucer device is suitable for water cups with various shapes. The vehicle saucer device has the advantages that picking and placing are convenient, water cups can be fixed effectively, and the water cups can be effectively prevented from toppling or slipping off. The vehicle saucer device comprises a base used for the placement of the placing the water cups and a clamping device and a width adjusting device which are arranged on the base. The clamping device comprises a clamping component, a left clamping subsidiary device and a right clamping subsidiary device. Both the clamping subsidiary devices comprise a driving motor and an adjusting gear train. The output shafts of the driving motors are connected with driving gears in the adjusting gear trains through couplers, and the driving gears control collecting and placing of the clamping component. The width adjusting device comprises a spindle motor, a spindle lead screw which is connected with an output shaft of the spindle motor and two nut seats arranged on the spindle lead screw. Thread sections with adverse turning directions are arranged on the spindle lead screw, the two nut seats are arranged on different thread sections respectively, and each nut seat is connected with one clamping subsidiary device.

Owner:BAOJI HUSN ENG VEHICLE

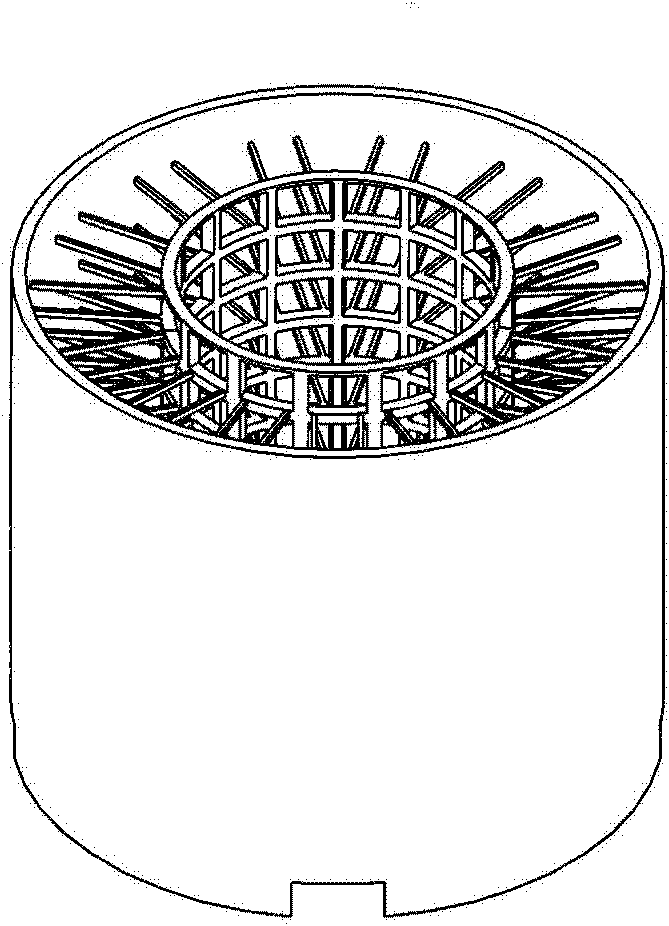

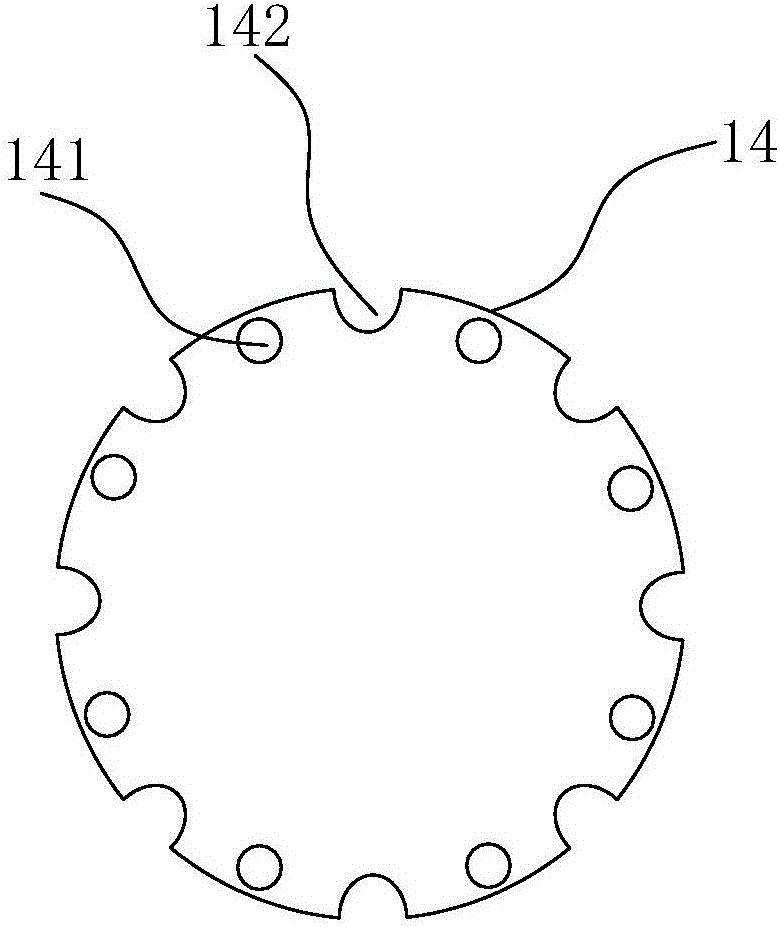

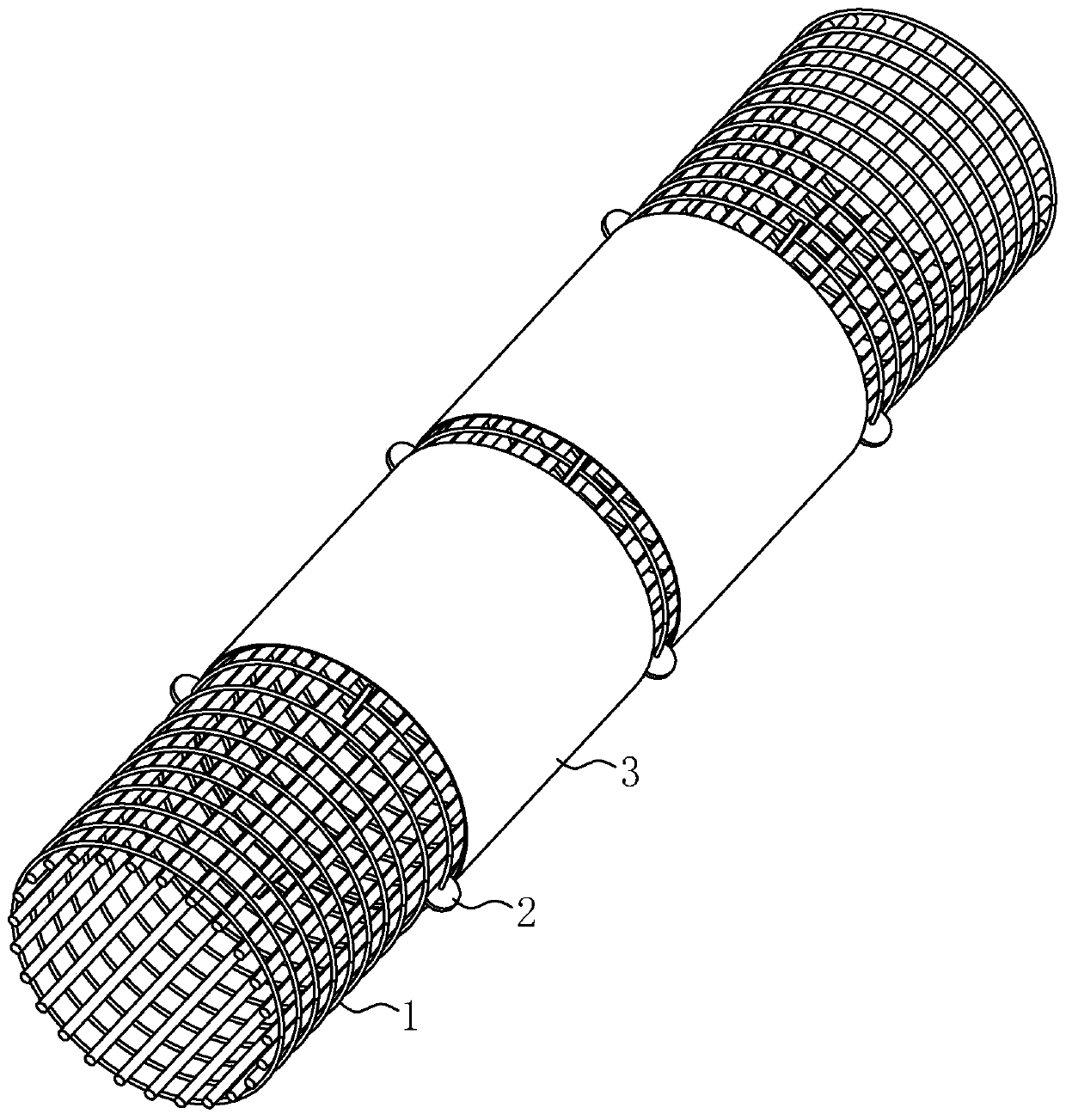

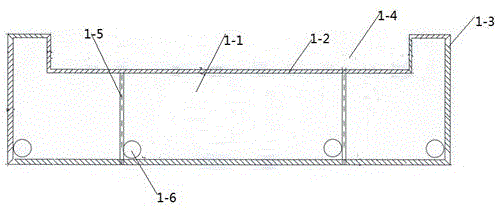

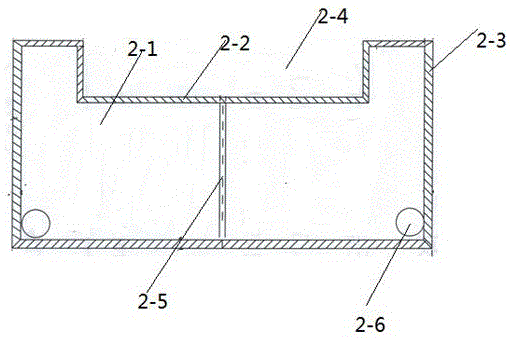

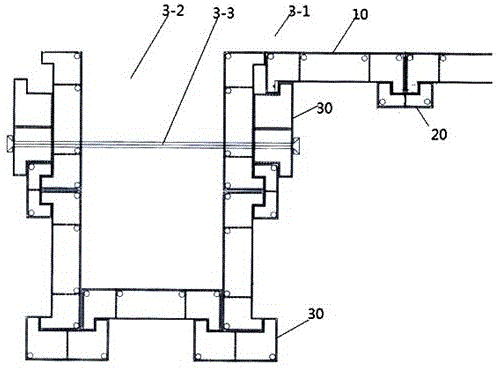

Reinforcement skeleton cage for concrete prefabricated pile

ActiveCN106087979ASolid structureGuaranteed tensile strength and impact resistanceBulkheads/pilesRebarPre stress

The invention belongs to the technical field of concrete prefabricated piles, and in particular, relates to a reinforcement skeleton cage for a concrete prefabricated pile. The reinforcement skeleton cage comprises a stirrup, prestressed reinforcements arranged in the length direction of the prefabricated pile, and glass fiber ribs; and the prestressed reinforcements are welded in the peripheral direction of the stirrup at intervals to form a cage body. The reinforcement skeleton cage is characterized in that a positioning disc is clamped in the cage body; and a positioning hole for penetrating through the glass fiber rib is formed in the positioning disc. The positioning disc is clamped in the cage body; the glass fiber rib is positioned and mounted in the cage body after penetrating through the positioning hole; and the mounting structure keeps stable mounting position of the glass fiber rib in the manufacturing or use process of the concrete prefabricated pile, so that the reinforcement skeleton cage is more firm in structure, and largely guarantees the tensile strength and the impact resistance of the concrete prefabricated pile.

Owner:ANHUI INST OF BUILDING RES & DESIGN

Local transparent shell structure

InactiveCN102469712ASolid structureSave spaceCasings/cabinets/drawers detailsTelephone set constructionsEngineeringSurface layer

The invention discloses a local transparent shell structure which is used for a handheld electronic terminal and is provided with a shell main body, wherein the shell main body comprises a surface layer, a rear layer and a shading layer, wherein the shading layer is provided with one or more transparent areas, and the rear layer and the shading layer are double-color injection mould inserts. A shading bracket and a plastic shell with a transparent exterior are integrated into a whole part. According to the invention, the transparent or shading demand on a lighting effect of the handheld electronic terminal is effectively met; the structure is firm; the space is saved; the external surface is scratch-resisting; the color of the inner pattern is kept bright for a long time and is difficult to fade; especially, the whole thickness of the handheld electronic terminal can be efficiently controlled; the structural design is more compact; and an appearance effect is excellently realized.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

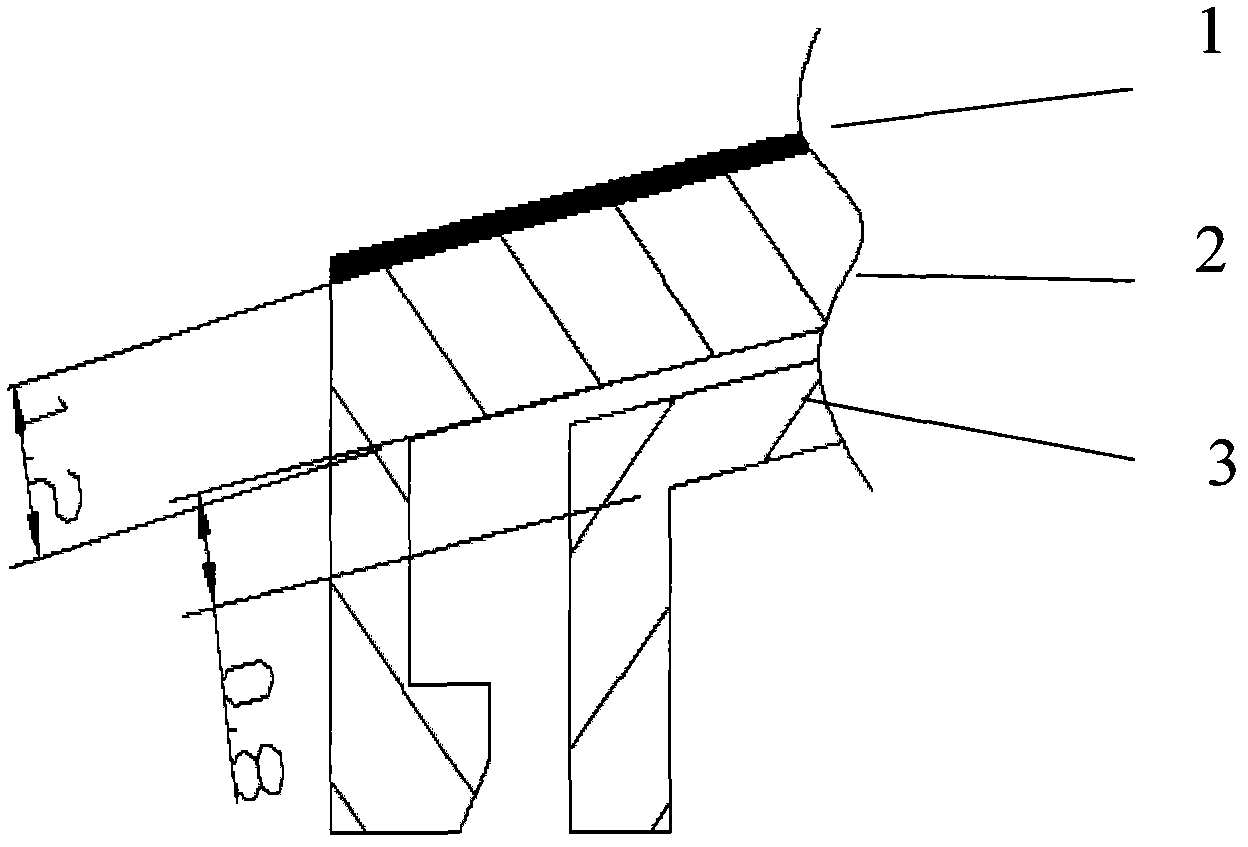

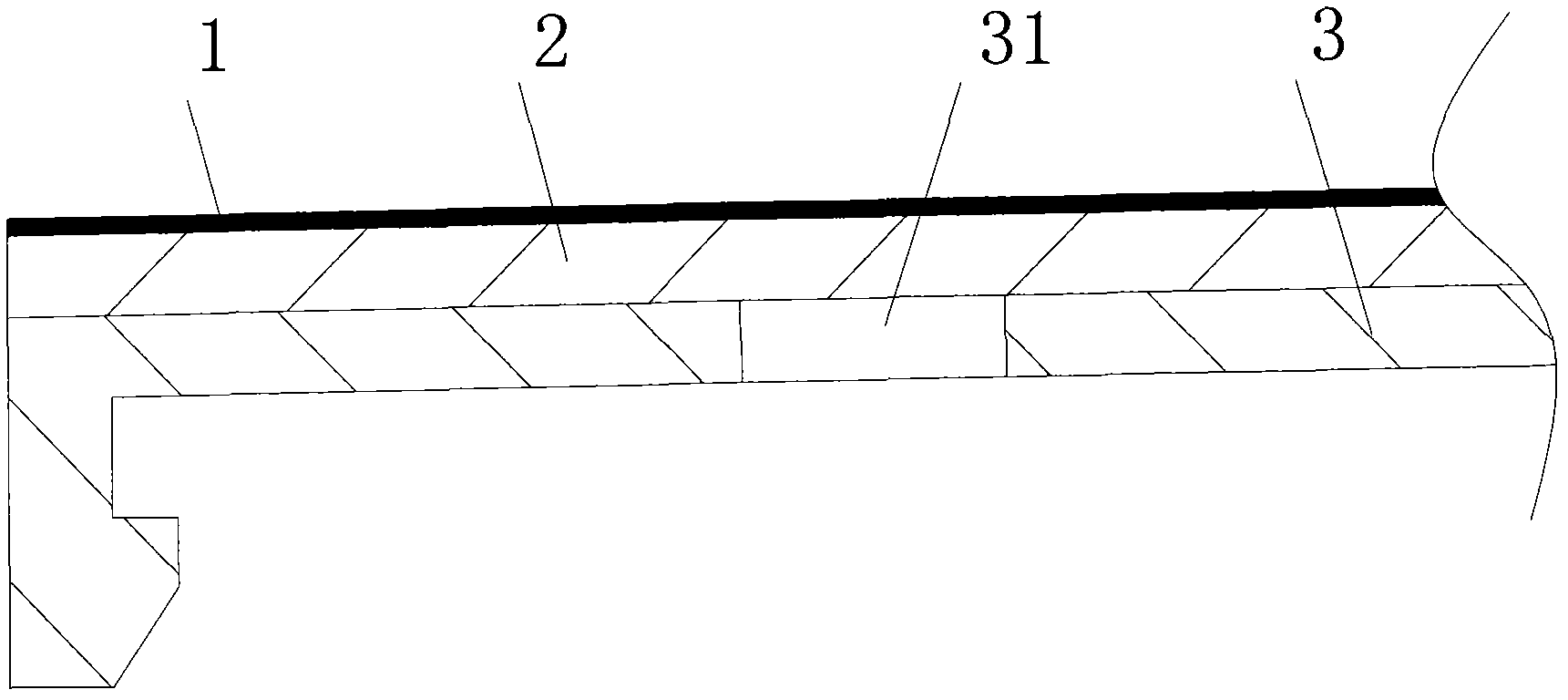

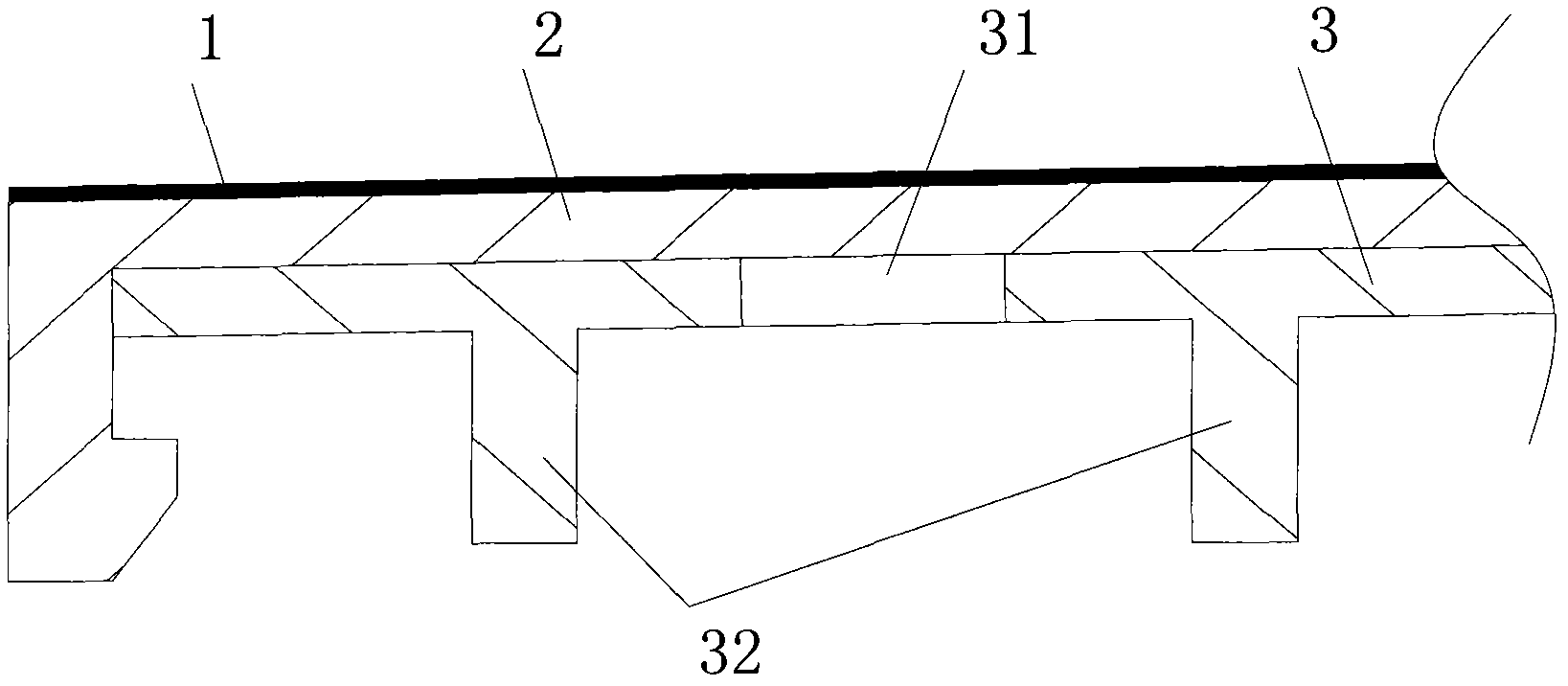

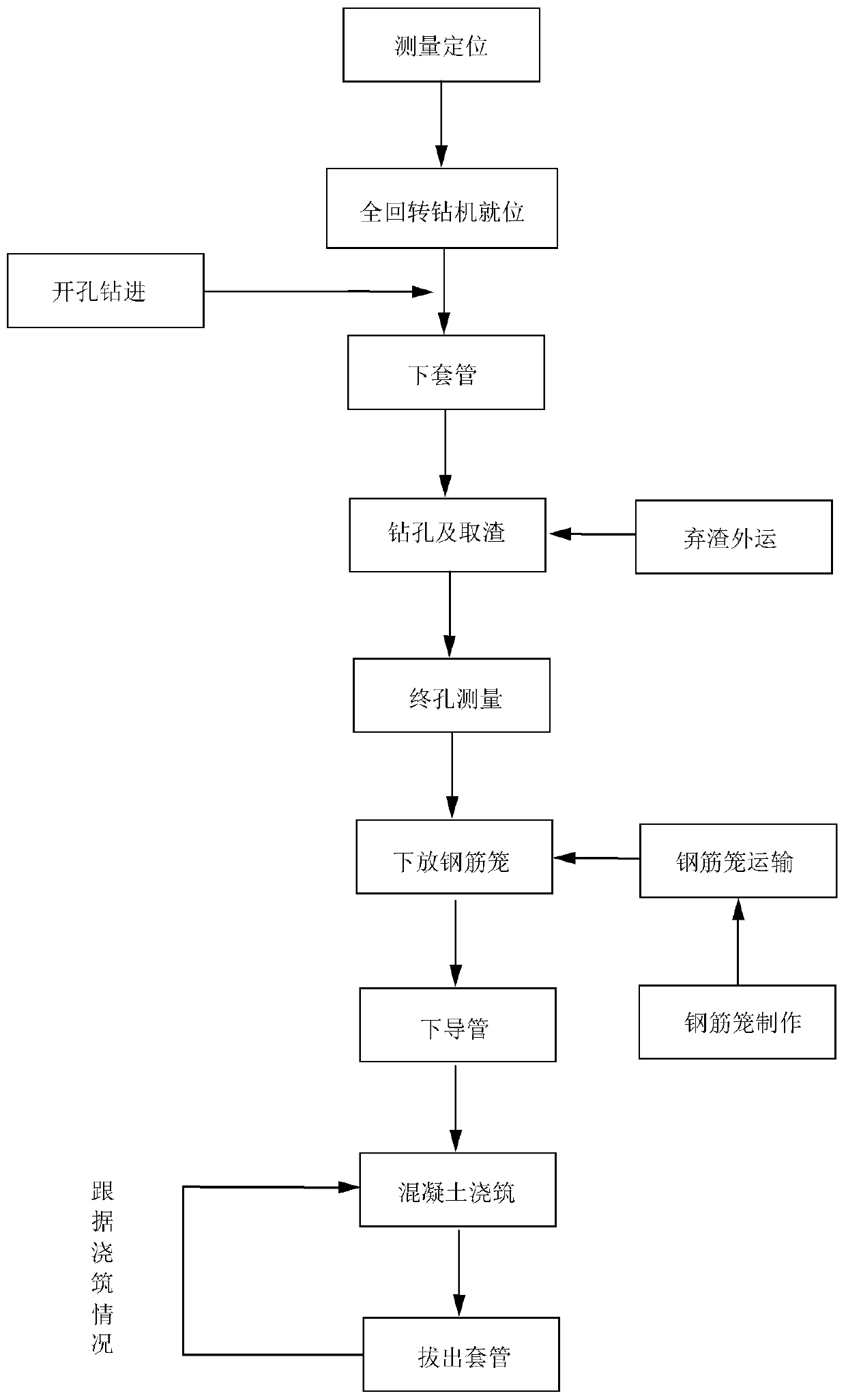

Pile foundation full-casing full-rotation construction process under complex geological conditions

The invention relates to a pile foundation full-casing full-rotation construction process under complex geological conditions. The pile foundation full-casing full-rotation construction process comprises the following steps: site preparation before drilling is conducted; casings with cutting edges are inserted in a drilling rig body, soil layers in the casings are dug through a grab, and then a self-rotation device of a drilling rig is utilized to rotate the casings and to be pressed into a formation simultaneously; the casings are spliced till drilling is completed; concrete is poured througha tremie method; and the casings are pulled out. According to a pile foundation construction method, mud does not need to be used, especially a full casing form is adopted in a strongly developed karst area, drilling and casing mounting are simultaneously conducted, and the phenomenon of hole collapse in the drilling process is avoided.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

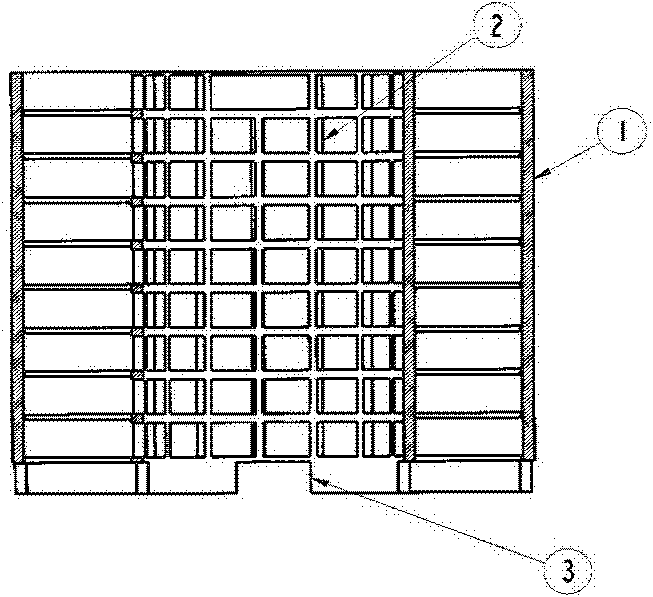

Aluminum alloy formwork for buildings and method for applying aluminum alloy formwork

ActiveCN105155836ASolid structureGood stabilityForming/stuttering elementsAluminium alloyUltimate tensile strength

The invention discloses an aluminum alloy formwork for buildings and a method for applying the aluminum alloy formwork. The aluminum alloy formwork comprises universal planar aluminum plates and reinforcement clip aluminum plates. The universal planar aluminum plates and the reinforcement clip aluminum plates are respectively of 'concave' hollow structures and comprise hollow cavities and frames, the frames comprise convex edges and grooves, the heights of the convex edges of the universal planar aluminum plates are equal to those of the grooves of the reinforcement clip aluminum plates, and the sum of the widths of the two convex edges of each universal planar aluminum plate is equal to the widths of the grooves of each reinforcement clip aluminum plate, so that the grooves of each reinforcement clip aluminum plates can be exactly connected with the convex edges of the two corresponding universal planar aluminum plates in a clamped manner when the convex edges of the universal planar aluminum plates are connected and parallelly arranged and spliced with one another pairwise. The aluminum alloy formwork can be applied to constructing concrete structures of walls, columns, beams, plates, balconies, bay windows, exterior decoration lines and the like. The aluminum alloy formwork and the method have the advantages that the aluminum alloy formwork is high in strength and free of rusting, is light, can be poured at one step after being completely spliced and has obvious merits in the aspect of construction periods and prices as compared with aluminum formworks for identical floors; seams are fine, formed walls are attractive, and decoration at late periods can be facilitated.

Owner:ZHEJIANG EHOME CURTAIN WALL TECH

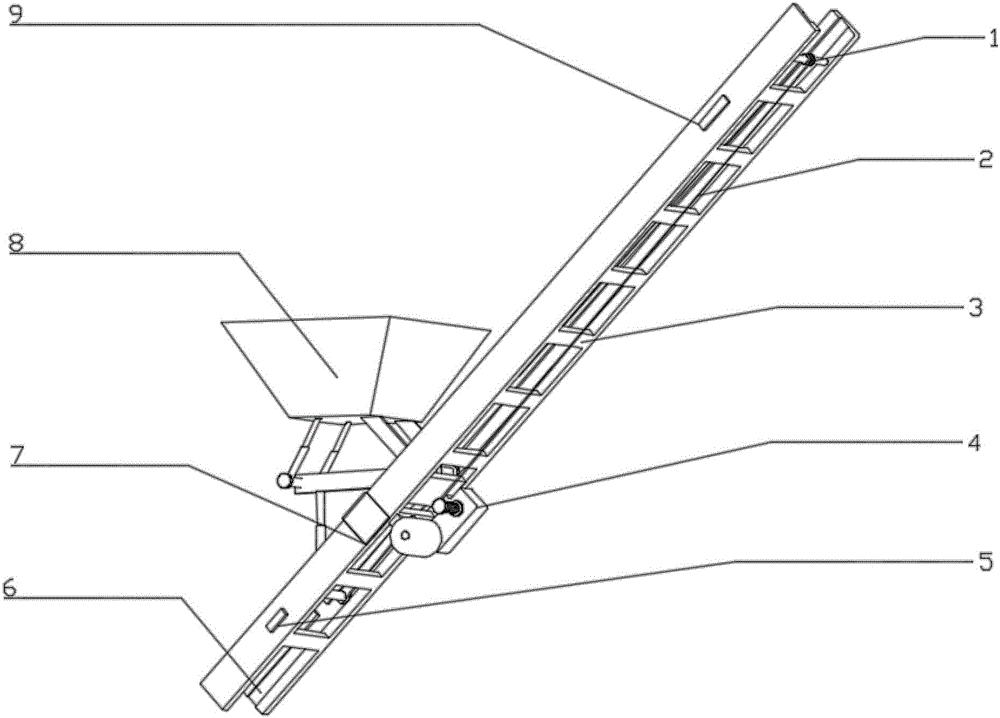

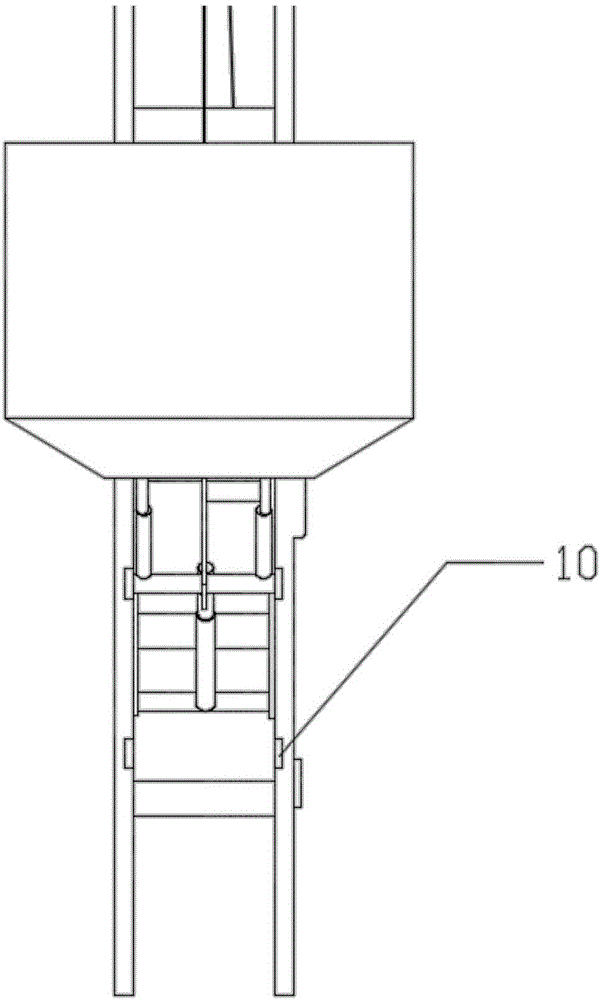

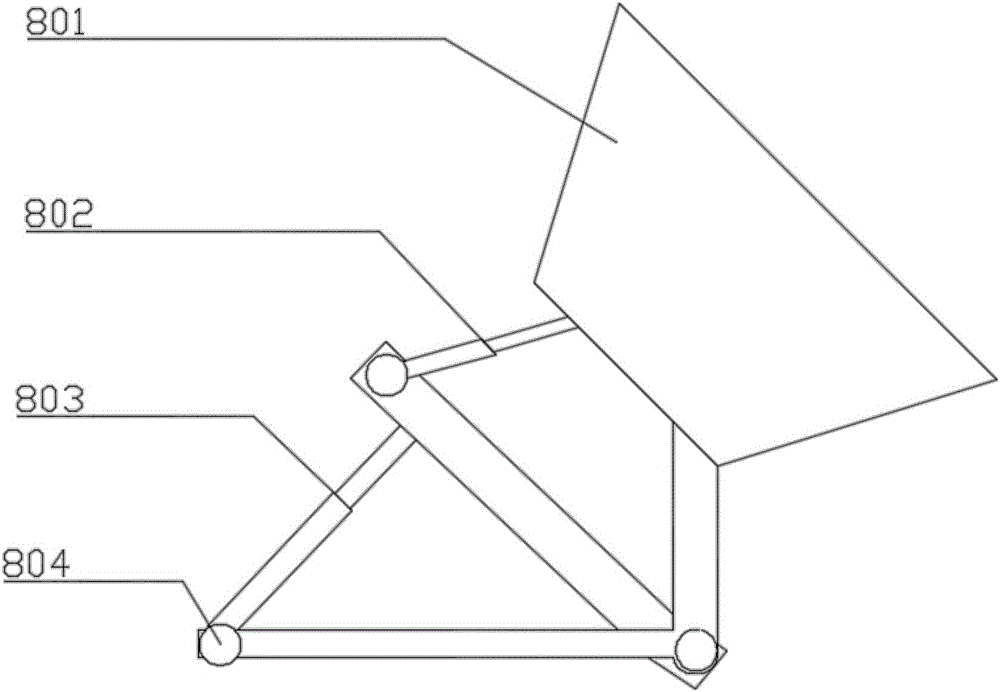

A Weight Lifting Ladder

ActiveCN106335856ASolid structureEasy to manufacture and maintainLifting devicesAgricultural engineeringLimit switch

A weight elevator applied to agricultural machinery, including fixed pulley, steel wire rope, ladder, hoist engine, bottom limit switch, top limit switch, chute, controller, lifting boxes, and loading and unloading ports. Hoist engine is arranged on the middle and lower part of the ladder, bottom limit switch is arranged on the bottom of ladder, top limit switch is arranged on the top of ladder, controller is arranged on the side of ladder and hoist engine at the same level, elevator chamber is located at the top of lift on the chute of ladder at both sides, on end of the steel wire is connect to the lower part of lifting box, and the other end connected to hoist engine, and the middle part is located in the slot of fixed pulley, and it lifts the heavy goods in the lifting box through hoist engine to the high position to conduct automatic-dumping. The lift is easy to disassemble, easy to move and deposit, and can be used as common ladder at ordinary time. It reduces production cost, saves labor force, improves labor efficiency, and reduces the danger coefficient of hand labor.

Owner:徐州茂宏冷链仓储有限公司

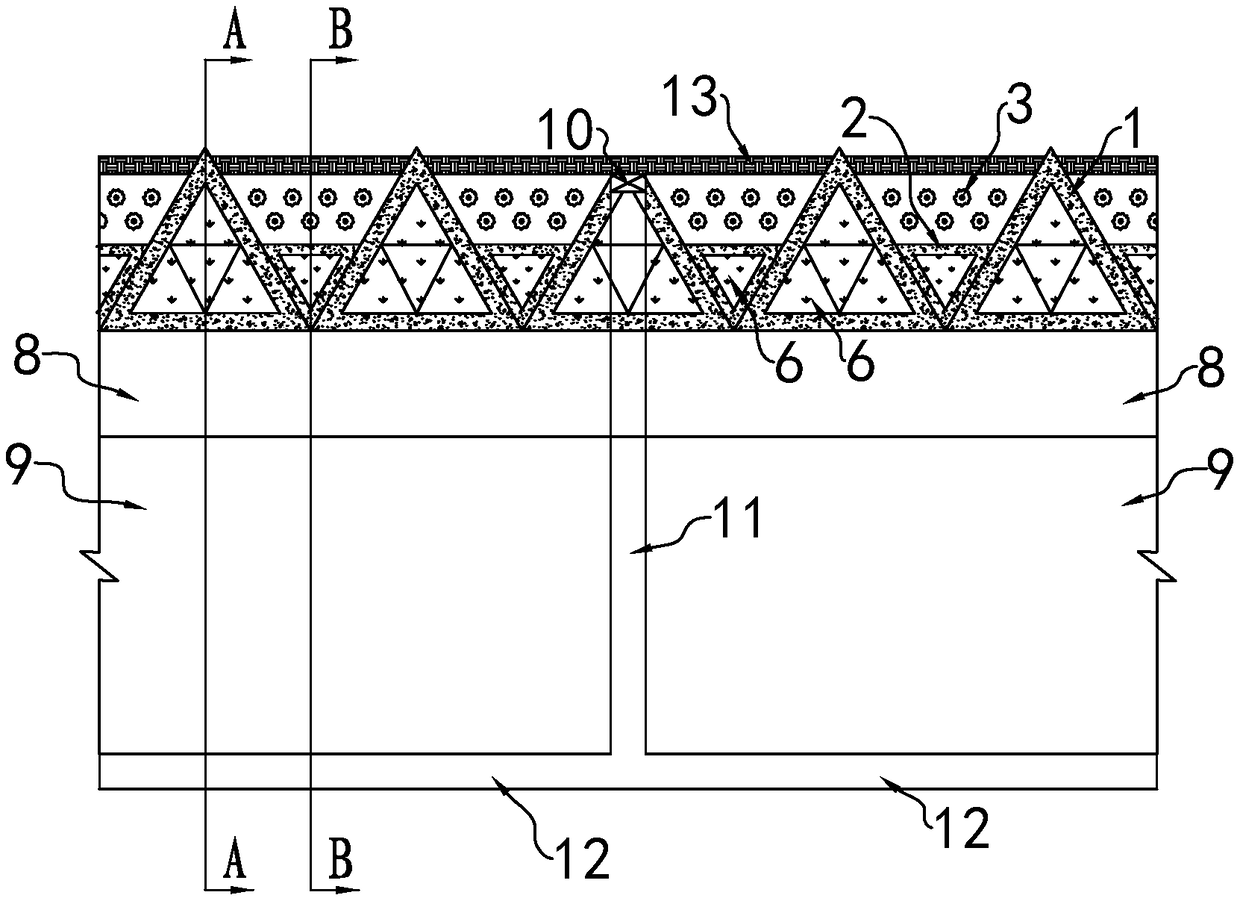

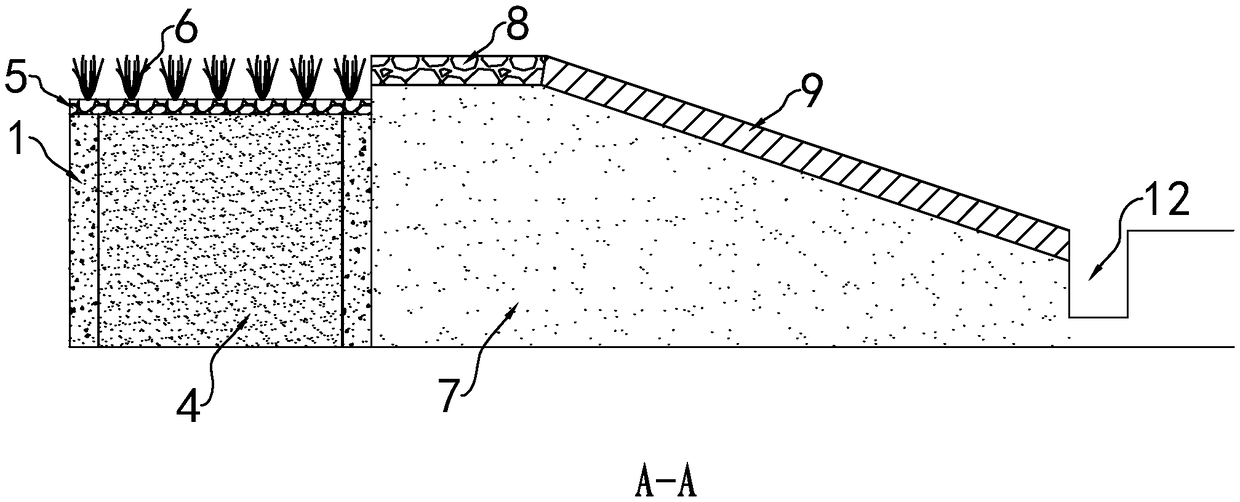

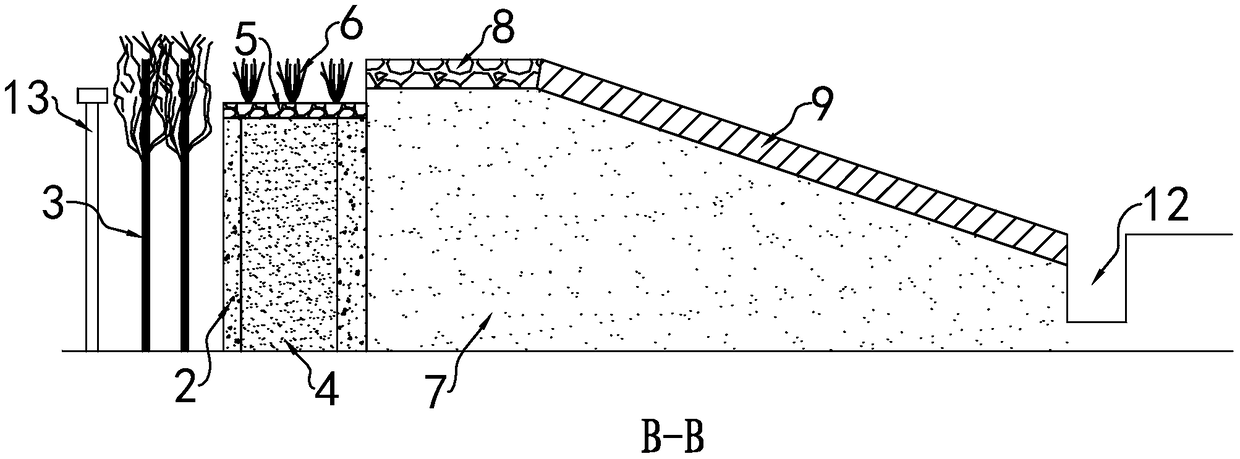

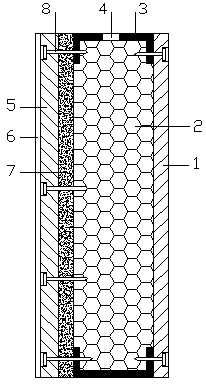

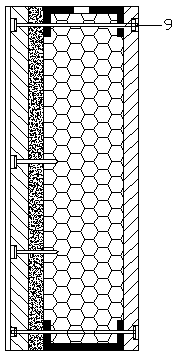

Triangularly modular ecological sea wall

The invention discloses a triangularly modular ecological sea wall and relates to a sea wall. The sea wall comprises a plurality of first prefabricated frameworks which are arranged in an arrayed mode. A second prefabricated framework and a wave break forest are arranged between every two adjacent first prefabricated frameworks and used for filling the gap between the two adjacent first prefabricated frameworks. The first prefabricated frameworks and the second prefabricated frameworks are each in a cylinder shape, and the cross section of each of the first prefabricated frameworks and the second prefabricated frameworks is triangular. Cylinder inner cavities of the first prefabricated frameworks and the second prefabricated frameworks are filled with first sea sand. The triangularly modular ecological sea wall has the beneficial effects that the first prefabricated frameworks and the second prefabricated frameworks are prefabricated and constructed modularly conveniently, the interiors of the first prefabricated frameworks and the second prefabricated frameworks are filled with the sea sand, the sea sand can be taken from a sea coastal site, and fast filling can be achieved easily; and the triangular structures of the first prefabricated frameworks and the second prefabricated frameworks enable the structure of the sea wall to be stable and reliable, the second prefabricated frameworks are smaller than the first prefabricated frameworks, the first prefabricated frameworks are made to form protruding pointed portions which have a wave dissipating effect, and the energy of storm surges can be greatly cut.

Owner:GUANGDONG RES INST OF WATER RESOURCES & HYDROPOWER

Manufacturing process of light prefabricated assembly type external wallboard

PendingCN109914685AImprove structural strengthSolid structureBuilding componentsThermal insulationIndustrial engineering

The invention relates to a manufacturing process of a light prefabricated assembly type external wallboard. The manufacturing process comprises the following steps: (1) a through hole is formed in anouter base plate, a thermal insulation material is poured, to bond the outer base plate and an inner base plate, and an outer side plate is bonded through the through hole in the outer base plate, sothat the whole wallboard forms a whole; (2) a keel framework is manufactured, and a pouring hole is formed in one side wall of the keel framework; (3) the inner base plate is fixed to the inner side face of the keel framework through a penetrating connecting piece, the outer base plate and the outer side plate are fixed to the outer side face of the keel framework through the penetrating connecting piece, the outer side plate is located on the outer side of the outer base plate, and a pouring cavity is defined by the outer base plate, the keel framework and the inner base plate; (4) a thermalinsulation material is poured into the pouring cavity, and foaming is carried out; and (5) after the thermal insulation material is solidified, the whole wallboard is moved.

Owner:山东省住房和城乡建设发展研究院

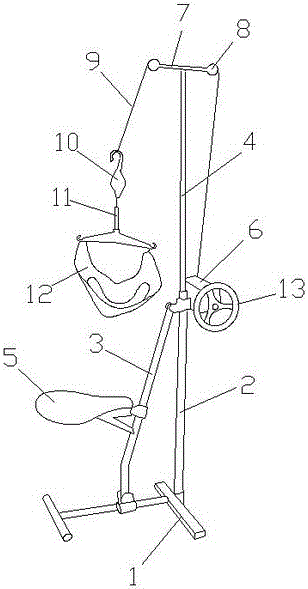

Medical traction chair

InactiveCN105997324AEasy to installSolid structureFractureAgricultural engineeringStructural stability

The invention discloses a medical traction chair. The medical traction chair comprises a base, a supporting sleeve, a connection rod and a lifting rod, wherein the supporting sleeve and the connection rod are arranged on the base; the connection rod is fixedly connected with the supporting sleeve and the base; the lifting rod is arranged on the supporting sleeve; a seat is mounted in the middle of the connection rod; a rope winding device is arranged on one side of the supporting sleeve; a cross rod is mounted at the top of the lifting rod; pulleys are arranged at two ends of the cross rod; a traction rope is arranged on the pulleys, one end of the traction rope is connected with the rope winding device, and a hook is mounted at the other end of the traction rope; a dynamometer and a traction sleeve are sequentially arranged below the hook. The medical traction chair is convenient to mount, high in structural stability and easy to adjust.

Owner:CHENGDU JIAMEIJIA SCI & TECH

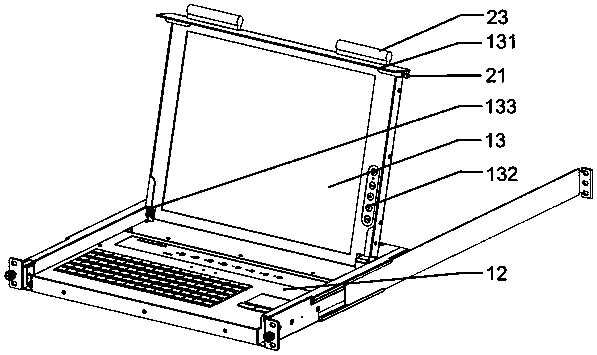

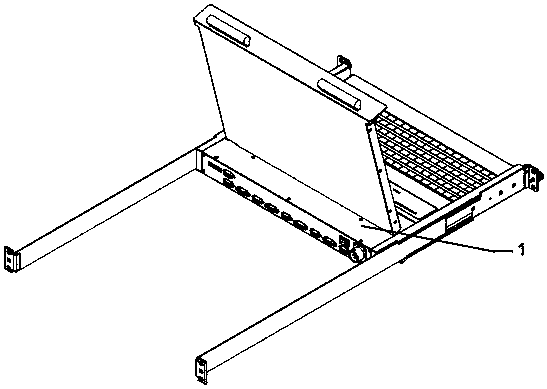

Compact type reinforced KVM switcher installing structure

InactiveCN108089639ASolid structureGood vibration resistanceDigital data processing detailsEngineeringKVM switch

The invention provides a compact type reinforced KVM switcher installing structure. Through arranging a cover plate at the top part of a displayer and arranging a buckling mechanism on the cover plate, thus the displayer location can be realized through the buckling and limit effects between the buckling mechanism and two sides; thus the KVM switcher structure is more firm and reliable, and the switcher has good anti-vibration and anti-impact effect; a control button component of the displayer is arranged at the side of the front panel, a connection data line for the displayer and the controlbutton component is connected with an integral box structure through a channel at the right end face of a bulge part; a wiring harness is more reasonable to lay, the line layout is more convenient andfaster; the working efficiency of operators is greatly improved while the operation technical difficulty is reduced; the whole structure is more reasonable, and the installing structure is simple andcompact; the volume is small, the cost investment is reduced; the installing structure is economical and practical, high in space utilization rate, reasonable in setting, and wide in application range.

Owner:合肥恒研智能科技有限公司

Production method of building concrete bamboo formworks

InactiveCN106182213AUniform density and mechanical strengthSolid structureCane mechanical workingLaminationWater contentSurface plate

The invention discloses a production method of building concrete bamboo formworks. The production method comprises the following steps: 1, curtain manufacturing: weaving bamboo chips of which the thicknesses are smaller than or equal to 1.5 into bamboo curtains, and drying the bamboo curtains until the water content is smaller than or equal to 10%; 2, gum dipping: dipping the dried bamboo curtains with gum for 20 minutes, and secondarily drying the bamboo curtains until the water content is 12% after gum dipping; 3, plywood manufacturing: pre-pressing high-polymer plastics into plywood of which the thicknesses are smaller than or equal to 2 mm, and coating a single surface of each piece of plywood with gum for subsequent use; 4, blank assembling: spreading the high-polymer plastic bottom plate of which a gum surface faces upwards, laying the bamboo curtains layer by layer, and spreading the high-polymer plastic face plate of which a gum surface faces downwards; 5, hot pressing: feeding a plate blank into a hot press, and gluing and forming at high temperature under high pressure; and 6, edge trimming: carrying out edge trimming to obtain the final products. Gaps among the adjacent bamboo curtains are filled owing to hot melting of the upper high-polymer plastic plate and the lower high-polymer plastic plate. The invention aims to provide the production method of the building concrete bamboo formworks. Density and mechanical strength are uniform, a separation layer does not exist, the structure is firm, the shear strength is high, the surface is smooth so that water cannot permeate easily, and the service life is greatly prolonged.

Owner:益阳桃花江竹业发展有限公司

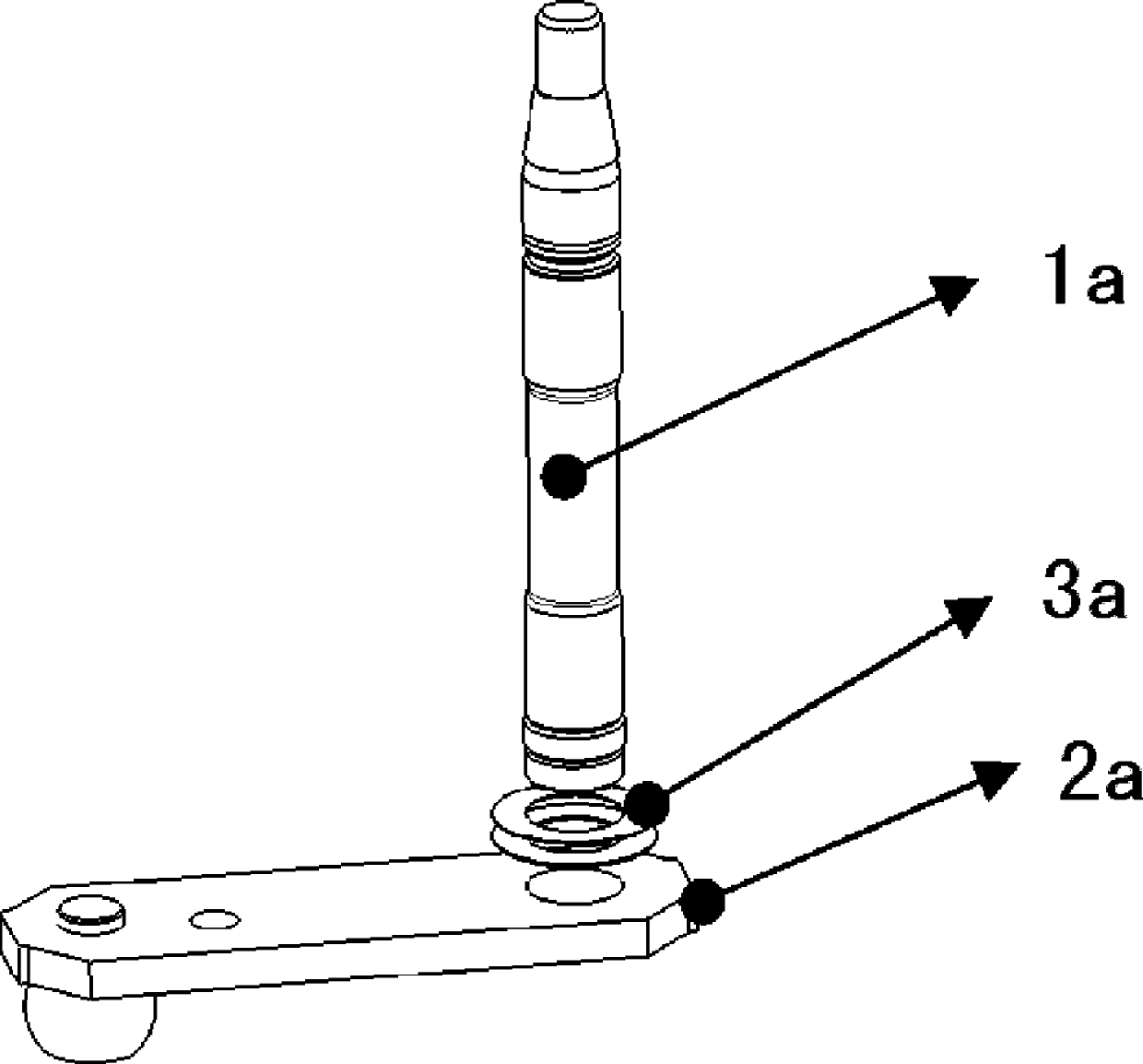

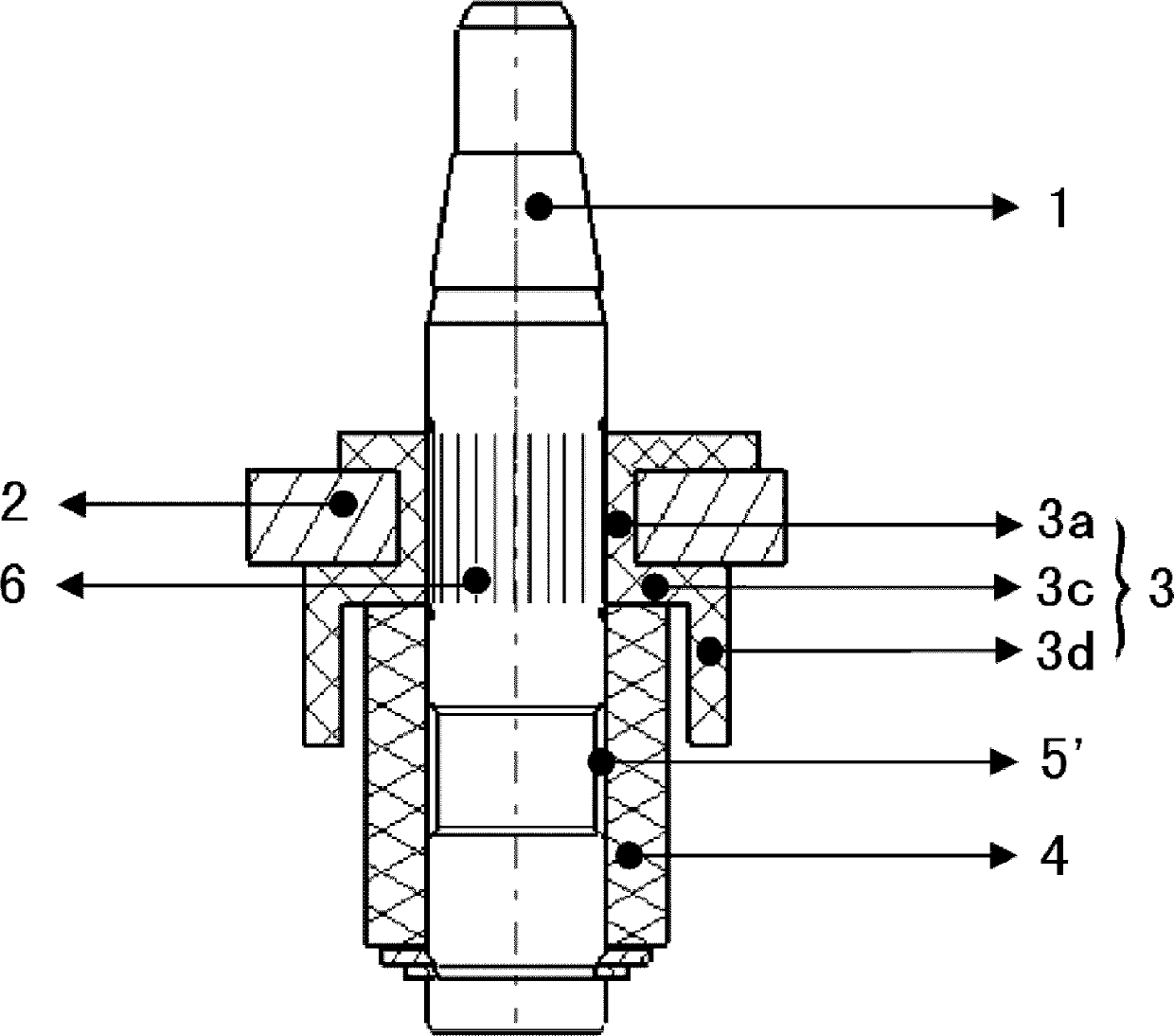

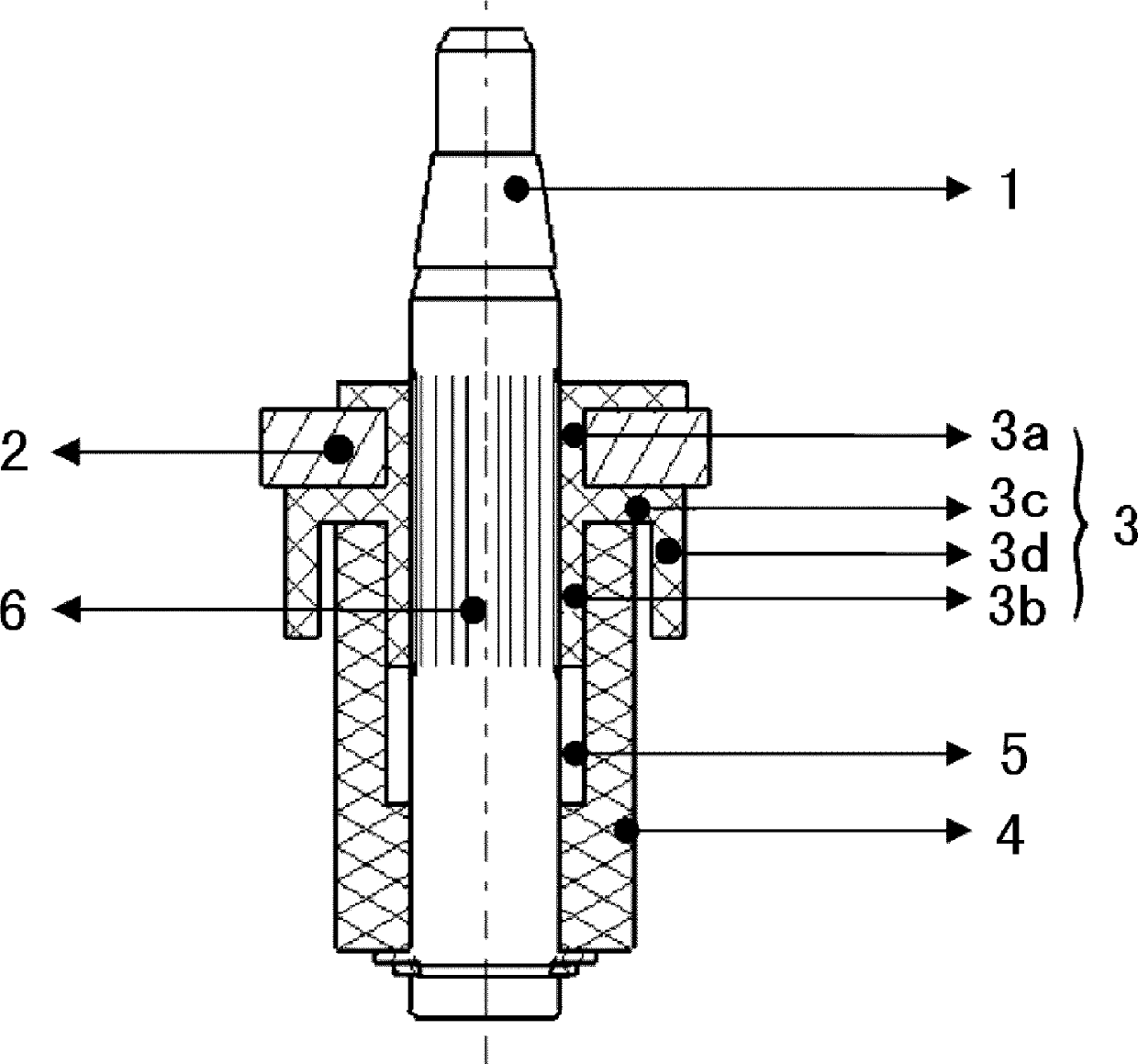

Pivot assembly for windscreen wiper and windscreen wiper

ActiveCN103963743ASolid structureDimensional tolerances are easy to controlVehicle cleaningWindscreen wiperEngineering

The invention relates to a pivot assembly for a windscreen wiper and the windscreen wiper. The pivot assembly comprises a windscreen wiper shaft, a crankshaft and a wrapping molding part, wherein the windscreen wiper shaft is inserted in a through hole of the crankshaft, the wrapping molding part is formed by a wrapping molding technology and provided with a combination part, the combination part is arranged between the windscreen wiper shaft and the crankshaft so as to combine the windscreen wiper shaft and the crankshaft, and the wrapping molding part is further preferably provided with a first bushing part serving as a bushing, a washer part serving as a washer and / or a water-proof part serving as a water-proof cover. Due to the adoption of the pivot assembly, not only can the structural reliability of the existing windscreen wiper be obviously improved, but also the functions of the bushing, the washer, the water-proof cover, lubricating oil storage and the like can be combined.

Owner:BOSCH AUTOMOTIVE PROD CHANGSHA

Environment-friendly floor

InactiveCN106592912ASolid structureWear-resistant and long service lifeConstructions elementsCoatingsActivated carbonSolid wood

The invention discloses an environment-friendly floor. The environment-friendly floor comprises a polyurethane coating layer, a first bamboo board layer, a second bamboo board layer, a cedarwood layer and a high-density fiberboard layer, wherein the second bamboo board layer is formed through mutually clamped connection; the polyurethane coating layer, the first bamboo board layer, the second bamboo board layer, the cedarwood layer and the high-density fiberboard layer are sequentially arranged from top to bottom; the first bamboo board layer and the second bamboo board layer are distributed in a perpendicularly staggered mode; through holes are formed in the middle of the cedarwood layer and filled with activated carbon layers; and rubber suction cups are arranged at the bottom of the high-density fiberboard layer, the top of each rubber suction cup is provided with a protruding portion, and the protruding portions are inserted in the high-density fiberboard layer. The environment-friendly floor can adsorb formaldehyde of the floor, the material stability is good, and compared with a solid wood floor, the environment-friendly floor is higher in structure strength.

Owner:CHENGDU GERUISI CULTURAL COMM

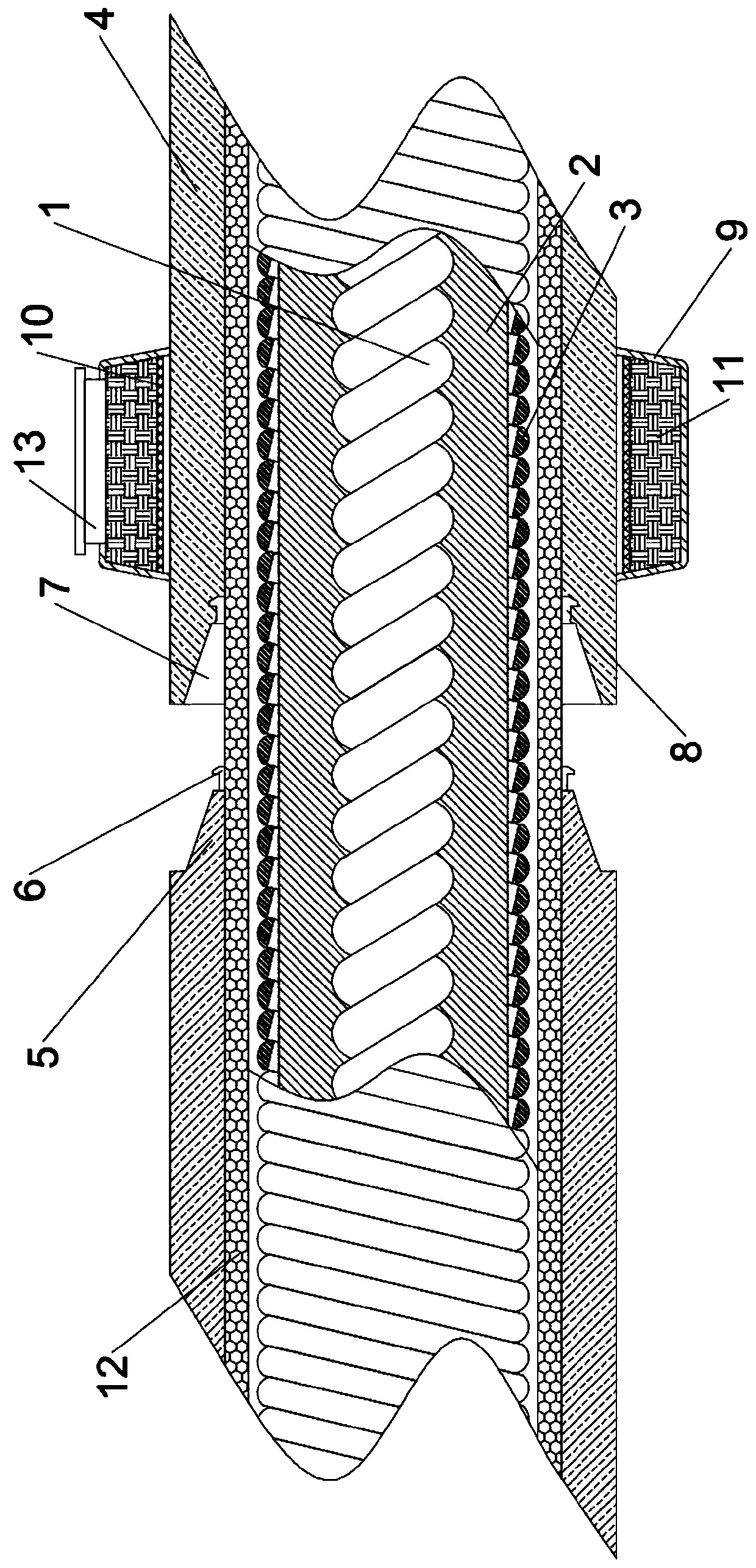

Ceramic halogen-free low-smoke fire-resistant cable

ActiveCN109920589ASolid structureEasy to installRubber insulatorsInsulated cablesEngineeringSingle section

The invention discloses a ceramic halogen-free low-smoke fire-resistant cable. The cable comprises a plurality of cable lines with the same structure, an insulating layer, an isolation layer and a plurality of outer protection layers with the same structure, wherein the insulating layer wraps the plurality of cable lines, the isolation layer wraps the insulating layer, the outer protection layerswrap the isolation layer, connection fastening mechanisms are installed among the plurality of outer protection layers, and a fire-extinguishing isolation mechanism is wrapped in each connection fastening mechanism. The ceramic halogen-free low-smoke fire-resistant cable is firm in structure and easy to install; the outer protection layers made of a ceramic material are tightly connected through the connection fastening mechanisms, the installation length of a single outer protection layer is shortened, and therefore installation is more convenient; meanwhile, through each fire-extinguishing isolation mechanism arranged on a single outer protection layer, the fire behavior is effectively isolated and controlled within the length of a single outer protection layer; and moreover, by adding halogen-free low-smoke TPE rubber into the insulating layer, the cable cannot generate a large amount of smoke in a fire, and the problems that the visual field of a rescuer is influenced and the health of the rescuer is harmed are avoided.

Owner:重庆科力线缆股份有限公司

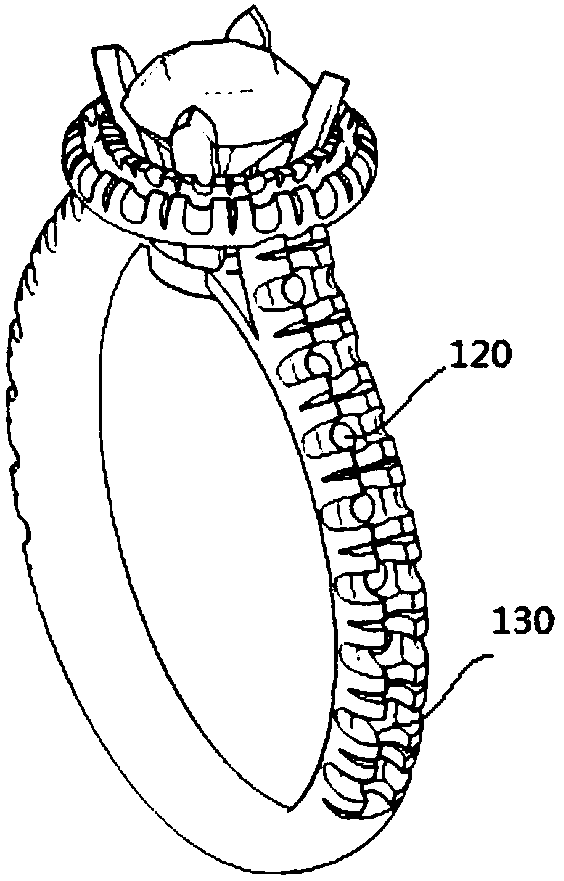

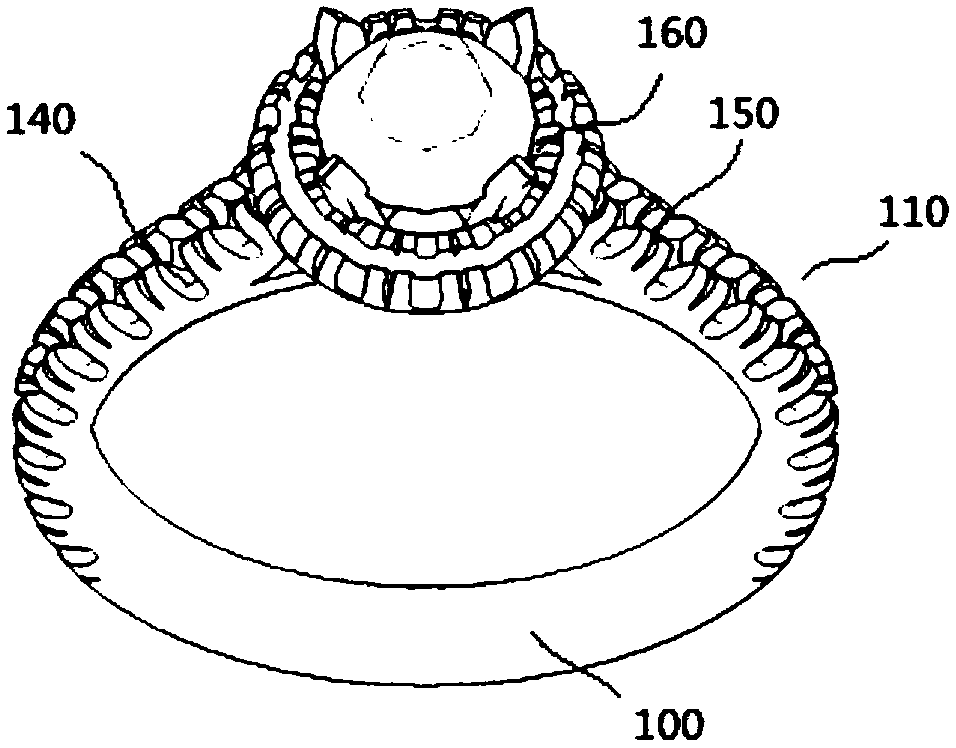

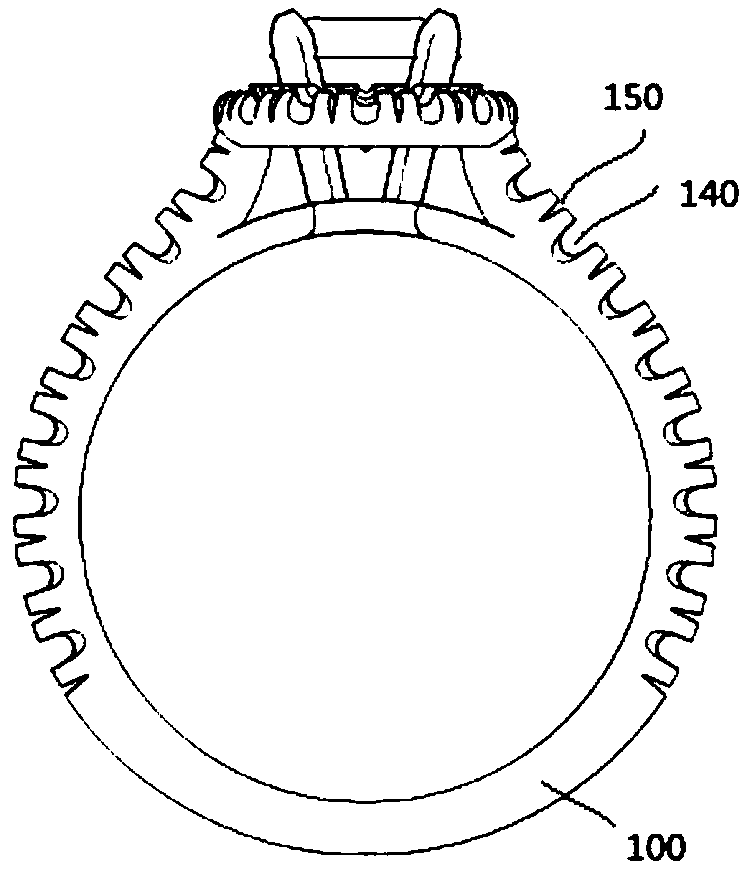

Gemstone colorful micro-inlaying process and wearing jewelry

A gemstone colorful micro-inlaying process and wearing jewelry are provided. The process includes that follow steps: the length of the gem alignment region is determined on the outer peripheral surface of a metal bracket ring; gemstone mounting holes are provided in a gemstone arrangement area, the gem mounting holes are arranged linearly, a first groove is formed in the gemstone arrangement area,the first groove extends in the length direction along the arrangement direction of the gemstone mounting holes, the first groove communicates with the gemstone mounting holes; a second groove is formed on the metal bracket ring corresponding to the positions of the gemstone mounting holes, the length direction of the second groove is inclined to the length direction of the first groove, a partition section is formed between adjacent second grooves, a third groove is formed on the partition section, the length direction of the third groove is inclined to the length direction of the first groove, and a gemstone is embedded in a corresponding gemstone mounting hole. After the gemstone is inlaid, the structure is firm and reliable, and the light can enter from the bottom of the gem after thegem is installed, so that the light transmission effect of the gem is good and the ornamental property is strong.

Owner:植福缘珠宝有限公司

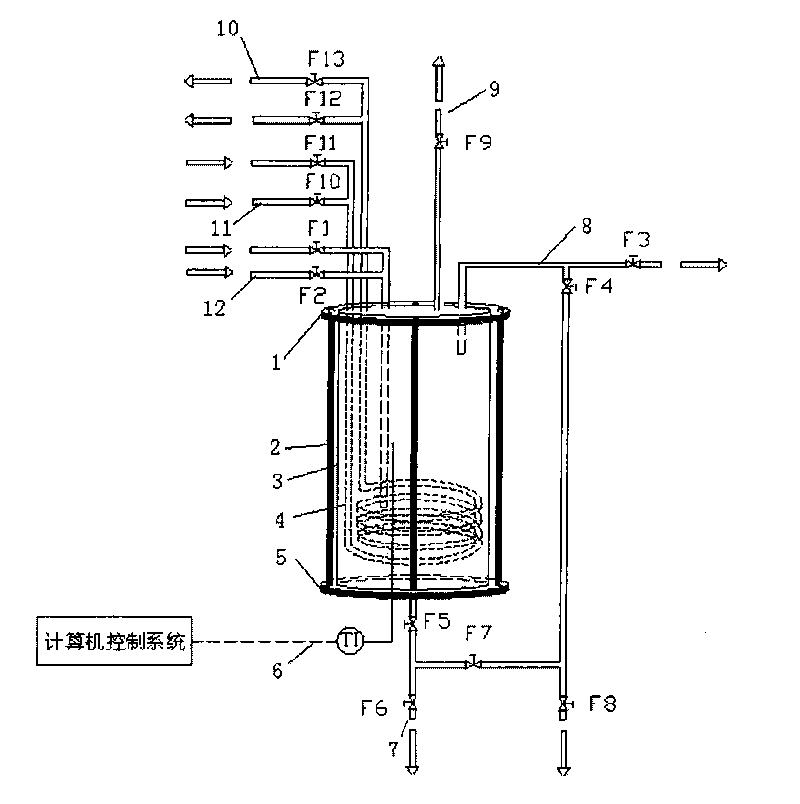

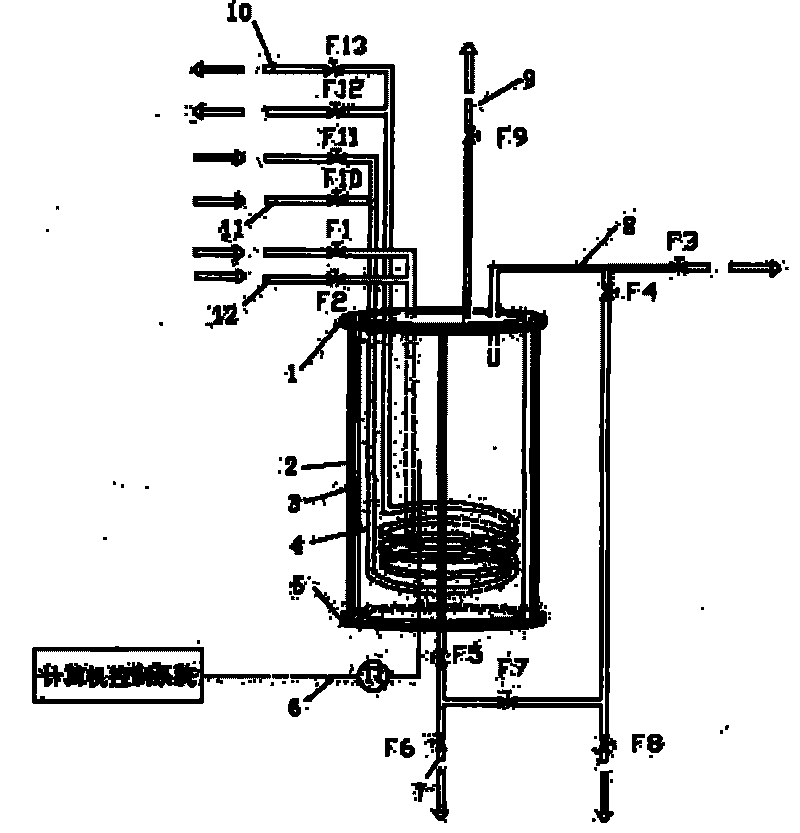

Constant-temperature liquid-liquid equilibrium separation unit

InactiveCN101745252ASolid structureGood sealing performanceLiquid separation auxillary apparatusCooling coilFastener

The invention discloses a constant-temperature liquid-liquid equilibrium separation unit which comprises a cooling coil, a temperature-measuring element, a temperature control system, feed and discharge pipes and regulating valves and is characterized in that a cover and a bottom are made of stainless steel; a cylindrical shell is made of transparent organic glass; the cover, the cylindrical shell and the bottom are sequentially closely attached to one another; and the cover is fixedly connected with the bottom through a fixing bolt. The constant-temperature liquid-liquid equilibrium separation unit has the positive effects that the stainless steel cover and the bottom are fixed by using a fastener (fixing bolt), thereby clamping the transparent organic glass cylindrical shell in the middle. The separation unit has firm structure and good airtightness, not only has the advantages of convenient observation of the glass transparent split-phase interface, but also has the advantages of firmness and good heat transfer of the stainless steel. The feed and discharge pipes are respectively provided with the regulating valves, the flow rate and mutual proportion of two-way refrigerating medium are regulated by utilizing a computer-aided control temperature regulation system, the random regulation and accurate regulation in a wide range of temperature can be realized, the liquid-liquid equilibrium data are collected and the separation simulation tests of changeable immiscible substances are easily carried out.

Owner:SHANGHAI WUJING CHEM

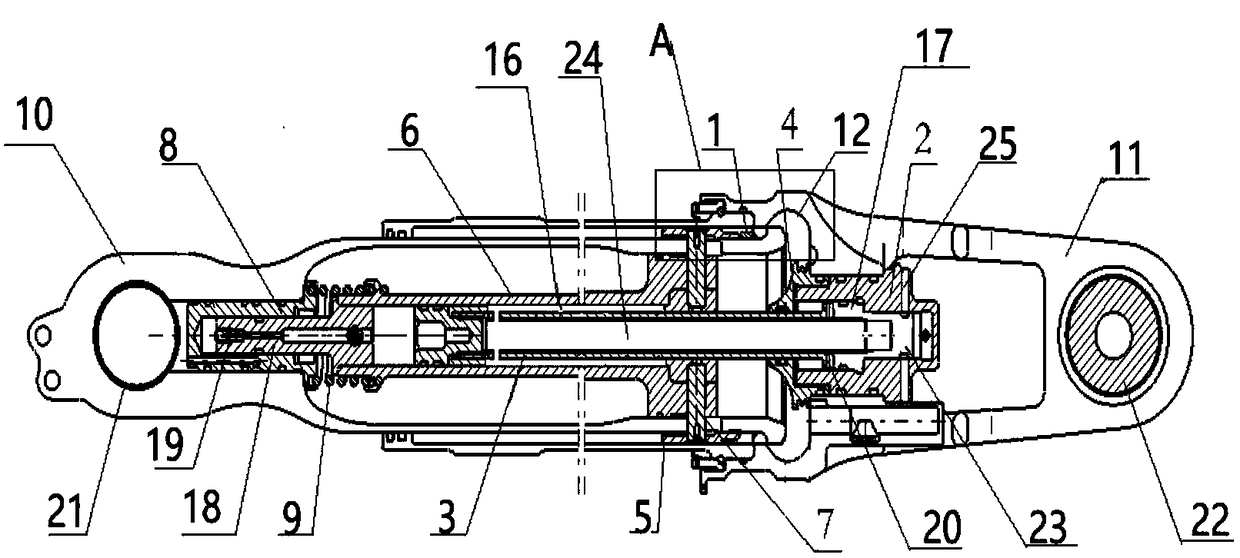

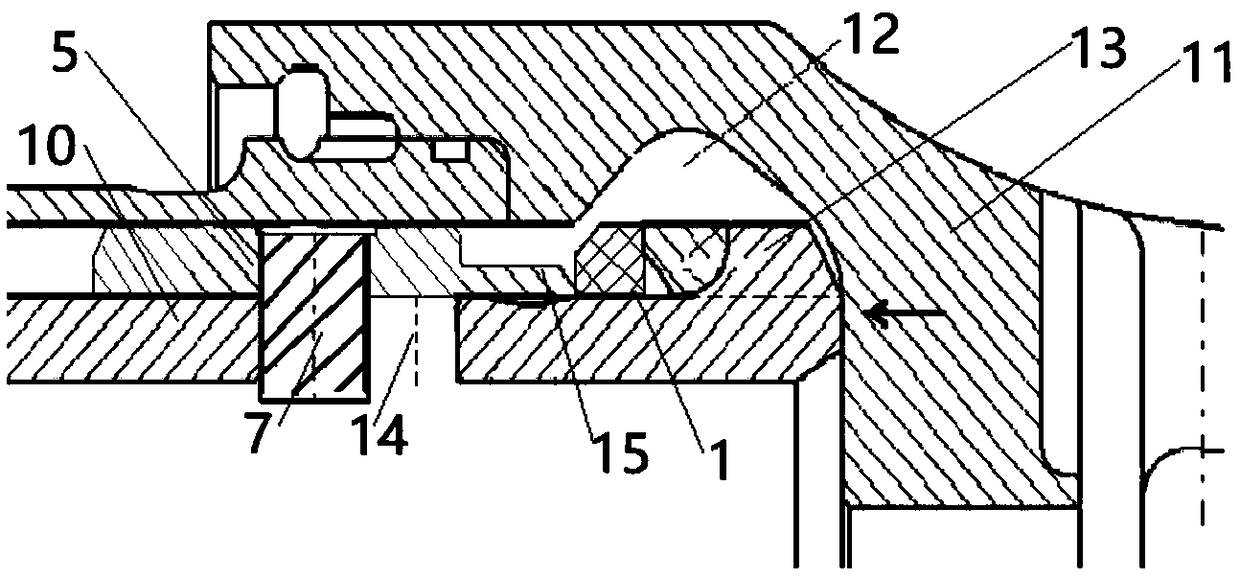

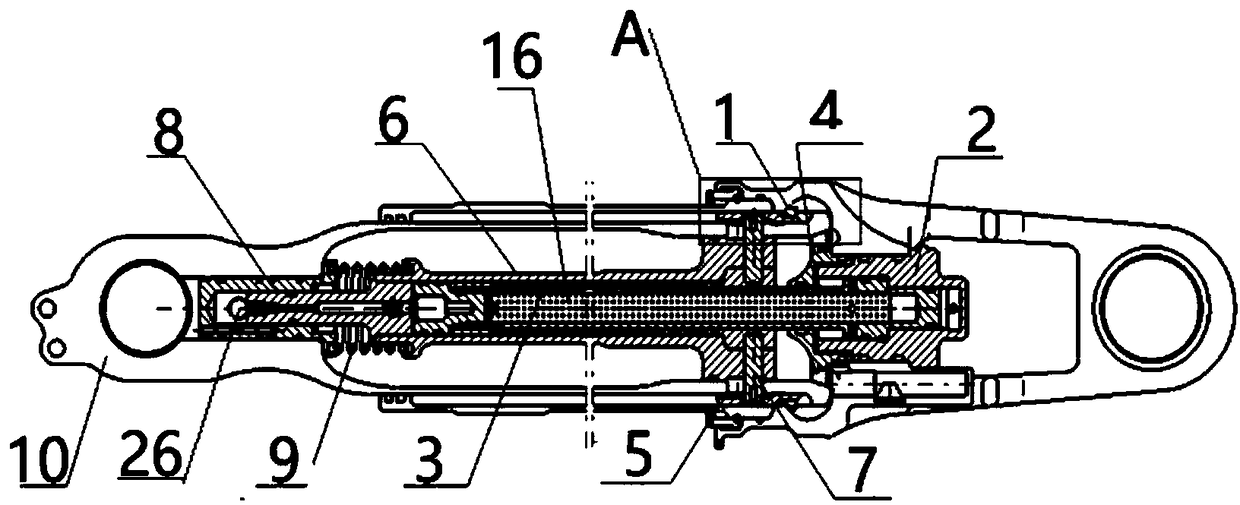

Locking mechanism of strut device

ActiveCN109278989ARealize the stable lock functionSolid structureUndercarriagesEngineeringPiston rod

The invention relates to a strut design, in particular to a locking mechanism of a strut device. According to the invention, the inner wall of a sleeve structure of an end cover is provided with a first ring groove; one end of a piston rod is installed in the sleeve structure of the end cover; a lock rod sleeve is axially installed in the cavity of the piston rod; one end of lock rod is installedin the lock rod sleeve and is capable of performing relative movement in an axial direction, and the other end of lock rod is fixedly mounted in the end cover; a support bush sleeves the piston rod; one end, close to a limiting ring, is provided with an annular notch; the support bush is fixed on the lock rod by a pin and can move axially with the lock rod; a snap ring has a locked state and an unlocked state; when the support bush moves towards the limiting ring, the snap ring is squeezed to the annular notch, and the annular notch, the limiting ring and the first ring groove clamp the snap ring, so the snap ring is in the locked state; and when the support bush moves away from the limiting ring, the snap ring is separated from the annular notch and tightly sleeves the piston rod, so thesnap ring is in the unlocked state.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

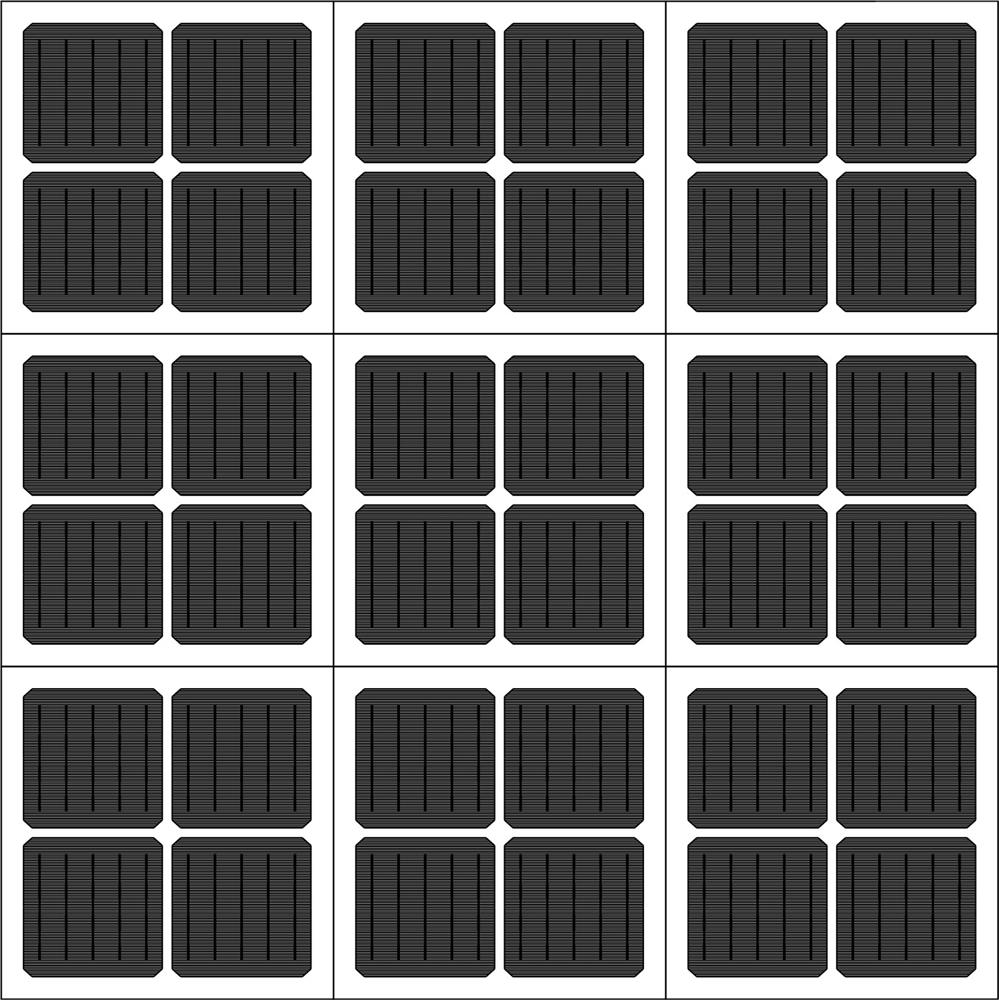

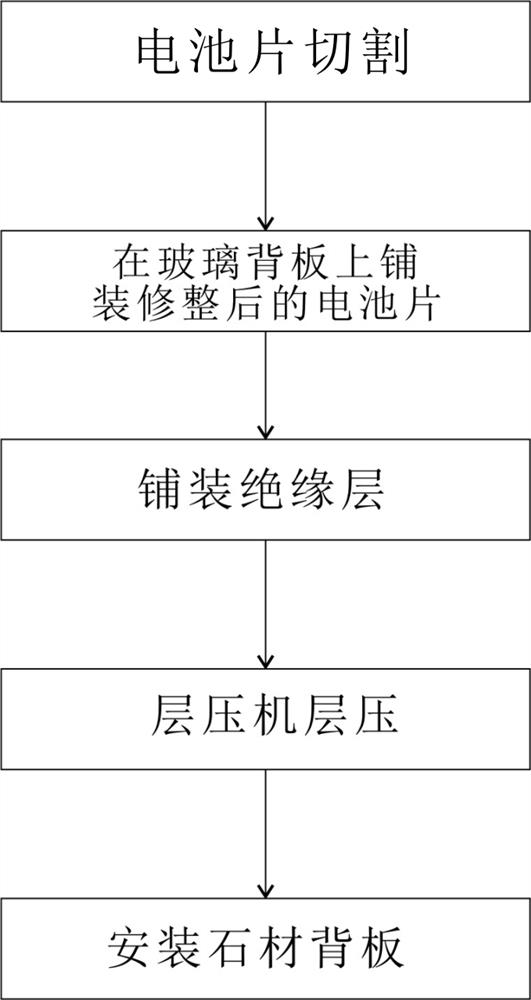

Production process for photoelectric building material of back plate BIPV curtain wall by using inorganic building material

PendingCN114520275ASimple structureSolid structurePhotovoltaic supportsWallsWeather resistanceBuilding material

The invention discloses a production process of a back plate BIPV curtain wall photoelectric building material with an inorganic building material, which comprises the following steps of: cutting solar cells, and connecting the cut cells in series and parallel to form a power generation layer; paving the formed power generation layer on the back surface of the photovoltaic transparent material plate according to requirements, and adding a packaging adhesive film between the back surface of the photovoltaic transparent material plate and the power generation layer; installing an anti-hot-spot parallel circuit; paving an insulating layer back material on the other side of the power generation layer, and adding a packaging adhesive film between the insulating layer back material and the power generation layer; feeding into a laminating machine for laminating; mounting an inorganic building material back plate on the inner side of the laminated insulating layer; a special cable connector is installed on the plate provided with the inorganic building material back plate, and the inorganic building material is formed to be a back plate BIPV curtain wall photoelectric building material; the technology is simple, the production efficiency is high, the inorganic building material processed through the technology is the back plate BIPV curtain wall photoelectric building material, the structure is firm, the weather resistance is high, the series-parallel connection design is adopted in the power generation layer, and efficient power generation can be achieved.

Owner:崔永祥

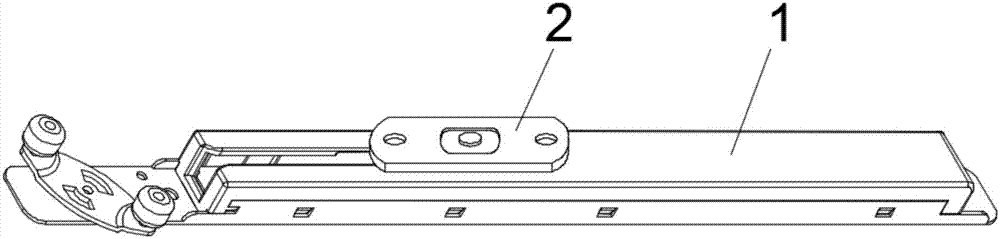

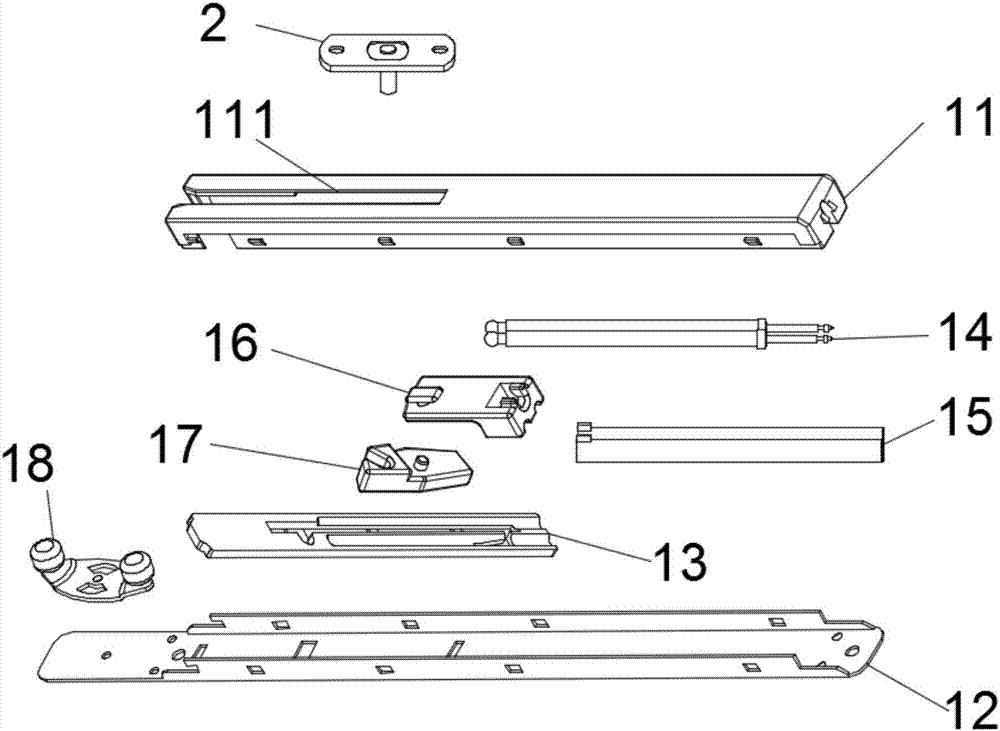

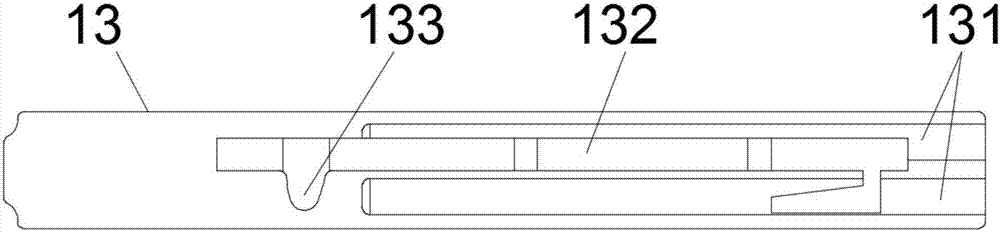

Small sliding door damper

InactiveCN107288467AIncrease the scope of applicationSolid structureBuilding braking devicesWing accessoriesEngineeringUltimate tensile strength

The invention relates to a small damper for sliding doors. A small damper for a sliding door, including a damper body and a paddle; the damper body includes an upper rail casing, a lower iron piece, a lower rail bottom plate, a buffer rod, a double pipe, a sliding body, a release claw and a rotating wheel; the upper rail casing The upper side of the left half of the body is provided with an upper track groove; the bottom plate of the lower track is provided with a buffer rod expansion slot, a lower track groove, and a release claw slot arranged at the left end of the lower track groove; the release claw passes through the pin on the top side and slides The left end of the body is hinged, and moves along the lower track groove of the lower track floor through two pins on the bottom side. A small sliding door damper of the present invention has a width as small as 21mm, and also solves the problem of different frame spacings by means of rotating wheels, increasing the scope of application of the damper, with two track grooves on the upper and lower sides, and a more reliable structure; Overlap buckle structure saves some screw fixing, saves cost and increases the strength of the damper.

Owner:SUZHOU SHENGDE PRECISION ELECTRIC

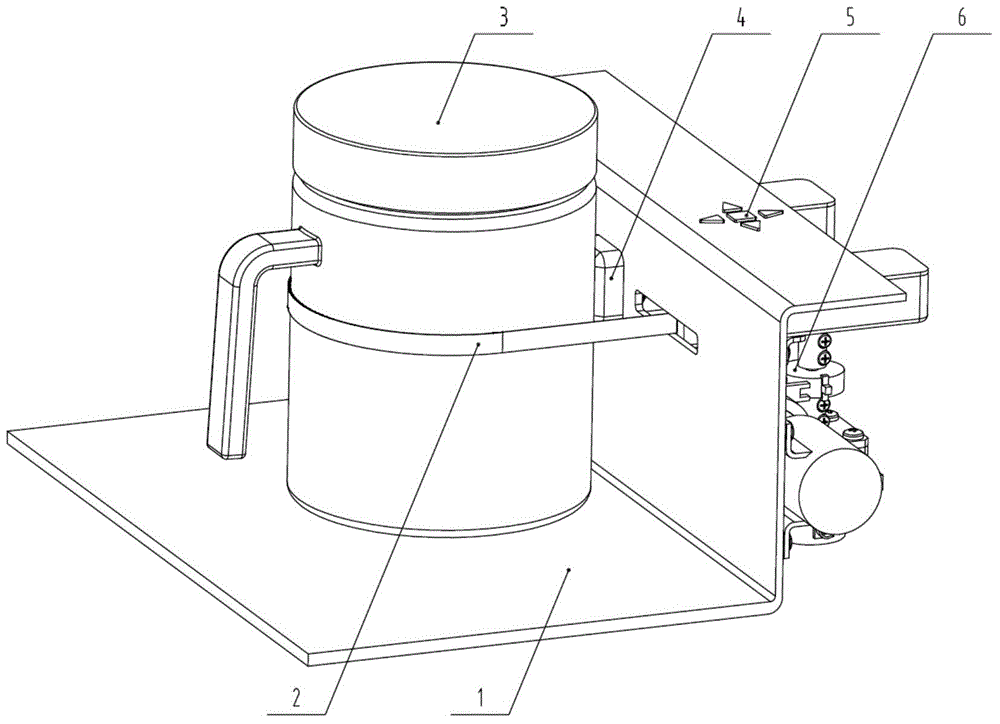

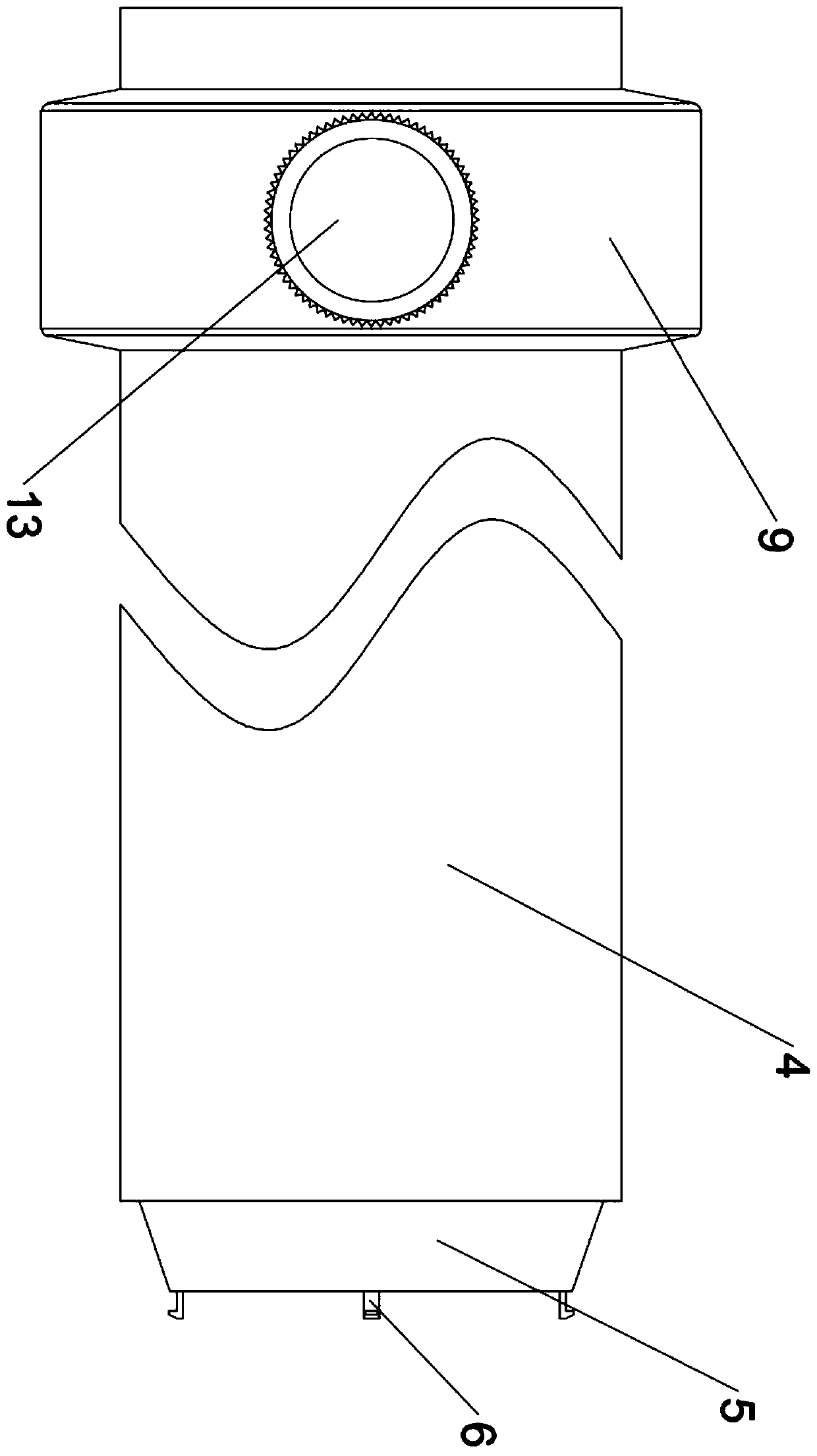

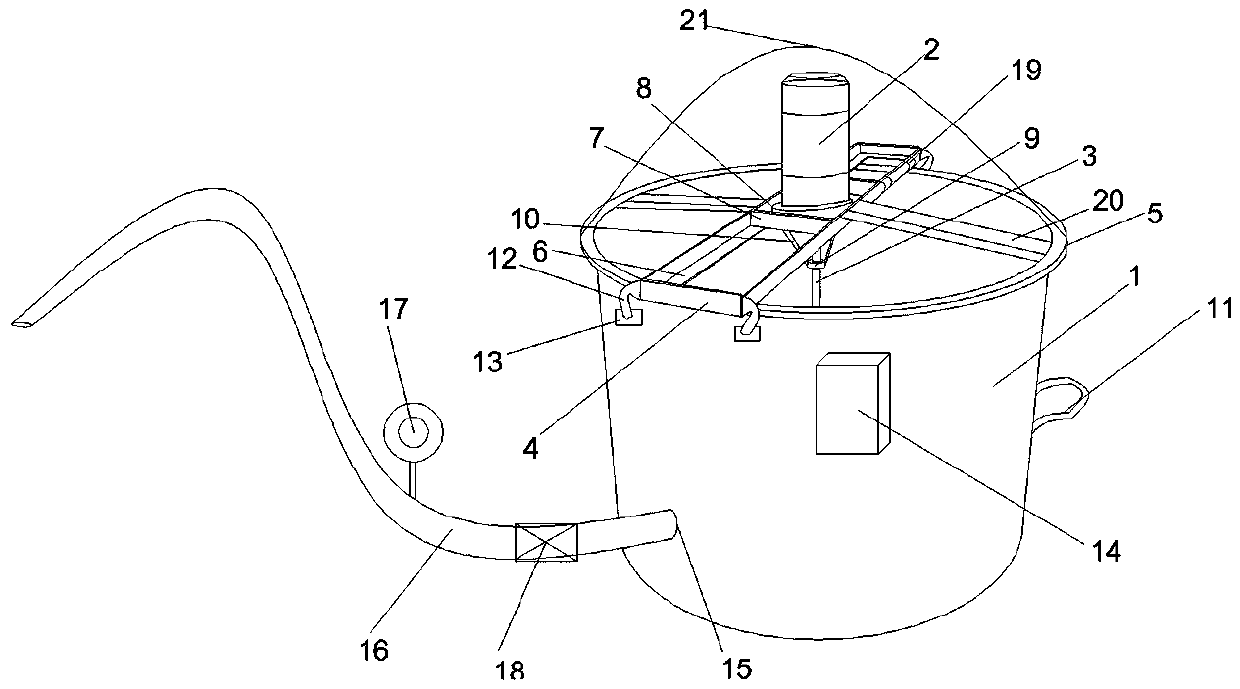

Lacquer stirring barrel capable of accurately controlling discharging amount and working method thereof

PendingCN107930471ASolid structureSecure installationTransportation and packagingRotary stirring mixersLacquerRaw material

The invention discloses a latex stirring barrel capable of accurately controlling discharging amount. The latex stirring barrel comprises a barrel body, a stirring motor, a stirring shaft and a plurality of stirring blades. A discharging outlet is arranged on the bottom side of the barrel body, and a discharging tube is arranged on the discharging outlet. The discharge tube is provided with a flowmeter, a PLC controller is arranged on the front side of the barrel body, a solenoid valve is arranged on the discharge tube, the flow meter is connected with the signal receiving end of the PLC controller, and the control end of the PLC controller is respectively connected with the solenoid valve and the stirring motor; the top of the barrel body is provided with an opening, and the stirring motor is installed on the opening at the top of the barrel body through a motor bracket. The middle of the motor bracket is provided with a stirring shaft stabilizing structure. The stirring shaft stabilizing structure includes a shaft sleeve, a bearing and two connecting rods. The tops of the connecting rods are connected with the motor bracket, and the bottoms of the connecting rods are connected with the bearing. The latex stirring barrel can accurately control the amount of latex to be discharged and control the cost of raw materials, and at the same time, the overall structure is stable andreliable, the installation of the stirring motor is firm and reliable, and the use flexibility is high. At the same time, the rotation stability of the stirring shaft is good, and the stirring effectis ensured.

Owner:WENZHOU KAMARY LATEX PROD

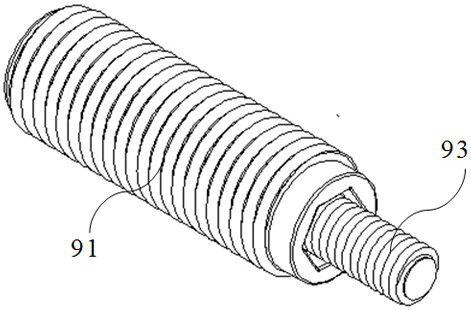

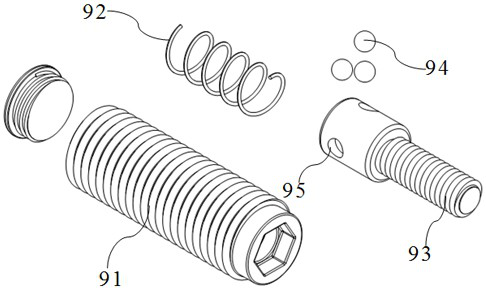

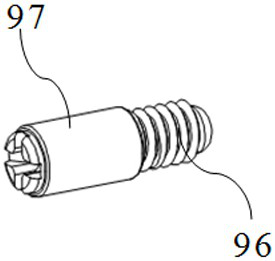

Cabinet connecting piece and cabinet

The invention discloses a cabinet connecting piece and a cabinet The cabinet connecting piece comprises a spiral shell, a spring and a connecting screw rod which abut against each other are arranged in the spiral shell, and the connecting screw rod extends out of the spiral shell; and rolling balls are arranged on the connecting screw and make contact with the inner wall of the spiral shell. The cabinet connecting piece also comprises hangers which comprise a hook plate, a fixing plate and a hanging buckle, a hook is arranged at the top of the hook plate, and the hanging buckle is clamped withthe hook; an adjusting piece is connected to the bottom of the hook plate, a gear adjusting bolt is perpendicularly connected to the adjusting piece in a threaded mode, and a rotatable gear rotatingdisc is installed on the fixing plate and is in transmission connection with the gear adjusting bolt. The hangers are stable and reliable in structure, convenient and rapid to use and convenient for modular production and manufacturing, and the height of the cabinet and the distance between the cabinet and the wall can be conveniently and rapidly adjusted. The cabinet can be conveniently and rapidly connected to a wall through the hangers, exposed holes do not exist in the connecting positions, flaws do not need to be shielded, and the cabinet can be simple and attractive in structure.

Owner:青岛海尔全屋家居有限公司

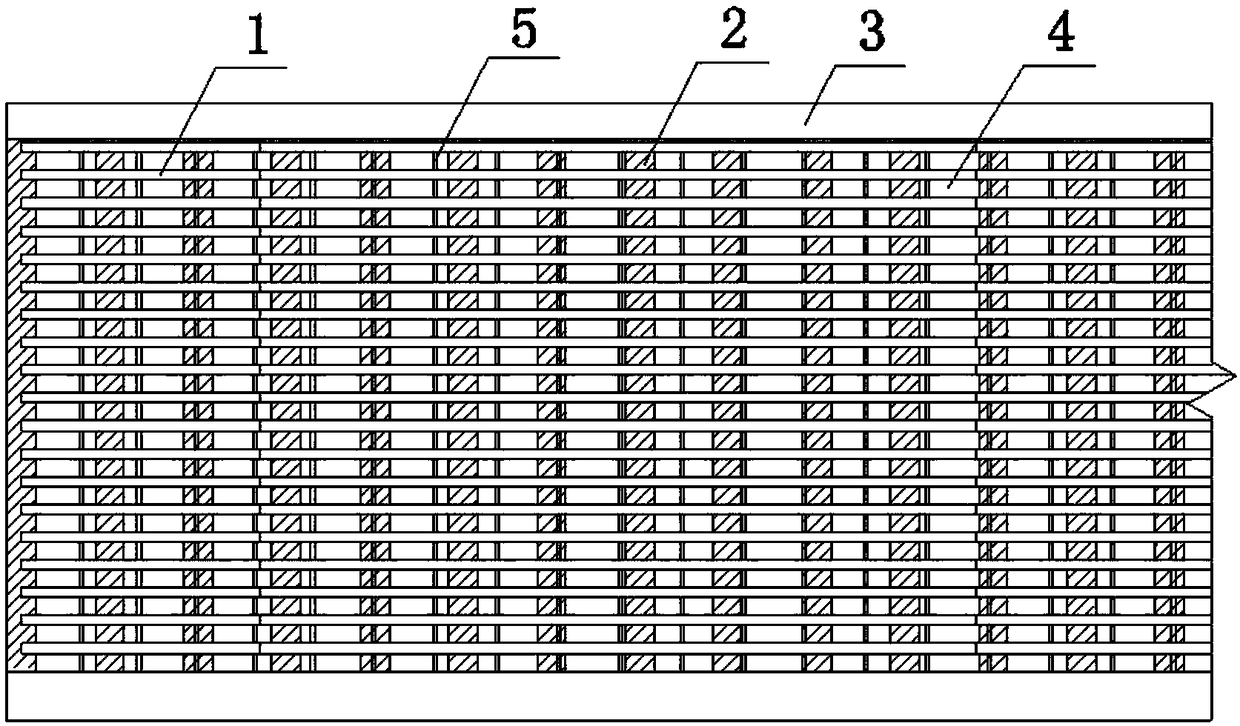

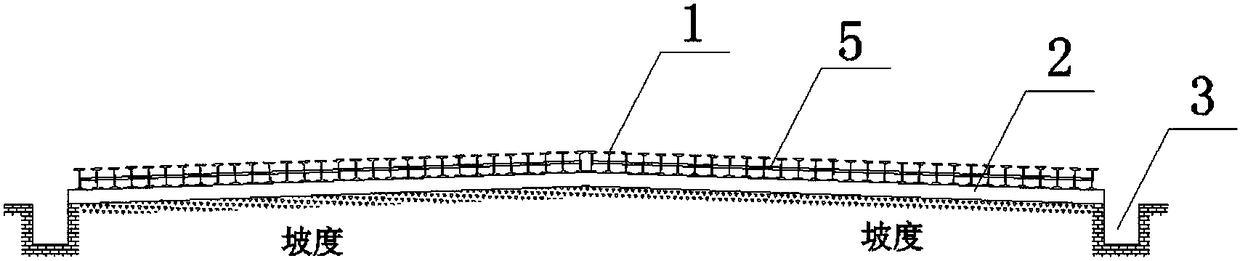

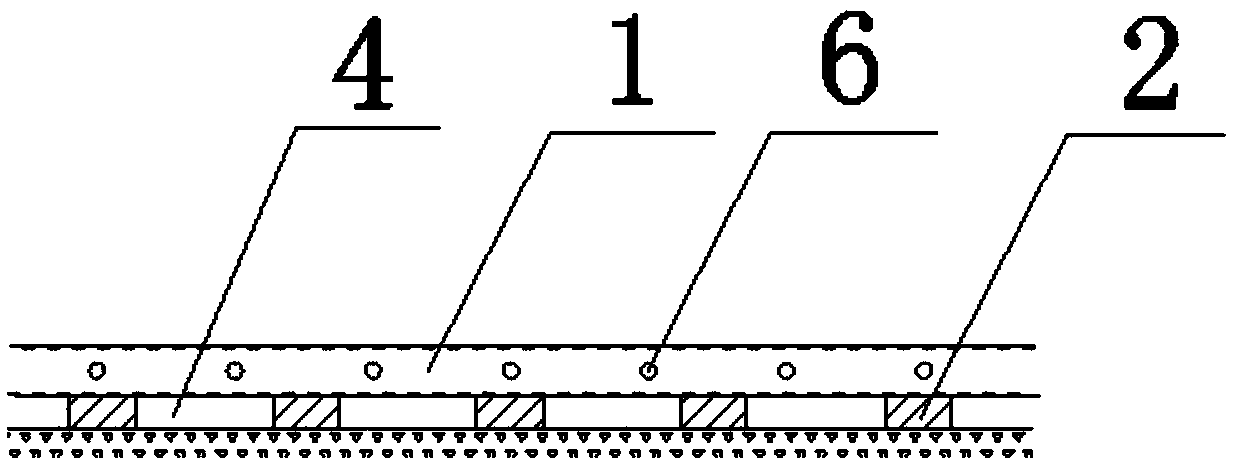

H-shaped fiber reinforced plastic grating construction site temporary pavement and construction method

PendingCN108385468ASolid structureEasy to assemble and disassemblePaving gutters/kerbsTemporary pavingsMortise and tenonEngineering

The invention discloses an H-shaped fiber reinforced plastic grating construction site temporary pavement and a construction method. The construction site temporary pavement comprises more than two rows of supporting abutments, more than two rows of fiber reinforced plastic main beams are paved on each supporting abutment, each fiber reinforced plastic main beam is formed by connecting more than two H-shaped fiber reinforced plastic beams through mortise-tenon structures, through holes are formed in each fiber reinforced plastic beam at certain intervals, and connection rods penetrate the through holes in the fiber reinforced plastic main beams to connect the same together. Connection is realized through the mortise-tenon structures which can be meshed with each other and are arranged at two ends of the H-shaped fiber reinforced plastic main beams, and connection rods are used to penetrate the through holes in the fiber reinforced plastic main beams to connect the same together to formthe integral H-shaped fiber reinforced plastic grating construction site temporary pavement. The temporary pavement is firm in structure, convenient to mount and demount, high in construction efficiency and suitable for transfer use.

Owner:中建四局华南建设有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com